clock INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2613 of 5598

![INFINITI QX56 2011 Factory Owners Manual

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring INFINITI QX56 2011 Factory Owners Manual

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring](/img/42/57033/w960_57033-2612.png)

FUEL INJECTOR AND FUEL TUBEEM-51

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Install an injector seal drift set [SST: KV101197S0 (—)] (A) to

fuel injector (1).

b. Set seal ring (1) to injector seal drift set [SST: KV101197S0 (—)]

(A).

c. Straightly insert seal ring (1), which is set in step 2, to fuel injec- tor as shown in the figure and install.

CAUTION:

Be careful that seal ring do es not exceed the groove portion

of fuel injector.

d. Insert injector seal drift set [SST: KV101197S0 (—)] (A) to injec- tor and rotate clockwise and counterclockwise by 90 ° while

pressing seal ring to fit it.

NOTE:

Compress seal ring, because this operation is for rectifying

stretch of seal ring caused by installation and for preventing

sticking when inserting injector into cylinder head.

2. Install O-ring and backup ring to fuel injector. When handing new O-ring and backup ring, paying attention to the following caution items:

CAUTION:

Handle O-ring with bare hands. Never wear gloves.

Lubricate O-ring with new engine oil.

Never clean O-ring with solvent.

Check that O-ring and its mating pa rt are free of foreign material.

When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretched wh ile it was being attached, never insert it quickly

into fuel tube.

Insert new O-ring straight into fu el rail. Never decenter or twist it.

