lock INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 478 of 5598

BR-8

< PERIODIC MAINTENANCE >

BRAKE PEDAL

Brake Pedal Height

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

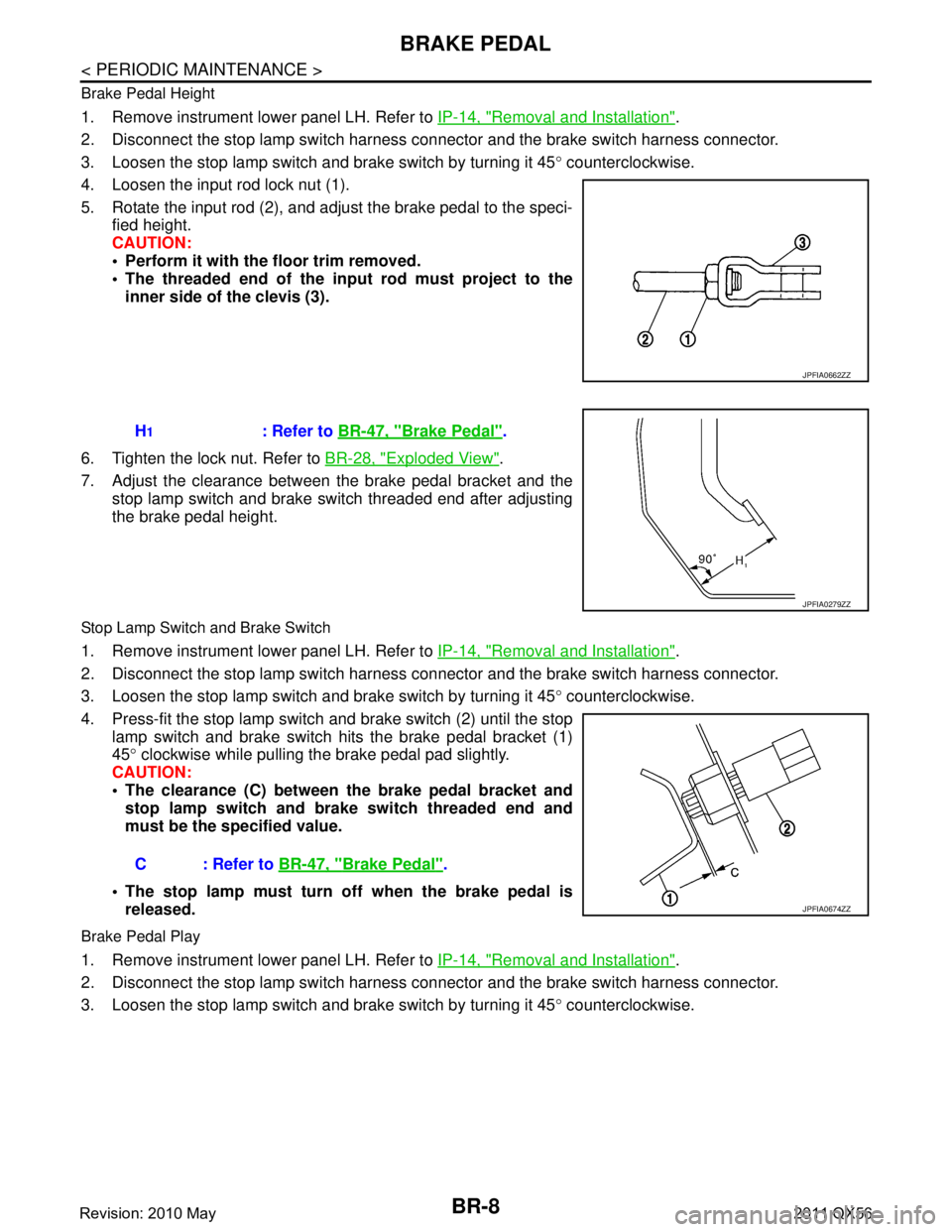

4. Loosen the input rod lock nut (1).

5. Rotate the input rod (2), and adjust the brake pedal to the speci- fied height.

CAUTION:

Perform it with the floor trim removed.

The threaded end of the in put rod must project to the

inner side of the clevis (3).

