clock INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3745 of 5598

MWI-2

DIAGNOSIS SYSTEM (COMBINATION

METER) ..............................................................

29

On Board Diagnosis Function .............................. ...29

CONSULT-III Function ...........................................30

ECU DIAGNOSIS INFORMATION ..............35

COMBINATION METER ................................. ...35

Reference Value .................................................. ...35

Fail-Safe .................................................................42

DTC Index ..............................................................43

IPDM E/R ...........................................................44

List of ECU Reference ......................................... ...44

WIRING DIAGRAM .....................................45

METER SYSTEM ............................................ ...45

Wiring Diagram .................................................... ...45

CLOCK ...............................................................55

Wiring Diagram .................................................... ...55

BASIC INSPECTION ...................................57

DIAGNOSIS AND REPAIR WORKFLOW

(METER SYSTEM ) .......................................... ...

57

Work flow ............................................................. ...57

DTC/CIRCUIT DIAGNOSIS ...................... ...59

U1000 CAN COMM CIRCUIT ......................... ...59

Description ........................................................... ...59

DTC Logic ...............................................................59

Diagnosis Procedure .............................................59

U1010 CONTROL UNIT (CAN) .........................60

Description ........................................................... ...60

DTC Logic ...............................................................60

Diagnosis Procedure ..............................................60

B2205 VEHICLE SPEED ...................................61

Description ........................................................... ...61

DTC Logic ...............................................................61

Diagnosis Procedure .............................................61

B2267 ENGINE SPEED .....................................62

Description ........................................................... ...62

DTC Logic ...............................................................62

Diagnosis Procedure ..............................................62

B2268 WATER TEMP ........................................63

Description ........................................................... ...63

DTC Logic ...............................................................63

Diagnosis Procedure ..............................................63

POWER SUPPLY AND GROUND CIRCUIT .....64

COMBINATION METER ........................................ ...64

COMBINATION METER : Diagnosis Procedure ....64

TRIP RESET AND ILLUMINATION CON-

TROL SWITCH SIGNAL CIRCUIT ....................

65

Diagnosis Procedure ............................................ ...65

Component Inspection ............................................66

TRIP COMPUTER SWITCH SIGNAL CIRCUIT

...

67

Diagnosis Procedure ............................................ ...67

Component Inspection ............................................68

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......69

Component Function Check ................................ ...69

Diagnosis Procedure ..............................................69

Component Inspection ............................................70

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...71

Component Function Check ...................................71

Diagnosis Procedure ...............................................71

Component Inspection ............................................71

WASHER LEVEL SWITCH SIGNAL CIRCUIT ...73

Diagnosis Procedure ............................................ ...73

Component Inspection ............................................73

A/C AUTO AMP. CONNECTION RECOGNI-

TION SIGNAL CIRCUIT ....................................

74

Diagnosis Procedure ........................................... ...74

SYMPTOM DIAGNOSIS ............................75

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE ....................................................... ...

75

Description ........................................................... ...75

Diagnosis Procedure ...............................................75

THE TRIP RESET AND ILLUMINATION CON-

TROL SWITCH IS INOPERATIVE ....................

76

Description ........................................................... ...76

Diagnosis Procedure ...............................................76

THE TRIP COMPUTER SWITCH IS INOPER-

ATIVE .................................................................

77

Description ........................................................... ...77

Diagnosis Procedure ...............................................77

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .................................... ...

78

Description ........................................................... ...78

Diagnosis Procedure ...............................................78

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF .................................. ...

79

Description ........................................................... ...79

Diagnosis Procedure ...............................................79

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ............................................................

80

Description ........................................................... ...80

Diagnosis Procedure ...............................................80

Revision: 2010 May2011 QX56

Page 3746 of 5598

MWI

MWI-3

C

DE

F

G H

I

J

K L

M B

A

O P

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY .............................................................. ....

81

Description .......................................................... ....81

Diagnosis Procedure ...............................................81

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ..........

82

Description .......................................................... ....82

Diagnosis Procedure ...............................................82

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT .......................................................

83

Description .......................................................... ....83

Diagnosis Procedure ...............................................83

NORMAL OPERATING CONDITION .................84

INFORMATION DISPLAY ..................................... ....84

INFORMATION DISPLAY : Description ..................84

REMOVAL AND INSTALLATION ...............85

COMBINATION METER ...................................85

Exploded View ..................................................... ....85

Removal and Installation .........................................85

Disassembly and Assembly .....................................85

TRIP RESET AND ILLUMINATION CON-

TROL SWITCH ..................................................

