service INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4799 of 5598

SRC-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006219946

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

ServiceINFOID:0000000006219947

Never use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OF F, disconnect battery negative terminal and wait 3 minutes

or more.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, never work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Never turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Never solder the harness when making repairs. Check that harness is not pinched and that there is no con-

tact with other components.

Never allow harness to come in contact with oil, grease, waste oil, or water.

Never insert foreign materials, such as a screwdriver , into the harness connector. (This is to prevent acci-

dental activation caused by static electricity.)

Always use CONSULT-III or SRS air bag warning lamp to perform the circuit diagnosis. (Never use an elec- tric tester such as a circuit tester.)

Never enter in the deployment area of the pop-up roll bar. Never put an object in the deployment area of the

pop-up roll bar. (This is to prevent injury in case of an unintentional deployment.)

Revision: 2010 May2011 QX56

Page 4830 of 5598

DIAGNOSIS AND REPAIR WORK FLOWSRC-37

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

1.INTERVIEW THE CUSTOMER FOR THE SYMPTOM

Interview the customer for the symptom (the condi tion and the environment when the incident/malfunction

occurs).

>> GO TO 2.

2.CHECK SYMPTOM

Check the symptom from the customer information.

>> GO TO 3.

3.CHECK WARNING LAMP OPERATION

Check air bag warning lamp operation in the user mode. Refer to SRC-14, "

On Board Diagnosis Function".

Are any malfunction detected?

YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK LOW VOLTAGE

Check low voltage with CONSULT-III (Special function). Refer to SRC-19, "

CONSULT-III Function".

Are any malfunction detected?

YES >> GO TO 9.

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

5.CHECK SELF DIAGNOSTIC RESULTS

Check self diagnostic result with CONSULT-III or diagnosis mode.

If it is impossible to switch to diagnosis mode, follow the same pr ocedure that DTC is not detected.

NOTE:

Perform the following procedure if DTC is detected.

Record DTC (Print them out with CONSULT-III.)

Erase self diagnostic result.

Study the relationship between the malfunction that DT C or air bag warning lamp indicates and the symptom

that the customer describes.

Check related service bulletins for information.

Is DTC detected?

YES >> GO TO 6.

NO >> GO TO 7.

6.PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC CONFIRMATION PROCEDURE for the DTC.

>> GO TO 8.

7.PERFORM DIAGNOSIS ACCORDING TO WARNING LAMP OPERATION

1. Check air bag warning lamp operation in the user mode. Refer to SRC-14, "

On Board Diagnosis Func-

tion".

2. Perform Diagnosis Procedure for the air bag warning lamp operation. Refer to SRC-14, "

On Board Diag-

nosis Function" (USER MODE).

>> GO TO 9.

8.DETECT MALFUNCTIONING PA RT BY DIAGNOSTIC PROCEDURE

Inspect according to Diagnostic Procedure of the DTC.

>> GO TO 9.

9.REPAIR OR REPLACE THE MALFUNCTION PART

Revision: 2010 May2011 QX56

Page 4832 of 5598

INSPECTION AND ADJUSTMENTSRC-39

< BASIC INSPECTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000006219959

When replacing or removing and installing passenger seat, always perform zero point reset so that Occupant

Detection System is activated normally.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000006219960

WORK PROCEDURE WHEN REPLACING CONTROL UNIT

1.PERFORM ZERO POINT RESET

Perform zero point reset. Refer to SRC-39, "

ZERO POINT RESET : Special Repair Requirement".

>> END

ZERO POINT RESET

ZERO POINT RESET : DescriptionINFOID:0000000006219961

Zero point reset is an initializing procedure for occupant detection sensor that must be performed when replac-

ing or removing and installing passenger seat.

If zero point reset is not performed, the initializati on is incomplete and Occupant Detection System does not

operate normally.

NOTE:

When replacing passenger seat with a NISSAN genuine part, air bag warning lamp blinks if zero point reset

is incomplete.

