tire type INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 163 of 5598

AV

SYSTEMAV-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

The current position is calculated by detecting the travel distance

from the previous calculation point, and its direction change.

Travel distance The travel distance is generat ed from the vehicle speed sensor

input signal. The automatic distance correction function is adopted

for preventing a miss-detection of the travel distance because of

tire wear etc.

Travel direction The gyroscope (angular veloci ty sensor) and GPS antenna (GPS

information) generate the change of t he travel direction. Both have

advantages and disadvantages as per the following descriptions.

Input signals are prioritized in each situation. However, this order of priority may change in accordance with

more detailed travel conditions so that the tr avel direction is detected more accurately.

Map-matching

Map-matching repositions the vehicle on the road map when a new

location is judged to be more accurate. This is done by comparing

the current vehicle position (calculated by the normal position detec-

tion method) from the map data stored in the HDD (Hard Disk Drive).

There is a possibility that the vehicle position may not be corrected in the following case, and when vehicle is

driven over a certain distance or time in which GPS in formation is hard to receive. Correct manually the cur-

rent location mark on the screen.

In map-matching, several alternative routes are prepared and pri- oritized in addition to the road judged as currently driving on.

Therefore, due to errors in the distance and/or direction, an incor-

rect road may be prioritized, and the current location mark may be

repositioned to the incorrect road.

If two roads are running in parallel, they are of the same priority.

Therefore, the current location mark may appear on either of them

alternately, depending on maneuvering of the steering wheel and

configuration of the road, etc.

SEL684V

Type Advantage Disadvantage

Gyroscope (angular velocity

sensor) The turning angle is precisely detected.

Errors are accumulated when driving a long dis-

tance without stopping.

GPS antenna (GPS informa-

tion) The travel direction (North/South/East/West) is

detected. The travel direction is not precisely detected when

driving slowly.

SEL685V

SEL686V

Revision: 2010 May2011 QX56

Page 182 of 5598

AV-34

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

The steering angle output value detected with the gyroscope is

adjusted.

SPEED CALIBRATION

During normal driving, distance error caused by tire wear and tire

pressure change is automatically adjusted for by the automatic dis-

tance correction function. This function, on the other hand, is for

immediate adjustment, in cases such as driving with tire chain fitted

on tires.

Error History

The self-diagnosis results are judged depending on whether any error occurs from when “Self-diagnosis” is

selected until the self-diagnosis results are displayed.

However, the diagnosis results are judged normal if an error has occurred before the ignition switch is turned

ON and then no error has occurred until the self-diagnosis start. Check the “Error Record” to detect any error

that may have occurred before the self-di agnosis start because of this situation.

The error record displays the time and place of the most recent occurrence of that error. However, take note of

the following points.

If there is a malfunction with the GPS antenna circuit board in the AV control unit, the correct date and time

of occurrence may not be able to be displayed.

Place of the error occurrence is represented by the posit ion of the current location mark at the time an error

occurred. If current location mark has deviated from t he correct position, then the place of the error occur-

rence cannot be located correctly.

The frequency of occurrence is displayed in a count up manner. The actual count up method differs depend- ing on the error item.

Count up method A

The counter resets to 0 if an error occurs when igniti on switch is turned ON. The counter increases by 1 if

the condition is normal at a next ignition ON cycle.

The counter upper limit is 39. Any counts exceeding 39 are ignored.“ The counter can be reset (no error

record display) with the “Delete log” switch or CONSULT-III.

Count up method B

The counter increases by 1 if an error occurs when i gnition switch is ON. The counter will not decrease even

if the condition is normal at the next ignition ON cycle.

The counter upper limit is 50. Any counts exceeding 50 are ignored. “ The counter can be reset (no error

record display) with the “Delete log” switch or CONSULT-III.

JSNIA2179ZZ

JSNIA2180ZZ

Display type of occur-

rence frequency Error history display item

Count up method A CAN communication line, control unit (CAN), AV communication line, control unit (AV)