6. Tighten the lock nut. Refer to BR-28, "

Exploded View".

7. Adjust the clearance between the brake pedal bracket and the stop lamp switch and brake switch threaded end after adjusting

the brake pedal height.

Stop Lamp Switch and Brake Switch

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

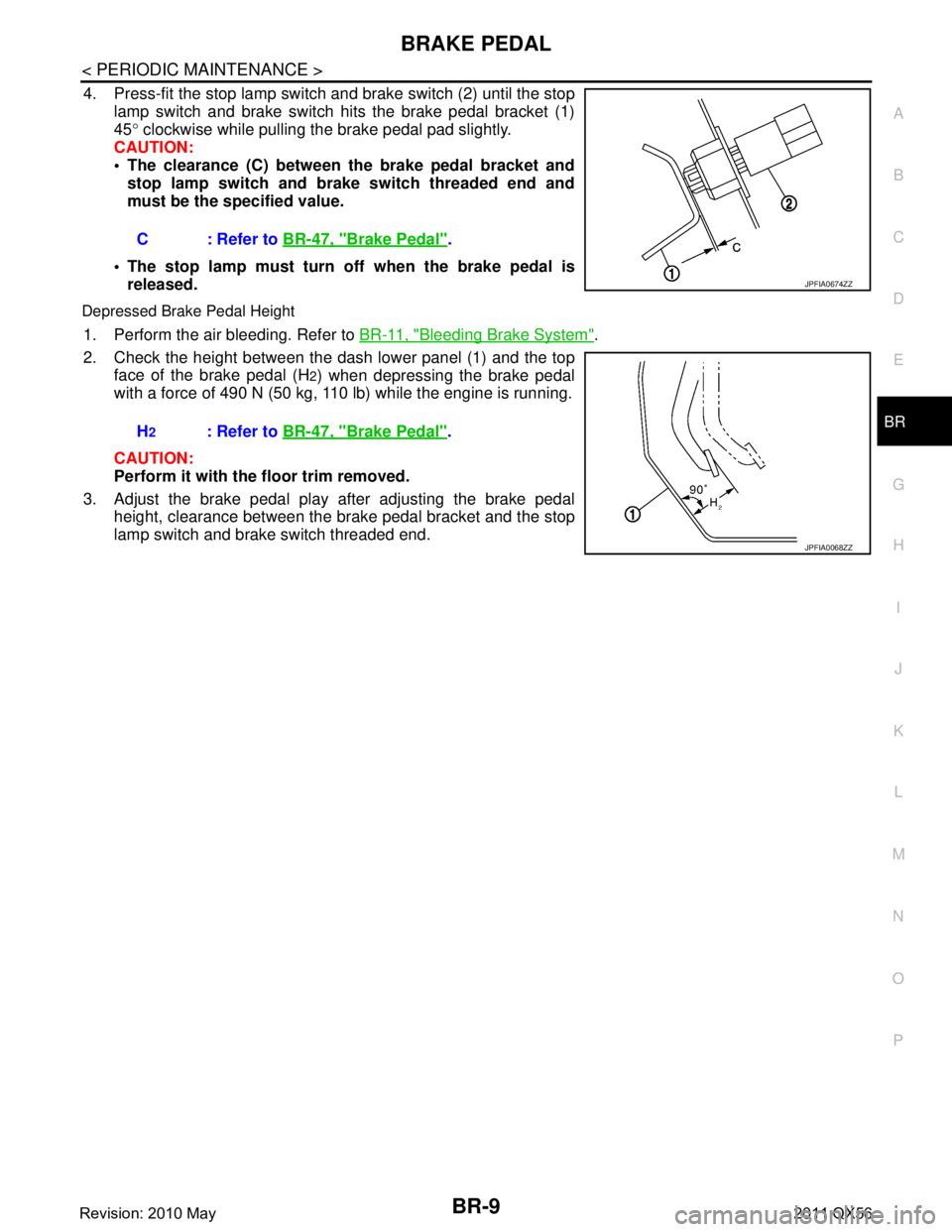

4. Press-fit the stop lamp switch and brake switch (2) until the stop

lamp switch and brake switch hits the brake pedal bracket (1)

45 ° clockwise while pulling the brake pedal pad slightly.

