display INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2735 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)EXL-25

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

*: Only models for Canada display this item.

FLASHER

FLASHER : CONSULT-III F unction (BC INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)EXL-25

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

*: Only models for Canada display this item.

FLASHER

FLASHER : CONSULT-III F unction (BC](/img/42/57033/w960_57033-2734.png)

DIAGNOSIS SYSTEM (BCM)EXL-25

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE TEST

*: Only models for Canada display this item.

FLASHER

FLASHER : CONSULT-III F unction (BCM - FLASHER)INFOID:0000000006213912

WORK SUPPORT

DOOR SW-DR

[On/Off] The switch status input from front door switch (driver side)

DOOR SW-AS

[On/Off] The switch status input from front door switch (passenger side)

DOOR SW-RR

[On/Off] The switch status input from rear door switch RH

DOOR SW- RL

[On/Off] The switch status input from rear door switch LH

DOOR SW-BK

[On/Off] The switch status input from back door switch

OPTICAL SENSOR

[On/Off] The sensor status input from optical sensor

OPTI SEN (DTCT)

[V] The value of outside brightness voltage input from the optical sensor

OPTI SEN (FILT)

[V] The value of outside brightness voltage filtered by BCM

Monitor item

[Unit] Description

Test item Operation Description

TAIL LAMP On

Transmits the position light request signal to IPDM E/R via CAN commu-

nication to turn the tail lamp ON

Off Stops the tail lamp request signal transmission

HEAD LAMP Hi

Transmits the high beam request signal via CAN communication to turn

the headlamp (HI)

Lo Transmits the low beam request signal via CAN communication to turn

the headlamp (LO)

Off Stops the high & low beam request signal transmission

FR FOG LAMP On

Transmits the front fog lights request signal to IPDM E/R via CAN com-

munication to turn the front fog lamp ON

Off Stops the front light request signal transmission

RR FOG LAMP On

NOTE:

This item is indicated, but can not tested

Off

DAYTIME RUNNING LIGHT* On

Transmits the front fog lights request signal to IPDM E/R via CAN com-

munication to turn the front fog lamp ON (daytime running light system)

Off Stops the front light request signal transmission (daytime running light

system)

ILL DIM SIGNAL On Transmits the dimmer signal to combination meter via CAN communi-

cation and dims combination meter

Transmits the dimmer signal to AV control unit and dims display

Off Stops the dimmer signal transmission

Revision: 2010 May2011 QX56

Page 2739 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)EXL-29

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

CONSULT-III Function (IPDM E/R)INFOID:0000000006368067

APPLICATION ITEM

CONSULT-III performs th INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (IPDM E/R)EXL-29

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

CONSULT-III Function (IPDM E/R)INFOID:0000000006368067

APPLICATION ITEM

CONSULT-III performs th](/img/42/57033/w960_57033-2738.png)

DIAGNOSIS SYSTEM (IPDM E/R)EXL-29

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

CONSULT-III Function (IPDM E/R)INFOID:0000000006368067

APPLICATION ITEM

CONSULT-III performs the following functi ons via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to PCS-22, "DTCIndex".

DATA MONITOR

Monitor item

Oil pressure warning lamp does not operate Perform auto active test.

Does the oil pressure warning

lamp blink?YES

Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item [Unit] MAIN SIG-

NALS Description

RAD FAN REQ

[1/2/3/4] ×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On] ×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TAIL&CLR REQ

[Off/On] ×

Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On] ×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On] ×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On] ×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi] ×

Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P] ×

Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK] ×

Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On] Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

IGN RLY

[Off/On] ×

Displays the status of the ignition relay judged by IPDM E/R.

Revision: 2010 May2011 QX56

Page 2740 of 5598

![INFINITI QX56 2011 Factory Service Manual

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP S INFINITI QX56 2011 Factory Service Manual

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP S](/img/42/57033/w960_57033-2739.png)

EXL-30

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On] Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On] Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On] Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST ON/INHI ON/UNKWN] Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On] Displays the status of the A/T shift selector (detention switch) judged by IPDM E/

R.

S/L RLY -REQ

[Off/On] Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLK/UNKWN] Displays the status of the steering lock judged by IPDM E/R.

OIL P SW

[Open/Close] Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On] Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off/On] Displays the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On] Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On] Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

Monitor Item

[Unit] MAIN SIG-

NALS Description

Test item Operation Description

CORNERING LAMP LH

NOTE:

This item is indicated, but cannot be tested.

