lock INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5429 of 5598

WCS

COMBINATION METERWCS-25

< ECU DIAGNOSIS INFORMATION >

C

DE

F

G H

I

J

K L

M B A

O P

SHIFT IND Ignition switch

ONDuring the indication of “P” by shift position

indicator

P

During the indication of “R” by shift position

indicator R

During the indication of “N” by shift position

indicator N

During the indication of “D” by shift position

indicator D

During the indication of “M1” by shift posi-

tion indicator M1

During the indication of “M2” by shift posi-

tion indicator M2

During the indication of “M3” by shift posi-

tion indicator M3

During the indication of “M4” by shift posi-

tion indicator M4

During the indication of “M5” by shift posi-

tion indicator M5

During the indication of “M6” by shift posi-

tion indicator M6

During the indication of “M7” by shift posi-

tion indicator M7

4WD IND Ignition switch

ON4WD shift switch in AUTO position AUTO

4WD shift switch in 4H position LOCK

4WD shift switch in 4L position LOCK/4Lo

BSW IND Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

BSW W/L Ignition switch

ONBSW warning lamp ON On

BSW warning lamp OFF Off

AT S MODE SW Ignition switch

ONSnow mode switch ON On

Snow mode switch OFF Off

M RANGE SW Ignition switch

ONSelector lever in manual mode position On

Other than the above Off

NM RANGE SW Ignition switch

ONSelector lever in manual mode position Off

Other than the above On

AT SFT UP SW Ignition switch

ONSelector lever in + position On

Other than the above Off

AT SFT DWN SW Ignition switch

ONSelector lever in – position On

Other than the above Off

PKB SW Ignition switch

ONParking brake switch ON On

Parking brake switch OFF Off

BUCKLE SW Ignition switch

ONDriver seat belt not fastened On

Driver seat belt fastened Off

BRAKE OIL SW Ignition switch

ONBrake fluid level switch ON On

Brake fluid level switch OFF Off

A/C AMP CONN Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 5453 of 5598

PRECAUTIONSWT-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006256474

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006256475

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5454 of 5598

WT-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for TPMSINFOID:0000000006225485

Low tire pressure warning lamp blinks for 1min, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories for low tire pressure warning control unit, or register the ID

to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-29, "

Work Procedure".

ID registration is required when replacing or rotating wheel s, replacing transmitter or low tire pressure warn-

ing control unit. Refer to WT-29, "

Work Procedure".

Replace grommet seal, valve core and cap of transmitter in TPMS, when replacing each tire by reaching the

wear limit. Refer to WT-66, "

Exploded View".

For tire inflation indicator function, refer to the following.

- When inflating the tires, park the vehicle in the safe area and ensure the safety of the working area.

- Read and understand the tire inflation indicator function prior to use.

- Inflate the tires one at a time.

- If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

tire inflation indicator function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try

again. The air filler pressure may be weak or out of service area.

- Despite the high-precision TPMS pressure sensor, an i ndicated value may differ from that of the pressure

gauge.

- Air pressure is measured rather high due to the rise in tire air temperature after driving.

- If TPMS is malfunctioning, the tire inflation indicator is unusable.

Service Notice or Precautions for Road WheelINFOID:0000000006225486

Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

Use Genuine NISSAN parts for the wheel nuts.

Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other it ems that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

After driving on roads scattered with anti-ici ng salts, wash off the wheels completely.

When installing road wheels onto the vehicle, always wipe of f any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Never apply oil to nut and bolt threads.

Revision: 2010 May2011 QX56

Page 5501 of 5598

POWER SUPPLY AND GROUND CIRCUITWT-51

< DTC/CIRCUIT DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000006225530

1.CHECK FUSE/FUSIBLE LINK

1. Turn the ignition switch OFF.

2. Check for fusing of the fuse and fusible link at the low tire pressure warning control unit.

- Check the 10 A fuse [No. 3 in fuse block (J/B)]

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK LOW TIRE PRESSURE WARNING CONTROL UNIT POWER SUPPLY CIRCUIT

1. Disconnect the low tire pressure warning control unit harness connector.

2. Turn the ignition switch ON. CAUTION:

Never start engine.

3. Check the voltage between the low tire pressure warning control unit and ground.

4. Turn the ignition switch OFF.

5. Check the voltage between the low tire pressure warning control unit and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the following. If any items are damaged, repair or replace damaged parts. Harness for short or open between ignition switch and low tire pressure warning control unit har-ness connector

Battery voltage.

3.CHECK LOW TIRE PRESSURE WARNI NG CONTROL UNIT GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check the continuity between the low tire pressure warning control unit harness connector and ground.

