door INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4222 of 5598

RF-8

< ECU DIAGNOSIS INFORMATION >

SUNROOF SYSTEM

SUNROOF SYSTEM

Reference ValueINFOID:0000000006141227

TERMINAL LAYOUT

PHYSICAL VALUES

JMKIA2225ZZ

Te r m i n a l N o .(Wire color) Description

ConditionVoltage (V)

(Approx.)

+ – Signal name Input/

Output

1

(B) Ground Ground — — 0

3

(Y) Ground Retained power signal Input Ignition switch ON

12

Within 45 seconds after ignition

switch is turned to OFF

When driver side or passenger side

door is opened during retained pow-

er operation 0

5

(P) Ground Sunroof open signal Input Sunroof switch in following position

TILT DOWN

SLIDE OPEN

0

Ignition switch ON 12

6

(W) Ground Sunroof power supply Input — 12

8

(SB) Ground Vehicle speed signal (2-

pulse)

InputSpeedometer operated [When vehi-

cle speed is approx.40km/ h

(25MPH)]

10

(GR) Ground Sunroof close signal Input Sunroof switch in following position

TILT UP

SLIDE CLOSE

0

Ignition switch ON 12

ELF1080D

Revision: 2010 May2011 QX56

Page 4239 of 5598

RETAINED POWER OPERATION DOES NOT OPERATE PROPERLY

RF-25

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

RF

N

O P

RETAINED POWER OPERATION DOES NOT OPERATE PROPERLY

Diagnosis ProcedureINFOID:0000000006141241

1.CHECK DOOR SWITCH

Check door switch.

Refer to DLK-117, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONFIRM THE OPERATION

Confirm the operation again.

