BATTERY INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4174 of 5598

![INFINITI QX56 2011 Factory Service Manual

PWO

SYSTEMPWO-15

< SYSTEM DESCRIPTION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

System DescriptionINFOID:0000000006257071

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

When turning ON the AC 120 INFINITI QX56 2011 Factory Service Manual

PWO

SYSTEMPWO-15

< SYSTEM DESCRIPTION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

System DescriptionINFOID:0000000006257071

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

When turning ON the AC 120](/img/42/57033/w960_57033-4173.png)

PWO

SYSTEMPWO-15

< SYSTEM DESCRIPTION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

System DescriptionINFOID:0000000006257071

SYSTEM DIAGRAM

SYSTEM DESCRIPTION

When turning ON the AC 120 V outlet main switch with the ignition switch ON, the indicator turns ON and the

inverter unit is activated.

The inverter unit converts power supply voltage to AC 120 V and outputs the converted voltage to the AC

120 V outlet two seconds after the AC 120 V outlet main switch is turned ON.

Fail-safeINFOID:0000000006257269

When a malfunction listed below occurs, the inverter unit turns OFF the AC 120 V outlet main switch indicator

and stops the output by operating the fail-safe.

JSMIA0295GB

Malfunction item Fail-safe condition Fail-safe cancellation condition

Inverter unit is overheat-

ed When the inverter unit is overheated, the output

stops to protect the inverter unit. After the inverter unit temperature is lowered, the

AC 120 V outlet main switch ON

⇒ OFF ⇒ ON op-

eration allows normal return.

Inverter unit power sup-

ply voltage is 11.5 V or

less When inverter unit input voltage is lowered, the out-

put stops to protect the battery from running out.

Automatic normal return wh

en inverter unit power

supply voltage reaches 11.5 V - 16 V.

Inverter unit power sup-

ply voltage is 16 V - 18 V When inverter unit input voltage reaches 16 V - 18 V,

the output stops to protect the inverter unit. Automatic normal return wh

en inverter unit power

supply voltage reaches 11.5 V - 16 V.

Inverter unit power sup-

ply voltage is 18 V or

more When inverter unit input voltage reaches 18 V or

more, the output stops to protect the inverter unit. After the inverter unit power supply voltage reaches

11.5 V - 16 V, the AC 120 V outlet main switch ON

⇒

OFF ⇒ ON operation allows normal return.

Inverter unit output cur-

rent is 2.8 A or more When inverter unit output current reaches 2.8 A or

more, the output stops to prevent over current. (e.g.

connecting an electric appliance exceeding rated

output)

Automatic normal return wh

en inverter output cur-

rent reaches 2.8 A.

Inverter unit output signal

(AC 120 V output signal)

is shorted When inverter unit output signal is shorted, the out-

put stops. After recovering from inverter unit output signal

short, the AC 120 V outlet main switch ON

⇒ OFF

⇒ ON operation allows normal return.

Revision: 2010 May2011 QX56

Page 4175 of 5598

![INFINITI QX56 2011 Factory Service Manual

PWO-16

< ECU DIAGNOSIS INFORMATION >[AC 120 V OUTLET]

INVERTER UNIT

ECU DIAGNOSIS INFORMATION

INVERTER UNIT

Reference ValueINFOID:0000000006257074

TERMINAL LAYOUT

PHYSICAL VALUES

JSMIA0395ZZ

Te r m i INFINITI QX56 2011 Factory Service Manual

PWO-16

< ECU DIAGNOSIS INFORMATION >[AC 120 V OUTLET]

INVERTER UNIT

ECU DIAGNOSIS INFORMATION

INVERTER UNIT

Reference ValueINFOID:0000000006257074

TERMINAL LAYOUT

PHYSICAL VALUES

JSMIA0395ZZ

Te r m i](/img/42/57033/w960_57033-4174.png)

PWO-16

< ECU DIAGNOSIS INFORMATION >[AC 120 V OUTLET]

INVERTER UNIT

ECU DIAGNOSIS INFORMATION

INVERTER UNIT

Reference ValueINFOID:0000000006257074

TERMINAL LAYOUT

PHYSICAL VALUES

JSMIA0395ZZ

Te r m i n a l N o .

(Wire color) Description

Condition Va l u e

(Approx.)