CAUTION:

The clearance (C) between the brake pedal bracket and

stop lamp switch and brake switch threaded end and

must be the specified value.

The stop lamp must turn off when the brake pedal is released.

Brake Pedal Play

1. Remove instrument lower panel LH. Refer to IP-14, "Removal and Installation".

2. Disconnect the stop lamp switch harness c onnector and the brake switch harness connector.

3. Loosen the stop lamp switch and brake switch by turning it 45 ° counterclockwise.

JPFIA0662ZZ

H1: Refer to BR-47, "Brake Pedal".

JPFIA0279ZZ

C : Refer to BR-47, "Brake Pedal".

JPFIA0674ZZ

Revision: 2010 May2011 QX56

Page 479 of 5598

BRAKE PEDALBR-9

< PERIODIC MAINTENANCE >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

4. Press-fit the stop lamp switch and brake switch (2) until the stop

lamp switch and brake switch hits the brake pedal bracket (1)

45 ° clockwise while pulling the brake pedal pad slightly.

CAUTION:

The clearance (C) between the brake pedal bracket and stop lamp switch and brake switch threaded end and

must be the specified value.

The stop lamp must turn off when the brake pedal is released.

Depressed Brake Pedal Height

1. Perform the air bleeding. Refer to BR-11, "Bleeding Brake System".

2. Check the height between the dash lower panel (1) and the top face of the brake pedal (H

2) when depressing the brake pedal

with a force of 490 N (50 kg, 110 lb) while the engine is running.

CAUTION:

Perform it with the floor trim removed.

3. Adjust the brake pedal play after adjusting the brake pedal height, clearance between the brake pedal bracket and the stop

lamp switch and brake switch threaded end.C : Refer to

BR-47, "

Brake Pedal".

JPFIA0674ZZ

H2: Refer to BR-47, "Brake Pedal".