Count up method B Other than the above

Revision: 2010 May2011 QX56

Page 358 of 5598

AV-210

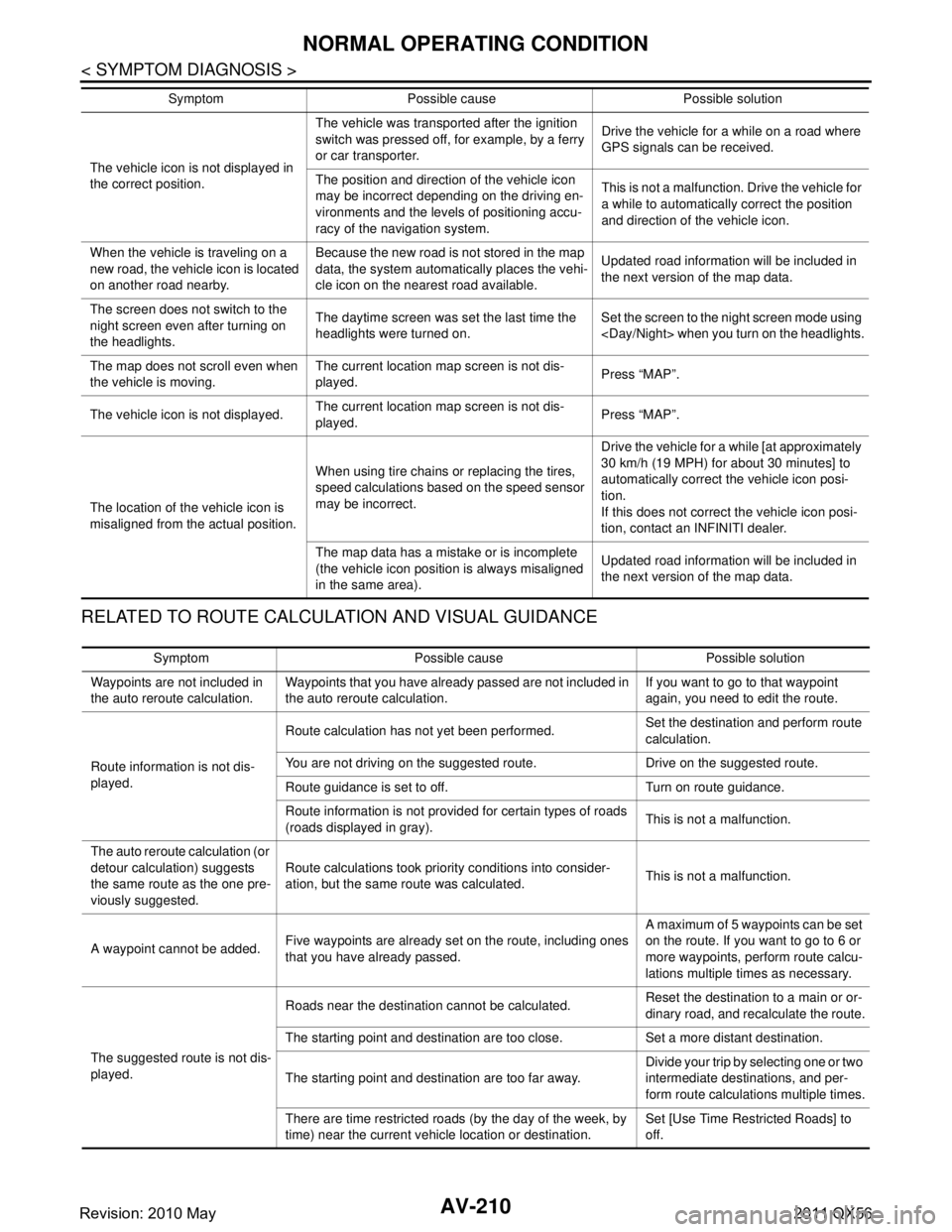

< SYMPTOM DIAGNOSIS >

NORMAL OPERATING CONDITION

RELATED TO ROUTE CALCULATION AND VISUAL GUIDANCE

The vehicle icon is not displayed in

the correct position.The vehicle was transported after the ignition

switch was pressed off, for example, by a ferry

or car transporter.

Drive the vehicle for a while on a road where

GPS signals can be received.

The position and direction of the vehicle icon

may be incorrect depending on the driving en-

vironments and the levels of positioning accu-

racy of the navigation system. This is not a malfunction. Drive the vehicle for

a while to automatically correct the position

and direction of the vehicle icon.

When the vehicle is traveling on a

new road, the vehicle icon is located

on another road nearby. Because the new road is not stored in the map

data, the system automatically places the vehi-

cle icon on the nearest road available.

Updated road information will be included in

the next version of the map data.

The screen does not switch to the

night screen even after turning on

the headlights. The daytime screen was set the last time the

headlights were turned on.

Set the screen to the night screen mode using

The map does not scroll even when

the vehicle is moving. The current location map screen is not dis-

played.

Press “MAP”.

The vehicle icon is not displayed. The current location map screen is not dis-

played.

Press “MAP”.

The location of the vehicle icon is

misaligned from the actual position. When using tire chains or replacing the tires,

speed calculations based on the speed sensor

may be incorrect. Drive the vehicle for a while [at approximately

30 km/h (19 MPH) for about 30 minutes] to

automatically correct the vehicle icon posi-

tion.

If this does not correct the vehicle icon posi-

tion, contact an INFINITI dealer.

The map data has a mistake or is incomplete

(the vehicle icon position is always misaligned

in the same area). Updated road information will be included in

the next version of the map data.

Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

Waypoints are not included in

the auto reroute calculation. Waypoints that you have already passed are not included in

the auto reroute calculation. If you want to go to that waypoint

again, you need to edit the route.

Route information is not dis-

played. Route calculation has not yet been performed.

Set the destination and perform route

calculation.

You are not driving on the suggested route. Drive on the suggested route.

Route guidance is set to off. Turn on route guidance.

Route information is not provided for certain types of roads

(roads displayed in gray). This is not a malfunction.

The auto reroute calculation (or

detour calculation) suggests

the same route as the one pre-

viously suggested. Route calculations took priority conditions into consider-

ation, but the same route was calculated.

This is not a malfunction.

