body int INFINITI QX56 2011 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3030 of 5598

GW-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION GW

A

B

GW

N

O P

CONTENTS

GLASS & WINDOW SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Precaution for Procedure without Cowl Top Cover ......3

Handling for Adhesive and Primer ............................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools ........................................ ......4

Commercial Service Tools .......................................4

SYMPTOM DIAGNOSIS ...............................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

5

Work Flow ........................................................... ......5

Inspection Procedure ................................................7

Diagnostic Worksheet ...............................................9

REMOVAL AND INSTALLATION ...............11

WINDSHIELD GLASS .................................... ....11

Exploded View .................................................... ....11

Removal and Installation .........................................12

Inspection ................................................................13

SIDE WINDOW GLASS ....................................14

Exploded View ..................................................... ....14

Removal and Installation .........................................15

Inspection ................................................................15

BACK DOOR WINDOW GLASS ......................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

Inspection ................................................................17

FRONT DOOR GLASS .....................................19

Exploded View .........................................................19

Removal and Installation .........................................19

Inspection and Adjustment ......................................20

FRONT REGULATOR .......................................21

Exploded View .........................................................21

Removal and Installation .........................................21

Disassembly and Assembly .....................................21

Inspection and Adjustment ......................................22

REAR DOOR GLASS .......................................23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection and Adjustment ......................................25

REAR REGULATOR .........................................26

Exploded View .........................................................26

Removal and Installation .........................................26

Disassembly and Assembly .....................................27

Inspection and Adjustment ......................................27

Revision: 2010 May2011 QX56

Page 3035 of 5598

GW-6

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

Placing a piece of paper between components that you suspect are causing the noise.

Looking for loose components and contact marks. Refer to GW-7, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loos ening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A Nissan Squeak and Rattle Kit (J-43980) is available through your authorized Nissan Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Departm ent for the latest parts information.

The following materials are contained in the Nissan Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-

71L02:15 ×25 mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-

50Y00: 10 mm (0.39 in) thick, 50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97in)

FELT CLOTHTAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

Revision: 2010 May2011 QX56

Page 3041 of 5598

GW-12

< REMOVAL AND INSTALLATION >

WINDSHIELD GLASS

Removal and Installation

INFOID:0000000006220814

REMOVAL

1. Remove front pillar garnish (LH and RH). Refer to INT-14, "Removal and Installation".

2. Remove partially headlining (front edge). Refer to INT-29, "

Removal and Installation".

3. Disconnect inside mirror harness connector.

4. Remove rain sensor cover and then disconnect rain sensor harness connector. Refer to WW-72,

"Removal and Installation".

5. Remove drip molding. Refer to EXT-43, "

Removal and Installation".

6. Remove windshield molding upper using pliers. Refer to GW-11, "

Exploded View".

7. Remove front wiper arm (LH and RH). Refer to WW-66, "

Removal and Installation".

8. Remove cowl top cover. Refer to EXT-21, "

Removal and Installation".

9. Remove front fender cover (LH and RH). Refer to EXT-21, "

Exploded View".

10. Disconnect wiper deicer harness connector (with wiper deicer).

11. Remove front pillar finisher (LH and RH). Refer to EXT-40, "

Removal and Installation".

12. Apply protective tape around the windshield glas s to protect the painted surface from damage.

13. Remove glass using piano wire or power cutting tool (A) and an inflatable pump bag (B).

NOTE:

Mark the body and the glass with matching ma rks if the windshield glass is reused.

WARNING:

Always wear safety glasses and heavy gloves to prevent injury.

CAUTION:

Never use a cutting knife or power cutting tool when the windshield glass is reused.

Be careful not to scratch the glass when removing.

Never set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

The dam sealant rubber and insulator should be installed in position.

Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions pro- vided with it.

Open a door window while the urethane adhesive is curing. This prevents the glass from being forced out by

passenger room air pressure when all door windows are closed.

The molding must be installed securely so that it is in position and leaves no clearance.

Inform the customer that the vehicle should rema in stationary until the urethane adhesive has completely

cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

Keep heat and open flames away as primers and adhesive are flammable.

