door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3334 of 5598

INTERIOR LIGHTING SYSTEM SYMPTOMSINL-67

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

SYMPTOM DIAGNOSIS

INTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000006216080

CAUTION:

Perform the self-diagnosis with CONS ULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom Possible cause Inspection item

All the following lamps do not turn ON.

Map lamp

Personal lamp

Vanity mirror lamp

Foot lamp

Step lamp

Puddle lamp

Luggage room lamp

Automatic back door close switch illumination Harness between BCM and each

interior room lamp

BCM Interior room lamp

power supply cir-

cuit

Refer to INL-56, "

Component Func-

tion Check".

Interior room lamp does not turn ON even though the door is open.

(It turns ON when turning the interior room

lamp ON.)

Interior room lamp does not turn OFF even

though the door is closed. Harness between BCM and each

door switch

Harness between BCM and each

interior room lamp

BCM Door switch circuit

Refer to

DLK-117,

"ComponentFunctionCheck".

Interior room lamp control circuit

Refer to INL-58, "

Component Func-

tion Check".

Interior room lamp timer does not activate.

(It turns ON/ OFF when the door opens/closes.) —Check the interior room lamp setting.

Refer to

INL-14

.

Puddle lamp does not turn ON even though the door is open.

Puddle lamp does not turn OFF even though the door is closed. Harness between BCM and each

door switch

Harness between BCM and puddle lamp

BCM Door switch circuit

Refer to

DLK-117,

"ComponentFunctionCheck".

Puddle lamp circuit

Refer to INL-64, "

Diagnosis Proce-

dure".

Luggage room lamp or automatic back door close switch illumination does not turn ON even

though the back door is open.

(It turns ON when turning the luggage room

lamp ON.)

Luggage room lamp or automatic back door

close switch illumination does not turn OFF

even though the back door is closed. Harness between BCM and back

door switch

Harness between BCM and lug- gage room lamp

Harness between BCM and auto- matic back door close switch

BCM Back door switch circuit

Refer to

DLK-120,

"ComponentFunctionCheck".

Luggage room lamp circuit

Refer to INL-60, "

Diagnosis Proce-

dure".

Step lamps (ALL) do not turn ON.

Step lamps (ALL) do not turn OFF. Harness between BCM and each

step lamp

BCM Door switch circuit

Refer to

DLK-117,

"ComponentFunctionCheck".

Step lamp circuit

Refer to INL-62

.

Push-button ignition switch illumination does not

illuminate. Harness between BCM and push-

button ignition switch

BCM Push-button ignition switch illumina-

tion circuit

Refer to

INL-65, "

Component Func-

tion Check".

Interior room lamp battery saver does not acti-

vate. BCMReplace BCM.

Refer to

BCS-81, "

Removal and In-

stallation".

Revision: 2010 May2011 QX56

Page 3341 of 5598

INL-74

< REMOVAL AND INSTALLATION >

STEP LAMP

STEP LAMP

Exploded ViewINFOID:0000000006288655

Removal and InstallationINFOID:0000000006288656

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

Never touch the glass of bulb directly by hand. Keep grease and other oily substaces away from it.

Never touch bulb by hand while it is lit or right after it is off.

Never leave bulb out of lamp reflector for a long ti me because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bu lb, be sure to replace it with a new one.

REMOVAL

1. Insert any appropriate tool into the gap between the step lamp and door finisher.

2. Disconnect the step lamp harness connector, and then remove the step lamp.

INSTALLATION

Install in the reverse order of removal.

ReplacementINFOID:0000000006288657

STEP LAMP BULB

1. Remove the step lamp.

2. Remove the lens.

3. Remove the bulb.

1. Step lamp housing 2. Bulb 3. Lens

: Pawl

: Metal clip

JMLIA0541ZZ

Revision: 2010 May2011 QX56

Page 3342 of 5598

MOOD LAMPINL-75

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

MOOD LAMP

FRONT DOOR ARMREST

FRONT DOOR ARMREST : Exploded ViewINFOID:0000000006288658

FRONT DOOR ARMREST : ReplacementINFOID:0000000006288659

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

Never touch the glass of bulb directly by hand. Keep grease and other oily substaces away from it.