Is the result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 4240 of 5598

RF-26

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES

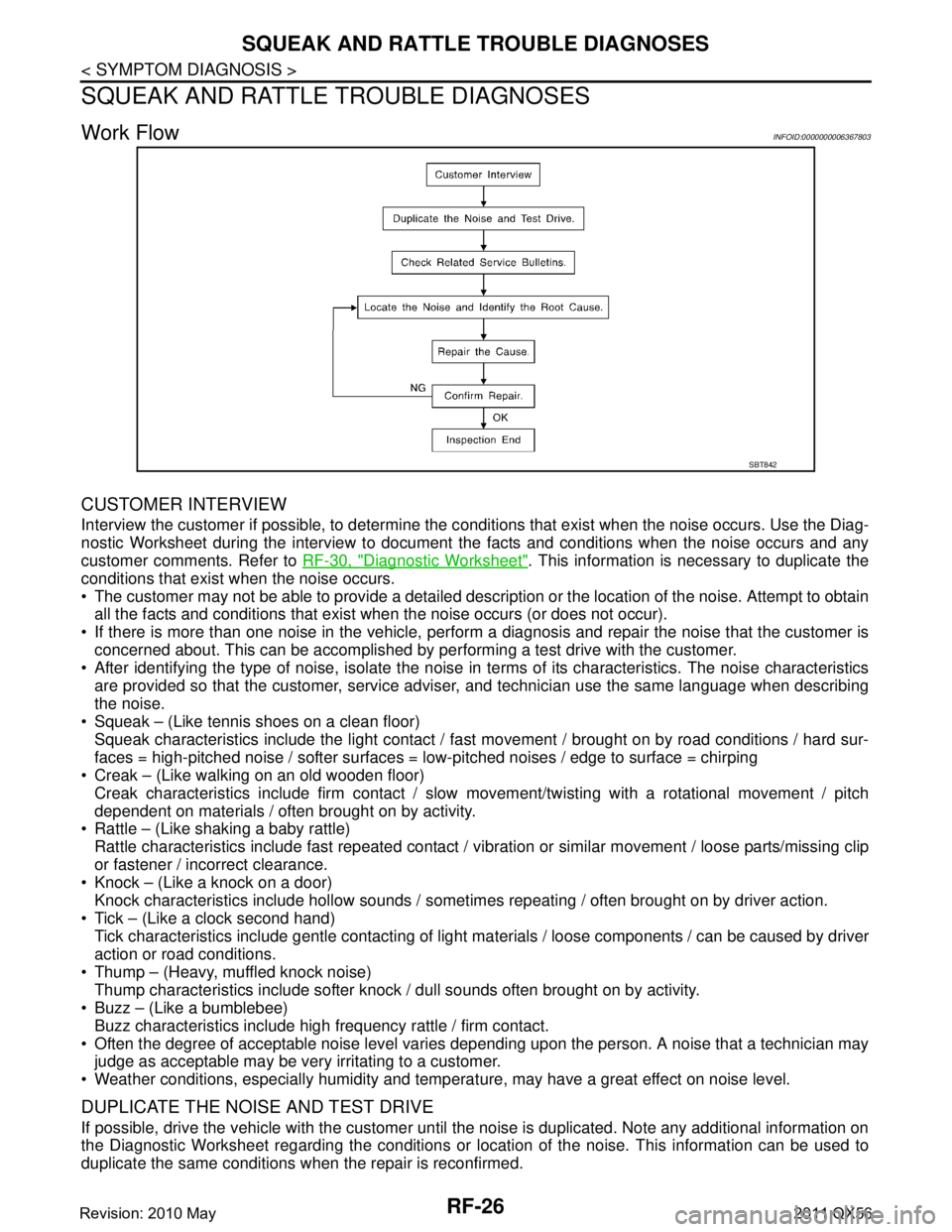

Work FlowINFOID:0000000006367803

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the c onditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer comments. Refer to RF-30, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain all the facts and conditions that exist w hen the noise occurs (or does not occur).

If there is more than one noise in the vehicle, perform a diagnosis and repair the noise that the customer is

concerned about. This can be accomplished by per forming a test drive with the customer.

After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so that the customer, service advis er, and technician use the same language when describing

the noise.

Squeak – (Like tennis shoes on a clean floor)

Squeak characteristics include the light contact / fast movement / brought on by road conditions / hard sur-

faces = high-pitched noise / softer surfaces = low-pitched noises / edge to surface = chirping

Creak – (Like walking on an old wooden floor)

Creak characteristics include firm contact / slow movement/twisting with a rotational movement / pitch

dependent on materials / often brought on by activity.

Rattle – (Like shaking a baby rattle)

Rattle characteristics include fast repeated contact / vibr ation or similar movement / loose parts/missing clip

or fastener / incorrect clearance.

Knock – (Like a knock on a door)

Knock characteristics include hollow sounds / someti mes repeating / often brought on by driver action.

Tick – (Like a clock second hand) Tick characteristics include gentle contacting of light materials / loose components / can be caused by driver

action or road conditions.

Thump – (Heavy, muffled knock noise) Thump characteristics include softer knock / dull sounds often brought on by activity.

Buzz – (Like a bumblebee)

Buzz characteristics include high frequency rattle / firm contact.

Often the degree of acceptable noise level varies depending upon the person. A noise that a technician may

judge as acceptable may be very irritating to a customer.

Weather conditions, especially humidity and temperat ure, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

SBT842

Revision: 2010 May2011 QX56

Page 4241 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-27

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following items:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to the concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis ear: J-39570, engine ear, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the component(s) in the area that is / are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component(s) that is / are suspected to be the cause of the noise.

Do not tap or push/pull the component(s) with excessive force, otherwise the noise is eliminated only tempo-

rarily.

Feeling for a vibration by hand by touching the component(s ) that is / are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to RF-28, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the components, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape, or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through the authorized NISSAN Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSA N Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.937 ×5.315 in)

76884-71L01: 60 ×85 mm (2.362 ×3.346 in)

76884-71L02: 15 ×25 mm (0.591 ×0.984 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.772 in) thick, 50 ×50 mm (1.969 ×1.969 in)

73982-50Y00: 10 mm (0.394 in) thick, 50 ×50 mm (1.969 ×1.969 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.181 in) thick, 30 ×50 mm (1.181 ×1.969in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

Revision: 2010 May2011 QX56

Page 4242 of 5598

RF-28

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confir m that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006367804