RH

HORN On Operates horn relay for 20 ms.

REAR DEFOGGER Off OFF

On Operates the rear window defogger relay.

FRONT WIPER Off OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN* 1OFF

2 Transmits 50% pulse duty signal (PWM signal) to the cooling fan control module.

3 Transmits 75% pulse duty signal (PWM signal) to the cooling fan control module.

4

Transmits 100% pulse duty signal (PWM signal) to the cooling fan control mod-

ule.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 second.

Revision: 2010 May2011 QX56

Page 2742 of 5598

![INFINITI QX56 2011 Factory Service Manual

EXL-32

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (AFS)

DIAGNOSIS SYSTEM (AFS)

CONSULT-III Function (ADAPTIVE LIGHT)INFOID:0000000006213915

APPLICATION ITEM

WORK SUPPORT

*: Adjusts the steer INFINITI QX56 2011 Factory Service Manual

EXL-32

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (AFS)

DIAGNOSIS SYSTEM (AFS)

CONSULT-III Function (ADAPTIVE LIGHT)INFOID:0000000006213915

APPLICATION ITEM

WORK SUPPORT

*: Adjusts the steer](/img/42/57033/w960_57033-2741.png)

EXL-32

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (AFS)

DIAGNOSIS SYSTEM (AFS)

CONSULT-III Function (ADAPTIVE LIGHT)INFOID:0000000006213915

APPLICATION ITEM

WORK SUPPORT

*: Adjusts the steering angle sensor neutral position on ABS actuator and electrical unit (control unit) side. Refer to

BRC-64, "Work Pro-

cedure".

DATA MONITOR

*: The swivel angle "0°" (feedback value) of the swivel position sensor signal may differ from the swivel angle "0 °" of the swivel motor

(AFS control unit command value). This causes that the swivel motor initializes the value based on the step number from the sto pper.

ACTIVE TEST

Diagnostic mode Description

Ecu Identification Allows confirmation of AFS control unit part number.

Self Diagnostic Result Displays the diagnosis results judged by AFS control unit.

Work support Sets each sensor.

Data monitor Indicates AFS control unit input data in real time.

Active test Provides the drive signal to the load. Checks operation.

Service item Description

ST ANG SEN ADJUSTMENT

*—

LEVELIZER ADJUSTMENT Adjusts the height sensor signal output value (AFS control unit recognized) in the un-

loaded vehicle condition.

Monitor item

[Unit] Description

STR ANGLS SIG

[deg] The steering angle value judged by the steering angle sensor signal received from

the steering angle sensor via CAN communication

VHCL SPD

[km/h] The vehicle speed signal value from the combination meter via CAN communication

SLCT LVR POSI

[P/R/N/D/M/FF] The selector lever status judged by the position indicator signal received from TCM

via CAN communication

HEAD LAMP

[On/Off] The headlamp On/Off status judged by the low beam headlamp (ON) signal received

from IPDM E/R via

CAN communication

AFS SW

[On/Off] The AFS On/Off status judged by AFS control unit

HI SEN OTP RR

[V] The rear height sensor signal voltage value input from the rear height sensor

HI SEN OTP FR

[V] The front height sensor signal voltage value input from the front height sensor

LEV ACTR VLTG

[%] The ratio value to the battery voltage generated by the levelizer activation signal con-

trol value judged by AFS control unit

SWVL SEN RH

*

[deg] The head lamp swivel angle value judged by AFS control unit received from the swiv-

el position sensor signal input from the swivel actuator

SWVL SEN LH

*

[deg]

SWVL ANGLE RH

*

[deg]

The swivel angle command value to the swivel motor judged by AFS control unit

SWVL ANGLE LH

*

[deg]

Revision: 2010 May2011 QX56

Page 2749 of 5598

![INFINITI QX56 2011 Factory Service Manual

AFS CONTROL UNITEXL-39

< ECU DIAGNOSIS INFORMATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DTC Inspection Priority ChartINFOID:0000000006213919

If some DTCs are displayed at the same time, p INFINITI QX56 2011 Factory Service Manual

AFS CONTROL UNITEXL-39

< ECU DIAGNOSIS INFORMATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DTC Inspection Priority ChartINFOID:0000000006213919

If some DTCs are displayed at the same time, p](/img/42/57033/w960_57033-2748.png)

AFS CONTROL UNITEXL-39

< ECU DIAGNOSIS INFORMATION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

DTC Inspection Priority ChartINFOID:0000000006213919

If some DTCs are displayed at the same time, per form inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 is displayed with other DTC, fi rst perform the trouble diagnosis for DTC U1000.