Never touch bulb by hand while it is lit or right after it is off.

Never leave bulb out of lamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bu lb, be sure to replace it with a new one.

MOOD LAMP

1. Remove front door finisher. Refer to INT-14, "Removal and Installation".

2. Remove the mood lamp from front door finisher.

REAR DOOR ARMREST

REAR DOOR ARMREST : Exploded ViewINFOID:0000000006288660

1. Mood lamp

JMLIA1054ZZ

1. Mood lamp

JMLIA1055ZZ

Revision: 2010 May2011 QX56

Page 3343 of 5598

INL-76

< REMOVAL AND INSTALLATION >

MOOD LAMP

REAR DOOR ARMREST : Replacement

INFOID:0000000006288661

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

Never touch the glass of bulb directly by hand. Keep grease and other oily substaces away from it.

Never touch bulb by hand while it is lit or right after it is off.

Never leave bulb out of lamp reflector for a long ti me because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bu lb, be sure to replace it with a new one.

MOOD LAMP

1. Remove rear door finisher. Refer to INT-14, "Removal and Installation".

2. Remove the mood lamp from rear door finisher.

Revision: 2010 May2011 QX56

Page 3346 of 5598

PUDDLE LAMPINL-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

PUDDLE LAMP

Exploded ViewINFOID:0000000006288665

Removal and InstallationINFOID:0000000006288666

CAUTION:

Disconnect the battery cable from negative terminal or remove the fuse.

Never touch puddle lamp directly by hand. Keep grease and other oily substaces away from it.

Never touch puddle lamp by hand while it is lit or right after it is off.

It is prohibited to disassemble puddle lamp.

Always replace puddle lamp as an assembly, when replacing.

REMOVAL

1. Remove door mirror assembly. Refer to MIR-32, "DOOR MIRROR ASSEMBLY : Removal and Installa-

tion".

2. Disconnect puddle lamp harness connector te rminal from door mirror harness connector.

3. Disengage base cover fixing pawls using a small flat-bladed screwdriver (A), and then remove base cover.

CAUTION:

Apply protective tape (B) around the base to protect thesurface from damage.

Apply protective tape to small flat-bladed screwdriver.

1. Door mirror assembly 2. Puddle lamp 3. Base cover

: Pawl

JMLIA1148ZZ

: Pawl

JMLIA0922ZZ

Revision: 2010 May2011 QX56

Page 3349 of 5598

INL-82

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Bulb SpecificationsINFOID:0000000006288670

Item Type Wattage (W)

Push-button ignition switch illumination LED —

Map lamp Wedge 8

Console lamp

(integrated into the map lamp assembly) LED —

Puddle lamp LED —

Vanity mirror lamp — 2

Glove box lamp Wedge 1.4

Foot lamp (driver and passenger) Wedge 1.4

Rear foot lamp LED —

Mood lamp (front and rear door armrest) LED —

Ste p lam p We dg e 8

Personal lamp Wedge 8

Luggage room lamp — 8

Revision: 2010 May2011 QX56

Page 3350 of 5598

INT-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION INT

A

B

INT

N

O P

CONTENTS

INTERIOR

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

Commercial Service Tools ........................................5

CLIP LIST ............................................................6

Clip List ............................................................... ......6

SYMPTOM DIAGNOSIS ...............................7

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

7

Work Flow ........................................................... ......7

Inspection Procedure ................................................9

Diagnostic Worksheet .............................................11

REMOVAL AND INSTALLATION ...............13

FRONT DOOR FINISHER .............................. ....13

Exploded View .................................................... ....13

Removal and Installation .........................................14

REAR DOOR FINISHER ....................................16

Exploded View .................................................... ....16

Removal and Installation .........................................16

BODY SIDE TRIM ..............................................18

Exploded View .................................................... ....18

DASH SIDE FINISHER .......................................... ....18

DASH SIDE FINISHER : Removal and Installation

....