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

Revision: 2010 May2011 QX56

Page 4303 of 5598

SBC-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

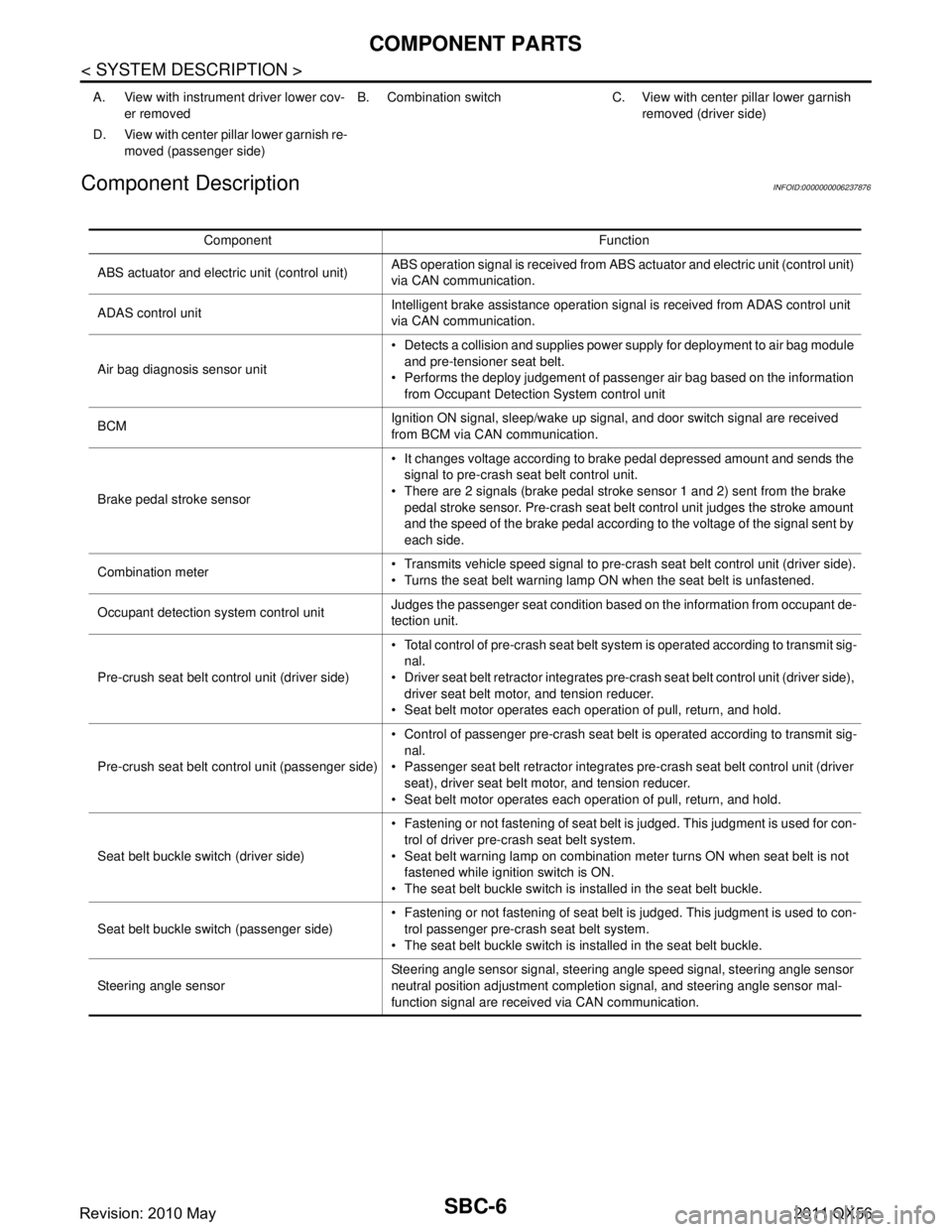

Component Description

INFOID:0000000006237876

A. View with instrument driver lower cov- er removed B. Combination switch C. View with center pillar lower garnish

removed (driver side)

D. View with center pillar lower garnish re- moved (passenger side)

Component Function

ABS actuator and electric unit (control unit) ABS operation signal is rece

ived from ABS actuator and el ectric unit (control unit)

via CAN communication.

ADAS control unit Intelligent brake assistance operation signal is received from ADAS control unit

via CAN communication.

Air bag diagnosis sensor unit Detects a collision and supplies power supply for deployment to air bag module

and pre-tensioner seat belt.

Performs the deploy judgement of passenger air bag based on the information from Occupant Detection System control unit

BCM Ignition ON signal, sleep/wake up signal, and door switch signal are received

from BCM via CAN communication.

Brake pedal stroke sensor It changes voltage according to brake pedal depressed amount and sends the

signal to pre-crash seat belt control unit.

There are 2 signals (brake pedal stroke sensor 1 and 2) sent from the brake

pedal stroke sensor. Pre-crash seat belt control unit judges the stroke amount

and the speed of the brake pedal according to the voltage of the signal sent by

each side.

Combination meter Transmits vehicle speed signal to pre-crash seat belt control unit (driver side).

