mirror INFINITI QX56 2011 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1531 of 5598

DOOR MIRROR DEFOGGER DOES NOT OPERATEDEF-39

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

DOOR MIRROR DEFOGGER DOES NOT OPERATE

BOTH SIDES

BOTH SIDES : DescriptionINFOID:0000000006299459

Driver side and passenger side door mirror defoggers do not operate.

BOTH SIDES : Diagnosis ProcedureINFOID:0000000006299460

1.CHECK DOOR MIRROR DEFOGGER

Check door mirror defogger.

Refer to DEF-29, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

DRIVER SIDE

DRIVER SIDE : DescriptionINFOID:0000000006299461

Driver side door mirror defogger does not operate.

DRIVER SIDE : Diag nosis ProcedureINFOID:0000000006299462

1.CHECK DRIVER SIDE DOOR MIRROR DEFOGGER

Check driver side door mirror defogger.

Refer to DEF-30, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

PASSENGER SIDE

PASSENGER SIDE : DescriptionINFOID:0000000006299463

Passenger side door mirror defogger does not operate.

PASSENGER SIDE : Dia gnosis ProcedureINFOID:0000000006299464

1.CHECK PASSENGER SIDE DOOR MIRROR DEFOGGER.

Check passenger side door mirror defogger.

Refer to DEF-31, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CONFIRM THE OPERATION

Revision: 2010 May2011 QX56

Page 1532 of 5598

DEF-40

< SYMPTOM DIAGNOSIS >

DOOR MIRROR DEFOGGER DOES NOT OPERATE

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 1702 of 5598

DLK-166

< DTC/CIRCUIT DIAGNOSIS >

INTEGRATED HOMELINK TRANSMITTER

INTEGRATED HOMELINK TRANSMITTER

Component Function CheckINFOID:0000000006256149

1.CHECK FUNCTION

Check that system receiver (garage door opener, et c.) operates with original hand-held transmitter.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Receiver or hand-held transmitter is malfunctioning.

2.CHECK ILLUMINATE

1. Turn ignition switch OFF.

2. Does red light of transmitter illuminat e when any transmitter button is pressed?

Is the inspection result normal?

YES >> GO TO 3.

NO >> Refer to DLK-166, "

Diagnosis Procedure".

3.CHECK TRANSMITTER

Check transmitter with Tool*.

*:For details, refer to Technical Service Bulletin.

Is the inspection result normal?

YES >> Receiver or hand-held transmitter malfunction, not vehicle related.

NO >> Replace auto anti-dazzling inside mirror (integrated homelink transmitter).

Diagnosis ProcedureINFOID:0000000006256150

1.CHECK POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect auto anti-dazzling inside mirror (integrated homelink transmitter) connector.

3. Check voltage between auto anti-dazzling inside mirro r (integrated homelink transmitter) harness connec-

tor and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Check 10 A fuse [No. 6 located in the fuse block (J/B)].

NO-2 >> Harness for open or short between fuse and aut o anti-dazzling inside mirror (integrated homelink

transmitter).

2.CHECK GROUND CIRCUIT

Check continuity between auto anti-dazzling inside mi rror (integrated homelink transmitter) harness connector

and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

(+)

(–)Vo l ta g e

(Approx.)

Auto anti-dazzling inside mirror

(Integrated homelink transmitter)

Connector Terminal

R25 6

Ground Battery voltage

10

Auto anti-dazzling inside mirror

(Integrated homelink transmitter) GroundContinuity

Connector Terminal

R25 8 Existed

Revision: 2010 May2011 QX56

Page 1744 of 5598

DLK-208

< SYMPTOM DIAGNOSIS >

INTEGRATED HOMELINK TRANSMITTER DOES NOT OPERATE

INTEGRATED HOMELINK TRANSMITTER DOES NOT OPERATE

Diagnosis ProcedureINFOID:0000000006256148

1.CHECK INTEGRATED HOMELINK TRANSMITTER

Check integrated homelink transmitter.

