body int INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2732 of 5598

![INFINITI QX56 2011 Factory Repair Manual

EXL-22

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON ITEM)INFOID:0000000006368037

APPLICATION ITEM

CON INFINITI QX56 2011 Factory Repair Manual

EXL-22

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON ITEM)INFOID:0000000006368037

APPLICATION ITEM

CON](/img/42/57033/w960_57033-2731.png)

EXL-22

< SYSTEM DESCRIPTION >[XENON TYPE]

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu

nction (BCM - COMMON ITEM)INFOID:0000000006368037

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 2831 of 5598

![INFINITI QX56 2011 Factory Repair Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio INFINITI QX56 2011 Factory Repair Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio](/img/42/57033/w960_57033-2830.png)

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparation before adjusting

NOTE:

for details, refer to the regulations in your own country.

perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

before performing aiming adjustment, check the following. adjust the tire pressure to the specification.

fill with fuel, engine coolant and each oil.

maintain the unloaded vehicle condition. (remove luggage from the passenger compartment and the lug- gage room.)

NOTE:

do not remove the temporary tire, jack and on-vehicle tool.

wipe out dirt on the headlamp.

CAUTION:

never use organic solvent (thinner, gasoline etc.)

ride alone on the driver seat.

aiming adjustment screw

JMLIA1319ZZ

A. Headlamp RH HI /LO (UP/DOWN)

adjustment screw B. Headlamp LH HI/LO (UP/DOWN)

adjustment screw

: Vehicle center

Revision: 2010 May2011 QX56

Page 2833 of 5598

![INFINITI QX56 2011 Factory Repair Manual

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE INFINITI QX56 2011 Factory Repair Manual

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE](/img/42/57033/w960_57033-2832.png)

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

Before performing aiming adjustm ent, check the following. Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the trunk

room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp. CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000006213993

1. Place the screen. NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Turn the front fog lamp ON. NOTE:

Shut off the headlamp light with the board to pr event from illuminating the adjustment screen.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

4. Adjust the cutoff line height (A) with the aiming adjus tment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

A: UP

B: DOWN

JPLIA0915ZZ

Revision: 2010 May2011 QX56

Page 2856 of 5598

EXT-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION EXT

A

B

EXT

N

O P

CONTENTS

EXTERIOR

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Commercial Service Tools ................................. ......5

SYMPTOM DIAGNOSIS ...............................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

6

Work Flow ........................................................... ......6

Inspection Procedure ................................................8

Diagnostic Worksheet .............................................10

REMOVAL AND INSTALLATION ...............12

FRONT BUMPER ........................................... ....12

Exploded View .................................................... ....12

Removal and Installation .........................................13

REAR BUMPER .................................................16

Exploded View .................................................... ....16

Removal and Installation .........................................17

FRONT GRILLE .................................................19

Exploded View .................................................... ....19

Removal and Installation .........................................19

COWL TOP .........................................................21

Exploded View .................................................... ....21

Removal and Installation .........................................21

FENDER PROTECTOR ......................................23

FENDER PROTECTOR ......................................... ....23

FENDER PROTECTOR : Exploded View ...............23

FENDER PROTECTOR : Removal and Installa-

tion ...........................................................................

23

REAR WHEEL HOUSE PROTECTOR .................. ....23

REAR WHEEL HOUSE PROTECTOR : Exploded

View .........................................................................

24

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation ........................................................

24

FLOOR SIDE FAIRING .....................................25

Exploded View .........................................................25

Removal and Installation .........................................25

OVER FENDER .................................................26

Exploded View .........................................................26

Removal and Installation .........................................26

ROOF RAIL .......................................................29

Exploded View .........................................................29

Removal and Installation .........................................29

ROOF SIDE MOLDING .....................................31

Exploded View .........................................................31

Removal and Installation .........................................31

DOOR OUTSIDE MOLDING .............................32

Exploded View .........................................................32

Removal and Installation .........................................32

DOOR PARTING SEAL ....................................34

Exploded View .........................................................34

Removal and Installation .........................................34

SILL MOLDING .................................................36

Exploded View .........................................................36

Removal and Installation .........................................36

DOOR SASH COVER .......................................37

Exploded View .........................................................37

Removal and Installation .........................................37

Revision: 2010 May2011 QX56

Page 2862 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when the repair is reconfirmed.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following items:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to the concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis ear: J-39570, engine ear, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the component(s) in the area that is / are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component(s) that is / are suspected to be the cause of the noise.

