body int INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 733 of 5598

BRM-58

< SERVICE DATA AND SPECIFICATIONS (SDS)

LOCATION OF PLASTIC PARTS

LOCATION OF PLASTIC PARTS

Precautions for PlasticsINFOID:0000000006248513

CAUTION:

When repairing and painting a portion of the body adjacent to plastic parts, consider their characteristics (influence of heatand solvent) and remove them if necessary or take suitable measures to protect them.

Plastic parts should be repaired and painted using methods suiting the materials

, characteristics.

Abbre-

viation Material name Heat resisting

temperature °C ( °F) Resistance to gasoline and

solvents Other cautions

PE Polyethylene 60 (140) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Flammable

ABS Acrylonitrile Butadiene Styrene 80 (176) Avoid gasoline and solvents. —

EPM/

EPDM Ethylene Propylene (Diene) co-

polymer

80 (176)Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly). Flammable

PS Polystyrene 80 (176) Avoid solvents. Flammable

PVC Poly Vinyl Chloride 80 (176) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Poisonous gas is emitted

when burned.

TPO Thermoplastic Olefine 80 (176) ↑Flammable

AAS Acrylonitrile Acrylic Styrene 85 (185) Avoid gasoline and solvents. —

PMMA Poly Methyl Methacrylate 85 (185) ↑—

EVAC Ethylene Vinyl Acetate 90 (194) ↑—

PP Polypropylene 90 (194) Gasoline and most solvents are

harmless if applied for a very

short time (wipe out quickly).Flammable, avoid bat-

tery acid.

PUR Polyurethane 90 (194) Avoid gasoline and solvents. —

UP Unsaturated Polyester 90 (194) ↑Flammable

ASA Acrylonitrile Styrene Acrylate 100 (212) ↑Flammable

PPE Poly Phenylene Ether 110 (230) ↑—

TPU Thermoplastic Urethane 110 (230) ↑—

PBT+

PC Poly Butylene Terephthalate +

Polycarbonate

120 (248)

↑Flammable

PC Polycarbonate 120 (248) ↑—

POM Poly Oxymethylene 120 (248) ↑Avoid battery acid.

PA Polyamide 140 (284) ↑Avoid immersing in wa-

ter.

PBT Poly Butylene Terephthalate 140 (284) ↑—

PAR Polyarylate 180 (356) ↑—

PET Polyethylene terephthalate 180 (356) ↑—

PEI Polyetherimide 200 (392) ↑—

Revision: 2010 May2011 QX56

Page 807 of 5598

![INFINITI QX56 2011 Factory Owners Guide

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aimi INFINITI QX56 2011 Factory Owners Guide

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aimi](/img/42/57033/w960_57033-806.png)

CCS-72

< BASIC INSPECTION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

DescriptionINFOID:0000000006224293

OUTLINE OF LASER BEAM AIMING ADJUSTMENT

Always adjust the laser beam aiming after removing and installing or replacing the ICC sensor.

CAUTION:

The system does not operate normally

unless the laser beam aiming adjustment is performed. Always

perform it.

1. Set the ICC target board [SST: KV99110100 (J-45718)] to the correct position in front of the vehicle.

2. Set the laser beam aiming mode (“LASER BEAM AD JUST” on “Work support”) with CONSULT-III, and

then perform the adjustment according to the displa y. (Manually turn the up-down direction adjusting

screw for vertical adjustment. ICC sensor adjusts the automatic aiming for the horizontal direction.)

CAUTIONARY POINT FOR LASER BEAM AIMING ADJUSTMENT

CAUTION:

For laser beam aiming adjustment, choose a level location where a view can be obtained without any

obstruction as far as 12 m (39 ft) or more in the forward direction.

Adjust laser beam aiming for 5 second s or more after starting engine.

Adjust the laser beam aiming with CONSULT-III. (The laser beam aiming cannot be adjusted without

CONSULT-III.)

Never enter the vehicle during laser beam aiming adjustment.

Never look directly into the laser beam sour ce (ICC sensor body window) during laser beam aiming

adjustment.

Laser beam aiming adjustment is performed at idle. At this time, turn the headlamps OFF.