A waypoint cannot be added. Five waypoints are already set on the route, including ones

that you have already passed. A maximum of 5 waypoints can be set

on the route. If you want to go to 6 or

more waypoints, perform route calcu-

lations multiple times as necessary.

The suggested route is not dis-

played. Roads near the destination cannot be calculated.

Reset the destination to a main or or-

dinary road, and recalculate the route.

The starting point and destination are too close. Set a more distant destination.

The starting point and destination are too far away. Divide your trip by selecting one or two

intermediate destinations, and per-

form route calculations multiple times.

There are time restricted roads (by the day of the week, by

time) near the current vehicle location or destination. Set [Use Time Restricted Roads] to

off.

Revision: 2010 May2011 QX56

Page 2831 of 5598

![INFINITI QX56 2011 Factory Service Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio INFINITI QX56 2011 Factory Service Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio](/img/42/57033/w960_57033-2830.png)

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparation before adjusting

NOTE:

for details, refer to the regulations in your own country.

perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

before performing aiming adjustment, check the following. adjust the tire pressure to the specification.

fill with fuel, engine coolant and each oil.

maintain the unloaded vehicle condition. (remove luggage from the passenger compartment and the lug- gage room.)

NOTE:

do not remove the temporary tire, jack and on-vehicle tool.

wipe out dirt on the headlamp.

CAUTION:

never use organic solvent (thinner, gasoline etc.)

ride alone on the driver seat.

aiming adjustment screw

JMLIA1319ZZ

A. Headlamp RH HI /LO (UP/DOWN)

adjustment screw B. Headlamp LH HI/LO (UP/DOWN)

adjustment screw

: Vehicle center

Revision: 2010 May2011 QX56

Page 2833 of 5598

![INFINITI QX56 2011 Factory Service Manual

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE INFINITI QX56 2011 Factory Service Manual

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE](/img/42/57033/w960_57033-2832.png)

FRONT FOG LAMP AIMING ADJUSTMENTEXL-123

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

FRONT FOG LAMP AI MING ADJUSTMENT

DescriptionINFOID:0000000006213992

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

Before performing aiming adjustm ent, check the following. Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the trunk

room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp. CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000006213993

1. Place the screen. NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Turn the front fog lamp ON. NOTE:

Shut off the headlamp light with the board to pr event from illuminating the adjustment screen.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

4. Adjust the cutoff line height (A) with the aiming adjus tment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

A: UP

B: DOWN

JPLIA0915ZZ

Revision: 2010 May2011 QX56

Page 2949 of 5598

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000006225640

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: Refer to WT-64, "

Inspection".

Wheel bearing axial end play: Refer to FA X - 7 , "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Lower link and upper link ball joint axial end play: Refer to FSU-15, "

Inspection" and FSU-18, "Inspection".

Shock absorber operation.

Each mounting part of axle and suspension for looseness and deformation

Lower link for cracks, deformation and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225641

CAMBER, CASTER

1. Adjust with the front/rear side adjusting bolts (1) on the lower link

(2).

2. See the following table for the amount of cam bolt scale move- ment and the variation of camber and caster.

CAUTION:

Align the adjusting bolt cutout with the stamp of lower link

bracket.

: Vehicle front

JPEIA0235ZZ

Revision: 2010 May2011 QX56

Page 3447 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine INFINITI QX56 2011 Factory Service Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine](/img/42/57033/w960_57033-3446.png)

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine CAN system type from the following specification chart.

NOTE:

Refer to LAN-18, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

×: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Body type Wagon

Axle 2WD 4WD

Engine VK56VD

Transmission A/T

Brake control VDC

ICC system ××

CAN system type 1 2 3 4 CAN communication unit

ECM ××××

Transfer control unit ××

ABS actuator and electric unit (control unit) ××××

TCM ××××

Air bag diagnosis sensor unit ××××

AFS control unit ××

AV control unit ××××

BCM ××××

CAN gateway ××

Data link connector ××××

A/C auto amp. ××××

Combination meter ××××

Steering angle sensor ××××

Low tire pressure warning control unit ××××

IPDM E/R ××××

Driver seat control unit ××××

Pre-crash seat belt control unit (driver side) ××

Air levelizer control module ××××

ADAS control unit ××

Automatic back door control module ××××

ITS communication unit

ADAS control unit ××

Side radar RH ××

Side radar LH ××

Lane camera unit ××

Accelerator pedal actuator ××

ICC sensor ××

Revision: 2010 May2011 QX56

Page 3551 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-131

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256254

1.CHECK CONNECTO INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-131

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256254

1.CHECK CONNECTO](/img/42/57033/w960_57033-3550.png)

LAN

TPMS BRANCH LINE CIRCUITLAN-131

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 1)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256254

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the low ti re pressure warning control unit for damage, bend and

loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressure warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3577 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTO INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTO](/img/42/57033/w960_57033-3576.png)

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the low ti re pressure warning control unit for damage, bend and

loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressure warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3609 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTO INFINITI QX56 2011 Factory Service Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTO](/img/42/57033/w960_57033-3608.png)

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the low ti re pressure warning control unit for damage, bend and

loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressure warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56