body int INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1 of 5598

A

B

D

E

F

G

H

I

J

K

L

M

N

P

O

C

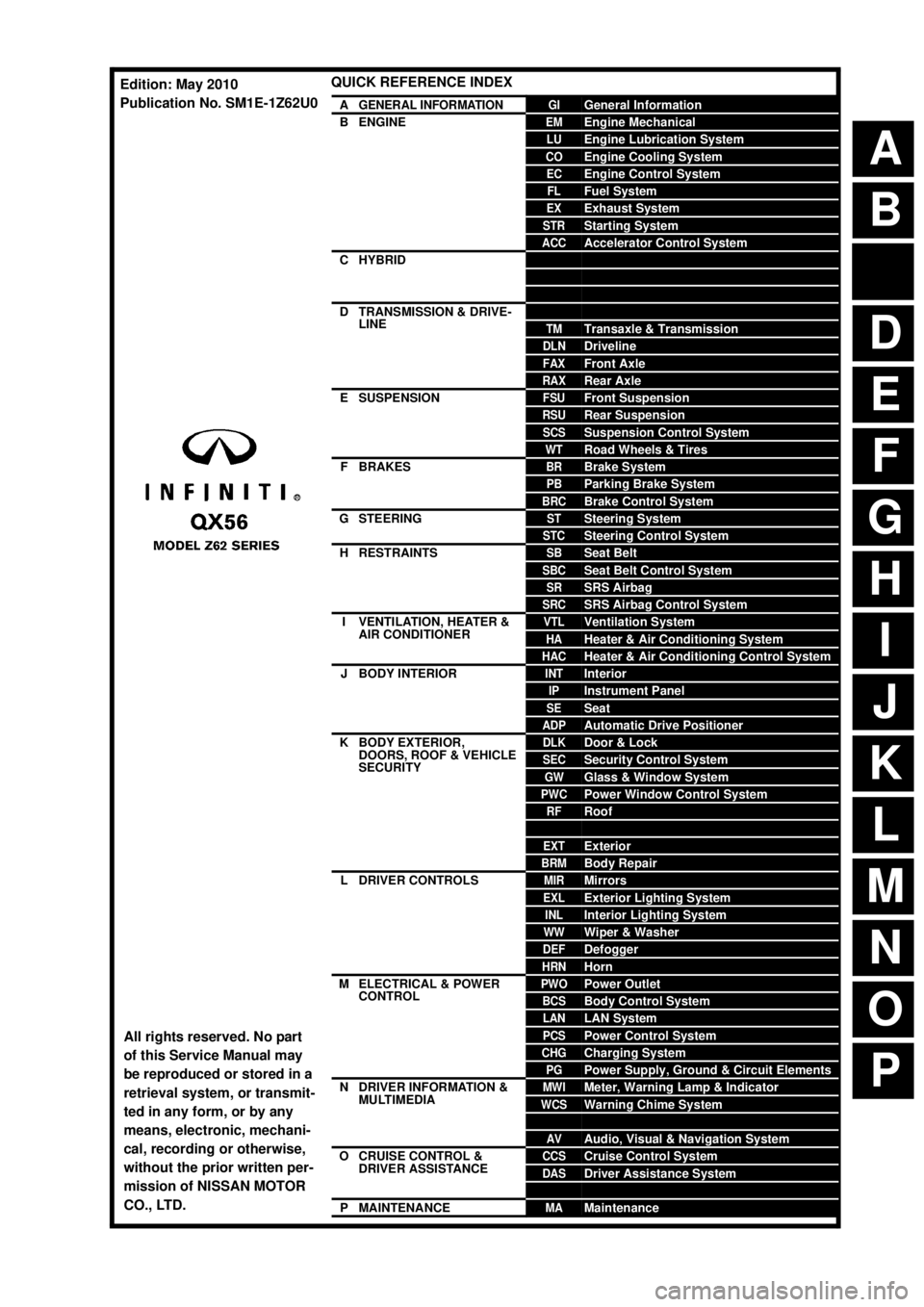

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINECLClutch

TMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Positioner

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

HDHood

EXTExterior

BRMBody Repair

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROL &

DRIVER ASSISTANCECCSCruise Control System

DASDriver Assistance System

DMSDrive Mode System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, recording or otherwise,

without the prior written per-

mission of NISSAN MOTOR

CO., LTD.