The materials contained in the ki t are harmful if swallowed, and may irritate skin and eyes. Never let

them come in contact with the skin and eyes.

Use in an open, well ventilated location. Never br eathe the vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

Perform adjustment of front wiper arms stop location. Refer to WW-66, "

Adjustment".

PIIB5779E

Revision: 2010 May2011 QX56

Page 3042 of 5598

WINDSHIELD GLASSGW-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

Never use an adhesive which is past its usable term. Shelf life of this product is limited to six months

after the date of manufacture. Carefully adhere to the expiration or manufacture date printed on the

box.

Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

Never leave primers or adhesive cartridge un attended with their caps open or off.

The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depe nding on temperature and humidity . The curing time increases under

lower temperature and lower humidity.

InspectionINFOID:0000000006220815

REPAIRING WATER LEAKAGE FOR WINDSHIELD GLASS

Leakage can be repaired without removing the glass.

Determine the extent of leakage if water is leaki ng between the urethane adhesive material and body or glass.

This can be done by applying water to the windshield area while pushing glass outward.

Apply primer (if necessary) and then urethane adhes ive to the leakage point to stop the leakage.

Revision: 2010 May2011 QX56

Page 3044 of 5598

SIDE WINDOW GLASSGW-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

Removal and InstallationINFOID:0000000006220817

CAUTION:

Replace the side window glass assembly with a new part after removal as it cannot be reused.

REMOVAL

1. Remove third seat cushion and third seatback assembly. Refer to SE-138, "Removal and Installation".

2. Remove luggage side lower finisher. Refer to INT-36, "

LUGGAGE SIDE LOWER FINISHER : Removal

and Installation".

3. Remove rear pillar finisher. Refer to INT-37, "

REAR PILLAR FINISHER : Removal and Installation".

4. Remove back pillar garnish. Refer to INT-37, "

BACK PILLAR GARNISH : Removal and Installation".

5. Remove luggage side upper finisher. Refer to INT-38, "

LUGGAGE SIDE UPPER FINISHER : Removal

and Installation".

6. Disconnect the harness connector from side window glass.

7. Apply protective tape around the side window to protect the painted surface from damage.

8. Remove the side window glass using piano wire. WARNING:

Always wear safety glasses and heavy gloves to prevent injury.

CAUTION:

Be careful not to scratch the glass when removing.

Never set or stand the glass on its edge. Small chips may develop into cracks.

INSTALLATION

Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions pro- vided with it.

Open a door window while the urethane adhesive is curing. This prevents the glass from being forced out by

passenger room air pressure when all door windows are closed.

Inform the customer that the v ehicle should remain stationary until the urethane adhesive has completely

cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

Keep heat and open flames away as primers and adhesive are flammable.

The materials contained in the ki t are harmful if swallowed, and may irritate skin and eyes. Never let

them come in contact with the skin and eyes.

Use in an open, well ventilated location. Never breathe the vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the side window in case of an accident.

CAUTION:

Never use an adhesive which is past its usable term. Shelf life of this product is limited to six months

after the date of manufacture. Carefully adhere to the expiration or manufacture date printed on the

box.

Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

Never leave primers or adhesive cartridge un attended with their caps open or off.

The vehicle should not be driven for at least 24 hours or until the urethane adhesive has completely

cured. Curing time varies depe nding on temperature and humidity . The curing time increases under

lower temperature and lower humidity.

InspectionINFOID:0000000006220818

REPAIRING WATER LEAKAGE FOR SIDE WINDOW GLASS

Leakage can be repaired without removing glass.

Determine the extent of leakage if water is leaki ng between the urethane adhesive material and body or glass.

This can be done by applying water to the side window glass area while pushing glass outward.

Apply primer (if necessary) and then urethane adhes ive to the leakage point to stop the leakage.

: Clip

: Do not reuse

Unit : mm (in)

Revision: 2010 May2011 QX56

Page 3046 of 5598

BACK DOOR WINDOW GLASSGW-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

3. Remove rear wiper arm. Refer to WW-74, "Removal and Installation".

4. Remove rear wiper motor. Refer to WW-76, "

Removal and Installation".