Work Procedure (Preparation)INFOID:0000000006224294

1.ADVANCE PREPARATION FOR LASER BEAM AIMING ADJUSTMENT

1. Adjust all tire pressure to the specified value.

2. Empty the vehicle. (Remove any luggage from the passenger compartment, luggage room, etc.)

3. Shift the selector lever to “P” pos ition, and release the parking brake.

4. Fully fill the fuel tank, and then check that t he coolant and oils are filled up to correct level.

5. Clean off the ICC sensor body window with a soft cloth.

>> Go to CCS-72, "

Work Procedure (Setting The ICC Tar-

get Board)".

Work Procedure (Setting The ICC Target Board)INFOID:0000000006224295

DESCRIPTION

Accurate adjustment of the laser beam requires t hat the ICC target board be accurately positioned.

CAUTION:

If the laser beam is adjusted with the ICC target board in the incorrect position, the ICC system does

not function normally.

1.ICC TARGET BOARD HEIGHT ADJUSTMENT

1 : ICC sensor

JSOIA0372ZZ

Revision: 2010 May2011 QX56

Page 810 of 5598

![INFINITI QX56 2011 Factory Owners Guide

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in th INFINITI QX56 2011 Factory Owners Guide

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in th](/img/42/57033/w960_57033-809.png)

CCS

LASER BEAM AIMING ADJUSTMENTCCS-75

< BASIC INSPECTION > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

5.CHECK THE ICC TARGET BOARD INSTALLATION AREA

Do not place anything other than ICC target board in the space shown in the figure (view from top).

NOTE:

In case the space shown in the figure is not avail able, cover the side of the ICC target board with a 1400

mm(4.6 ft)-size frosted black board or black cloth.

>> Go to CCS-75, "

Work Procedure (Laser Beam Aiming Adjustment)".

Work Procedure (Laser B eam Aiming Adjustment)INFOID:0000000006224296

DESCRIPTION

Adjust the laser beam aiming in a vertical di rection with CONSULT-III as per the following.

The laser beam aiming adjustment in a horizontal dire ction is performed automatically with CONSULT-III.

CAUTION:

Never look directly into the laser beam source (ICC sensor body window) during laser beam aiming

adjustment.

Perform all necessary work for laser beam aiming adjustment until the adjustment completes as

shown in the procedure. If the procedure do es not complete, the ICC system is inoperable.

1.SET CONSULT-III TO THE LASER BEAM AIMING ADJUSTMENT MODE

1. Start the engine.

2. Connect CONSULT-III and select “Work support” of “LASER”.

3. Select “LASER BEAM ADJUST” after t he “Work support” screen is displayed.

4. Select “START” after the “LASER BEAM ADJUST” screen is displayed.

NOTE:

If the adjustment screen does not appear within approx imately 10 seconds after “LASER BEAM ADJUST”

is selected, the following causes are possible.

The ICC target board is not installed in the correct position.

Adequate space is not secured around the ICC target board.

The laser beam aiming adjustment exceeds its proper installation range.

- Deformation of vehicle body.

- Deformation of unit.

- Deformation of bracket.

The area is not suitable for the adjustment work.

ICC sensor body window is not clean.

The ICC system warning lamp illuminates.

>> GO TO 2.

2.LASER BEAM AIMING ADJUSTMENT

After “ADJUST THE VERTICAL OF LASER BEAM AIMI NG” is displayed on CONSULT-III screen, adjust by

turning the up-down direction adjusting screw until “U/D CORRECT” becomes ±4 or less.

NOTE:

1. ICC target board 2. ICC sensor

L

1.6.5 m (21.3 ft) L2. 4.0 m (13.0 ft) W. 3.5 m (11.5 ft)

JSOIA0027ZZ

Revision: 2010 May2011 QX56

Page 842 of 5598

![INFINITI QX56 2011 Factory Owners Guide

CCS

C1A16 RADAR STAINCCS-107

< DTC/CIRCUIT DIAGNOSIS > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ICC SENSOR : Diagnosis ProcedureINFOID:0000000006224334

1.VISUAL CHECK 1

Check ICC sensor body window for c INFINITI QX56 2011 Factory Owners Guide

CCS

C1A16 RADAR STAINCCS-107

< DTC/CIRCUIT DIAGNOSIS > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ICC SENSOR : Diagnosis ProcedureINFOID:0000000006224334

1.VISUAL CHECK 1

Check ICC sensor body window for c](/img/42/57033/w960_57033-841.png)

CCS

C1A16 RADAR STAINCCS-107

< DTC/CIRCUIT DIAGNOSIS > [ICC]

C

D

E

F

G H

I

J

K L

M B

N P A

ICC SENSOR : Diagnosis ProcedureINFOID:0000000006224334

1.VISUAL CHECK 1

Check ICC sensor body window for c ontamination and foreign materials.