Edition: May 2010

Publication No. SM1E-1Z62U0

Page 10 of 5598

ADP-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

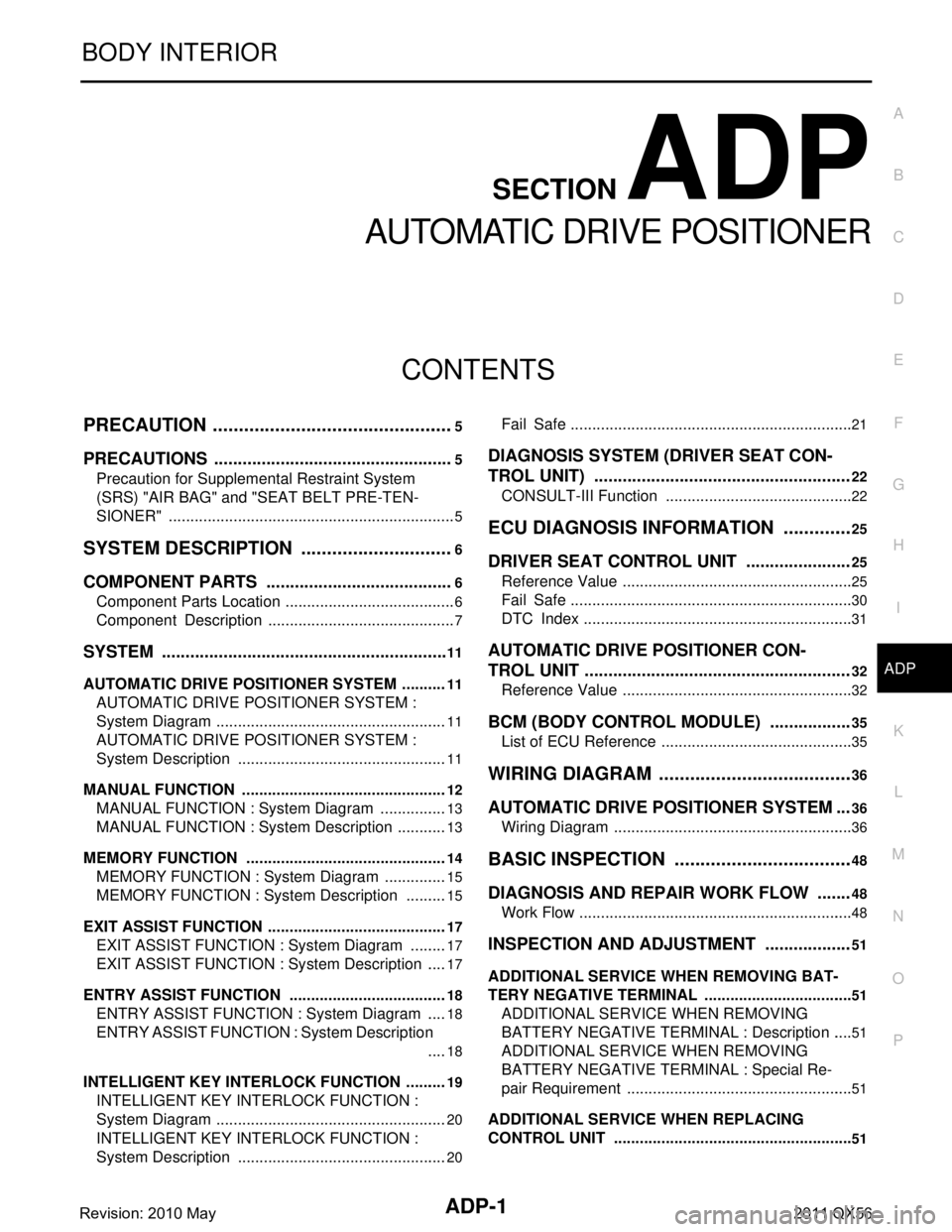

SECTION ADP

A

B

ADP

N

O P

CONTENTS

AUTOMATIC DRIVE POSITIONER

PRECAUTION ................ ...............................5

PRECAUTIONS .............................................. .....5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description ............................................7

SYSTEM .............................................................11

AUTOMATIC DRIVE POSITIONER SYSTEM ....... ....11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Diagram ......................................................