86

Exploded View .........................................................86

Removal and Installation .........................................86

TRIP COMPUTER SWITCH ..............................87

Exploded View .........................................................87

Removal and Installation .........................................87

CLOCK ..............................................................88

Exploded View .........................................................88

Removal and Installation .........................................88

Revision: 2010 May2011 QX56

Page 3750 of 5598

MWI

COMPONENT PARTSMWI-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Com ponent DescriptionINFOID:0000000006221691

CLOCK

Unit Description

Combination meter Controls the following with the signals received from each unit via CAN communication and the sig-

nals from switches and sensors.

Speedometer

Tachometer

Engine coolant temperature gauge

Fuel gauge

Engine oil pressure gauge

Voltmeter

Warning lamps

Indicator lamps

Meter illumination control

Meter effect function

Information display

Trip computer switch Transmits the following signals to the combination meter.

Enter switch signal

Select switch signal

Trip reset and illumination con-

trol switch Transmits the following signals to the combination meter.

Trip reset switch signal

Illumination control switch signal (+)

Illumination control switch signal (

−)

ECM Transmits the following signals to the combination meter via CAN communication.

Engine speed signal

Engine coolant temperature signal

Engine status signal

Fuel consumption monitor signal

ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter via CAN communication.

IPDM E/R Transmits the oil pressure switch signal to the BCM via CAN communication.

BCM Transmits the following signals to the combination meter via CAN communication.

Oil pressure switch signal

Position light request signal

Dimmer signal

Door switch signal

Meter ring illumination request signal

Starter relay status signal

TCM Transmits the shift position signal to the combination meter via CAN communication.

A/T shift selector Transmits the following signals to the combination meter.

Manual mode signal

Non-manual mode signal

Manual mode shift up signal

Manual mode shift down signal

Fuel level sensor unit Transmits the fuel level sensor signal to the combination meter.

Oil pressure switch Transmits the oil pressure switch signal to the IPDM E/R.

Ambient sensor Transmits the ambient sensor signal to the combination meter.

A/C auto amp. Transmits the A/C auto amp. connection recognition signal to the combination meter.

Parking brake switch Transmits the parking brake switch signal to the combination meter.

Washer level switch Transmits the washer level switch signal to the combination meter.

Revision: 2010 May2011 QX56

Page 3751 of 5598

MWI-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

CLOCK : Component Parts Location

INFOID:0000000006221692

1: Clock

JSNIA3119ZZ

Revision: 2010 May2011 QX56

Page 3798 of 5598

MWI

CLOCKMWI-55

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

M B A

O P

CLOCK

Wiring DiagramINFOID:0000000006221726

JCNWM4735GB

Revision: 2010 May2011 QX56

Page 3799 of 5598

MWI-56

< WIRING DIAGRAM >

CLOCK

JCNWM4805GB

Revision: 2010 May2011 QX56

Page 3831 of 5598

MWI-88

< REMOVAL AND INSTALLATION >

CLOCK

CLOCK

Exploded ViewINFOID:0000000006221783

REMOVAL

Refer to IP-13, "Exploded View".