JPFIA0068ZZ

Revision: 2010 May2011 QX56

Page 490 of 5598

BR-20

< REMOVAL AND INSTALLATION >

BRAKE PEDAL

REMOVAL AND INSTALLATION

BRAKE PEDAL

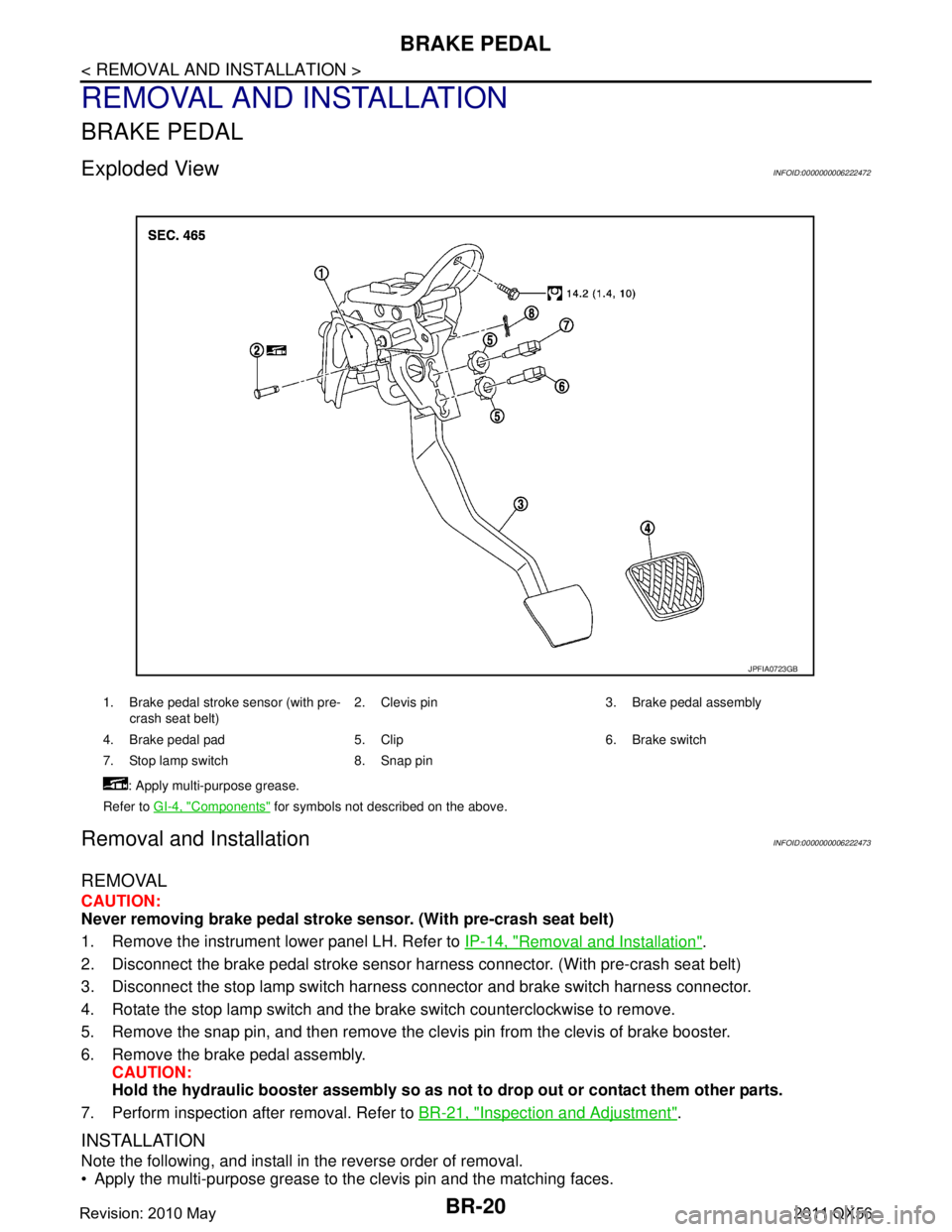

Exploded ViewINFOID:0000000006222472

Removal and InstallationINFOID:0000000006222473

REMOVAL

CAUTION:

Never removing brake pedal stroke sensor. (With pre-crash seat belt)

1. Remove the instrument lower panel LH. Refer to IP-14, "

Removal and Installation".

2. Disconnect the brake pedal stroke sensor har ness connector. (With pre-crash seat belt)

3. Disconnect the stop lamp switch harness connector and brake switch harness connector.

4. Rotate the stop lamp switch and the brake switch counterclockwise to remove.

5. Remove the snap pin, and then remove the clevis pin from the clevis of brake booster.

6. Remove the brake pedal assembly. CAUTION:

Hold the hydraulic booster assembly so as not to drop out or contact them other parts.

7. Perform inspection after removal. Refer to BR-21, "

Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

Apply the multi-purpose grease to the clevis pin and the matching faces.

