door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3478 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LA INFINITI QX56 2011 Factory Service Manual

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LA](/img/42/57033/w960_57033-3477.png)

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LAN-68, "

Diagnosis Procedure"

Transfer control unit branch line circuitLAN-69, "Diagnosis Procedure"

ABS actuator and electric unit (control unit) branch line circuit LAN-70, "Diagnosis Procedure"

TCM branch line circuit LAN-71, "Diagnosis Procedure"

Air bag diagnosis sensor unit branch line circuitLAN-72, "Diagnosis Procedure"

AFS control unit branch line circuitLAN-73, "Diagnosis Procedure"

AV control unit branch line circuitLAN-74, "Diagnosis Procedure"

BCM branch line circuitLAN-75, "Diagnosis Procedure"

CAN gateway branch line circuit (CAN communication circuit 1)LAN-76, "Diagnosis Procedure"

CAN gateway branch line circuit (CAN communication circuit 2)LAN-77, "Diagnosis Procedure"

Data link connector branch line circuitLAN-78, "Diagnosis Procedure"

A/C auto amp. branch line circuitLAN-79, "Diagnosis Procedure"

Combination meter branch line circuitLAN-80, "Diagnosis Procedure"

Steering angle sensor branch line circuitLAN-81, "Diagnosis Procedure"

Low tire pressure warning control unit branch line circuitLAN-82, "Diagnosis Procedure"

IPDM E/R branch line circuitLAN-83, "Diagnosis Procedure"

Driver seat control unit branch line circuitLAN-84, "Diagnosis Procedure"

Pre-crash seat belt control unit (driver side) branch line circuitLAN-85, "Diagnosis Procedure"

Air levelizer control module branch line circuitLAN-86, "Diagnosis Procedure"

ADAS control unit branch line circuitLAN-87, "Diagnosis Procedure"

Automatic back door control module branch line circuitLAN-88, "Diagnosis Procedure"

Malfunction area Reference

CAN communication circuit (Without ICC system) LAN-94, "

Diagnosis Procedure"

CAN communication circuit 1 (With ICC system)LAN-96, "Diagnosis Procedure"

CAN communication circuit 2 (With ICC system)LAN-98, "Diagnosis Procedure"

Malfunction area Reference

Main line between side radar RH and side radar LH LAN-64, "

Diagnosis Procedure"

Main line between side radar LH and lane camera unitLAN-65, "Diagnosis Procedure"

Main line between lane camera unit and accelerator pedal actu-

atorLAN-67, "Diagnosis Procedure"

Malfunction area Reference

Side radar RH branch line circuit LAN-89, "

Diagnosis Procedure"

Side radar LH branch line circuitLAN-90, "Diagnosis Procedure"

Lane camera unit branch line circuitLAN-91, "Diagnosis Procedure"

Accelerator pedal actuator branch line circuitLAN-92, "Diagnosis Procedure"

ICC sensor branch line circuitLAN-93, "Diagnosis Procedure"

Revision: 2010 May2011 QX56

Page 3483 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-63

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006220540

1.CHE INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-63

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006220540

1.CHE](/img/42/57033/w960_57033-3482.png)

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-63

< DTC/CIRCUIT DIAGNOSIS > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006220540

1.CHECK HARNESS CONTI

NUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect the following harness connectors.

- CAN gateway

- Harness connectors B460 and B24

- Automatic back door control module

4. Check the continuity between the harness connecto r and the automatic back door control module harness

connector.

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main li ne between the driver seat control unit and the automatic

back door control module.

NO >> Repair the main line between the harness c onnector B24 and the automatic back door control

module.