- Also check harness for short to ground and short to power.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

Low tire pressure warning control unit —Voltage

Connector Terminal

M96 15 Ground Battery voltage

Low tire pressure warning control unit —Voltage

Connector Terminal

M96 15 Ground 0 V

Low tire pressure warning control unit —Continuity

Connector Terminal

M96 32 Ground Existed

Revision: 2010 May2011 QX56

Page 5522 of 5598

PRECAUTIONSWW-3

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006349780

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006300446

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5523 of 5598

WW-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006300447

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Revision: 2010 May2011 QX56

Page 5529 of 5598

WW-10

< SYSTEM DESCRIPTION >

SYSTEM

IPDM E/R detects front wiper stop position by a front wiper stop position signal.

When a front wiper stop position signal is in the conditi ons listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/ R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

BCM

BCM detects the rain sensor serial link error and the light & rain sensor malfunction.

BCM controls the following fail-safe when light & rain sensor has a malfunction.

Fail-safe Control

Front wiper control

- Front wiper switch AUTO and sensing rain drop: The c ondition just before the activation of fail-safe is main-

tained until the front wiper switch is turned OFF.

- Front wiper switch AUTO and not sensing rain drop: Front wiper is LO operation until the front wiper switch is

turned off.

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM : System DiagramINFOID:0000000006300457

REAR WIPER AND WASHER S YSTEM : System DescriptionINFOID:0000000006300458

OUTLINE

The rear wiper is controlled by each function of BCM.

Control by BCM

Combination switch reading function

Control part Fail-safe operation

Front wiper The status just before activation of fail-safe control is maintained until the ignition switch

is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-safe

control is activated while the front wiper is set in the AUTO mode and the front wiper

motor is operating.

Headlamp washer relay Headlamp washer relay OFF

Ignition switch Front wiper switch Front wiper stop position signal

ON OFF

The front wiper stop position signal (stop

position) cannot be input for 10 seconds.

ON The front wiper stop position signal does

not change for 10 seconds.

JMLIA0612GB

Revision: 2010 May2011 QX56

Page 5531 of 5598

WW-12

< SYSTEM DESCRIPTION >

SYSTEM

- Rear washer switch ON (0.4 second or more)

The washer pump is grounded through the combination switch with the rear washer switch ON.

REAR WIPER OPERATION LINKED WITH REVERSE (WITH RAIN SENSOR)

BCM controls rear wiper to operate once according to the conditions of rear wiper operation linked with

reverse.

Condition of rear wiper operation linked with reverse - Ignition switch ON

- Front wiper switch: LO, HI or AUTO, and the front wiper auto operation ON judgement.

- Rear wiper switch OFF

- Selector lever “R”

TCM transmits the shift position signal to BCM thr ough the CAN communication line when the selector lever

is shifted to "R".

BCM supplies power to the rear wiper motor when receiving the shift position signal.

REAR WIPER OPERATION LINKED WITH REVERSE (WITHOUT RAIN SENSOR)

BCM controls rear wiper to operate once according to the conditions of rear wiper operation linked with

reverse.

Condition of rear wiper operation linked with reverse

- Ignition switch ON

- Front wiper switch: LO, HI or INT.

- Rear wiper switch OFF

- Selector lever “R”

TCM transmits the shift position signal to BCM thr ough the CAN communication line when the selector lever

is shifted to "R".

BCM supplies power to the rear wiper motor when receiving the shift position signal.

REAR WIPER DROP WIPE OPERATION

BCM controls the rear wiper to operate once acco rding to the rear wiper drop wipe operating condition.

Rear wiper drop wipe operating condition- Ignition switch ON

- Rear wiper switch OFF

- Rear washer switch OFF

BCM controls the rear wiper so that it operates once approximately three seconds later after the washer

interlocking operation of the rear wiper.

REAR WIPER AND WASHER SYSTEM : Fail SafeINFOID:0000000006300459

REAR WIPER MOTOR PROTECTION

BCM detects the rear wiper stopping position ac cording to the rear wiper auto stop signal.

When the rear wiper auto stop signal does not change more than 5 seconds while driving the rear wiper, BCM

stops power supply to protect the rear wiper motor.