+ − Signal name Input/

Output

1

(R) 5

(G) AC 120 V output Output Ignition

switch

ON When AC 120 V outlet

main switch OFF

0 V

When AC 120 V outlet

main switch ON

(When using circuit tester) AC 120 V

When AC 120 V outlet

main switch ON

(When using oscilloscope) Reference value

AC 120 V

4

(G/R) Ground Battery power supply Input Ignition switch OFF Battery power supply

5

(G) 1

(R) AC 120 V output Output Ignition

switch ON When AC 120 V outlet

main switch OFF

0 V

When AC 120 V outlet

main switch ON

(When using circuit tester) AC 120 V

When AC 120 V outlet

main switch ON

(When using oscilloscope) Reference value

AC 120 V

JSMIA0397GB

JSMIA0397GB

Revision: 2010 May2011 QX56

Page 4176 of 5598

![INFINITI QX56 2011 Factory Service Manual

PWO

INVERTER UNITPWO-17

< ECU DIAGNOSIS INFORMATION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

CAUTION:

To measure AC 120 V output signal, always use th

e circuit tester or oscilloscope AC r INFINITI QX56 2011 Factory Service Manual

PWO

INVERTER UNITPWO-17

< ECU DIAGNOSIS INFORMATION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

CAUTION:

To measure AC 120 V output signal, always use th

e circuit tester or oscilloscope AC r](/img/42/57033/w960_57033-4175.png)

PWO

INVERTER UNITPWO-17

< ECU DIAGNOSIS INFORMATION > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

CAUTION:

To measure AC 120 V output signal, always use th

e circuit tester or oscilloscope AC range.

Never allow the probes to contact each other.

Because of modified sine wave output of the AC 120 V output signal, voltage cannot be measured

accurately without using a circuit tester that can measure true RMS (root mean square).

Fail-safeINFOID:0000000006257075

When a malfunction listed below occurs, the inverter unit turns OFF the AC 120 V outlet main switch indicator

and stops the output by operating the fail-safe.

6

(W)

Ground AC 120 V outlet main

switch

InputIgnition

switch ON When AC 120 V outlet

main switch OFF

0 V

When AC 120 V outlet

main switch ON 12 V

7

(O) AC 120 V outlet main

switch indicator

OutputIgnition

switch ON When AC 120 V outlet

main switch OFF

0 V

When AC 120 V outlet

main switch ON 5.2 V

8

(G/Y) Ground — Ignition switch ON 0 V

Te r m i n a l N o .

(Wire color) Description

Condition Va l u e

(Approx.)

+ − Signal name Input/

Output

Malfunction item Fail-safe condition Fail-safe cancellation condition

Inverter unit is overheat-

ed When the inverter unit is overheated, the output

stops to protect the inverter unit. After the inverter unit temperature is lowered, the

AC 120 V outlet main switch ON

⇒ OFF ⇒ ON op-

eration allows normal return.

Inverter unit power sup-

ply voltage is 11.5 V or

less When inverter unit input voltage is lowered, the out-

put stops to protect the battery from running out.

Automatic normal return wh

en inverter unit power

supply voltage reaches 11.5 V - 16 V.

Inverter unit power sup-

ply voltage is 16 V - 18 V When inverter unit input voltage reaches 16 V - 18 V,

the output stops to protect the inverter unit. Automatic normal return wh

en inverter unit power

supply voltage reaches 11.5 V - 16 V.

Inverter unit power sup-

ply voltage is 18 V or

more When inverter unit input voltage reaches 18 V or

more, the output stops to protect the inverter unit. After the inverter unit power supply voltage reaches

11.5 V - 16 V, the AC 120 V outlet main switch ON

⇒

OFF ⇒ ON operation allows normal return.

Inverter unit output cur-

rent is 2.8 A or more When inverter unit output current reaches 2.8 A or

more, the output stops to prevent over current. (e.g.

connecting an electric appliance exceeding rated

output) Automatic normal return wh

en inverter output cur-

rent reaches 2.8 A.

Inverter unit output signal

(AC 120 V output signal)

is shorted When inverter unit output signal is shorted, the out-

put stops. After recovering from inverter unit output signal

short, the AC 120 V outlet main switch ON

⇒ OFF

⇒ ON operation allows normal return.

Revision: 2010 May2011 QX56

Page 4182 of 5598

![INFINITI QX56 2011 Factory Service Manual

PWO

POWER SUPPLY AND GROUND CIRCUITPWO-23

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:000 INFINITI QX56 2011 Factory Service Manual

PWO

POWER SUPPLY AND GROUND CIRCUITPWO-23

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:000](/img/42/57033/w960_57033-4181.png)

PWO

POWER SUPPLY AND GROUND CIRCUITPWO-23

< DTC/CIRCUIT DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

DTC/CIRCUIT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000006257089

1.CHECK FUSE

Check that the following fuse is not blown.

Is the fuse fusing?

YES >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

NO >> GO TO 2.

2.CHECK INVERTER UNIT POWER SUPPLY CIRCUIT

Check voltage between inverter unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the inverter unit power supply circuit.

3.CHECK INVERTER UNIT GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect the inverter unit connector.

3. Check for continuity between inverter unit harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace the inverter unit ground circuit.

Signal name Fuse No.