Do not tap or push/pull the component(s) with excessive force, otherwise the noise is eliminated only tempo-

rarily.

Feeling for a vibration by hand by touching the component(s ) that is / are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to EXT-8, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the components, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape, or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through the authorized NISSAN Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSA N Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.937 ×5.315 in)

76884-71L01: 60 ×85 mm (2.362 ×3.346 in)

76884-71L02: 15 ×25 mm (0.591 ×0.984 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.772 in) thick, 50 ×50 mm (1.969 ×1.969 in)

73982-50Y00: 10 mm (0.394 in) thick, 50 ×50 mm (1.969 ×1.969 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.181 in) thick, 30 ×50 mm (1.181 ×1.969in)

FELT CLOTHTAPE

Revision: 2010 May2011 QX56

Page 2882 of 5598

OVER FENDEREXT-27

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

3. Disengage front over fender rear side fixing pawls from behind of front fender, and the pull front over fender front side toward

the direction shown in the figure.

CAUTION:

Never pull the front over fender strongly.

4. Remove front fender protector. Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installation"

5. Remove side step front side fixing clips.

6. Disengage front over fender rear side fixing pawls from behind

of fender, and then pull front over fender front side toward the

direction shown in the figure.

CAUTION:

Never pull the front over fender strongly.

7. Remove front over fender.

Rear over fender

1. Remove rear over fender rear side fixing screws and bolts.

2. Remove rear fender protector rear side. Keep the service area. Refer to EXT-24, "

REAR WHEEL HOUSE

PROTECTOR : Removal and Installation".

3. Disengage rear over fender rear side fixing pawls from behind of rear fender, and the pull rear over fender rear side toward the

direction shown in the figure.

4. Remove rear fender protctor. Refer to EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal and

Installation".

5. Remove rear over fender front side fixing screws and bolts.

6. Using a remover tool (A), disengage the clips from the rear over fender by starting from the rear.

CAUTION:

Apply a protective tape (B) on the body to protect the

painted surface from damage.

Disengage the clips slowly and carefully.

Never pull the front o ver fender strongly.

: Pawl

JMKIA5452ZZ

: Clip

JMKIA5453ZZ

: Pawl

JMKIA5471ZZ

: Clip

JMKIA5472ZZ

Revision: 2010 May2011 QX56

Page 2896 of 5598

REAR SPOILEREXT-41

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

REAR SPOILER

Exploded ViewINFOID:0000000006367627

Removal and InstallationINFOID:0000000006367628

REMOVAL

1. Remove back door trim. Refer to INT-39, "Removal and Installation".

2. Remove rear spoiler mounting nuts.

3. Cut rear spoiler fixing double-sided tape with cutter knife.

4. Disengage rear spoiler fixing clips with remover tool (A), and then remove rear spoiler.

CAUTION:

Apply a protective tape (B) on body panel and rear spoiler

to protect the painted surface from damage.

1. Rear spoiler assembly 2. Grommet 3. High-mounted stop lamp

4. High-mounted stop lamp cover 5. Washer nozzle 6. EPT sealer [t: 5.0 mm (0.197 in)]

7. Double-sided tape

[t: 1.6 mm (0.063 in)] 8. EPT sealer [t: 4.0 mm (0.157 in)]

: Clip

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5322ZZ

: Clip

JMKIA5383ZZ

Revision: 2010 May2011 QX56

Page 2898 of 5598

DRIP MOLDINGEXT-43

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

DRIP MOLDING

Exploded ViewINFOID:0000000006367629

Removal and InstallationINFOID:0000000006367630

REMOVAL

Remove drip molding fixing clips from rear end to front end using

remover tool (A).

CAUTION:

Apply protective tape (B) on body panel to protect the painted

damage from damage.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

When installing, check visually the drip molding and clips, then replace them with new parts if they are

damaged.