Harness connector Automatic back door control module

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

B24 13

B26 7 Existed

12 6 Existed

Revision: 2010 May2011 QX56

Page 3508 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-88

< DTC/CIRCUIT DIAGNOSIS >[CAN]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220564

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the INFINITI QX56 2011 Factory Service Manual

LAN-88

< DTC/CIRCUIT DIAGNOSIS >[CAN]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220564

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the](/img/42/57033/w960_57033-3507.png)

LAN-88

< DTC/CIRCUIT DIAGNOSIS >[CAN]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220564

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors fo r damage, bend and loose connection (unit side and con-

nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC sy stem)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CA N gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic ba ck door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3555 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-135

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256260

1.CHECK CONNECTOR INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-135

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256260

1.CHECK CONNECTOR](/img/42/57033/w960_57033-3554.png)

LAN

PWBD BRANCH LINE CIRCUITLAN-135

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256260

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con- nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC system)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CAN gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic bac k door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3559 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-139

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000 INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-139

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000](/img/42/57033/w960_57033-3558.png)

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-139

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006256282

1.CHECK HARNESS CONTI

NUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect the following harness connectors.

- CAN gateway

- Harness connectors B460 and B24

- Automatic back door control module

4. Check the continuity between the harness connecto r and the automatic back door control module harness

connector.

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main li ne between the driver seat control unit and the automatic

back door control module.

NO >> Repair the main line between the harness c onnector B24 and the automatic back door control

module.

Harness connector Automatic back door control module

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

B24 13

B26 7 Existed

12 6 Existed

Revision: 2010 May2011 QX56

Page 3583 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-163

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256306

1.CHECK CONNECTOR INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-163

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256306

1.CHECK CONNECTOR](/img/42/57033/w960_57033-3582.png)

LAN

PWBD BRANCH LINE CIRCUITLAN-163

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256306

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con- nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC system)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CAN gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic bac k door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3613 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-193

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256353

1.CHECK CONNECTOR INFINITI QX56 2011 Factory Service Manual

LAN

PWBD BRANCH LINE CIRCUITLAN-193

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256353

1.CHECK CONNECTOR](/img/42/57033/w960_57033-3612.png)

LAN

PWBD BRANCH LINE CIRCUITLAN-193

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256353

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con- nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC system)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CAN gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic bac k door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3617 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000 INFINITI QX56 2011 Factory Service Manual

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:00000](/img/42/57033/w960_57033-3616.png)

LAN

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

LAN-197

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 4)]

C

D

E

F

G H

I

J

K L

B A

O P

N

MAIN LINE BETWEEN ADP AND PWBD CIRCUIT

Diagnosis ProcedureINFOID:0000000006256369

1.CHECK HARNESS CONTI

NUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Disconnect the following harness connectors.

- CAN gateway

- Harness connectors B460 and B24

- Automatic back door control module

4. Check the continuity between the harness connecto r and the automatic back door control module harness

connector.

Is the inspection result normal?

YES (Present error)>>Check CA N system type decision again.

YES (Past error)>>Error was detected in the main li ne between the driver seat control unit and the automatic

back door control module.

NO >> Repair the main line between the harness c onnector B24 and the automatic back door control

module.

Harness connector Automatic back door control module

harness connector Continuity

Connector No. Terminal No. Connector No. Terminal No.

B24 13

B26 7 Existed

12 6 Existed

Revision: 2010 May2011 QX56

Page 3642 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

INFINITI QX56 2011 Factory Service Manual

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/42/57033/w960_57033-3641.png)

LAN-222

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

PWBD BRANCH LINE CIRCUIT

PWBD BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256393

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors fo r damage, bend and loose connection (unit side and con-

nector side).

- Automatic back door control module

- CAN gateway (With ICC system)

Is the inspection result normal?

YES (With ICC system)>>GO TO 2.

YES (Without ICC sy stem)>>GO TO 3.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect the connector of CAN gateway.

2. Check the continuity between the CA N gateway harness connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause (CAN communication circuit 2). Refer to LAN-57,

"System Diagram".

3.CHECK HARNESS FOR OPEN CIRCUIT

1. Connect the connector of CAN gateway. (With ICC system)

2. Disconnect the connector of automatic back door control module.

3. Check the resistance between the automatic ba ck door control module harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 4.

NO >> Repair the automatic back door control module branch line.

4.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of t he automatic back door control module. Refer to DLK-116,

"AUTOMATIC BACK DOOR CONTROL UNIT : Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the automat ic back door control module. Refer to DLK-262, "Removal and

Installation".