Removal and InstallationINFOID:0000000006221784

REMOVAL

1. Remove cluster lid C assembly. Refer to IP-14, "Removal and Installation".

2. Disengage the tabs to separate clock.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56

Page 4240 of 5598

RF-26

< SYMPTOM DIAGNOSIS >

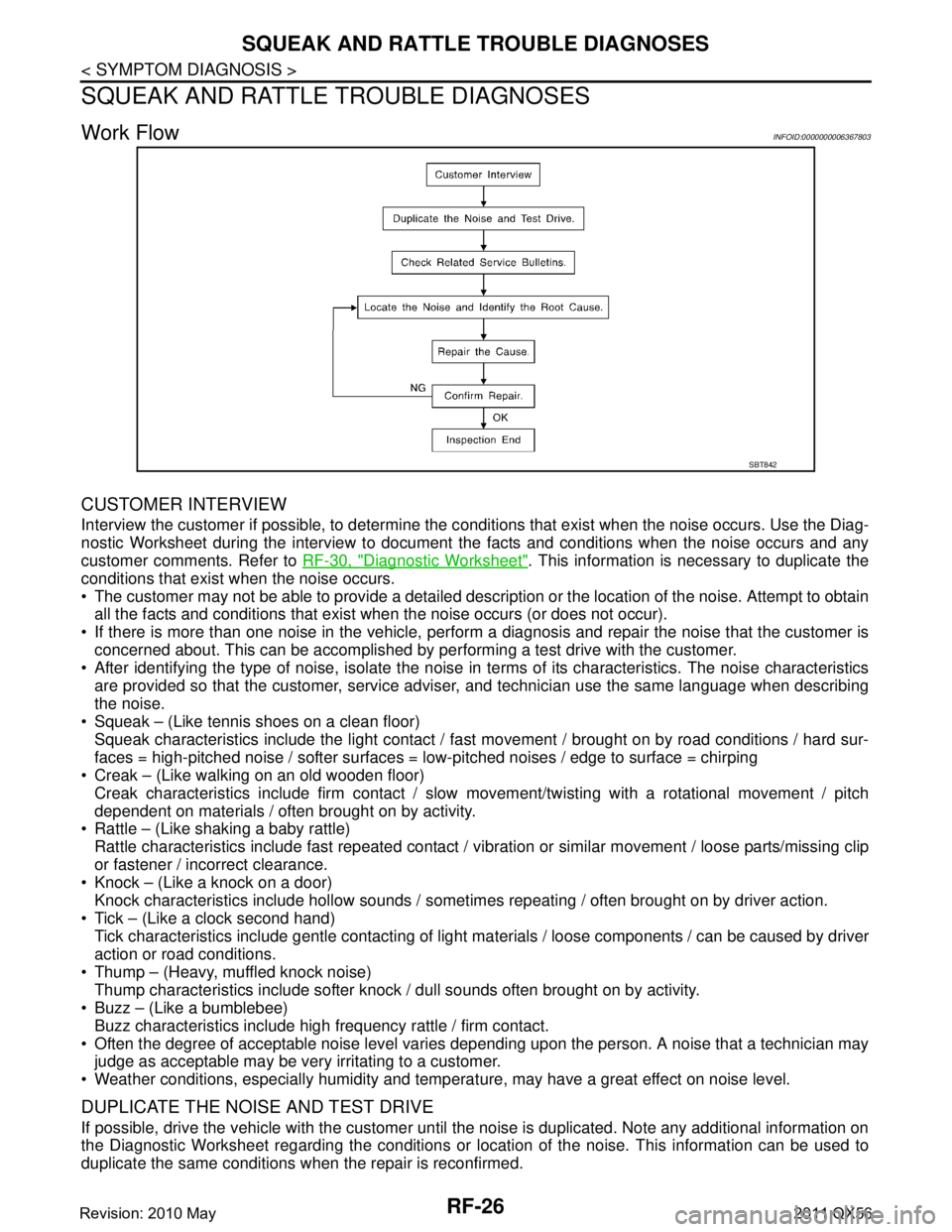

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000006367803

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer comments. Refer to RF-30, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by per forming a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact / slow movement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include fast repeated contact / vibr ation or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise) Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee)

Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

SBT842

Revision: 2010 May2011 QX56

Page 4558 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-99

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work FlowINFOID:0000000006219938

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document t he facts and conditions when the noise occurs and any of

customer's comments; refer to SE-103, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist when the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by performing a cruise test on the vehicle with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact/slow mo vement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include the fast repeated contac t/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounding/someti mes repeating/often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of li ght materials/loose components/can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise) Thump characteristics include softer k nock/dead sound often brought on by activity.

Buzz – (Like a bumblebee)

Buzz characteristics include high frequency rattle/firm contact.

Often the degree of acceptable noise level will vary depending up on the person. A noise that a technician may judge as acceptable may be very irritating to the customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

SBT842

Revision: 2010 May2011 QX56

Page 4607 of 5598

SE-148

< REMOVAL AND INSTALLATION >

CLIMATE CONTROLLED SEAT BLOWER FILTER

CLIMATE CONTROLLED SEAT BLOWER FILTER

SEAT CUSHION

SEAT CUSHION : Removal and InstallationINFOID:0000000006217445

REMOVAL

CAUTION:

When removing and installing, use shop cloths to protect parts from damage.

1. Remove the seat.

2. Turn blower filter counter counterclockwise and remo ve it from climate controlled seat cushion blower

motor.

INSTALLATION

Install in the reverse order of removal.

SEATBACK

SEATBACK : Removal and InstallationINFOID:0000000006217446

REMOVAL

CAUTION:

When removing and installi ng, use shop cloths to protect parts from damage.

1. Remove the seatback board.

2. Turn blower filter counter counterclockwise and re move it from climate controlled seat blower motor.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56