1. Drip molding clip 2. Drip molding

JMKIA5314ZZ

: Clip

JMKIA5474ZZ

Revision: 2010 May2011 QX56

Page 2978 of 5598

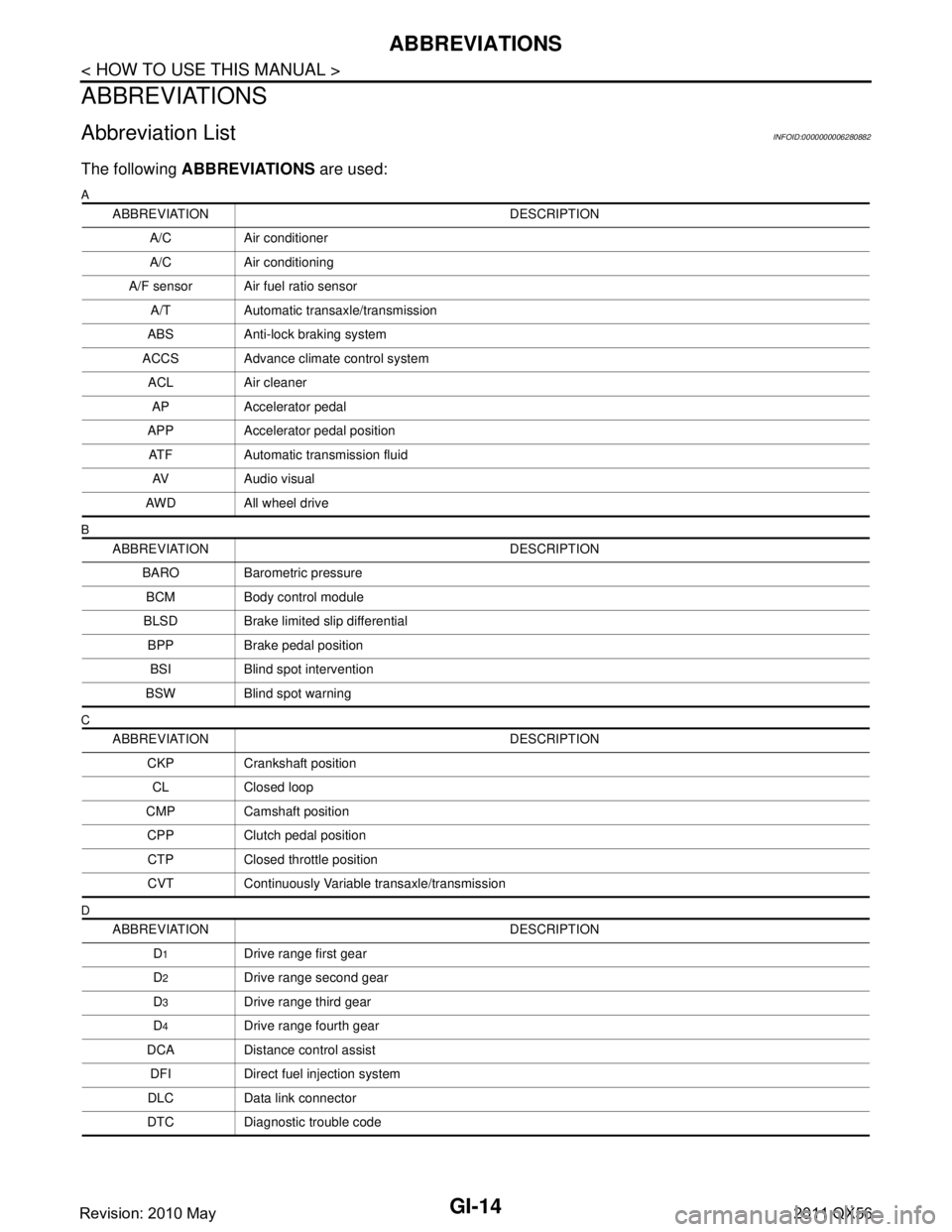

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

ABBREVIATIONS

Abbreviation ListINFOID:0000000006280882

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION

A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position ATF Automatic transmission fluid AV Audio visual

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously Variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: 2010 May2011 QX56

Page 2996 of 5598

GI-32

< PRECAUTION >

LIFTING POINT

LIFTING POINT

Pantograph JackINFOID:0000000006280877

WARNING:

Never get under the vehicle while it is supported only by the jack. Always use safety stands to sup-

port the frame when you have to get under the vehicle.

Place wheel chocks at both front an d back of the wheels on the ground.

Garage Jack and Safety StandINFOID:0000000006280878

CAUTION:

Place a wooden or rubber block between safety stan d and vehicle body when the supporting body is

flat.

Remove engine under cover before jacking up the front side of the vehicle with garage jack. Refer to

BRM-39, "

Rear Fender".

JMAIA0247ZZ

Revision: 2010 May2011 QX56