BATTERY INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4308 of 5598

DIAGNOSIS SYSTEM (PRE-CRASH SEAT BELT)SBC-11

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

DIAGNOSIS SYSTEM (P RE-CRASH SEAT BELT)

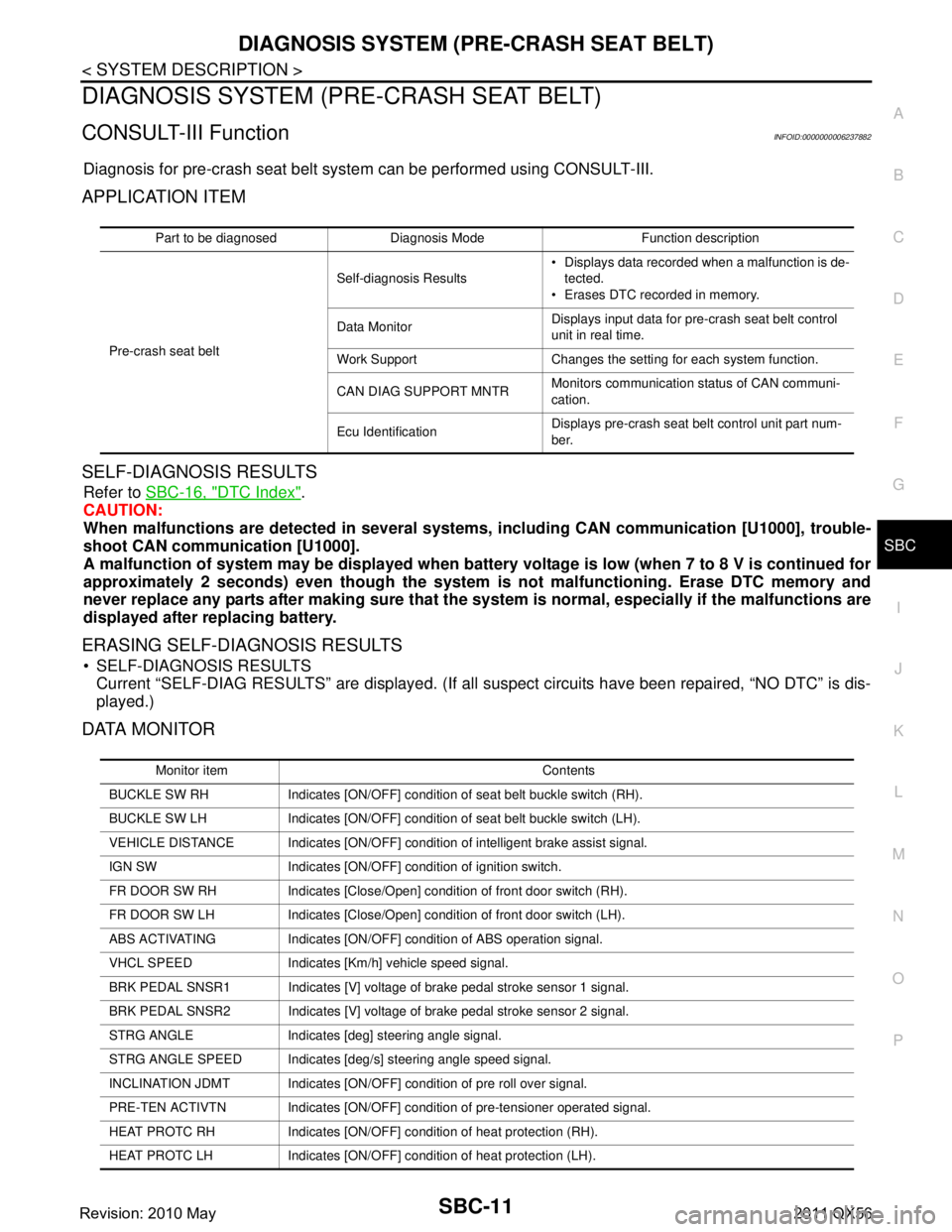

CONSULT-III FunctionINFOID:0000000006237882

Diagnosis for pre-crash seat belt syst em can be performed using CONSULT-III.