Refer to DLK-166, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.REPLACE AUTO ANTI-DAZZLING INSIDE MIRROR

Replace auto anti-dazzling inside mirror.

Refer to MIR-30, "

Removal and Installation".

Is the result normal?

YES >> INSPECTION END

NO >> Check intermittent incident. Refer to GI-40, "

Intermittent Incident".

Revision: 2010 May2011 QX56

Page 2608 of 5598

EM-46

< REMOVAL AND INSTALLATION >

HIGH PRESSURE FUEL PUMP AND FUEL HOSE

Check that rotation stopper (A) of fuel feed hose contact highpressure fuel pump.

6. Tighten mounting bolts that are temporarily tightened in step 3.

7. Connect harness connector to high pressure fuel pump.

8. Install fuel pump connector protector.

9. Connect harness connector to low fuel pressure sensor.

10. Note the following, and connect quick connector to install fuel feed hose.

a. Check the connection for foreign material and damage.

b. Align center to insert quick connector straightly into fuel tube. NOTE:

The figure shows engine side as an example.

Insert fuel tube into quick connector until the top spool on fueltube is inserted completely and the second level spool is posi-

tioned slightly below quick connector bottom end.

CAUTION:

Hold “A” position in the figure when inserting fuel tube

into quick connector.

Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

Insert until you hear a “c lick” sound and actually feel

the engagement.

To avoid misidentification of engagement with a similar sound , be sure to perform the next

step.

c. Before clamping fuel feed hose with hose clamps, pull quick connector hard by hand holding “A” position.

Check it is completely engaged (connected) so that it does not come out from fuel feed tube.

d. Install quick connector cap to quick connector connection. Install so that the arrow mark on the side faces up.

CAUTION:

Check that quick connector and fuel tube are securely fitinto quick connector cap installation groove.

If quick connector cap canno t be installed smoothly,

quick connector may have not been installed correctly.

Check connection again.

11. Install in the reverse order of removal.

InspectionINFOID:0000000006289555

INSPECTION AFTER INSTALLATION

Check for Fuel Leakage

1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, check that

there is no fuel leakage at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, check again that there is no fuel leakage at connection

points.

JSBIA0364ZZ

KBIA0272E

PBIC2348E

Revision: 2010 May2011 QX56

Page 2615 of 5598

FUEL INJECTOR AND FUEL TUBEEM-53

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Apply engine oil to O-ring.

Tighten mounting bolts in numerical order as shown in the fig-

ure.

8. Install fuel feed tube (pump side) to fuel feed tube (bank side) as per the following:

CAUTION:

Never reuse fuel feed tube (pump side).

a. Apply engine oil to flare screw parts of high pr essure pump side and fuel feed tube (bank side) side.

b. Manually tighten 2 flare nuts without using a t ool until they are seated to screw thread.

c. Tighten mounting bolt (A).

d. Tighten flare nuts in numerical order as shown in the figure.

9. Install in the reverse order of removal.

InspectionINFOID:0000000006289558

INSPECTION AFTER INSTALLATION

Check for Fuel Leakage

1. Turn ignition switch “ON” (with the engine stopped). With fuel pressure applied to fuel piping, check that

there is no fuel leakage at connection points.

NOTE:

Use mirrors for checking at points out of clear sight.

2. Start the engine. With engine speed increased, check again that there is no fuel leakage at connection

points.

CAUTION:

Never touch the engine immediately after it is stopped because the engine is extremely hot.