11

AUTOMATIC DRIVE POSITIONER SYSTEM :

System Description .................................................

11

MANUAL FUNCTION ............................................ ....12

MANUAL FUNCTION : System Diagram ................13

MANUAL FUNCTION : System Description ............13

MEMORY FUNCTION ........................................... ....14

MEMORY FUNCTION : System Diagram ...............15

MEMORY FUNCTION : System Description ..........15

EXIT ASSIST FUNCTION ...................................... ....17

EXIT ASSIST FUNCTION : System Diagram .........17

EXIT ASSIST FUNCTION : Sy stem Description .....17

ENTRY ASSIST FUNCTION ................................. ....18

ENTRY ASSIST FUNCTION : System Diagram .....18

ENTRY ASSIST FUNCTION : System Description

....

18

INTELLIGENT KEY INTERLOCK FUNCTION ...... ....19

INTELLIGENT KEY INTERLOCK FUNCTION :

System Diagram ......................................................

20

INTELLIGENT KEY INTERLOCK FUNCTION :

System Description .................................................

20

Fail Safe .............................................................. ....21

DIAGNOSIS SYSTEM (DRIVER SEAT CON-

TROL UNIT) ......................................................

22

CONSULT-III Function ............................................22

ECU DIAGNOSIS INFORMATION ..............25

DRIVER SEAT CONTROL UNIT ......................25

Reference Value .................................................. ....25

Fail Safe ..................................................................30

DTC Index ...............................................................31

AUTOMATIC DRIVE POSITIONER CON-

TROL UNIT ........................................................

32

Reference Value ......................................................32

BCM (BODY CONTROL MODULE) .................35

List of ECU Reference .............................................35

WIRING DIAGRAM ......................................36

AUTOMATIC DRIVE POSITIONER SYSTEM ...36

Wiring Diagram .................................................... ....36

BASIC INSPECTION ...................................48

DIAGNOSIS AND REPAIR WORK FLOW .......48

Work Flow ............................................................ ....48

INSPECTION AND ADJUSTMENT ..................51

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ....

51

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description .....

51

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement .....................................................

51

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

51

Revision: 2010 May2011 QX56

Page 360 of 5598

AV-212

< REMOVAL AND INSTALLATION >

AV CONTROL UNIT

REMOVAL AND INSTALLATION

AV CONTROL UNIT

Removal and InstallationINFOID:0000000006216377

CAUTION:

Before replacing AV control unit, perform “READ CONFIGURATION” to save or print current vehicle

specification. For details, refer to AV-108, "

Description".

REMOVAL

1. Remove cluster lid C. Refer to IP-13, "Exploded View".

2. Remove AV control unit with a A/C auto amp. as a single unit from the body.

3. Remove bracket screws, and then remove AV control unit.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be sure to perform “WRITE CONFIGURATION” when replacing AV control unit.

Revision: 2010 May2011 QX56

Page 389 of 5598

BCS

BCS-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION BCS

A

O P

N

CONTENTS

BODY CONTROL SYSTEM

PRECAUTION ................

...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

BODY CONTROL SYSTEM ........................................4

BODY CONTROL SYSTEM : Component Parts

Location ............................................................... ......

4

POWER CONSUMPTION CONTROL SYSTEM ... ......4

POWER CONSUMPTION CONTROL SYSTEM :

Component Parts Location ........................................

4

SYSTEM ..............................................................6

BODY CONTROL SYSTEM ........................................6

BODY CONTROL SYSTEM : System Description ......6

COMBINATION SWITCH READING SYSTEM ..... ......7

COMBINATION SWITCH READING SYSTEM :

System Diagram ........................................................

7

COMBINATION SWITCH READING SYSTEM :

System Description ...................................................