JSBIA0347ZZ

JSBIA0348ZZ

JSBIA0350ZZ

JSBIA0351ZZ

Revision: 2010 May2011 QX56

Page 2634 of 5598

EM-72

< REMOVAL AND INSTALLATION >

TIMING CHAIN

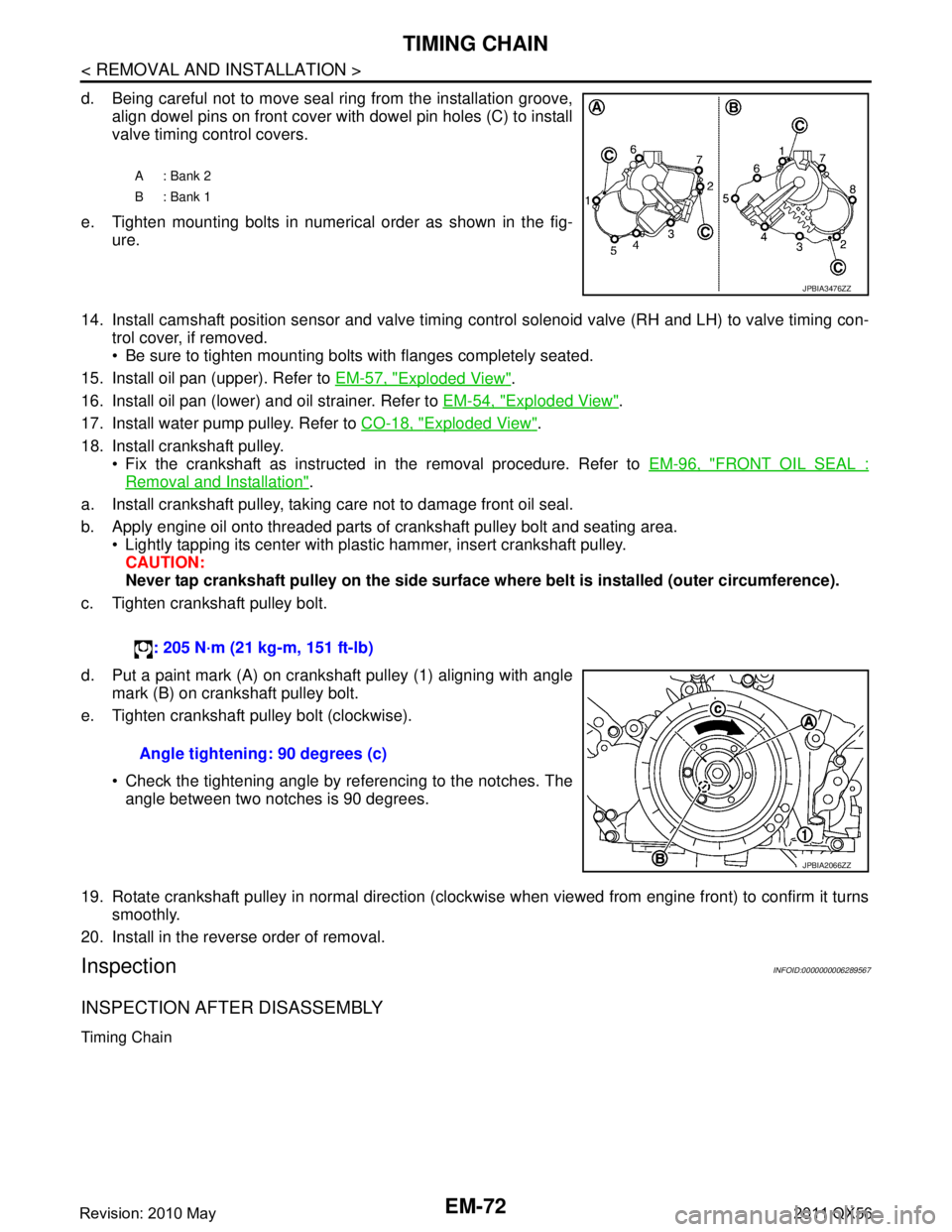

d. Being careful not to move seal ring from the installation groove,align dowel pins on front cover with dowel pin holes (C) to install

valve timing control covers.

e. Tighten mounting bolts in numerical order as shown in the fig- ure.

14. Install camshaft position sensor and valve timing c ontrol solenoid valve (RH and LH) to valve timing con-

trol cover, if removed.

Be sure to tighten mounting bolts with flanges completely seated.

15. Install oil pan (upper). Refer to EM-57, "

Exploded View".

16. Install oil pan (lower) and oil strainer. Refer to EM-54, "

Exploded View".

17. Install water pump pulley. Refer to CO-18, "

Exploded View".

18. Install crankshaft pulley. Fix the crankshaft as instructed in the removal procedure. Refer to EM-96, "

FRONT OIL SEAL :

Removal and Installation".

a. Install crankshaft pulley, taking care not to damage front oil seal.

b. Apply engine oil onto threaded parts of crankshaft pulley bolt and seating area. Lightly tapping its center with plastic hammer, insert crankshaft pulley.

CAUTION:

Never tap crankshaft pulley on the side surface wh ere belt is installed (outer circumference).

c. Tighten crankshaft pulley bolt.

d. Put a paint mark (A) on crankshaft pulley (1) aligning with angle mark (B) on crankshaft pulley bolt.

e. Tighten crankshaft pulley bolt (clockwise).

Check the tightening angle by referencing to the notches. Theangle between two notches is 90 degrees.

19. Rotate crankshaft pulley in normal direction (clockwise when viewed from engine front) to confirm it turns smoothly.

20. Install in the reverse order of removal.

InspectionINFOID:0000000006289567

INSPECTION AFTER DISASSEMBLY

Timing Chain

A: Bank 2

B: Bank 1

JPBIA3476ZZ

: 205 N·m (21 kg-m, 151 ft-lb)

Angle tightening: 90 degrees (c)

JPBIA2066ZZ

Revision: 2010 May2011 QX56

Page 2650 of 5598

EM-88

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

2. Install new cylinder head gaskets.

3. Install cylinder head as per the following: CAUTION:

If cylinder head bolts are re-used, check their ou ter diameters before installation. Refer to EM-92,

"Inspection".

Before installing cylinder head, inspect cylinder head distortion. Refer to EM-92, "

Inspection".

Tighten cylinder head bolts in numerical order as shown in fig- ure.

Use TORX socket.

a. Apply new engine oil to threads and seat surfaces of cylinder head bolts.

b. Tighten all cylinder head bolts.

c. Tighten all cylinder head bolts (clockwise).

d. Completely loosen all cylinder head bolts.

CAUTION:

In step “d”, loosen bolts in the reverse order of that indi-

cated in the figure.

e. Tighten all cylinder head bolts.

f. Tighten all cylinder head bolts (clockwise).

g. Tighten all cylinder head bolts again (clockwise).

CAUTION:

Check the tightening angle us ing the angle wrench [SST:

KV10112100 (BT8653-A)] (A). Never make judgment by

visual inspection.

Check tightening angle indicated on the angle wrench indica- tor plate.

4. Install valve lifter. Install it in the original position.

5. Install in the reverse order of removal.

A: Bank 2

B: Bank 1

: Engine front

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

Angle tightening: 75 degrees : 0 N·m (0 kg-m, 0 ft-lb)

: 40.0 N·m (4.1 kg-m, 30 ft-lb)

JPBIA2145ZZ

Angle tightening: 90 degrees

Angle tightening: 90 degrees

JPBIA0175ZZ

Revision: 2010 May2011 QX56

Page 2674 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

e. Tighten main bearing cap bolts (M12) in order of No. 1 - 10(clockwise).