Does contamination or foreign materials adhere?

YES >> Wipe out the contamination and foreign materials from the ICC sensor body window.

NO >> GO TO 2.

2.VISUAL CHECK 2

Check ICC sensor body window for cracks and scratches.

Is it found?

YES >> Replace the ICC sensor. Refer to CCS-176, "Exploded View".

NO >> GO TO 3.

3.INTERVIEW

1. Ask if there is any trace of contamination or fo reign materials adhering to the ICC sensor body window.

2. Ask if ICC sensor body window was frosted during driving or if vehicle was driven in snow.

3. Ask if ICC sensor body window wa s temporarily fogged. (Windshield glass may also tend to fog, etc.)

Is any of above conditions seen?

YES >> Explain to the customer about the differ ence between the contamination detection function and

the indication when the malfunction is detected and tell them “This is not malfunction”.

NO >> Replace the ICC sensor. Refer to CCS-176, "

Exploded View".

Revision: 2010 May2011 QX56

Page 1036 of 5598

![INFINITI QX56 2011 Factory Owners Guide

DAS

SYSTEMDAS-71

< SYSTEM DESCRIPTION > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

Operation Condition

ADAS control unit performs the control when the following conditions are satisfied.

When the DCA sy INFINITI QX56 2011 Factory Owners Guide

DAS

SYSTEMDAS-71

< SYSTEM DESCRIPTION > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

Operation Condition

ADAS control unit performs the control when the following conditions are satisfied.

When the DCA sy](/img/42/57033/w960_57033-1035.png)

DAS

SYSTEMDAS-71

< SYSTEM DESCRIPTION > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

Operation Condition

ADAS control unit performs the control when the following conditions are satisfied.

When the DCA system setting on the navigation screen is ON.

When the dynamic driver assistance switch is turned to ON.

When the brake pedal is not depressed.

When the vehicle speed is above approximately 5 km/h (3 MPH).

When the vehicle ahead is detected.

When the ICC system is not set.

No Operation Condition

The ADAS control unit is not operat e when the system is under any condi tions of the no operation condition.

When the brake pedal depressed.

When the ICC system is set.

When the system judges that the vehicle co mes to a standstill by the system control.

When the vehicle ahead is not detected.

Operation Cancellation Condition

The ADAS control unit cancels the operation when the syst em is under any conditions of the operation cancel-

lation condition.

When the dynamic driver assistance switch is turned to OFF.

When the system malfunction occurs.

When ABS or VDC (including the TCS) operates.

When the VDC is turned OFF.

When the SNOW mode switch is turned ON.

When the 4WD shift switch is turned to not AUTO position.

When driving into a strong light (i.e., sunlight).

When the ICC sensor body window is dirty and the measurement of the distance between the vehicles

becomes difficult.

Operation At The Driver Operation

Give priority to the driver operation in the following situation.

When vehicle approaches a vehicle ahead If the driver is not depressing the acceler-

ator pedal, the system activates the

brakes to decelerate smoothly as neces-

sary

If the driver is depressing the accelerator

pedal, the system moves the accelerator

pedal upward to assist the driver to re-

lease the accelerator pedal

When brake operation by driver is required The system alerts the driver by a warning

chime and blinking the vehicle ahead de-

tection indicator. If the driver is depressing

the accelerator pedal after the warning,

the system moves the accelerator pedal

upward to assist the driver to switch to the

brake pedal

Deceleration control It transmits the brake fluid

pressure control signal to the ABS actuator and electric unit (control unit) via

CAN communication and performs the brake control

Accelerator pedal actuation

control It transmits the accelerator pedal feedback force control signal to the accelerator pedal actuator via ITS

communication and controls the accelerator pedal in the upward directionJSOIA0222ZZ