JPBIA3924ZZ

: Engine front

JSBIA0355ZZ

B :To high pressure fuel pump

: Engine front

JSBIA0356ZZ

Revision: 2010 May2011 QX56

Page 2809 of 5598

![INFINITI QX56 2011 Factory Manual PDF

TURN SIGNAL LAMP CIRCUITEXL-99

< DTC/CIRCUIT DIAGNOSIS > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

TURN SIGNAL LAMP CIRCUIT

Component Function CheckINFOID:0000000006213967

1.CHECK TURN SIGNAL LA INFINITI QX56 2011 Factory Manual PDF

TURN SIGNAL LAMP CIRCUITEXL-99

< DTC/CIRCUIT DIAGNOSIS > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

TURN SIGNAL LAMP CIRCUIT

Component Function CheckINFOID:0000000006213967

1.CHECK TURN SIGNAL LA](/img/42/57033/w960_57033-2808.png)

TURN SIGNAL LAMP CIRCUITEXL-99

< DTC/CIRCUIT DIAGNOSIS > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

TURN SIGNAL LAMP CIRCUIT

Component Function CheckINFOID:0000000006213967

1.CHECK TURN SIGNAL LAMP

CONSULT-III ACTIVE TEST

1. Select “FLASHER” of BCM (FLASHER) active test item.

2. With operating the test items, check that the turn signal lamp is turned ON.

Is the inspection result normal?

YES >> Turn signal lamp circuit is normal.

NO >> Refer to EXL-99, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006213968

1.CHECK TURN SIGNAL LAMP BULB

Check applicable lamp bulb.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace bulb.

2.CHECK TURN SIGNAL LA MP OUTPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect front combination lamp connector, door mirror connector and rear combination lamp connec- tor.

3. Turn ignition switch ON.

4. With operating the turn signal switch, check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4. LH : Turn signal lamps (LH) ON

RH : Turn signal lamps (RH) ON

Off : Turn signal lamps OFF

(+)

(–) Condition Vo l ta g e

(Approx.)

BCM

Connector Terminal

M70 60

GroundTurn signal

switch LH

OFF 0 V

61 RH

OFF 0 V

PKID0926E

PKID0926E

Revision: 2010 May2011 QX56

Page 2810 of 5598

![INFINITI QX56 2011 Factory Manual PDF

EXL-100

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

TURN SIGNAL LAMP CIRCUIT

3.CHECK TURN SIGNAL LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM INFINITI QX56 2011 Factory Manual PDF

EXL-100

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

TURN SIGNAL LAMP CIRCUIT

3.CHECK TURN SIGNAL LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM](/img/42/57033/w960_57033-2809.png)

EXL-100

< DTC/CIRCUIT DIAGNOSIS >[XENON TYPE]

TURN SIGNAL LAMP CIRCUIT

3.CHECK TURN SIGNAL LAMP OPEN CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM harness connector and front combination lamp, door mirror or rear combi- nation lamp harness connector.

Front turn signal lamp

Side turn signal lamp

Rear turn signal lamp

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness.

4.CHECK TURN SIGNAL LAMP SHORT CIRCUIT

Check continuity between BCM harness connector and ground.

Is the inspection result normal?

YES >> Check each bulb socket for internal short circuit. Replace BCM if check result is normal. Refer to BCS-81, "

Removal and Installation".

NO >> Repair or replace harness.

5.CHECK TURN SIGNAL LAMP GROUND OPEN CIRCUIT

Check continuity between front combination lamp, door mirror or rear combination lamp and ground.

Front turn signal lamp

Side turn signal lamp

BCM Front combination lamp Continuity

Connector Terminal Connector Terminal

LH M7060 E118

8 Existed

RH 61 E119

BCM Door mirror Continuity

Connector Terminal Connector Terminal

Driver side M7060 D3

20 Existed

Passenger side 61 D23

BCM Rear combination lamp Continuity

Connector Terminal Connector Terminal

LH M7060 B60

3 Existed

RH 61 B232

BCM

GroundContinuity

Connector Terminal

M70 60

Not existed

61

Front combination lamp

GroundContinuity

Connector Terminal

LH E118 3 Existed

RH E119

Door mirror GroundContinuity

Connector Terminal

Driver side D3 19 Existed

Passenger side D23

Revision: 2010 May2011 QX56

Page 2840 of 5598

![INFINITI QX56 2011 Factory Manual PDF

EXL-130

< REMOVAL AND INSTALLATION >[XENON TYPE]