CAUTION:

Use the angle wrench [SST: KV10112100 (BT8653-A)] (A) to

ch INFINITI QX56 2011 Factory Owners Manual

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

e. Tighten main bearing cap bolts (M12) in order of No. 1 - 10(clockwise).

CAUTION:

Use the angle wrench [SST: KV10112100 (BT8653-A)] (A) to

ch](/img/42/57033/w960_57033-2673.png)

EM-112

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

e. Tighten main bearing cap bolts (M12) in order of No. 1 - 10(clockwise).

CAUTION:

Use the angle wrench [SST: KV10112100 (BT8653-A)] (A) to

check tightening angl e. Never make judgment by visual

inspection.

f. Tighten main bearing cap sub bolts (M9) in order of No. 11 - 20. (clockwise)

g. Tighten side bolts (M10) in order of No. 21 - 30. After installing bolts, check that crankshaft can be rotated smoothly by hand.

Check the crankshaft end play. Refer to EM-137, "

CylinderBlock".

8. Install rear oil seal retainer. Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to rear oil seal retainer as shown in

the figure.

Use Genuine RTV silicone seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

9. Install rear oil seal on rear oil seal retainer.

Apply new engine oil to both oil seal lip (A) and dust seal lip(B).

Install it so that each seal lip is oriented as shown in the figure. CAUTION:

Be careful not to scratch or make burrs on circumference

of oil seal.

Press in rear oil seal (1) to the position as shown in the figure.

Using a suitable drift [outer diameter: 101 mm (3.98 in)].

Check the garter spring is in position and seal lips are not inverted.

10. Install piston to connecting rod as per the following: Angle tightening: 40 degrees

Angle tightening: 30 degrees

JPBIA2149ZZ

: 49.0 N·m (5.0 kg-m, 36 ft-lb)

A : Protrusion

b : 4.0 - 5.6 mm (0.157 - 0.220 in)

c:

φ3.4 - 4.4 mm (0.134 - 0.173 in)

JPBIA2102ZZ

: Engine inside

: Engine outside

JPBIA0054ZZ

B : Rear oil seal retainer rear end face

a : 0 - 0.5 mm (0 - 0.020 in)

JPBIA0152ZZ

Revision: 2010 May2011 QX56

Page 2677 of 5598

![INFINITI QX56 2011 Factory Owners Manual

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)]. INFINITI QX56 2011 Factory Owners Manual

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)].](/img/42/57033/w960_57033-2676.png)

CYLINDER BLOCKEM-115

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

f. Tighten connecting rod bolts. (clockwise)

CAUTION:

Always use the angle wrench [SST: KV10112100 (B T8653-A)]. Never make judgment by visual

inspection.

After tightening connecting rod bolts, c heck that crankshaft rotates smoothly.

Check the connecting rod side clearance. Refer to EM-115, "

Inspection".

16. Install knock sensors (1). Install knock sensors in the direction shown in the figure.

After installing knock sens or, connect harness connector, and

lay it out to front of the engine.

CAUTION:

Never tighten mounting bolts while holding connector.

If any impact by dropping is applied to knock sensor,

replace it with new one.

NOTE:

Check that there is no foreign material on the cylinder block

mating surface and the back surface of knock sensor.

Check that knock sensor does not interfere with other parts.

17. Install oil filter (for VVEL ladder assembly).

18. Install drive plate. Install drive plate (4) and reinforcement plate (3) as shown inthe figure.

When installing drive plate to crankshaft (1), be sure to cor- rectly align crankshaft side dowel pin and drive plate side

dowel pin hole.

CAUTION:

If these are not aligned correct ly, engine runs roughly and

“MIL” illuminates.

Holding ring gear with the ring gear stopper [SST: KV10119200 (J-49277)].

Tighten the mounting bolts crosswise over several times.

19. Assemble in the reverse order of disassembly.

InspectionINFOID:0000000006289584

CRANKSHAFT END PLAY

Measure the clearance between thrust bearings and crankshaft arm when crankshaft is moved fully forward or backward with a dial

indicator (A).

If the measured value exceeds t he limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also. : 19.6 N·m (2.0 kg-m, 14.5 ft-lb)

Angle tightening: 90 degrees

: Engine front

2 : Pilot converter

A : Rounded : Engine front

JPBIA4515ZZ

JPBIA2275ZZ

Standard and limit : Refer to EM-137, "CylinderBlock".