If DTC U1010 is displayed with other DTC, fi rst perform the trouble diagnosis for DTC U1010.

DTC IndexINFOID:0000000006213920

×: Applicable

Priority Detected items (DTC)

1 U1000: CAN COMM CIRCUIT

U1010: CONTROL UNIT (CAN)

2 B2519: LEVELIZER CALIB

B2521: ECU CIRC

C0428: ST ANG SEN CALIB

3 B2503: SWIVEL ACTUATOR [RH]

B2504: SWIVEL ACTUATOR [LH]

B2513: HI SEN UNUSUAL [FR]

B2514: HI SEN UNUSUAL [RR]

B2516: SHIFT SIG [P, R]

B2517: VEHICLE SPEED SIG

C0126: ST ANG SEN SIG

CONSULT display Fail-safe

AFS OFF indicator

lamp Reference

U1000: CAN COMM CIRCUIT ××EXL-82

U1010: CONTROL UNIT (CAN) ××EXL-83

B2503: SWIVEL ACTUATOR [RH] ××EXL-63

B2504: SWIVEL ACTUATOR [LH] ××EXL-63

B2513: HI SEN UNUSUAL [FR] ×EXL-68

B2514: HI SEN UNUSUAL [RR] ×EXL-71

B2516: SHIFT SIG [P, R] ××EXL-74

B2517: VEHICLE SPEED SIG ××EXL-75

B2519: LEVELIZER CALIB ×EXL-76

B2521: ECU CIRC ××EXL-77

C0126: ST ANG SEN SIG ××EXL-80

C0428: ST ANGLE SEN CALIB ××EXL-81

Revision: 2010 May2011 QX56

Page 2792 of 5598

![INFINITI QX56 2011 Factory Service Manual

EXL-82

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000006213948

CAN (Controller Area Network) is the serial transmissi

on for real time a INFINITI QX56 2011 Factory Service Manual

EXL-82

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000006213948

CAN (Controller Area Network) is the serial transmissi

on for real time a](/img/42/57033/w960_57033-2791.png)

EXL-82

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

U1000 CAN COMM CIRCUIT

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000006213948

CAN (Controller Area Network) is the serial transmissi

on for real time application. CAN is the multiplex com-

munication for the vehicle with superior data transmi ssion speed and error detection ability. Many electronic

control units are equipped on the vehicle. These control units do not operate individually, but associates with

other control units by sharing information. In CA N communication, each control unit is connected with two

communication lines (CAN-H and CAN-L). Much inform ation is transmitted with fewer communication lines

than before. Each control unit transmits/rec eives data and reads the necessary data only.

CAN Communication Signal Chart. Refer to LAN-27, "

CAN COMMUNICATION SYSTEM : CAN System Spec-

ification Chart".

DTC LogicINFOID:0000000006213949

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000006213950

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result”.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-18, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-40, "

Intermittent Incident".

DTC No. Trouble diagnosis name DTC detection condition Possible causes

U1000 CAN communication circuit When AFS control unit does not trans-

mit/receive CAN communication signal

continuously for 2 seconds or more

CAN communication system

Revision: 2010 May2011 QX56

Page 2949 of 5598

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000006225640

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: Refer to WT-64, "

Inspection".

Wheel bearing axial end play: Refer to FA X - 7 , "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Lower link and upper link ball joint axial end play: Refer to FSU-15, "

Inspection" and FSU-18, "Inspection".

Shock absorber operation.

Each mounting part of axle and suspension for looseness and deformation

Lower link for cracks, deformation and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225641

CAMBER, CASTER

1. Adjust with the front/rear side adjusting bolts (1) on the lower link

(2).

2. See the following table for the amount of cam bolt scale move- ment and the variation of camber and caster.

CAUTION:

Align the adjusting bolt cutout with the stamp of lower link

bracket.