APPLICATION ITEM

SELF-DIAGNOSIS RESULTS

Refer to SBC-16, "DTC Index".

CAUTION:

When malfunctions are detect ed in several systems, includin g CAN communication [U1000], trouble-

shoot CAN communication [U1000].

A malfunction of system may be disp layed when battery voltage is low (when 7 to 8 V is continued for

approximately 2 seconds) even though the system is not malfunctioning. Erase DTC memory and

never replace any parts after making sure that the syst em is normal, especially if the malfunctions are

displayed after replacing battery.

ERASING SELF-DIAGNOSIS RESULTS

SELF-DIAGNOSIS RESULTS Current “SELF-DIAG RESULTS” are displayed. (If all suspect circuits have been repaired, “NO DTC” is dis-

played.)

DATA MONITOR

Part to be diagnosed Diagnosis Mode Function description

Pre-crash seat belt Self-diagnosis Results

Displays data recorded when a malfunction is de-

tected.

Erases DTC recorded in memory.

Data Monitor Displays input data for pre-crash seat belt control

unit in real time.

Work Support Changes the setting for each system function.

CAN DIAG SUPPORT MNTR Monitors communication status of CAN communi-

cation.

Ecu Identification Displays pre-crash seat belt control unit part num-

ber.

Monitor item Contents

BUCKLE SW RH Indicates [ON/OFF] condition of seat belt buckle switch (RH).

BUCKLE SW LH Indicates [ON/OFF] condition of seat belt buckle switch (LH).

VEHICLE DISTANCE Indicates [ON/OFF] condit ion of intelligent brake assist signal.

IGN SW Indicates [ON/OFF] condition of ignition switch.

FR DOOR SW RH Indicates [Close/Open] condition of front door switch (RH).

FR DOOR SW LH Indicates [Close/Open] condition of front door switch (LH).

ABS ACTIVATING Indicates [ON/OFF] co ndition of ABS operation signal.

VHCL SPEED Indicates [Km/h] vehicle speed signal.

BRK PEDAL SNSR1 Indicates [V] voltage of brake pedal stroke sensor 1 signal.

BRK PEDAL SNSR2 Indicates [V] voltage of brake pedal stroke sensor 2 signal.

STRG ANGLE Indicates [deg] steering angle signal.

STRG ANGLE SPEED Indicates [deg/s] steering angle speed signal.

INCLINATION JDMT Indicates [ON/OFF] condition of pre roll over signal.

PRE-TEN ACTIVTN Indicates [ON/OFF] condition of pre-tensioner operated signal.

HEAT PROTC RH Indicates [ON/OFF] condition of heat protection (RH).

HEAT PROTC LH Indicates [ON/OFF] condition of heat protection (LH).

Revision: 2010 May2011 QX56

Page 4311 of 5598

SBC-14

< ECU DIAGNOSIS INFORMATION >

PRE-CRASH SEAT BELT CONTROL UNIT (DRIVER SIDE)

TERMINAL LAYOUT

PHYSICAL VALUES

Fail SafeINFOID:0000000006237884

When a system malfunction is detected, deactivates a part of the system or all functions depending on the

malfunctioning part.

When the malfunction condition recovers to the normal condition, the system returns to the normal opera-

tion.