JPBIA2477ZZ

Revision: 2010 May2011 QX56

Page 2832 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EXL-122

< PERIODIC MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure

INFOID:0000000006369513

1. Place the screen. NOTE:

Stop the vehicle facing the wall.

Place the INFINITI QX56 2011 Factory Owners Manual

EXL-122

< PERIODIC MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure

INFOID:0000000006369513

1. Place the screen. NOTE:

Stop the vehicle facing the wall.

Place the](/img/42/57033/w960_57033-2831.png)

EXL-122

< PERIODIC MAINTENANCE >[XENON TYPE]

HEADLAMP AIMING ADJUSTMENT

Aiming Adjustment Procedure

INFOID:0000000006369513

1. Place the screen. NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the headlamp center and the screen.

3. Start the engine. Turn the headlamp (LO) ON. NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

4. Measure the distance (X) between the horizontal cent er line of headlamp (H) and the cutoff line (A) within

the light axis measurement range (R) from the vertical center line ahead of headlamp (V).

Low beam distribution on the screen

5. Adjust the cutoff line height (X) with the aiming adjus tment screw so as to enter in the adjustment range

(M–N) according to the horizontal center line of headlamp (H).

unit: mm (in)

Side view

Adjustment screw Screw driver rotation Facing direction

A Headlamp RH HI/LO (UP/DOWN) Clockwise UP

Counterclockwise DOWN

B Headlamp LH HI/LO (UP/DOWN) Clockwise UP

Counterclockwise DOWN

Light axis measurement range (R) : 350 ± 175 mm (13.78 ± 6.89 in)

JSLIA0005ZZ

Horizontal center line of headlamp (H) Highest cutoff line height (M) Lowest cutoff line height (N)

700 (27.56) or less 4 (0.16) 30 (1.18)

701(27.60) – 800 (31.50) 4 (0.16) 30 (1.18) 801 (31.54) or more 17 (0.67) 44 (1.73)

JSLIA0006ZZ

Distance between the headlamp center and the screen (L) : 10 m (32.8 ft)

Revision: 2010 May2011 QX56

Page 2836 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EXL-126

< REMOVAL AND INSTALLATION >[XENON TYPE]

FRONT COMBINATION LAMP

Disconnect the battery negative terminal or remove the fuse.

1. Remove front grille. Refer to

EXT-19, "

Removal and Installati INFINITI QX56 2011 Factory Owners Manual

EXL-126

< REMOVAL AND INSTALLATION >[XENON TYPE]

FRONT COMBINATION LAMP

Disconnect the battery negative terminal or remove the fuse.

1. Remove front grille. Refer to

EXT-19, "

Removal and Installati](/img/42/57033/w960_57033-2835.png)

EXL-126

< REMOVAL AND INSTALLATION >[XENON TYPE]

FRONT COMBINATION LAMP

Disconnect the battery negative terminal or remove the fuse.

1. Remove front grille. Refer to

EXT-19, "

Removal and Installation".

2. Remove front bumper molding. Refer to EXT-13, "

Removal and Installation".

3. Remove front bumper fascia. Refer to EXT-13, "

Removal and Installation".

4. Remove headlamp mounting bolts.

5. Pull out headlamp assembly forward vehicle.

6. Disconnect connectors before removing headlamp assembly.

INSTALLATION

Install in the reverse order of removal.

NOTE:

After installation, perform aiming adjustment. Refer to EXL-121, "

description".

ReplacementINFOID:0000000006369465

CAUTION:

Disconnect the battery negative terminal or remove the fuse.

After installing the bulb, install the resin cap and the bulb socket securely for watertightness.

Never touch the glass of bu lb directly by hand. Keep grease an d other oily matters away from it.

Never touch bulb by hand while it is lit or right after being turned off.

Never leave bulb out of lamp reflector for a long ti me because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

HEADLAMP BULB (HI/LO)

1. Remove fender protector. Refer to EXT-23, "FENDER PROTECTOR : Removal and Installation".

2. Rotate resin cap counterclockwise and unlock it.

3. Rotate bulb socket counterclockwise and unlock it.

4. Remove retaining spring lock. And then remove bulb from headlamp housing assembly.

CAUTION:

Never break the xenon bulb ceramic tube when replacing

the bulb.

PARKING LAMP BULB

1. Remove hood switch*.

*:When replace a right.

2. Rotate bulb socket counterclockwise and unlock it.

3. Remove bulb from bulb socket.

FRONT TURN SIGNAL LAMP BULB

1. Remove hood switch*.

*:When replace a right.