Battery power supply 79

Te r m i n a l Condition

Vo l ta g e

(Approx.)

(+) (–)

Inverter unit GroundIgnition switch

Connector Terminal

M143 4 OFF Battery voltage

Inverter unit GroundContinuity

Connector Terminal

M143 8 Existed

Revision: 2010 May2011 QX56

Page 4217 of 5598

PRECAUTIONSRF-3

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006141220

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 4276 of 5598

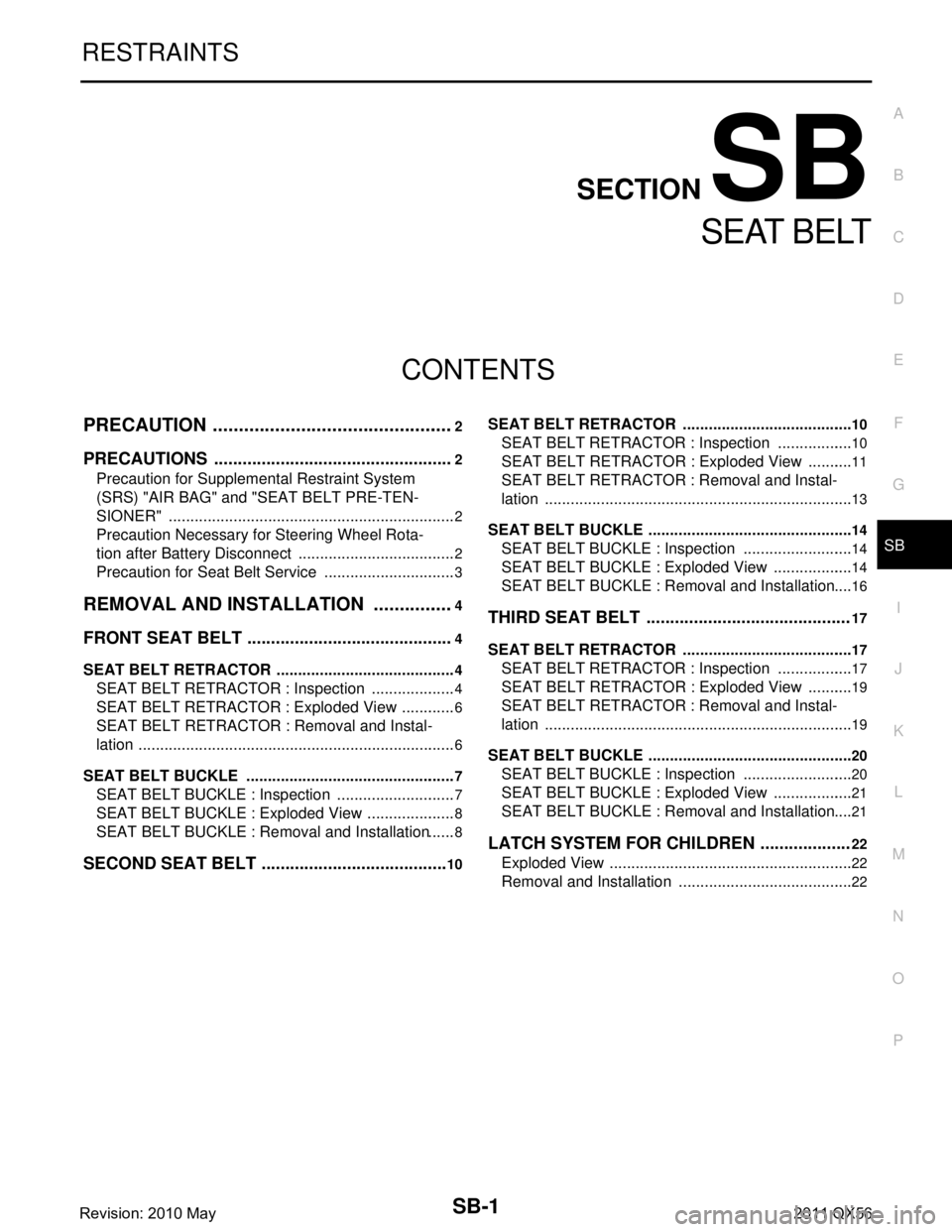

SB-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SB

A

B

SB

N

O P

CONTENTS

SEAT BELT

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Precaution for Seat Belt Service ...............................3

REMOVAL AND INSTALLATION ................4

FRONT SEAT BELT ....................................... .....4

SEAT BELT RETRACTOR .................................... ......4

SEAT BELT RETRACTOR : Inspection ....................4

SEAT BELT RETRACTOR : Exploded View .............6

SEAT BELT RETRACTOR : Removal and Instal-

lation ..........................................................................