Turns the seat belt warning lamp ON when the seat belt is unfastened.

Occupant detection system control unit Judges the passenger seat condition based on the information from occupant de-

tection unit.

Pre-crush seat belt control unit (driver side) Total control of pre-crash seat belt system is operated according to transmit sig-

nal.

Driver seat belt retractor integrates pre-crash seat belt control unit (driver side), driver seat belt motor, and tension reducer.

Seat belt motor operates each operation of pull, return, and hold.

Pre-crush seat belt control unit (passenger side) Control of passenger pre-crash seat belt is operated according to transmit sig-

nal.

Passenger seat belt retractor integrates pre-crash seat belt control unit (driver seat), driver seat belt motor, and tension reducer.

Seat belt motor operates each operation of pull, return, and hold.

Seat belt buckle switch (driver side) Fastening or not fastening of seat belt is judged. This judgment is used for con-

trol of driver pre-crash seat belt system.

Seat belt warning lamp on combination meter turns ON when seat belt is not fastened while ignition switch is ON.

The seat belt buckle switch is installed in the seat belt buckle.

Seat belt buckle switch (passenger side) Fastening or not fastening of seat belt is judged. This judgment is used to con-

trol passenger pre-crash seat belt system.

The seat belt buckle switch is installed in the seat belt buckle.

Steering angle sensor Steering angle sensor signal, steering angle speed signal, steering angle sensor

neutral position adjustment completion signal, and steering angle sensor mal-

function signal are received via CAN communication.

Revision: 2010 May2011 QX56

Page 4305 of 5598

SBC-8

< SYSTEM DESCRIPTION >

SYSTEM

When the vehicle inclined excessively

When comfort function operates

OPERATION CONDITION

Operation while driving

Operation start and stop conditions of pre-crash seat belt system are as shown in the following table.

The activation and deactivation conditions of pre-crush seat belt are as per the following.

NOTE:

For details of intelligent brake assist system.Refer to BRC-152, "

INTELLIGENT BRAKE ASSIST : System

Description".

Comfort function

Seat belt is retracted and the looseness is reduced in the state as shown in the following table.

Operation start and stop conditions of pre-crash seat belt system are as shown in the following table.

Operation Prohibition Condition

Pre-crash seat belt system does not operate in the following conditions.

When seat belt is not fastened (only the seat belt that is not fastened does not operate)

When motor is overheat due to contentious operation*1

When the system is in fail-safe mode *1: System operation is temporarily deactivated to av oid overheating, when comfort function is continuously

operated (18 times or more) during a short period of time by fastening and unfastening seat belts or opening

and closing doors.

MALFUNCTION WARNING

When system malfunction is detected, comfort function is deactivated to warn customer of system malfunc-

tion.