1. Brake pedal stroke sensor (with pre-

crash seat belt) 2. Clevis pin 3. Brake pedal assembly

4. Brake pedal pad 5. Clip 6. Brake switch

7. Stop lamp switch 8. Snap pin : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0723GB

Revision: 2010 May2011 QX56

Page 492 of 5598

BR-22

< REMOVAL AND INSTALLATION >

BRAKE PIPING

BRAKE PIPING

FRONT

FRONT : Exploded ViewINFOID:0000000006222475

1. Brake tube 2. Connector 3. Connector bracket

4. Hydraulic booster assembly 5. Lock plate 6. Brake hose bracket

7. Copper washer 8. Union bolt 9. Brake hose

A. To rear brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0794GB

Revision: 2010 May2011 QX56

Page 493 of 5598

BRAKE PIPINGBR-23

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

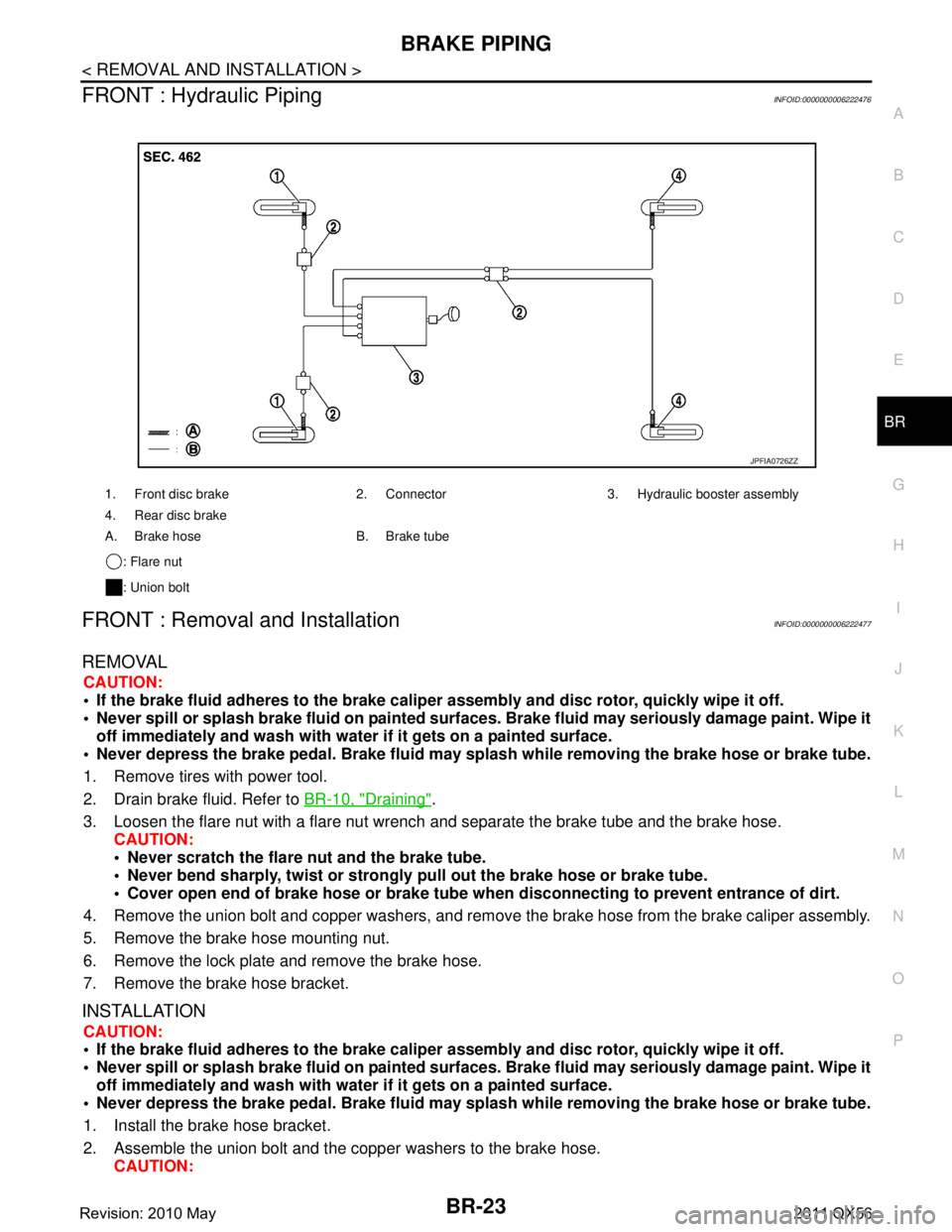

FRONT : Hydraulic PipingINFOID:0000000006222476

FRONT : Removal and InstallationINFOID:0000000006222477

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the brake hose mounting nut.

6. Remove the lock plate and remove the brake hose.

7. Remove the brake hose bracket.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Install the brake hose bracket.

2. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0726ZZ

Revision: 2010 May2011 QX56

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

Never reuse the copper washer.