: Vehicle front

JPEIA0235ZZ

Revision: 2010 May2011 QX56

Page 2980 of 5598

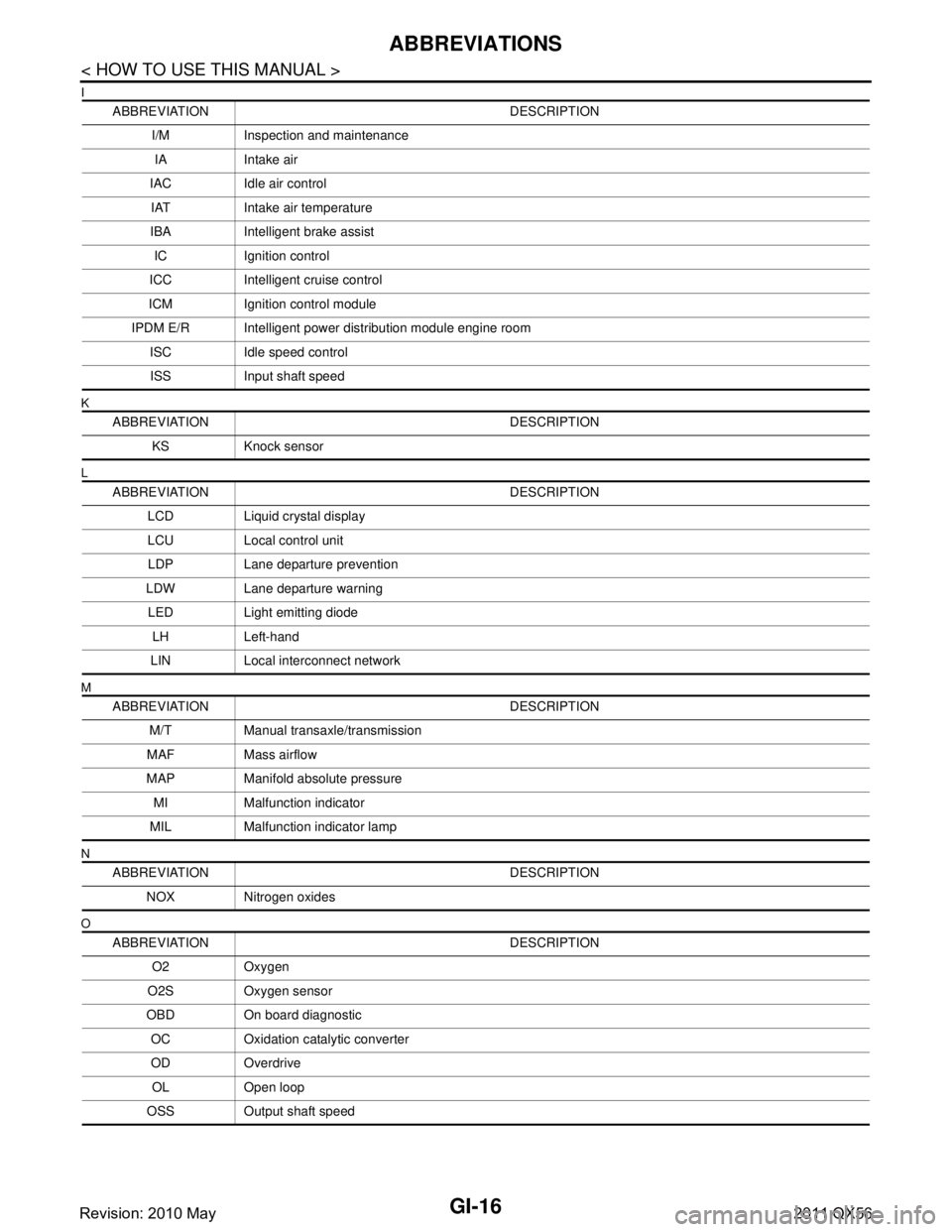

GI-16

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

I

K

L

M

N

O

ABBREVIATION DESCRIPTIONI/M Inspection and maintenanceIA Intake air

IAC Idle air control IAT Intake air temperature

IBA Intelligent brake assist IC Ignition control

ICC Intelligent cruise control

ICM Ignition control module

IPDM E/R Intelligent power distribution module engine room ISC Idle speed controlISS Input shaft speed