JSOIA0094ZZ

JPOIA0170GB

Revision: 2010 May2011 QX56

Page 1166 of 5598

![INFINITI QX56 2011 Factory Owners Guide

DAS

DCA SYSTEM NOT ACTIVATED (SWITCH IS ON)DAS-201

< SYMPTOM DIAGNOSIS > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

DCA SYSTEM NOT ACTIVA TED (SWITCH IS ON)

DescriptionINFOID:0000000006223655

The dynamic dr INFINITI QX56 2011 Factory Owners Guide

DAS

DCA SYSTEM NOT ACTIVATED (SWITCH IS ON)DAS-201

< SYMPTOM DIAGNOSIS > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

DCA SYSTEM NOT ACTIVA TED (SWITCH IS ON)

DescriptionINFOID:0000000006223655

The dynamic dr](/img/42/57033/w960_57033-1165.png)

DAS

DCA SYSTEM NOT ACTIVATED (SWITCH IS ON)DAS-201

< SYMPTOM DIAGNOSIS > [DCA]

C

D

E

F

G H

I

J

K L

M B

N P A

DCA SYSTEM NOT ACTIVA TED (SWITCH IS ON)

DescriptionINFOID:0000000006223655

The dynamic driver assistance switch can be tu rned ON/OFF, but the DCA system does not operate.

NOTE:

Never start the operation under the following conditions. No operation condition

When the brake pedal depressed

When the ICC system is set

When the system judges that the vehicle co mes to a standstill by the system control

When the vehicle ahead is not detected Operation cancellation condition

When the dynamic driver assistance switch is turned to OFF

When the system malfunction occurs

When ABS or VDC (including the TCS) operates

When the VDC is turned OFF

When driving into a strong light (i.e., sunlight)

When the ICC sensor body window is dirty and the measurement of the distance between the vehicles

becomes difficult

When ABS warning lamp is ON

When the SNOW mode switch is turned ON

When the 4WD shift switch is not AUTO position

Diagnosis ProcedureINFOID:0000000006223656

1.CHECK CAUSE OF AUTOMATIC CANCELLATION

Check if there is any cancellation cause in the “CAUSE OF AUTO-CANCEL” on “WORK SUPPORT” of “ICC/

ADAS” with CONSULT-III.

Is it displayed?

Not displayed>>GO TO 2.

“OPE SW VOLT CIRC”>>Refer to DAS-138, "

DTC Logic".

“VHCL SPD UNMATCH”>>Refer to DAS-131, "

DTC Logic".

“IGN LOW VOLT”>>Refer to DAS-130, "

DTC Logic".

“CAN COMM ERROR”>>Refer to DAS-182, "

ADAS CONTROL UNIT : DTC Logic".

“ICC SENSOR CAN COMM ERR”>>Refer to DAS-177, "

DTC Logic".

“ABS/TCS/VDC CIRC”>>Refer to DAS-133, "

DTC Logic".

“APA HI TEMP”>>Refer to DAS-170, "

DTC Logic".

“ECD CIRCUIT”>>Refer to DAS-156, "

DTC Logic".

2.PERFORM ALL OF THE SELF-DIAGNOSIS

1. Perform “All DTC Reading”.

2. Check if any DTC is detected in self-d iagnosis results of “ICC/ADAS”. Refer to DAS-100, "

DTC Index".

Is any DTC detected?

YES >> GO TO 3.

NO >> GO TO 4.

3.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts i dentified by the self-diagnosis result.

>> GO TO 6.

4.CHECK EACH SWITCH AND VEHICLE SPEED SIGNAL

1. Start the engine.

2. Check that the following items operate norma lly in “DATA MONITOR” of “ICC/ADAS”.

- “VHCL SPEED SE”

- “BRAKE SW”

- “DYNA ASIST SW”

Is there a malfunctioning item?