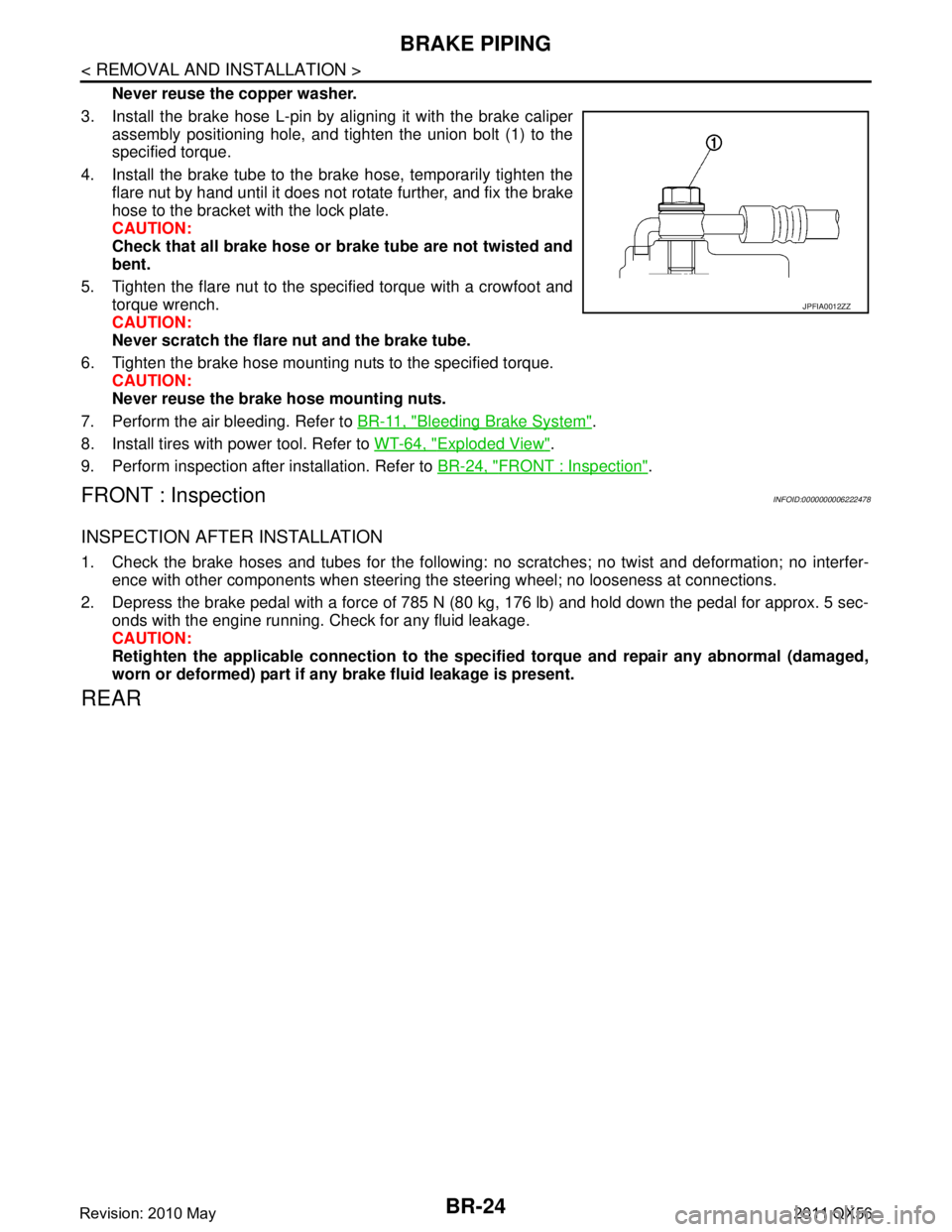

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56

Page 495 of 5598

BRAKE PIPINGBR-25

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Exploded ViewINFOID:0000000006222479

REAR : Hydraulic PipingINFOID:0000000006222480

1. Brake tube 2. Lock plate 3. Brake hose

4. Union bolt 5. Copper washer

A. To connector

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0795GB

JPFIA0726ZZ

Revision: 2010 May2011 QX56

Page 496 of 5598

BR-26

< REMOVAL AND INSTALLATION >

BRAKE PIPING

REAR : Removal and Installation

INFOID:0000000006222481

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose. CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