5. Remove back door window glass molding using a pliers. Refer to GW-16, "

Exploded View".

6. Apply protective tape around the back door window gl ass to protect the painted surface from damage.

7. Remove glass using piano wire or power cutting tool (A) and an inflatable pump bag (B).

NOTE:

Mark the body and the glass with matching ma rks if the back door window glass is reused.

WARNING:

Always wear safety glasses and heavy gloves to prevent injury.

CAUTION:

Be careful not to scratch the glass when removing.

Never set or stand the glass on its edge . Small chips may develop into cracks.

INSTALLATION

The dam rubber should be installed in position.

Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions pro-

vided with it.

Open a door window while the urethane adhesive is curing. This prevents the glass from being forced out by

passenger compartment air pressure when all door windows are closed.

Inform the customer that the v ehicle should remain stationary until the urethane adhesive has completely

cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

Keep heat and open flames away as primers and adhesive are flammable.

The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Never

let them come in contact with the skin and eyes.

Use in an open, well ventilated location. Never br eathe the vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the rear window in case of an accident.

CAUTION:

Perform adjustment of rear wipe r arm stop location. Refer to WW-74, "

Adjustment".

Never use an adhesive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefull y adhere to the expiration or manufacture date

printed on the box.

Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

Never leave primers or adhesive cartridge unattended with their caps open or off.

The vehicle should not be driven for at least 24 hours or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidity. The curing time

increases under lower temperature and lower humidity.

If the substrate of the glass joining surface on th e back door panel side is exploded to the air,

exchange the back door assembly without recoating.

Never apply paint on the back door panel surface wh ich is in contact with the glass when replacing

the back door assembly.

InspectionINFOID:0000000006220821

REPAIRING WATER LEAKAGE FOR BACK DOOR WINDOW GLASS

Leakage can be repaired without removing the glass.

Determine the extent of leakage if water is leaki ng between the urethane adhesive material and body or glass.

This can be done by applying water to the back door window glass area while pushing glass outward.

PIIB5779E

Revision: 2010 May2011 QX56

Page 3062 of 5598

HA-6

< PRECAUTION >

PRECAUTIONS

Turn the compressor shaft by hand more than five turns in both directions after compressor service

operation. This distributes equall y lubricant inside the compressor. Let the engine idle and operate

the compressor for one hour after the compressor is installed.

Apply voltage to the new one and check for norma l operation after replacing the compressor magnet

clutch.

LEAK DETECTION DYE

CAUTION:

The A/C system contains a fluorescent leak detect ion dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to il luminate the dye when inspecting for leakages.

Wear always fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacem ent for an electrical leak detector. The fluorescent

dye leak detector should be used in conjunction with an electrical leak detector to pin-point refriger-

ant leakages.

Read and follow all manufacture’ s operating instructions and precau tions prior to performing the

work for the purpose of safet y and customer’s satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after conf irming the leakage with an electrical leak detector.

Remove always any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cl eaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (eng ine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle [1/4 ounce (7.4 cc)] per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC- 12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R- 12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains fo r three or more years unless a compressor malfunc-

tion occurs.

NOTE:

Identification

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

Service EquipmentINFOID:0000000006276140

RECOVERY/RECYCLING RECHARGING EQUIPMENT

Be certain to follow the manufacturer’s instructions for machine operation and machine maintenance. Never

introduce any refrigerant other than that specified into the machine.

ELECTRICAL LEAK DETECTOR

Be certain to follow the manufacturer’s instruct ions for tester operation and tester maintenance.