When zero point reset is performed once after removal and installation of passenger seat, CONSULT-III dis-

plays “complete” and air bag warning does not blink.

When reinstalling passenger seat after removal, the initial value for occupant detection sensor changes, and

Occupant Detection System does not operate normally.

Always perform zero point reset after performing the work as per the following.

- Reinstallation of passenger seat

- Replacement of passenger seat with a seat that is zero point reset complete.

ZERO POINT RESET : Special Repair RequirementINFOID:0000000006219962

1.PERFORM ZERO POINT RESET

1. Perform zero point reset. NOTE:

When performing zero point reset, be careful of the items described as per the following.

Perform zero point reset after installing passenger seat to the vehicle

Do not put any objects on passenger seat

Do not apply excessive vibration to the vehicle

Do not touch the vehicle

Do not tilt the vehicle

2. Select start on “Zero point reset function” scr een from, WORK SUPPORT of CONSULT-III “OCCUPANT

DETECTION”.

3. “Zero point reset” starts.

>> GO TO 2.

2.CONFIRMATION OF SETTING

1. Proceed to “Zero point reset function” screen fr om work support of CONSULT-III “OCCUPANT DETEC-

TION”.

2. Check that “Complete” or “Incomplete” is displayed on “Zero point reset status”.

CAUTION:

Revision: 2010 May2011 QX56

Page 4988 of 5598

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for Steering System

......

4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

Commercial Service Tools ........................................6

SYSTEM DESCRIPTION ..............................7

COMPONENT PARTS ................................... .....7

Component Parts Location (Heated Steering

Wheel) ................................................................. ......

7

Component Description (Heated Steering Wheel) ......7

Heated Steering Wheel .............................................7

Heated Steering Wheel Switch .................................8

Heated Steering Wheel Relay ...................................8

SYSTEM ..............................................................9

System Description (Heated Steering Wheel) ..... ......9

WIRING DIAGRAM ......................................10

HEATED STEERING WHEEL ........................ ....10

Wiring Diagram ................................................... ....10

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORK FLOW .... ....13

WorkFlow (Heated Steering Wheel) .................... ....13

STEERING WHEEL ............................................14

Inspection ............................................................ ....14

DTC/CIRCUIT DIAGNOSIS .........................16

HEATED STEERING WHEEL SYSTEM ...........16

Component Function Check ................................ ....16

Diagnosis Procedure ...............................................16

Component Inspection (Heated Steering Wheel) ....18

Component Inspection (Heated Steering Wheel

Relay) ......................................................................

19

HEATED STEERING WHEEL SWITCH INDI-

CATOR LAMP ...................................................

20

Component Function Check ....................................20

Diagnosis Procedure ...............................................20

Component Inspection (Heated Steering Wheel

Relay) ......................................................................

22

SYMPTOM DIAGNOSIS ..............................23

HEATED STEERING WHEEL SYSTEM DOES

NOT ACTIVATE ................................................

23

Description ........................................................... ....23

Diagnosis Procedure ...............................................23

HEATED STEERING WHEEL SWITCH INDI-

CATOR LAMP DOES NOT TURN ON ..............

26

Description ...............................................................26

Diagnosis Procedure ...............................................26

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

29

NVH Troubleshooting Chart ....................................29

PERIODIC MAINTENANCE ........................30

POWER STEERING FLUID ..............................30

Inspection ............................................................ ....30

STEERING WHEEL ..........................................32

Inspection ................................................................32

REMOVAL AND INSTALLATION ...............33

Revision: 2010 May2011 QX56

Page 4989 of 5598

ST-2

STEERING WHEEL ...........................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