7

SIGNAL BUFFER SYSTEM ........................ ..............10

SIGNAL BUFFER SYSTEM : System Diagram .. ....10

SIGNAL BUFFER SYSTEM : System Description ....10

POWER CONSUMPTION CONTROL SYSTEM ... ....11

POWER CONSUMPTION CONTROL SYSTEM :

System Diagram ......................................................

11

POWER CONSUMPTION CONTROL SYSTEM :

System Description .................................................

11

DIAGNOSIS SYSTEM (BCM) ............................14

COMMON ITEM ..................................................... ....14

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

14

DOOR LOCK .......................................................... ....15

DOOR LOCK : CONSULT-III Function (BCM -

DOOR LOCK) ..........................................................

15

REAR WINDOW DEFOGGER ............................... ....16

REAR WINDOW DEFOGGER : CONSULT-III

Function (BCM - REAR DEFOGGER) .....................

17

BUZZER ................................................................. ....17

BUZZER : CONSULT-III Function (BCM - BUZZ-

ER) ..........................................................................

17

INT LAMP ............................................................... ....17

INT LAMP : CONSULT-III Function (BCM - INT

LAMP) ......................................................................

18

HEADLAMP ........................................................... ....19

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ...........................................................

19

WIPER .................................................................... ....21

WIPER : CONSULT-III Function (BCM - WIPER) ....21

FLASHER ............................................................... ....23

FLASHER : CONSULT-III Function (BCM -

FLASHER) ...............................................................

23

INTELLIGENT KEY ................................................ ....24

INTELLIGENT KEY : CONSULT-III Function

(BCM - INTELLIGENT KEY) ....................................

24

COMB SW .............................................................. ....27

COMB SW : CONSULT-III Function (BCM -

COMB SW) ..............................................................

27

BCM ....................................................................... ....28

BCM : CONSULT-III Function (BCM - BCM) ...........28

IMMU ...................................................................... ....28

IMMU : CONSULT-III Function (BCM - IMMU) ........28

Revision: 2010 May2011 QX56

Page 394 of 5598

BCS-6

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

BODY CONTROL SYSTEM

BODY CONTROL SYSTEM : System DescriptionINFOID:0000000006274789

OUTLINE

BCM (Body Control Module) controls the various electrical components. It inputs the information required to

the control from CAN communication and the signal received from each switch and sensor.

BCM has combination switch reading function for reading the operation status of combination switches (light,

turn signal, wiper and washer) in addition to a function fo r controlling the operation of various electrical com-

ponents. It also has the signal transmission function as the passed point of signal and the power saving con-

trol function that reduces the power c onsumption with the ignition switch OFF.

BCM is equipped with the diagnosis function that perfo rms the diagnosis with CONSULT-III and various set-

tings.

BCM CONTROL FUNCTION LIST

System Reference

Combination switch reading system BCS-7, "

COMBINATION SWITCH READING SYSTEM : System

Diagram"

Signal buffer system

BCS-10, "SIGNAL BUFFER SYSTEM : System Diagram"

Power consumption control systemBCS-11, "POWER CONSUMPTION CONTROL SYSTEM : Sys-

tem Diagram"

Auto light system

EXL-11, "AUTO LIGHT SYSTEM : System Diagram"

Turn signal and hazard warning lamp systemEXL-18, "TURN SIGNAL AND HAZARD WARNING LAMP SYS-

TEM : System Diagram"

Headlamp system

EXL-10, "HEADLAMP SYSTEM : System Diagram"

Daytime running light systemEXL-14, "DAYTIME RUNNING LIGHT SYSTEM : System Dia-

gram"

Parking, license plate, side maker and tail lamps system

EXL-18, "PARKING, LICENSE PLATE, SIDE MARKER AND

TAIL LAMP SYSTEM : System Diagram"

Front fog lamp system

EXL-20, "FRONT FOG LAMP SYSTEM : System Diagram"

Exterior lamp battery saver systemEXL-20, "EXTERIOR LAMP BATTERY SAVER SYSTEM : Sys-

tem Diagram"