Revision: 2010 May2011 QX56

Page 1499 of 5598

DIAGNOSIS SYSTEM (BCM)DEF-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006349773

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 1537 of 5598

DLK-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION DLK

A

B

DLK

N

O P

CONTENTS

DOOR & LOCK

PRECAUTION ................ ...............................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

8

Precautions For Xenon Headlamp Service ...............9

Work ..........................................................................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Commercial Service Tools .................................. ....10

SYSTEM DESCRIPTION .............................11

COMPONENT PARTS ................................... ....11

DOOR LOCK SYSTEM .............................................11

DOOR LOCK SYSTEM :

Component Parts Location ................................ ....

11

DOOR LOCK SYSTEM : Component Description ....12

AUTOMATIC BACK DOOR SYSTEM .......................13

AUTOMATIC BACK DOOR SYSTEM :

Component Parts Location ................................ ....

14

AUTOMATIC BACK DOOR SYSTEM :

Component Description ..........................................

15

SYSTEM (POWER DOOR LOCK SYSTEM) .....16

System Diagram .................................................. ....16

System Description .................................................16

SYSTEM (INTELLIGENT KEY SYSTEM) ..........18

INTELLIGENT KEY SYSTEM ...................................18

INTELLIGENT KEY SYSTEM : System Diagram ....18

INTELLIGENT KEY SYSTEM : System Descrip-

tion ..........................................................................

18

DOOR LOCK FUNCTION ...................................... ....19

DOOR LOCK FUNCTION : System Diagram ..........19

DOOR LOCK FUNCTION : System Description .....19

BACK DOOR OPEN FUNCTION ........................... ....21

BACK DOOR OPEN FUNCTION : System Dia-

gram ........................................................................

21

BACK DOOR OPEN FUNCTION : System De-

scription ...................................................................

21

REMOTE KEYLESS ENTRY FUNCTION ..................23

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Diagram ........................................................ ....

23

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Description ........................................................

23

KEY REMINDER FUNCTION ................................ ....25

KEY REMINDER FUNCTION : System Diagram ....25

KEY REMINDER FUNCTION : System Descrip-

tion ...........................................................................

26

WELCOME LIGHT FUNCTION ............................. ....26

WELCOME LIGHT FUNCTION : System Diagram

....

26

WELCOME LIGHT FUNCTION : System Descrip-

tion ...........................................................................

26

WARNING FUNCTION .......................................... ....27

WARNING FUNCTION : System Description ..........27

SYSTEM (AUTOMATIC BACK DOOR SYS-

TEM) ..................................................................

31

System Diagram .................................................. ....31

System Description ..................................................31

SYSTEM (INTEGRATED HOMELINK

TRANSMITTER) ................................................