SIDE TURN SIGNAL LAMP

SIDE TURN SIGNAL LAMP

Exploded ViewINFOID:0000000006369470

Removal and InstallationINFOID:0000000006369471

CAUTION:

Disconnect b INFINITI QX56 2011 Factory Manual PDF

EXL-130

< REMOVAL AND INSTALLATION >[XENON TYPE]

SIDE TURN SIGNAL LAMP

SIDE TURN SIGNAL LAMP

Exploded ViewINFOID:0000000006369470

Removal and InstallationINFOID:0000000006369471

CAUTION:

Disconnect b](/img/42/57033/w960_57033-2839.png)

EXL-130

< REMOVAL AND INSTALLATION >[XENON TYPE]

SIDE TURN SIGNAL LAMP

SIDE TURN SIGNAL LAMP

Exploded ViewINFOID:0000000006369470

Removal and InstallationINFOID:0000000006369471

CAUTION:

Disconnect battery negative terminal or remove the fuse.

REMOVAL

1. Remove the door mirror. Refer to

MIR-32, "DOOR MIRROR ASSEMBLY : Removal and Installation".

2. Remove the door mirror glass. Refer to MIR-35, "

GLASS MIRROR : Removal and Installation".

3. Remove the side camera finisher. Refer to MIR-33, "

DOOR MIRROR ASSEMBLY : Disassembly and

Assembly".

4. Remove side turn signal lamp fixing screws (E), and then remove side turn signal lamp (with side turn signal lamp models

only).

NOTE:

Pull slightly side camera finisher (1) covering side turn signal

lamp bottom screw.

INSTALLATION

Install in the reverse order of removal.