Condition of cancellation

1. Pass more than 1 minute after the rear wiper stop.

2. Operate the rear wiper switch.

HEADLAMP WASHER SYSTEM

Revision: 2010 May2011 QX56

Page 5533 of 5598

WW-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006349813

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

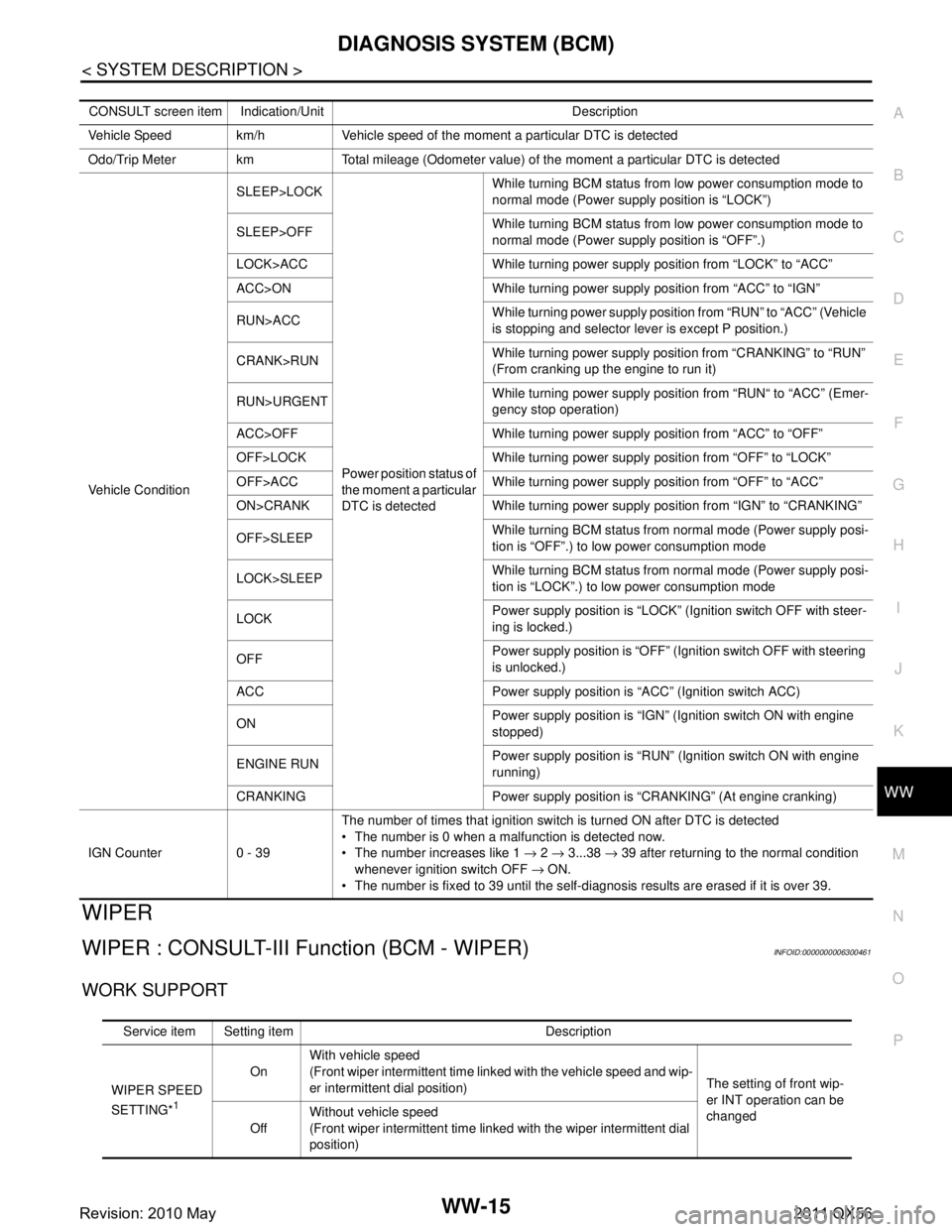

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5534 of 5598

DIAGNOSIS SYSTEM (BCM)WW-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

WW

N

O P

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000006300461

WORK SUPPORT

CONSULT screen item Indication/Unit Description

Vehicle Speed km/h Vehicle speed of the moment a particular DTC is detected

Odo/Trip Meter km Total mileage (Odometer value) of the moment a particular DTC is detected

Vehicle Condition SLEEP>LOCK

Power position status of

the moment a particular

DTC is detected While turning BCM status from low power consumption mode to

normal mode (Power supply position is “LOCK”)

SLEEP>OFF While turning BCM status from low power consumption mode to

normal mode (Power supply position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACC While turning power supply position

from “RUN” to “ACC” (Vehicle

is stopping and selector lever is except P position.)

CRANK>RUN While turning power su

pply position from “CRANKING” to “RUN”

(From cranking up the engine to run it)

RUN>URGENT While turning power su

pply position from “RUN“ to “ACC” (Emer-

gency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning po wer supply position from “IGN” to “CRANKING”

OFF>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “OFF”.) to low power consumption mode

LOCK>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “LOCK”.) to low power consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steer-

ing is locked.)

OFF Power supply position

is “OFF” (Ignition switch OFF with steering

is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine

stopped)

ENGINE RUN Power supply posi

tion is “RUN” (Ignition switch ON with engine

running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

IGN Counter 0 - 39 The number of times that ignition switch is turned ON after DTC is detected

The number is 0 when a malfunction is detected now.

The number increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition

whenever ignition switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

Service item Setting item Description

WIPER SPEED

SETTING*

1

On With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wip-

er intermittent dial position)

The setting of front wip-

er INT operation can be

changed

Off Without vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial

position)

Revision: 2010 May2011 QX56