6

SEAT BELT BUCKLE ........................................... ......7

SEAT BELT BUCKLE : Inspection ............................7

SEAT BELT BUCKLE : Exploded View .....................8

SEAT BELT BUCKLE : Removal and Installation ......8

SECOND SEAT BELT ........................................10

SEAT BELT RETRACTOR .................................... ....10

SEAT BELT RETRACTOR : Inspection ..................10

SEAT BELT RETRACTOR : Exploded View ...........11

SEAT BELT RETRACTOR : Removal and Instal-

lation ........................................................................

13

SEAT BELT BUCKLE ............................................ ....14

SEAT BELT BUCKLE : Inspection ..........................14

SEAT BELT BUCKLE : Exploded View ...................14

SEAT BELT BUCKLE : Removal and Installation ....16

THIRD SEAT BELT ...........................................17

SEAT BELT RETRACTOR .................................... ....17

SEAT BELT RETRACTOR : Inspection ..................17

SEAT BELT RETRACTOR : Exploded View ...........19

SEAT BELT RETRACTOR : Removal and Instal-

lation ........................................................................

19

SEAT BELT BUCKLE ............................................ ....20

SEAT BELT BUCKLE : Inspection ..........................20

SEAT BELT BUCKLE : Exploded View ...................21

SEAT BELT BUCKLE : Removal and Installation ....21

LATCH SYSTEM FOR CHILDREN ...................22

Exploded View .........................................................22

Removal and Installation .........................................22

Revision: 2010 May2011 QX56

Page 4277 of 5598

SB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006369606

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006369607

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 4278 of 5598

PRECAUTIONSSB-3

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Seat Belt ServiceINFOID:0000000006217608

CAUTION:

Before removing the front seat belt pre-tensioner assembly, turn the ignition switch off, disconnect

battery negative terminal and wait at least 3 minutes.

Never use electrical test equipment for front seat belt pre-tensioner connector.

After replacing or reinstalling front seat belt pre-tensioner assembly, or reconnecting front seat belt

pre-tensioner connector, check th e system function. Refer to SRC-14, "

Description".

Never use disassembled buckle or seat belt assembly.

Replace anchor bolts if th ey are deformed or worn out.

Never oil tongue and buckle.

If any component of seat belt assembly is questiona ble, do not repair. Replace the entire seat belt

assembly.

If webbing is cut, frayed or damaged, replace seat belt assembly.

When replacing seat belt assembly, u se a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN recommends that all seat belt assemblies in u se during a collision be replaced unless the col-

lision was minor and the belts show no damage a nd continue to operate properly. Failure to do so

could result in serious personal injury in an accide nt. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or im proper operation is noted. Seat belt pre-tensioners

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

The seat belt was damaged in an accident (i.e. torn webbing, bent retractor or guide).

The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage or distortion and repair as necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The front seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision

in which the air bags are deployed.

Revision: 2010 May2011 QX56

Page 4281 of 5598

SB-6

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

SEAT BELT RETRACTOR : Exploded View

INFOID:0000000006217616

SEAT BELT RETRACTOR : Removal and InstallationINFOID:0000000006217617

REMOVAL

CAUTION:

Before servicing SRS, turn the i gnition switch OFF, disconnect battery negative terminal and wait 3

minutes or more.

1. Remove the outer anchor.

1. Anchor nut 2. Shoulder anchor 3. Anchor bolt

4. Seat belt adjuster 5. Retaining washer 6. Seat belt pre-tensioner retractor (RH

side)

7. Outer anchor cover 8. Outer anchor 9. Spacer

10. Seat belt pre-tensioner retractor (LH side) 11. Lap pre-tensioner

Refer to GI-4, "

Components" for symbols in the figure.

JMHIA1566GB

Revision: 2010 May2011 QX56

Page 4300 of 5598

PRECAUTIONSSBC-3

< PRECAUTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006237873

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution for Seat Belt ServiceINFOID:0000000006237874

CAUTION:

Before removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect the

both battery cables and wait at least 3 minutes.

Do not use electrical test equipment for seat belt pre-tensioner connector.

After replacing or reinstalling seat belt pre-tens ioner assembly, or reconnecting front seat belt pre-

tensioner connector, check the system function. Refer to SRC-11, "

System Diagram".

Do not use disassemble buckle or seat belt assembly.

Replace anchor bolts if th ey are deformed or worn out.

Never oil tongue and buckle.

If any component of seat belt assembly is questio nable, do not repair. Replace the whole seat belt

assembly.

If webbing is cut, frayed, or damaged, replace seat belt assembly.

When replacing seat belt assembly, u se a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in u se during a collision be replaced unless the col-

lision was minor and the belts show no damage a nd continue to operate properly. Failure to do so

could result in serious personal injury in an accide nt. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or im proper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

Revision: 2010 May2011 QX56