STEERING COLUMN ........................................34

Exploded View ..................................................... ...34

Removal and Installation ........................................34

Inspection ...............................................................35

STEERING SHAFT ............................................37

Exploded View ..................................................... ...37

Removal and Installation ........................................37

Inspection ...............................................................39

STEERING GEAR AND LINKAGE ....................41

Exploded View ..................................................... ...41

Removal and Installation ........................................42

Disassembly and Assembly ....................................43

Inspection ...............................................................46

POWER STEERING OIL PUMP ........................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Disassembly and Assembly ....................................50

Inspection ...............................................................52

HYDRAULIC LINE .......................................... ...54

Exploded View ..................................................... ...54

HEATED STEERING WHEEL SWITCH ............56

Exploded View ..................................................... ...56

Removal and Installation .........................................56

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

57

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

57

General Specifications ......................................... ...57

Steering Wheel Axial End Play and Play ................57

Steering Wheel Turning Force ................................57

Steering Angle ........................................................57

Steering Column Length .........................................57

Steering Column Mounting Dimensions ..................57

Steering Column Operating Range .........................57

Steering Shaft Sliding Range ..................................58

Rack Sliding Force ..................................................58

Rack Stroke ............................................................58

Socket Swing Force and Rotating Torque ..............58

Socket Axial End Play .............................................58

Inner Socket Length ................................................58

Relief Oil Pressure ..................................................58

Revision: 2010 May2011 QX56

Page 4990 of 5598

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006272045

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006272046

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 4991 of 5598

ST-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for Steering SystemINFOID:0000000006225573

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehicle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Never reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