2. Rotate bulb socket counterclockwise and unlock it.

3. Remove bulb from bulb socket.

SIDE MARKER LAMP BULB

1. Remove fender protector. Refer to EXT-23, "FENDER PROTECTOR : Removal and Installation"

2. Rotate bulb socket counterclockwise and unlock it.

3. Remove bulb from bulb socket.

JPLIA0919ZZ

Revision: 2010 May2011 QX56

Page 2837 of 5598

![INFINITI QX56 2011 Factory Owners Manual

FRONT COMBINATION LAMPEXL-127

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

Disassembly and AssemblyINFOID:0000000006369466

DISASSEMBLY

1. Rotate resin cap counterclockw INFINITI QX56 2011 Factory Owners Manual

FRONT COMBINATION LAMPEXL-127

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

Disassembly and AssemblyINFOID:0000000006369466

DISASSEMBLY

1. Rotate resin cap counterclockw](/img/42/57033/w960_57033-2836.png)

FRONT COMBINATION LAMPEXL-127

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

Disassembly and AssemblyINFOID:0000000006369466

DISASSEMBLY

1. Rotate resin cap counterclockwise and unlock it.

2. Rotate xenon bulb socket counterclockwise and unlock it.

3. Remove retaining spring lock. Remove xenon bulb.

4. Remove bumper bracket.

5. Rotate parking lamp bulb socket counterclockwise and unlock it.

6. Remove bulb from parking lamp bulb socket.

7. Rotate front turn signal lamp bulb socket counterclockwise and unlock it.

8. Remove bulb from front turn signal lamp bulb socket.

9. Rotate side marker lamp bulb socket counterclockwise and unlock it.

10. Remove bulb from bulb socket.

ASSEMBLY

Assemble in the reverse order of disassembly.

CAUTION:

HID control unit and xenon bu lb socket cannot be disassembled.

After installing the bulb, install the resin cap and the bulb socket securely for watertightness.

Revision: 2010 May2011 QX56

Page 2839 of 5598

![INFINITI QX56 2011 Factory Owners Manual

FRONT FOG LAMPEXL-129

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

2. Remove front fog lamp bulb connector (1).

3. Rotate bulb (2) counterclockwise and unlock it.

JPLIA INFINITI QX56 2011 Factory Owners Manual

FRONT FOG LAMPEXL-129

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

2. Remove front fog lamp bulb connector (1).

3. Rotate bulb (2) counterclockwise and unlock it.

JPLIA](/img/42/57033/w960_57033-2838.png)

FRONT FOG LAMPEXL-129

< REMOVAL AND INSTALLATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

2. Remove front fog lamp bulb connector (1).

3. Rotate bulb (2) counterclockwise and unlock it.

JPLIA0921ZZ

Revision: 2010 May2011 QX56

Page 2852 of 5598

![INFINITI QX56 2011 Factory Owners Manual

EXL-142

< REMOVAL AND INSTALLATION >[XENON TYPE]

BACK-UP LAMP

Replacement

INFOID:0000000006369488

CAUTION:

Disconnect the battery negative terminal or remove the fuse.

Never touch the glass of bu INFINITI QX56 2011 Factory Owners Manual

EXL-142

< REMOVAL AND INSTALLATION >[XENON TYPE]

BACK-UP LAMP

Replacement

INFOID:0000000006369488

CAUTION:

Disconnect the battery negative terminal or remove the fuse.

Never touch the glass of bu](/img/42/57033/w960_57033-2851.png)

EXL-142

< REMOVAL AND INSTALLATION >[XENON TYPE]

BACK-UP LAMP

Replacement

INFOID:0000000006369488

CAUTION:

Disconnect the battery negative terminal or remove the fuse.

Never touch the glass of bu lb directly by hand. Keep grease an d other oily matters away from it.

Never touch bulb by hand while it is lit or right after being turned off.

Never leave bulb out of lamp reflector for a long ti me because dust, moisture smoke, etc. may affect

the performance of lamp. When replacing bulb, be sure to replace it with new one.

TAIL LAMP BULB

1. Remove lamp mask. Refer to INT-39, "Exploded View".

2. Disconnect tail lamp connector.

3. Tail bulb socket counterclockwise and unlock it.

4. Remove bulb from bulb socket.

BACK-UP LAMP BULB

1. Remove lamp mask. Refer to INT-39, "Exploded View".

2. Disconnect back-up lamp connector.

3. Turn bulb socket counterclockwise and unlock it.

4. Remove bulb from bulb socket.

Revision: 2010 May2011 QX56