18

FRONT PILLAR GARNISH .................................... ....19

FRONT PILLAR GARNISH : Removal and Instal-

lation ........................................................................

19

BODY SIDE WELT ................................................. ....20

BODY SIDE WELT : Removal and Installation ........20

KICKING PLATE INNER ....................................... ....20

KICKING PLATE INNER : Removal and Installa-

tion ...........................................................................

20

KICKING PLATE OUTER ...................................... ....21

KICKING PLATE OUTER : Removal and Installa-

tion ...........................................................................

21

CENTER PILLAR LOWER GARNISH ................... ....22

CENTER PILLAR LOWER GARNISH : Removal

and Installation ........................................................

22

CENTER PILLAR UPPER GARNISH ........................22

CENTER PILLAR UPPER GARNISH : Removal

and Installation .................................................... ....

22

FLOOR TRIM ....................................................24

Exploded View .........................................................24

FRONT FLOOR CARPET ...................................... ....25

FRONT FLOOR CARPET : Removal and Installa-

tion ....................................................................... ....

25

REAR FLOOR CARPET ........................................ ....27

REAR FLOOR CARPET : Removal and Installa-

tion ...........................................................................

27

HEADLINING ....................................................28

Exploded View .........................................................28

Removal and Installation .........................................29

LUGGAGE FLOOR TRIM .................................33

Exploded View .........................................................33

Revision: 2010 May2011 QX56

Page 3351 of 5598

INT-2

LUGGAGE FLOOR REAR BOARD ..........................34

LUGGAGE FLOOR REAR BOARD : Removal and

Installation ..............................................................

34

LUGGAGE REAR PLATE ...................................... ...35

LUGGAGE REAR PLATE : Removal and Installa-

tion ....................................................................... ...

35

LUGGAGE SIDE LOWER FINISHER .................... ...36

LUGGAGE SIDE LOWER FINISHER : Removal

and Installation .......................................................

36

REAR PILLAR FINISHER ...................................... ...37

REAR PILLAR FINISHER : Removal and Installa-

tion ..........................................................................

37

BACK PILLAR GARNISH ...................................... ...37

BACK PILLAR GARNISH : Removal and Installa-

tion ..........................................................................

37

LUGGAGE SIDE UPPER FINISHER ..................... ...38

LUGGAGE SIDE UPPER FINISHER : Removal

and Installation ........................................................