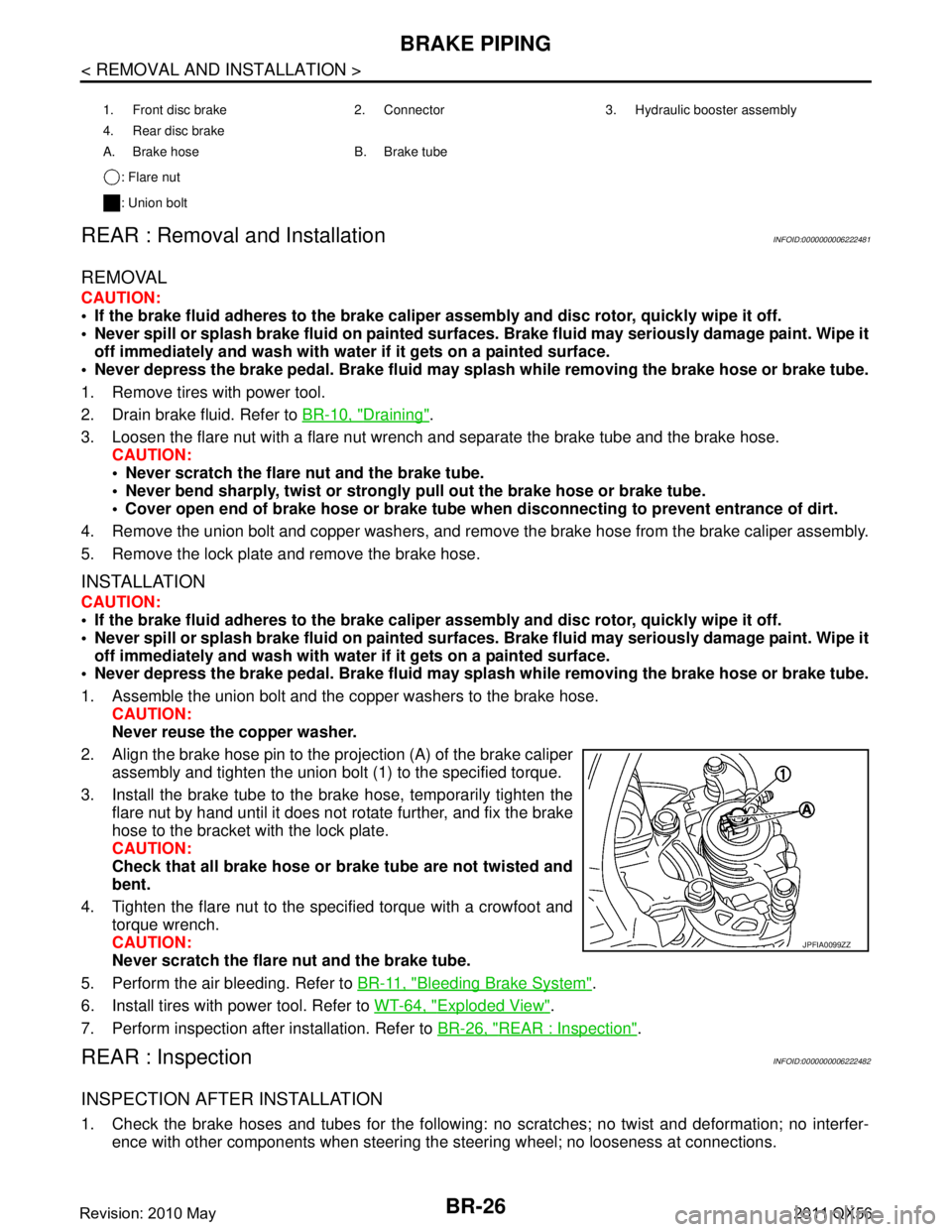

2. Align the brake hose pin to the projection (A) of the brake caliper

assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

7. Perform inspection after installation. Refer to BR-26, "

REAR : Inspection".

REAR : InspectionINFOID:0000000006222482

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0099ZZ

Revision: 2010 May2011 QX56

Page 498 of 5598

BR-28

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

HYDRAULIC BOOSTER ASSEMBLY

Exploded ViewINFOID:0000000006222483

REMOVAL

DISASSEMBLY

1. Hydraulic booster assembly 2. Lock nut 3. Clevis

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0767GB

Revision: 2010 May2011 QX56

Page 502 of 5598

BR-32

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

Apply new brake fluid to grommet of between reservoir tank and grommet and ABS actuator and electric unit

(control unit).