JMHIA0711ZZ

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(Y) Ground Power supply Input — Battery voltage

2

(G) Ground Brake pedal stroke sensor signal 1 Input Brake released

→ depressed 1 V - 4 V

4

(P) Ground CAN-L Input/

Output ——

6

(LG/R) Ground Seat belt buckle switch signal Input Seat belt is fastened 0 V

Seat belt is unfastened 5 V

8

(G) Ground Local Communication Line 2 Output IGN ON 5 V

9

(–) Ground Shield — — —

10

(R) Ground Brake pedal stroke sensor power circuit Output IGN ON 5 V

12

(B) Ground Brake pedal stroke sensor signal 2 Input Brake released

→ depressed 4 V - 1 V

14

(L) Ground CAN-H Input/

Output ——

16

(W) Ground Local Communication Line 1 Input/

Output ——

17

(W) Ground Brake pedal stroke sensor ground circuit — — 0 V

18

(B) Ground Ground — — 0 V

19

(W) Ground Motor drive circuit power supply Input — Battery voltage

20

(B) Ground Motor drive circuit ground — — 0 V

Revision: 2010 May2011 QX56

Page 4314 of 5598

PRE-CRASH SEAT BELT CONTROL UNIT (PASSENGER SIDE)

SBC-17

< ECU DIAGNOSIS INFORMATION >

C

D E

F

G

I

J

K L

M A

B

SBC

N

O P

PRE-CRASH SEAT BELT CONTROL UNIT (PASSENGER SIDE)

Reference ValueINFOID:0000000006237886

TERMINAL LAYOUT

PHYSICAL VALUES

Fail SafeINFOID:0000000006237887

When a system malfunction is detected, deactivates a part of the system or all functions depending on the

malfunctioning part.

When the malfunction condition recovers to the norma l condition, the system returns to the normal opera-

tion.

JMHIA0711ZZ

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

1

(Y) Ground Power supply Input — Battery voltage

6

(LG/B) Ground Seat belt buckle switch signal Input Seat belt is fastened 0 V

Seat belt is unfastened 5 V

8

(G) Ground Local Communication Line 2 Input/

Output IGN ON 5 V

9

(–) Ground Shield — — —

16

(W) Ground Local Communication Line 1

Input/

Output ——

18

(B) Ground Ground — — 0 V

19

(W) Ground Motor passenger circuit power supply Input — Battery voltage

20

(B) Ground Motor passenger circuit ground — — 0 V

Display contents of CONSULT-III Fail-safe

U0126 STRG ANG SEN SIG Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

U0428 STRG ANGL CAL Stops the operation in the conditions as per the following.

When lateral slippage during cornering occurs

When steering wheel is rotated for emergency

Revision: 2010 May2011 QX56

Page 4338 of 5598

B2454 SEAT BLT PWR DR CIRCSBC-41

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

B2454 SEAT BLT PWR DR CIRC

DTC LogicINFOID:0000000006237906

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.SELF-DIAGNOSIS WITH PRE-CRASH SEAT BELT CONTROL UNIT

1. Turn ignition switch ON.

2. Check “Self-diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SBC-41, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006237907

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 30 A fuse (No. 83).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK PRE-CRASH SEAT BELT MOTOR POWER SUPPLY

1. Disconnect pre-crash seat belt control unit (driver side) harness connector.

2. Check voltage between pre-crash seat belt control unit (driver side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness or connector.

3.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

DTC No. Self-diagnosis item DTC De tection Condition Possible causes

B2454 SEAT BLT PWR DR CIRC Seat belt motor (driver

side) power supply cir-

cuit is open or shorted Harness or connectors

[Pre-crash seat belt control unit (driver

side) circuit is open or shorted]

Pre-crash seat belt co ntrol unit (driver side)

Pre-crash seat belt control unit (driver side)

GroundVoltage (V)

Connector Terminal Battery voltage

B9 19

Revision: 2010 May2011 QX56

Page 4340 of 5598

B2456 SEAT BLT PWR ASSBC-43

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

B2456 SEAT BLT PWR AS

DTC LogicINFOID:0000000006237910

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.SELF-DIAGNOSIS WITH PRE-CRASH SEAT BELT CONTROL UNIT

1. Turn ignition switch ON.

2. Check “Self-diagnostic result” with CONSULT-III.

Is DTC detected?