Operation item Operation start condition Operation stop condition

During emergency brake operation Vehicle speed is 15 km/h (9 MPH) or more

Emergency braking status is detected

During acceleration

When stopped

When ABS continuously operates ABS continuously operates for 2 seconds or

more

Brake pedal is in depressed state

When intelligent brake assistance oper-

ates System detects that intelligent brake assistance is

in operating status

2 seconds after operation start

When lateral slippage during cornering

occurs Vehicle speed is 30 km/h (19 MPH) or more

System detects that the vehicle is in lateral slip-

page state

System detects that the vehicle is driving on a curve Vehicle stopped

1 second or more after maintaining

steering wheel angle in straight driv-

ing state

When steering wheel is rotated for emer-

gency Vehicle speed is 60 km/h (36 MPH) or more

Steering wheel angle is 90 degrees or more

System detects that steering wheel is rotated for

emergency

When the vehicle inclined excessively Vehicle speed is 30 km/h (19 MPH) or more

System detects that the vehicle inclined exces-

sively During acceleration

Vehicle stopped

Operation item Activating condition Deactivating condition

Door open Seat belt is in not fastened state

Door is operated to open from closed

Vehicle stopped Seat belt retract is complete

13 seconds after start retracting

Seat belt is fastened When door is closed

Seat belt is fastened Seat belt is unfastened

1 second after operation

Seat belt is release Seat belt is unfastened Seat belt retract is complete

10 seconds after start retracting

Revision: 2010 May2011 QX56

Page 4308 of 5598

DIAGNOSIS SYSTEM (PRE-CRASH SEAT BELT)SBC-11

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

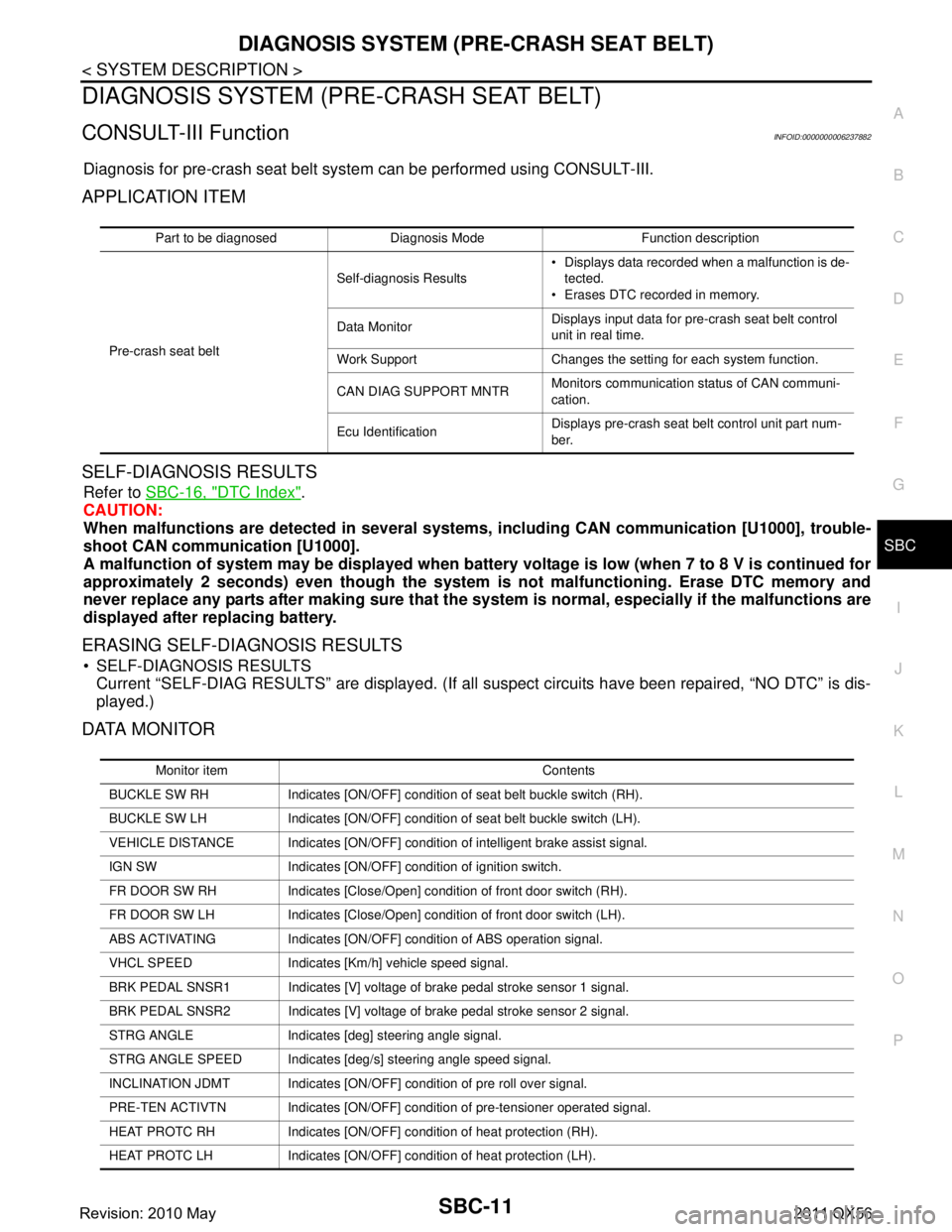

DIAGNOSIS SYSTEM (P RE-CRASH SEAT BELT)

CONSULT-III FunctionINFOID:0000000006237882

Diagnosis for pre-crash seat belt syst em can be performed using CONSULT-III.

APPLICATION ITEM

SELF-DIAGNOSIS RESULTS

Refer to SBC-16, "DTC Index".

CAUTION:

When malfunctions are detect ed in several systems, includin g CAN communication [U1000], trouble-

shoot CAN communication [U1000].

A malfunction of system may be disp layed when battery voltage is low (when 7 to 8 V is continued for

approximately 2 seconds) even though the system is not malfunctioning. Erase DTC memory and

never replace any parts after making sure that the syst em is normal, especially if the malfunctions are

displayed after replacing battery.