Inspection and AdjustmentINFOID:0000000006222486

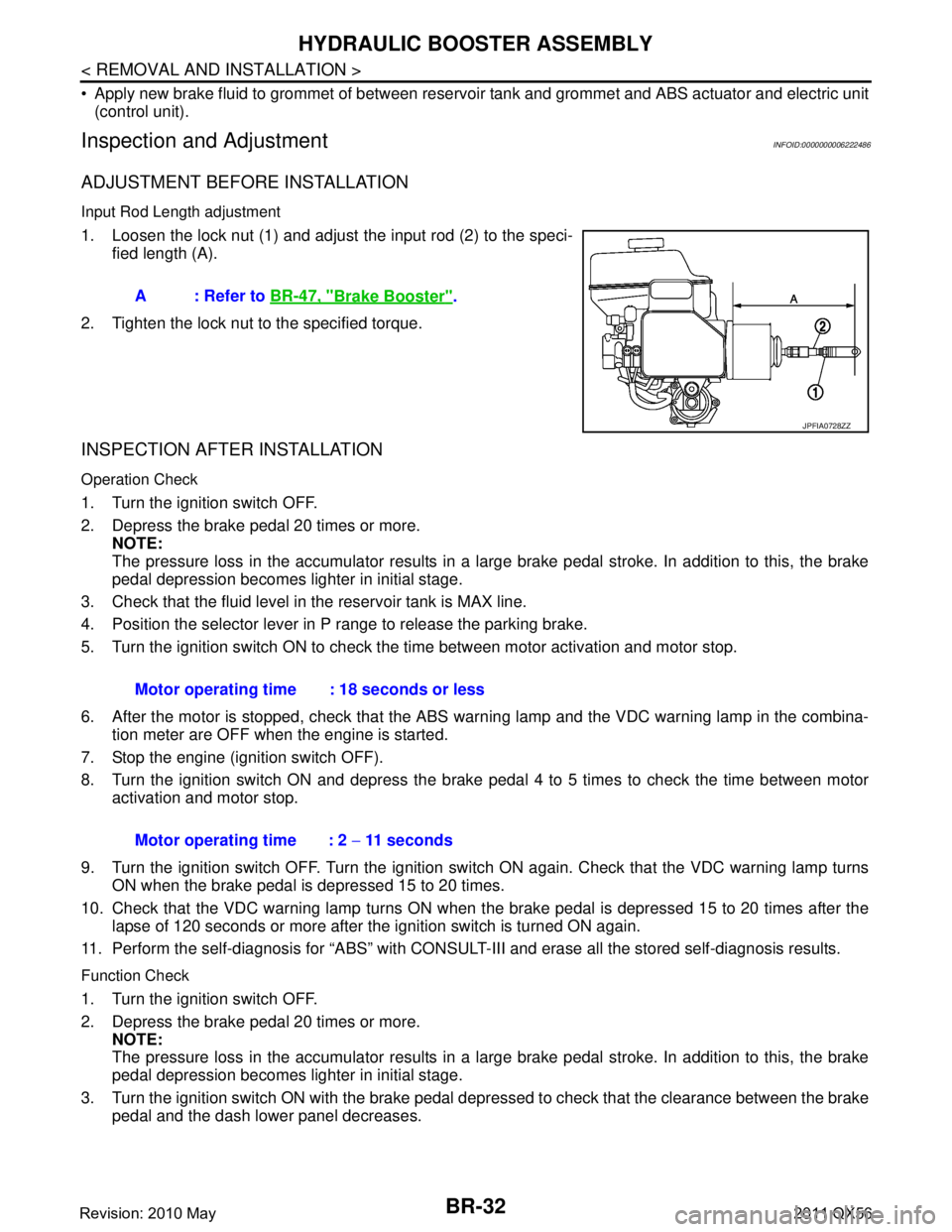

ADJUSTMENT BEFORE INSTALLATION

Input Rod Length adjustment

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (A).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warn ing lamp and the VDC warning lamp in the combina-

tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition swit ch ON again. Check that the VDC warning lamp turns

ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT- III and erase all the stored self-diagnosis results.

Function Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. A : Refer to

BR-47, "

Brake Booster".

JPFIA0728ZZ

Motor operating time : 18 seconds or less

Motor operating time : 2 − 11 seconds

Revision: 2010 May2011 QX56