YES >> Refer to SBC-43, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006237911

1.CHECK FUSE AND FUSIBLE LINK

1. Turn ignition switch OFF.

2. Check 30 A fuse (No.77).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK PRE-CRASH SEAT BELT MOTOR POWER SUPPLY

1. Disconnect pre-crash seat belt contro l unit (passenger side) harness connector.

2. Check voltage between pre-crash seat belt cont rol unit (passenger side) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness between pre-crash seat belt control unit (passenger side) and fuse.

3.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

DTC No. Self-diagnosis item DTC Detection Condition Possible causes

B2456 SEAT BLT PWR AS

CIRC Pre-crash seat belt control unit (passenger side)

power supply circuit is open or shorted Harness or connectors

[Pre-crash seat belt control unit (pas-

senger side) circuit is open or shorted]

Pre-crash seat belt control unit (pas-

senger side)

Pre-crash seat belt control unit (passenger side)

GroundVoltage (V)

(Approx.)

Connector Terminal Battery voltage

B231 19

Revision: 2010 May2011 QX56

Page 4349 of 5598

SBC-52

< DTC/CIRCUIT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000006237930

1.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect pre-crash seat belt control unit (driver side and passenger side) harness connector.

3. Check continuity between pre-crash seat belt c ontrol unit (driver side and passenger side) harness con-

nector and ground.

Is the measurement value normal?

YES >> GO TO 2.

NO >> Repair or replace harness or connector.

2.CHECK POWER SUPPLY CIRCUIT-I

Check voltage between pre-crash seat belt control unit (driver side and passenger side) harness connector

and ground.

Is the measurement value normal?

YES >> INSPECTION END

NO >> GO TO 3.

3.CHECKPOWER SUPPLY CIRCUIT-II

1. Disconnect fuse block (J/B) harness connector.

2. Check continuity between pre-crash seat belt c ontrol unit (driver side and passenger side) harness con-

nector and fuse block (J/B) harness connector.

3. Check continuity between pre-crash seat belt c ontrol unit (driver side and passenger side) harness con-

nector and ground.

Is the measurement value normal?

YES >> Check 10 A fuse (No. 6).

NO >> Repair or replace harness or connector.

Pre-crash seat belt control unit GroundContinuity

Connector Terminal

B9 (Driver side) 18

Existed

20

B231 (Passenger side) 18

20

Pre-crash seat belt control unit

GroundVo l ta g e

(Approx.)

Connector Terminal

B9 (Driver side) 1 Battery voltage

B231 (Passenger side)

Pre-crash seat belt control unit Fuse block (J/B) Continuity

Connector Terminal Connector Terminal

B9 (Driver side) 1 M2 6B Existed

B231 (Passenger side)

Pre-crash seat belt control unit GroundContinuity

Connector Terminal

B9 (Driver side) 1 Not existed

B231 (Passenger side)

Revision: 2010 May2011 QX56

Page 4354 of 5598

SEAT BELT WARNING LAMP CIRCUITSBC-57

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SBC

N

O P

SEAT BELT WARNING LAMP CIRCUIT

Component Function CheckINFOID:0000000006237937

1.CHECK SEAT BELT WARNI NG LAMP FUNCTION-I

1. Turn ignition switch ON.

2. Check seat belt warning lamp function.

Is the inspection results normal?

YES >> GO TO 2.

NO >> Check combination meter circuit. Refer to MWI-57, "

Work flow".

2.CHECK SEAT BELT WARNING LAMP FUNCTION-II

1. Sits in the passenger seat.

2. Fasten the seat belt (passenger side).

3. Check seat belt warning lamp function.

Is the inspection results normal?

YES >> Seat belt warning lamp circuit is normal.

NO >> Check seat belt warning lamp circuit. Refer to SBC-57, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006237938

WARNING:

Before servicing, turn ignition switch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK SEAT BELT ASSEMBLY (PASSENGER SIDE) CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect air bag diagnosis sensor unit harness connec tor and seat belt assembly (passenger side) har-

ness connector.