1. Door mirror assembly 2. Door mi rror cover 3. Side camera finisher

4. Side turn signal lamp housing 5. Side turn signal lamp bulb

JMLIA1110ZZ

JMLIA0914ZZ

Revision: 2010 May2011 QX56

Page 2986 of 5598

GI-22

< HOW TO USE THIS MANUAL >

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS

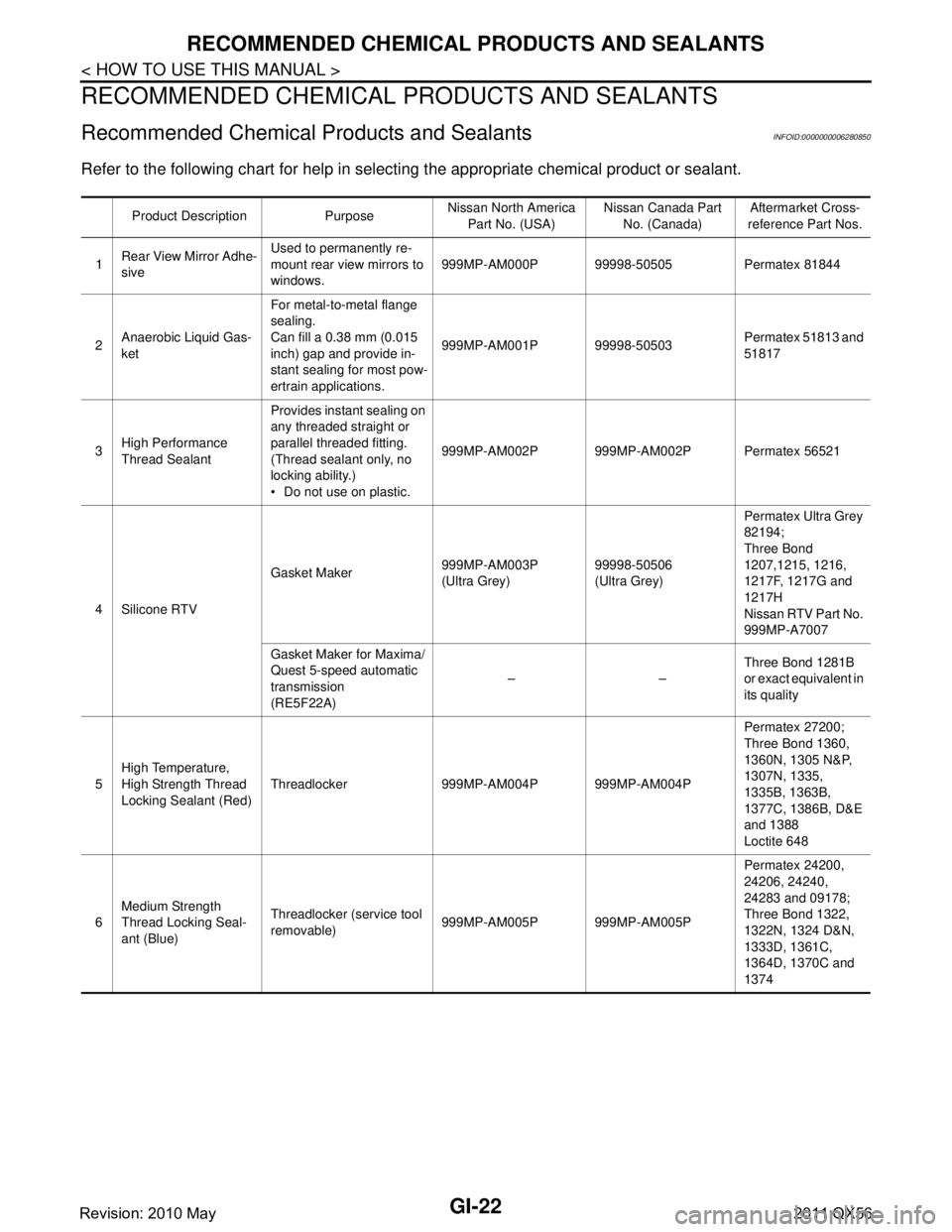

Recommended Chemical Products and SealantsINFOID:0000000006280850

Refer to the following chart for help in selecting the appropriate chemical product or sealant.

Product Description Purpose Nissan North America

Part No. (USA) Nissan Canada Part

No. (Canada) Aftermarket Cross-

reference Part Nos.

1 Rear View Mirror Adhe-

sive Used to permanently re-

mount rear view mirrors to

windows.

999MP-AM000P 99998-50505 Permatex 81844

2 Anaerobic Liquid Gas-

ket For metal-to-metal flange

sealing.

Can fill a 0.38 mm (0.015

inch) gap and provide in-

stant sealing for most pow-

ertrain applications.

999MP-AM001P 99998-50503

Permatex 51813 and

51817

3 High Performance

Thread Sealant Provides instant sealing on

any threaded straight or

parallel threaded fitting.

(Thread sealant only, no

locking ability.)

Do not use on plastic.

999MP-AM002P 999MP-AM002P Permatex 56521

4 Silicone RTV Gasket Maker

999MP-AM003P

(Ultra Grey)99998-50506

(Ultra Grey)Permatex Ultra Grey

82194;

Three Bond

1207,1215, 1216,

1217F, 1217G and

1217H

Nissan RTV Part No.

999MP-A7007

Gasket Maker for Maxima/

Quest 5-speed automatic

transmission

(RE5F22A) ––

Three Bond 1281B

or exact equivalent in

its quality

5 High Temperature,

High Strength Thread

Locking Sealant (Red)

Threadlocker 999MP-AM004P 999MP-AM004P Permatex 27200;

Three Bond 1360,

1360N, 1305 N&P,

1307N, 1335,

1335B, 1363B,

1377C, 1386B, D&E

and 1388

Loctite 648

6 Medium Strength

Thread Locking Seal-

ant (Blue) Threadlocker (service tool

removable)

999MP-AM005P 999MP-AM005P Permatex 24200,

24206, 24240,

24283 and 09178;

Three Bond 1322,

1322N, 1324 D&N,

1333D, 1361C,

1364D, 1370C and

1374

Revision: 2010 May2011 QX56