38

BACK DOOR TRIM ........................................ ...39

Exploded View ..................................................... ...39

Removal and Installation .........................................39

Revision: 2010 May2011 QX56

Page 3356 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

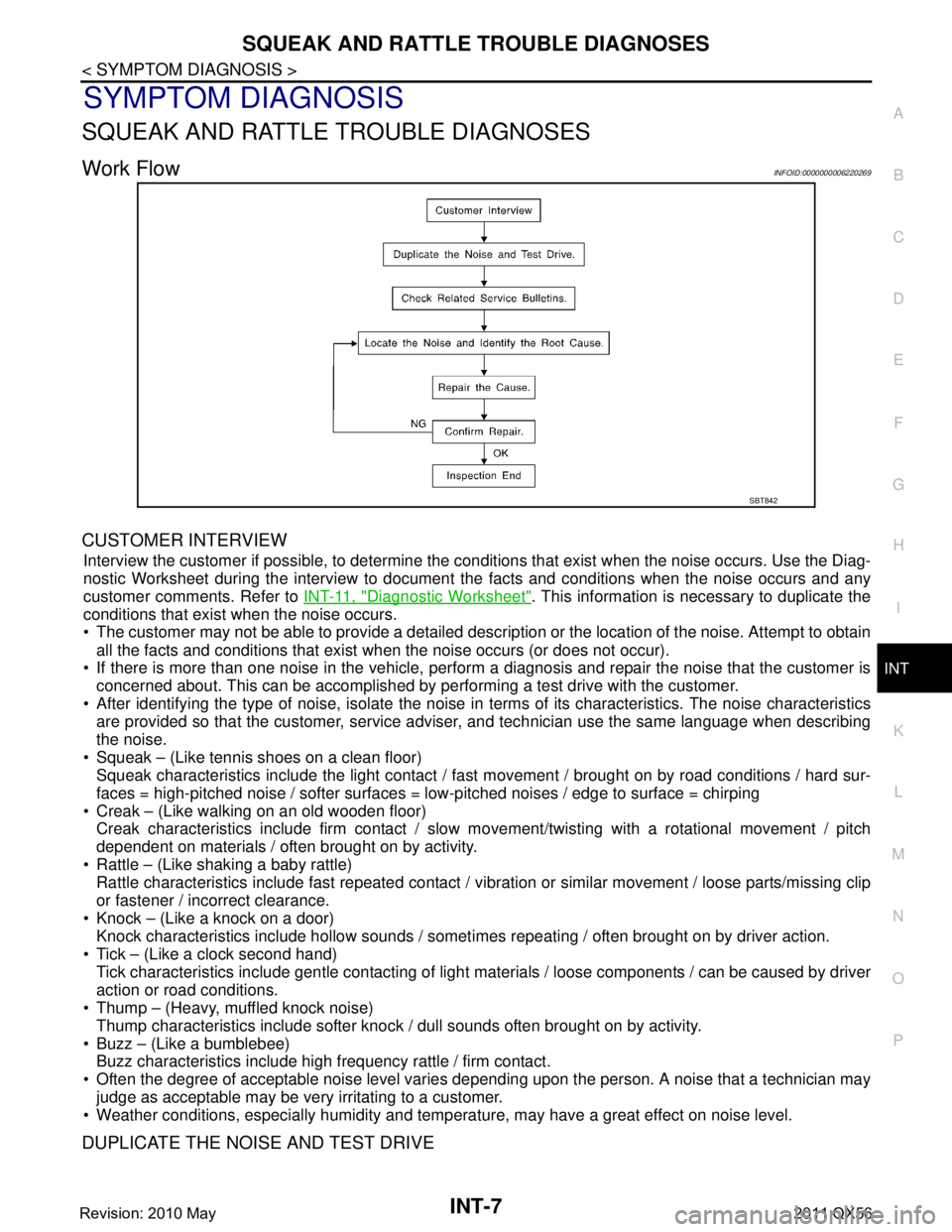

Work FlowINFOID:0000000006220269

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interv iew to document the facts and conditions when the noise occurs and any

customer comments. Refer to INT-11, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by performing a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor) Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor) Creak characteristics include firm contact / slow mo vement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle) Rattle characteristics include fast repeated contact / vi bration or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door) Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise)

Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee) Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

SBT842

Revision: 2010 May2011 QX56

Page 3357 of 5598

INT-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

If the noise can be duplicated easily during the test dr ive, do the following with the vehicle stopped to help

identify the source of the noise.

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to the concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis ear: J-39570, engine ear, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the component(s) in the area(s) that is / are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, creating a new noise.

Tapping or pushing/pulling the component(s) that is / are suspected to be the cause of the noise.

Do not tap or push/pull the component(s) with excessive force, otherwise the noise is eliminated only tempo-

rarily.

Feeling for a vibration by hand by touching the component(s ) that is / are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to INT-9, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the components, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape, or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through the authorized NISSAN Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.937 ×5.315 in)

76884-71L01: 60 ×85 mm (2.362 ×3.346 in)

76884-71L02: 15 ×25 mm (0.591 ×0.984 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.772 in) thick, 50 ×50 mm (1.969 ×1.969 in)

73982-50Y00: 10 mm (0.394 in) thick, 50 ×50 mm (1.969 ×1.969 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.181 ×1.969in)

FELT CLOTHTAPE

Revision: 2010 May2011 QX56