VACUUM PUMP

Revision: 2010 May2011 QX56

Page 3085 of 5598

NOISEHA-29

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

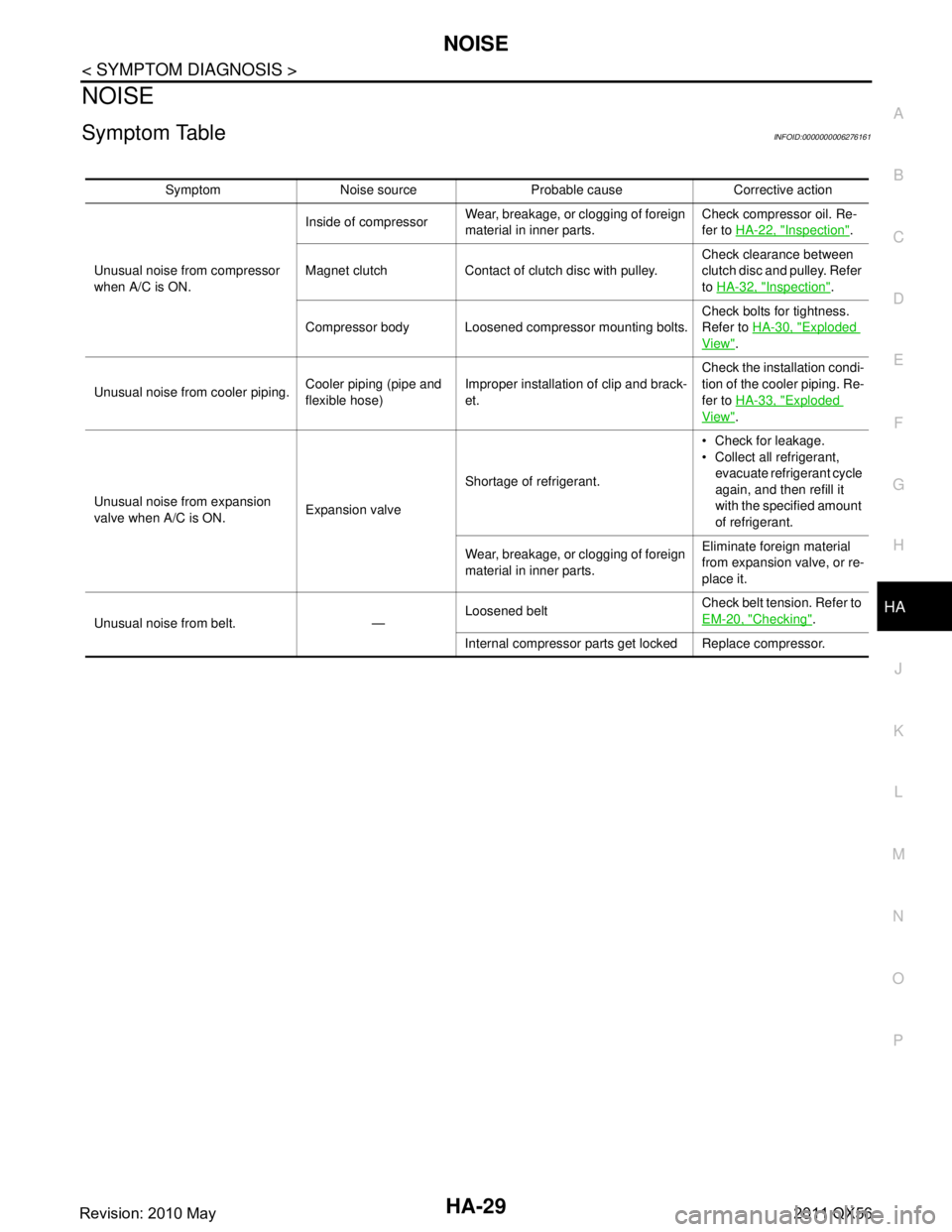

NOISE

Symptom TableINFOID:0000000006276161

Symptom Noise source Probable cause Corrective action

Unusual noise from compressor

when A/C is ON. Inside of compressor

Wear, breakage, or clogging of foreign

material in inner parts. Check compressor oil. Re-

fer to

HA-22, "

Inspection".

Magnet clutch Contact of clutch disc with pulley. Check clearance between

clutch disc and pulley. Refer

to

HA-32, "

Inspection".

Compressor body Loosened compressor mounting bolts. Check bolts for tightness.

Refer to

HA-30, "

Exploded

View".