3. Check continuity between air bag diagnosis sensor unit harness connector and seat belt assembly (pas-

senger side) harness connector.

4. Check continuity between air bag diagnosis sensor unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness or connector.

2.CHECK SEAT BELT ASSEMBLY (PASSENGER SIDE) CIRCUIT-II

Check continuity between seat belt assemb ly (passenger side) harness connector and ground.

Condition Seat belt warning lamp

Seat belt (driver side) is fastened Not illuminated

Seat belt (driver side) is unfastened Illuminated

Condition Seat belt warning lamp

Seat belt (passenger side) is fastened Not illuminated

Seat belt (passenger side) is unfastened Illuminated

Air bag diagnosis sensor unit Seat belt assembly (passenger side) Continuity

Connector Terminal Connector Terminal

B228 29 B245 3 Existed

Air bag diagnosis sensor unit GroundContinuity

Connector Terminal

B228 29 Not existed

Revision: 2010 May2011 QX56

Page 4361 of 5598

SCS-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION SCS

A

B

SCS

N

O PCONTENTS

SUSPENSION CONTROL SYSTEM

HBMC

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Hydraulic Body-Motion Control

System ......................................................................

5

PREPARATION ............................................6

PREPARATION .............................................. .....6

Special Service Tools .......................................... ......6

Commercial Service Tools ........................................6

SYSTEM DESCRIPTION ..............................7

DESCRIPTION ............................................... .....7

Description .......................................................... ......7

COMPONENT PARTS ........................................8

Component Parts Location .................................. ......8

Component Description .............................................8

STRUCTURE AND OPERATION ........................9

Hydraulic Body-Motion Control System .............. ......9

Shock Absorber .........................................................9

PPMU ......................................................................10

Accumulator ............................................................11

PPMU Pipe ..............................................................11

SYSTEM .............................................................12

System Diagram .................................................. ....12

System Description .................................................12

Component Description ...........................................14

BASIC INSPECTION ...................................15

CHECK SYSTEM PRESSURE .........................15

Work Procedure ................................................... ....15

PRESSURE REDUCING METHOD ..................17

Work Procedure .......................................................17

AIR BLEEDING METHOD ................................18

Work Procedure .......................................................18

CHECK INTERNAL LEAKAGE ........................20

Work Procedure .......................................................20

CHECK FOR MALFUNCTION ..........................22

Work Procedure .......................................................22

CHECK SHOCK ABSORBER FOR MAL-

FUNCTION ....................................... .................

24

Work Procedure ................................................... ....24

CHECK ORIFICE FOR CLOGGING .................27

Work Procedure .......................................................27

SYMPTOM DIAGNOSIS ..............................29

DIFFERENCE IN APPEARANCE .....................29

Description ........................................................... ....29

Inspection Procedure ...............................................29

LARGE ROLL ANGLE ......................................30

Description ...............................................................30

Inspection Procedure ...............................................30

REMOVAL AND INSTALLATION ...............31

HYDRAULIC BODY-MOTION CONTROL

SYSTEM ............................................................

31

Hydraulic Piping ................................................... ....31

FRONT TUBE ASSEMBLY .......................................31

FRONT TUBE ASSEMBLY : Exploded View ...... ....32

FRONT TUBE ASSEMBLY : Removal and Instal-

lation ........................................................................

32

FRONT TUBE ASSEMBLY : Inspection ..................34

Revision: 2010 May2011 QX56

Page 4362 of 5598

SCS-2

ACCUMULATOR ......................................................34

ACCUMULATOR : Exploded View .........................35

ACCUMULATOR : Removal and Installation ..........35

ACCUMULATOR : Inspection ................................38

ACCUMULATOR : Disposal ...................................38

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE ...38

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE

: Exploded View ......................................................

39

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE

: Removal and Installation ......................................

39

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE

: Inspection .............................................................

43

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE

: Disposal ................................................................

43

REAR TUBE ASSEMBLY ...................................... ...43

REAR TUBE ASSEMBLY : Exploded View ............44

REAR TUBE ASSEMBLY : Removal and Installa-

tion ....................................................................... ...