YES (Past error)>>Error was detected in the automatic back door control module branch line.

NO >> Repair the power supply and the ground circuit.

CAN gateway harness connector Continuity

Connector No. Terminal No.

M125 46Existed

10 12 Existed

Automatic back door control module harness connector Resistance (Ω)

Connector No. Terminal No.

B26 7 6 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3674 of 5598

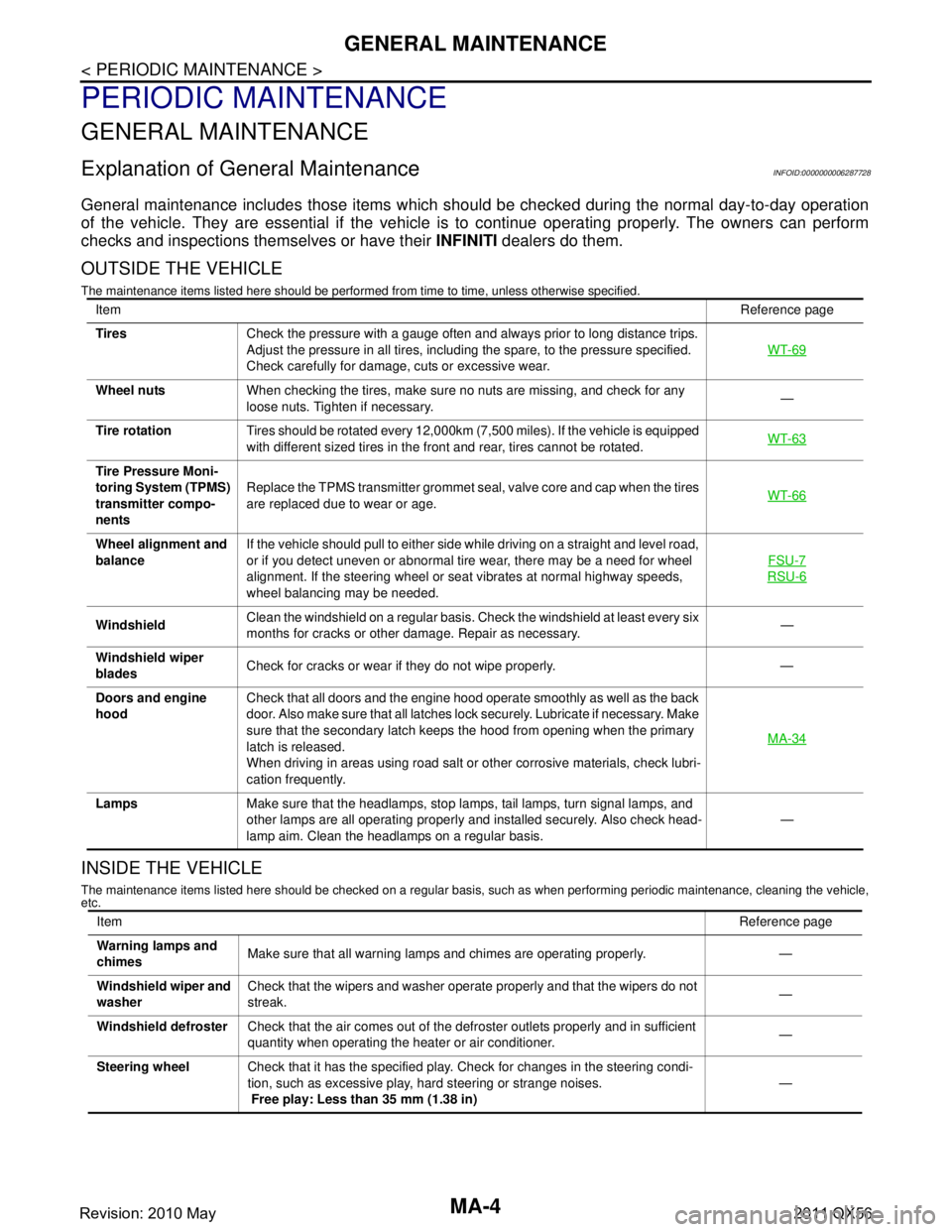

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56