Unusual noise from cooler piping. Cooler piping (pipe and

flexible hose)Improper installation of clip and brack-

et. Check the installation condi-

tion of the cooler piping. Re-

fer to

HA-33, "

Exploded

View".

Unusual noise from expansion

valve when A/C is ON. Expansion valveShortage of refrigerant. Check for leakage.

Collect all refrigerant,

evacuate refrigerant cycle

again, and then refill it

with the specified amount

of refrigerant.

Wear, breakage, or clogging of foreign

material in inner parts. Eliminate foreign material

from expansion valve, or re-

place it.

Unusual noise from belt. — Loosened belt

Check belt tension. Refer to

EM-20, "

Checking".

Internal compressor parts ge t locked Replace compressor.

Revision: 2010 May2011 QX56

Page 3093 of 5598

COOLER PIPE AND HOSEHA-37

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

Cap on wrap the joint of the A/C piping and expan sion valve with suitable material such as vinyl

tape to avoid the entry of air.

10. Remove low-pressure pipe from the vhiecle.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

REAR COOLER PIPE

REAR COOLER PIPE : Removal and InstallationINFOID:0000000006276177

CAUTION:

Perform lubricant return operati on before each refrigeration system disassembly. However, if a large

amount of refrigerant or lubricant is detected, n ever perform lubricant return operation. Refer to HA-

22, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-22, "Per-

form Lubricant Return Operation".

2. Separate frame and body. Refer to DLK-251, "

Removal and Installation".

3. Remove mounting bolts, and then disconnect high-pressure pipe and low-pressure pipe from rear cooler & heater pipe assembly.

CAUTION:

Cap or wrap the joint of the A/C piping with suitab le material such as vinyl tape to avoid the entry

air.

4. Remove clamps, and then disconnect rear heater bypas hoses from rear cooler & heater pipe assembly.

5. Remove mounting bolt, and then disconnect rear cooler &. heater pipe assembly from rear expansion

valve.

CAUTION:

Cap or wrap the joint of the A/C piping and rear expansion valve with suitable material such as

vinyl tape to avoid the entry air.

6. Remove clamps, and then disconnect rear cooler & heater pipe assembly from rear heater pipes.

7. Remove mounting nuts, and then remove rear cooler pipe cover.

8. Remove mounting bolts and nuts, and then remove rear cooler & heater pipe assembly from the vehicle.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

Revision: 2010 May2011 QX56

Page 3271 of 5598

INL-4

< SYSTEM DESCRIPTION >

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006216048

Component DescriptionINFOID:0000000006216049

1. BCMRefer to BCS-4, "

BODY CONTROL

SYSTEM : Componen t Parts Loca-

tion"

2. Personal lamp 3. Luggage room lamp

4. Remote keyless entry receiver Refer to DLK-11, "

DOOR LOCK

SYSTEM :

ComponentPartsLocation"

5. Back door lock assembly

(back door switch) 6. Automatic back door close switch

7. Door request switch 8. Door switch 9. Step lamp

10. Paddle lamp 11. Optical sensor 12. IPDM E/R Refer to PCS-4, "

Component Parts

Location"

13. Vanity mirror lamp 14. Combination meter 15. Combination switch

16. Front door lock assembly (driver

side) (door key cylinder switch, un-

lock sensor) 17. Door lock and unlock switch 18. Foot lamp

19. Push-button ignition switch 20. AV control unit Refer to AV- 9 , "

Component Parts Lo-

cation"

21. Map lamp

JMLIA0837ZZ

Part Description

BCM Controls the interior lighting system.

IPDM E/R Controls the integrated relay according to the request signal from BCM (via CAN com-

munication).

Remote keyless entry receiver Refer to DLK-12, "

DOOR LOCK SYSTEM : ComponentDescription".

AV control uni Receives the dimmer signal from BCM via CAN communication.

Optical sensor Refer to EXL-7, "

EXTERIOR LIGHTING SYSTEM : ComponentDescription".

Unlock sensor Detects door lock condition of driver side door.

Revision: 2010 May2011 QX56