44

REAR TUBE ASSEMBLY : Inspection ...................46

AIR LEVELIZER CONTROL SYSTEM

PRECAUTION ....... ....................... ...............

47

PRECAUTIONS .............................................. ...47

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

47

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ..................................

47

Precaution for Procedure without Cowl Top Cover ...48

Precaution for Air Levelizer Control System ...........48

SYSTEM DESCRIPTION ............................49

DESCRIPTION ................................................ ...49

Description ........................................................... ...49

COMPONENT PARTS .......................................50

Component Parts Location .................................. ...50

Component Description ..........................................50

Air Levelizer Control Module ..................................51

Vehicle Height Sensor ............................................51

Air Compressor .......................................................51

Air Compressor Relay ............................................51

CK SUSP Indicator Lamp .......................................51

STRUCTURE AND OPERATION ......................52

Rear Shock Absorber .......................................... ...52

Vehicle Height Sensor ............................................53

SYSTEM .......................................................... ...54

System Diagram .................................................. ...54

System Description .................................................54

Fail-safe ..................................................................55

DIAGNOSIS SYSTEM (AIR LEVELIZER

CONTROL MODULE) ........................................

56

CONSULT-III Function ........................................ ...56

ECU DIAGNOSIS INFORMATION .............58

AIR LEVELIZER CONTROL MODULE .......... ...58

Reference Value .................................................. ...58

Fail-safe ..................................................................59

DTC Inspection Priority Chart .................................59

DTC Index ...............................................................59

WIRING DIAGRAM ....................................61

AIR LEVELIZER CONTROL SYSTEM ........... ...61

Wiring Diagram .................................................... ...61

BASIC INSPECTION ..................................65

DIAGNOSIS AND REPAIR WORKFLOW ...... ...65

Work Flow ............................................................ ...65

Diagnostic Work Sheet ...........................................66

STANDARD VEHICLE HEIGHT SETTING .......67

Description ........................................................... ...67

Work Procedure ......................................................67

DTC/CIRCUIT DIAGNOSIS ........................69

C1801 VHCL HEIGHT SENSOR .................... ...69

DTC Logic ............................................................ ...69

Diagnosis Procedure ..............................................69

Component Inspection ............................................70

C1802 AIR SUS COMPRS RELAY ...................72

DTC Logic ............................................................ ...72

Diagnosis Procedure ..............................................72

C1803 AIR SUSPENSION EXH SOL ................74

DTC Logic ............................................................ ...74

Diagnosis Procedure ..............................................74

Component Inspection ............................................75

C1804 VHCL HEIGHT ADJ UP .........................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ..............................................77

Component Inspection (Air Compressor Relay) .....79

Component Inspection (Air Compressor) ............. ...79

C1805 VHCL HEIGHT ADJ DOWN ...................80

DTC Logic ............................................................ ...80

Diagnosis Procedure ..............................................80

C1806 VHCL HEIGHT SEN FIX ........................81

DTC Logic ............................................................ ...81

Diagnosis Procedure ...............................................81

C1807 VHCL HEIGHT SEN VOLT ....................82

DTC Logic ............................................................ ...82

Diagnosis Procedure ..............................................82

C1808 AIR SUS COMPRS FNCTN ...................84

DTC Logic ............................................................ ...84

Diagnosis Procedure ..............................................84

U1000 CAN COMM CIRCUIT ............................87

Revision: 2010 May2011 QX56

Page 4364 of 5598

![INFINITI QX56 2011 Factory Service Manual

SCS-4

< PRECAUTION >[HBMC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006256134

The Supplemental Res INFINITI QX56 2011 Factory Service Manual

SCS-4

< PRECAUTION >[HBMC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006256134

The Supplemental Res](/img/42/57033/w960_57033-4363.png)

SCS-4

< PRECAUTION >[HBMC]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006256134

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006256136

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56