ERASING SELF-DIAGNOSIS RESULTS

SELF-DIAGNOSIS RESULTS Current “SELF-DIAG RESULTS” are displayed. (If all suspect circuits have been repaired, “NO DTC” is dis-

played.)

DATA MONITOR

Part to be diagnosed Diagnosis Mode Function description

Pre-crash seat belt Self-diagnosis Results

Displays data recorded when a malfunction is de-

tected.

Erases DTC recorded in memory.

Data Monitor Displays input data for pre-crash seat belt control

unit in real time.

Work Support Changes the setting for each system function.

CAN DIAG SUPPORT MNTR Monitors communication status of CAN communi-

cation.

Ecu Identification Displays pre-crash seat belt control unit part num-

ber.

Monitor item Contents

BUCKLE SW RH Indicates [ON/OFF] condition of seat belt buckle switch (RH).

BUCKLE SW LH Indicates [ON/OFF] condition of seat belt buckle switch (LH).

VEHICLE DISTANCE Indicates [ON/OFF] condit ion of intelligent brake assist signal.

IGN SW Indicates [ON/OFF] condition of ignition switch.

FR DOOR SW RH Indicates [Close/Open] condition of front door switch (RH).

FR DOOR SW LH Indicates [Close/Open] condition of front door switch (LH).

ABS ACTIVATING Indicates [ON/OFF] co ndition of ABS operation signal.

VHCL SPEED Indicates [Km/h] vehicle speed signal.

BRK PEDAL SNSR1 Indicates [V] voltage of brake pedal stroke sensor 1 signal.

BRK PEDAL SNSR2 Indicates [V] voltage of brake pedal stroke sensor 2 signal.

STRG ANGLE Indicates [deg] steering angle signal.

STRG ANGLE SPEED Indicates [deg/s] steering angle speed signal.

INCLINATION JDMT Indicates [ON/OFF] condition of pre roll over signal.

PRE-TEN ACTIVTN Indicates [ON/OFF] condition of pre-tensioner operated signal.

HEAT PROTC RH Indicates [ON/OFF] condition of heat protection (RH).

HEAT PROTC LH Indicates [ON/OFF] condition of heat protection (LH).

Revision: 2010 May2011 QX56

Page 4309 of 5598

SBC-12

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (PRE-CRASH SEAT BELT)

WORK SUPPORT

Monitor item Description

DOOR OPENING RETRACT RETRY Changes the number of times for the seat belt retract retry when the door opens.

Revision: 2010 May2011 QX56

Page 4310 of 5598

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)SBC-13

< ECU DIAGNOSIS INFORMATION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

ECU DIAGNOSIS INFORMATION

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)

Reference ValueINFOID:0000000006237883

VALUES ON THE DIAGNOSIS TOOL

CONSULT-III MONITOR ITEM

Monitor item Condition Value/Status

(Approx.)

BUCKLE SW RH RH seat belt is not fastened OFF

RH seat belt is fastened ON

BUCKLE SW LH RH seat belt is not fastened OFF

RH seat belt is fastened ON

VEHICLE DISTANCE Not activated OFF

Activated ON

IGN SW Ignition switch OFF OFF

Ignition switch ON ON

FR DOOR SW RH LH door close CLOSE

LH door open OPEN

FR DOOR SW LH RH door close CLOSE

RH door open OPEN

ABS ACTIVATING ABS is inactive OFF

ABS is active ON

VHCL SPEED While driving Equival ent speedometer reading (km/h)

BRK PEDAL SNSR1 Brake released → depressed (1 V → 4 V)

BRK PEDAL SNSR2 Brake released → depressed (4 V → 1 V)

STRG ANGLE Steering wheel: 0

° (Neutral) ±2.5 (deg)

Steering wheel: 90 ° (Turned right) +90 (deg)

Steering wheel: 90 ° (Turned left) -90 (deg)

STRG ANGLE SPEED Steering wheel: Being turnedDepending on steering acceleration speed

(deg/s)

INCLINATION JDMT Vehicle is level OFF

Vehicle is inclined ON

PRE-TEN ACTIVTN Seat belt pre-tensioner is not activated OFF

Seat belt pre-tensioner is activated ON

HEAT PROTC RH RH heat protection is not activated OFF

RH heat protection is activated ON

HEAT PROTC LH LH heat protection is not activated OFF

LH heat protection is activated ON

Revision: 2010 May2011 QX56