Revision: 2010 May2011 QX56

Page 4992 of 5598

PREPARATIONST-5

< PREPARATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PREPARATION

PREPARATION

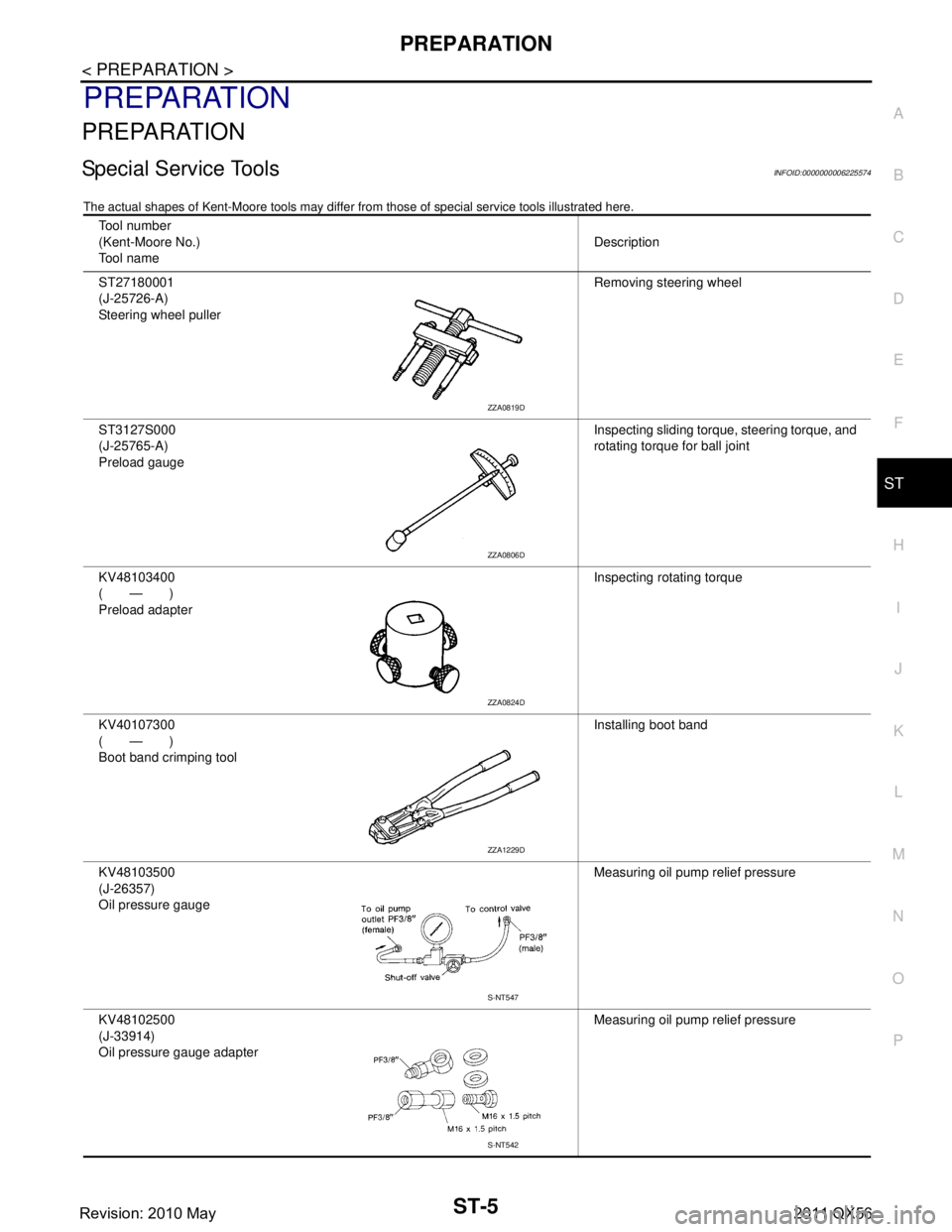

Special Service ToolsINFOID:0000000006225574

The actual shapes of Kent-Moore t ools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

ST27180001

(J-25726-A)

Steering wheel puller Removing steering wheel

ST3127S000

(J-25765-A)

Preload gauge Inspecting sliding torque, steering torque, and

rotating torque for ball joint

KV48103400

(—)

Preload adapter Inspecting rotating torque

KV40107300

(—)

Boot band crimping tool Installing boot band

KV48103500

(J-26357)

Oil pressure gauge Measuring oil pump relief pressure

KV48102500

(J-33914)

Oil pressure gauge adapter Measuring oil pump relief pressure

ZZA0819D

ZZA0806D

ZZA0824D

ZZA1229D

S-NT547

S-NT542

Revision: 2010 May2011 QX56

Page 4993 of 5598

ST-6

< PREPARATION >

PREPARATION

Commercial Service Tools

INFOID:0000000006225575

Tool name Description

Power tool Loosening bolts and nuts

Ball joint remover Remove steering outer socket

Drift

a: 35 mm (1.38 in) dia.

b: 21 mm (0.83 in) dia. Installing oil pump oil seal

PBIC0190E

S-NT146

S-NT474

Revision: 2010 May2011 QX56

Page 5030 of 5598

STEERING GEAR AND LINKAGEST-43

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

4. Remove cotter pin (1), and then loosen the nut.

5. Remove steering outer socket (2) from steering knuckle (3) so as not to damage ball joint boot (4) using suitable ball joint

remover (commercial service tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

6. Remove high pressure piping and low pressure piping of hydraulic piping, and then drain power steering fluid.

7. Remove power steering solenoid valve harness connector.

8. Remove lower joint fixing bolt (steering gear side).

9. Separate the lower joint from the steering gear assembly. Refer to ST-37, "

Exploded View".

CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

10. Remove steering gear assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub a ssembly and measure the distance of inner socket, and

then measure the intermediat e position of the distance.

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Never reuse cotter pin and steering gear mounting nut.

Perform inspection after installation. Refer to ST-46, "

Inspection".

Disassembly and AssemblyINFOID:0000000006225609

DISASSEMBLY

CAUTION:

Disassemble and assemble steering gear assembly by fixing the mounting area with a vise using

copper plates.

Clean steering gear assembly with kerosene before disassembling. Be careful to avoid splashing or

applying any kerosene over connector of discharge port or return port.

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

PGIA0063E

: Bolt

JPGIA0038ZZ

Revision: 2010 May2011 QX56