ABBREVIATION DESCRIPTION KS Knock sensor

ABBREVIATION DESCRIPTION LCD Liquid crystal display

LCU Local control unitLDP Lane departure prevention

LDW Lane departure warning LED Light emitting diode LH Left-hand

LIN Local interconnect network

ABBREVIATION DESCRIPTION M/T Manual transaxle/transmission

MAF Mass airflow

MAP Manifold absolute pressure MI Malfunction indicator

MIL Malfunction indicator lamp

ABBREVIATION DESCRIPTION NOX Nitrogen oxides

ABBREVIATION DESCRIPTION O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic OC Oxidation catalytic converter

OD OverdriveOL Open loop

OSS Output shaft speed

Revision: 2010 May2011 QX56

Page 3012 of 5598

GI-48

< BASIC INSPECTION >

CONSULT-III/GST CHECKING SYSTEM

CONSULT-III/GST CHECKING SYSTEM

DescriptionINFOID:0000000006280856

When CONSULT-III/GST is connected with a data link connector

(A) equipped on the vehicle side, it will communicate with the con-

trol unit equipped in the vehicle and then enable various kinds of

diagnostic tests.

Refer to “CONSULT-III Software Operation Manual” for more infor- mation.

CONSULT-III Function a nd System Application*1INFOID:0000000006280857

1 : Instrument lower panel LH

JPAIA0769ZZ

Diagnostic test

mode Function

ENGINE

TRANSMISSION AIR BAG

METER/M&A

AUTO BACK DOOR BCM

AUTO DRIVE POS. ABS

IPDM E/R

ALL MODE AWD/4WD MULTI AV

ICC/ADAS SONAR

AIR PRESSURE MONITOR AFS (ADAPTIVE LIGHT)

PRECRASH SEAT BELT HVAC

LASER

LANE CAMERA

ACCELE PEDAL ACT

E–SUS

SIDE RADAR LEFT

SIDE RADAR RIGHT CAN GATEWAY

Work Support This mode

enables a

technician to

adjust some

devices fast-

er and more

accurately.xx - - - xxx - xxxxxx - xxx - xxx -

Self Diagnostic

Results Retrieve DTC

from ECU

and display

diagnostic

items.

xxxxxxxxxxxxxxxxxxxxxxxx

Data Monitor Monitor the

input/output

signal of the

control unit in

real time.xx - xxxxxxxxxxxxxxxxxxxx -

CAN Diagnosis This mode

displays a

network diag-

nosis result

about CAN

by a diagram.xxxxxxxxxxxx -xxxxxxxxxxx

CAN Diagnosis

Support Moni-

tor It monitors

the status of

CAN commu-

nication.

xx - xxxxxxxxx -xxxxxxxxxxx

Revision: 2010 May2011 QX56

Page 3013 of 5598

CONSULT-III/GST CHECKING SYSTEMGI-49

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

x: Applicable

*1: If GST application is equipped , functions in accordance with SAE J1 979 and ISO 15031-5 can be used.

Active Test

Send the

drive signal

from CON-

SULT-III to

the actuator.

The opera-

tion check

can be per-

formed.x - - - - xxxx - - xxxx - x - - xxxx -

DTC & SRT

confirmation The status of

system moni-

toring tests

and the self-

diagnosis

status/result

can be con-

firmed.

xx----------------------

ECU Identifica-

tion Display the

ECU identifi-

cation num-

ber (part

number etc.)

of the select-

ed system.

xxx - xxxxxxxxxxxxxxxxxxxx

Function Test This mode

can show re-

sults of self-

diagnosis of

ECU with ei-

ther “OK” or

“NG”. For en-

gine, more

practical

tests regard-

ing sensors/

switches and/

or actuators

are available.xxx----x----------------

Configuration Function to

READ/

WRITE vehi-

cle configura-

tion.-----x----x------------x

Special

Function Other results

or histories,

etc. that are

recorded in

ECU are dis-

played.

-xxx--------------------

Diagnostic test

mode Function

ENGINE

TRANSMISSION AIR BAG

METER/M&A

AUTO BACK DOOR

BCM

AUTO DRIVE POS. ABS

IPDM E/R

ALL MODE AWD/4WD

MULTI AV

ICC/ADAS SONAR

AIR PRESSURE MONITOR AFS (ADAPTIVE LIGHT)

PRECRASH SEAT BELT HVAC

LASER

LANE CAMERA

ACCELE PEDAL ACT E–SUS

SIDE RADAR LEFT

SIDE RADAR RIGHT CAN GATEWAY

Revision: 2010 May2011 QX56