37

System Description .............................................. ....37

DIAGNOSIS SYSTEM (BCM) ...........................38

COMMON ITEM ..................................................... ....38

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

38

Revision: 2010 May2011 QX56

Page 1548 of 5598

DLK-12

< SYSTEM DESCRIPTION >

COMPONENT PARTS

DOOR LOCK SYSTEM : Component Description

INFOID:0000000006225834

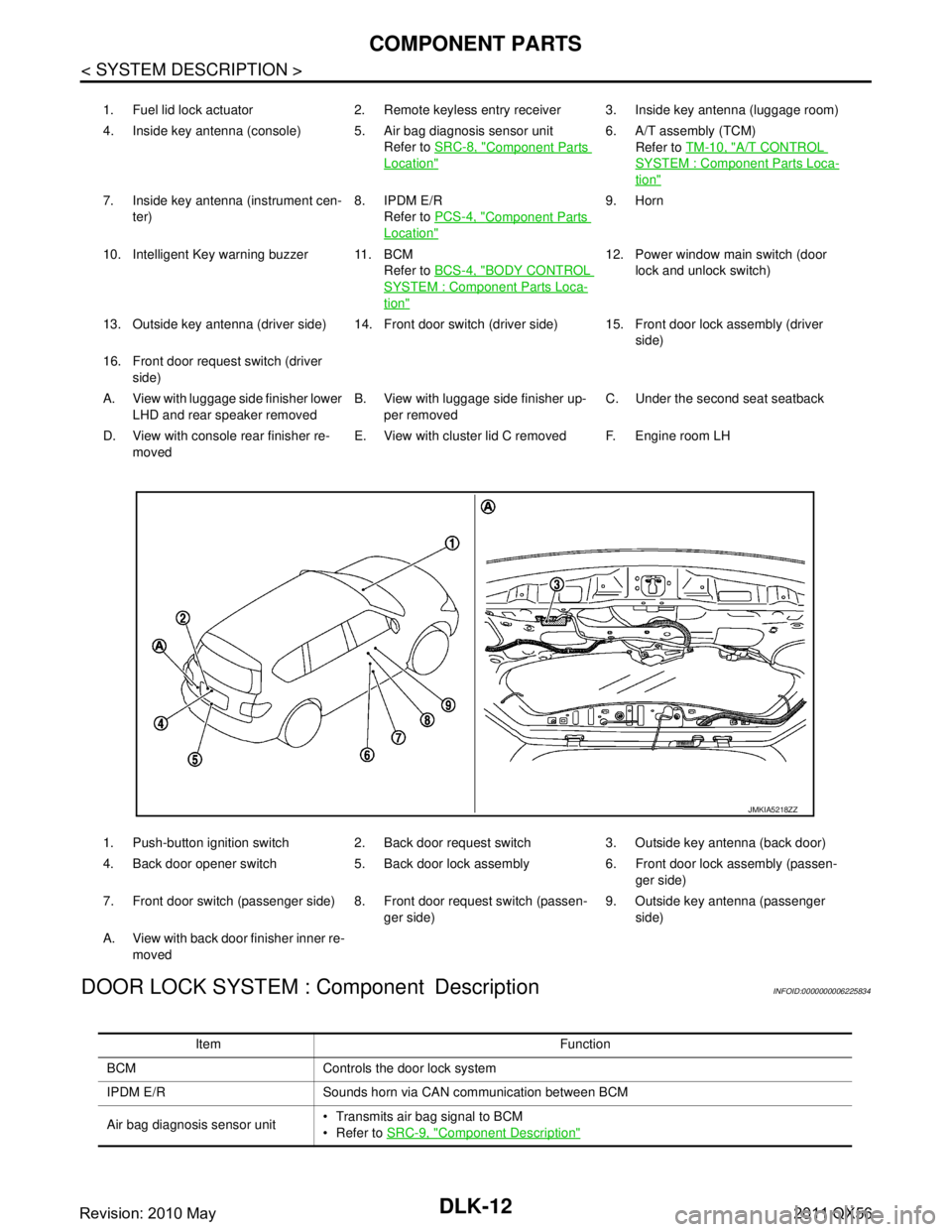

1. Fuel lid lock actuator 2. Remote keyless entry receiver 3. Inside key antenna (luggage room)

4. Inside key antenna (console) 5. Air bag diagnosis sensor unit Refer to SRC-8, "

Component Parts

Location"

6. A/T assembly (TCM)

Refer to TM-10, "

A/T CONTROL

SYSTEM : Component Parts Loca-

tion"

7. Inside key antenna (instrument cen-

ter) 8. IPDM E/R

Refer to PCS-4, "

Component Parts

Location"

9. Horn

10. Intelligent Key warning buzzer 11. BCM Refer to BCS-4, "

BODY CONTROL

SYSTEM : Component Parts Loca-

tion"

12. Power window main switch (door

lock and unlock switch)

13. Outside key antenna (driver side) 14. Front door switch (driver side) 15. Front door lock assembly (driver side)

16. Front door request switch (driver side)

A. View with luggage side finisher lower LHD and rear speaker removed B. View with luggage side finisher up-

per removed C. Under the second seat seatback

D. View with console rear finisher re- moved E. View with cluster lid C removed F. Engine room LH

1. Push-button ignition switch 2. Back door request switch 3. Outside key antenna (back door)

4. Back door opener switch 5. Back door lock assembly 6. Front door lock assembly (passen- ger side)

7. Front door switch (passenger side) 8. Front door request switch (passen- ger side)9. Outside key antenna (passenger

side)

A. View with back door finisher inner re- moved

JMKIA5218ZZ

Item Function

BCM Controls the door lock system

IPDM E/R Sounds horn via CAN communication between BCM

Air bag diagnosis sensor unit Transmits air bag signal to BCM

Refer to

SRC-9, "

Component Description"

Revision: 2010 May2011 QX56

Page 1574 of 5598

DLK-38

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006307583

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56