Interior room la

mp control system INL-6, "INTERIOR ROOM LAMP CONTROL SYSTEM : System

Diagram"

Interior room lamp battery saver system

INL-9, "INTERIOR ROOM LAMP BATTERY SAVER SYSTEM :

System Diagram"

Front wiper and washer systemWW-7, "FRONT WIPER AND WASHER SYSTEM : System Dia-

gram"

Rear wiper and washer systemWW-10, "REAR WIPER AND WASHER SYSTEM : System Dia-

gram"

Headlamp washer system

WW-13, "HEADLAMP WASHER SYSTEM : System Diagram"

Warning chime systemWCS-6, "WARNING CHIME SYSTEM : System Diagram"

Power door lock systemDLK-16, "System Diagram"

Infiniti Vehicle immobilizer System (IVIS)SEC-15, "INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS :

System Diagram"

Vehicle security systemTheft warning alarm

SEC-17, "VEHICLE SECURITY SYSTEM : System Diagram"Panic alarm

Rear window defogger system DEF-6, "

System Diagram"

Intelligent Key system/engine start systemDLK-18, "INTELLIGENT KEY SYSTEM : System Diagram"

Power window system PWC-8, "SystemDiagram"

Retained accessory power (RAP) systemPWC-8, "System Description"

Revision: 2010 May2011 QX56

Page 402 of 5598

BCS-14

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)INFOID:0000000006274796

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate ea ch device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 505 of 5598

FRONT DISC BRAKEBR-35

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Never deform the pad retainer when removing the pad retainers (2) from the torque member (1).

Never damage the piston boot.

Never drop the brake pads, shims and shim covers.

Remember each position of the removed brake pads.

5. Perform inspection after removal. Refer to BR-36, "

BRAKE PAD

: Inspection".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Install the torque member if the pad retainers has been removed. CAUTION:

Securely assemble the pad retainers (1) so that it will notbe lifted up from the torque member (2).

Never deform the pad retainers.

2. Apply MOLYKOTE

® AS880N or silicone-based grease mating

faces (A and B) between the brake pad, shim and shim cover,

and install shim and shim cover to the brake pad.

CAUTION:

Always replace the shims and shim covers when replacing

the brake pad.

3. Install the brake pads to the torque member.

4. Install pad return springs (1). CAUTION:

Correctly insert the pad return spring into the pad return

spring hole on the brake pad.

5. Install cylinder body to torque member. CAUTION:

Never damage the piston boot.

When replacing brake pad with new one, check a brakefluid level in the reservoir tank because brake fluid

returns to reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

6. Install lower sliding bolt and tighter it to the specified torque.

JPFIA0118ZZ

PFIA0763J

JPFIA0798ZZ

JPFIA0797ZZ

Revision: 2010 May2011 QX56

Page 507 of 5598

FRONT DISC BRAKEBR-37

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000006222492

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-23, "

FRONT : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and brake caliper assembly.

6. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(AWD).

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Torque member 2. Sliding pin boot 3. Sliding pin

4. Piston boot 5. Piston 6. Piston seal

7. Cylinder body 8. Bleeder valve 9. Cap

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0800GB

Revision: 2010 May2011 QX56

Page 509 of 5598

FRONT DISC BRAKEBR-39

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Apply rubber grease to piston seals (1), and install them to cali- per.

CAUTION:

Never reuse piston seals.

3. Apply rubber grease to piston boots (1). Cover the piston (2) end with piston boot, and then install cylinder side lip on piston boots

securely into a groove on cylinder body.

CAUTION:

Never reuse piston boots.

4. Apply new brake fluid to pistons (1). Push piston into cylinder body by hand and push piston boots (2) piston-side lip into the

piston groove.

CAUTION:

Press the pistons evenly and var y the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to sliding pin boots, and install sliding pin boots to torque member.

6. Apply rubber grease to sliding pin, and install the cylinder body.

7. Install sliding pin bolts and tighten it to the specified torque. Refer to BR-34, "

BRAKE PAD : Exploded View".

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000006222494

INSPECTION AFTER DISASSEMBLY

Check the following items and replace if necessary.

Cylinder Body

Check the cylinder inner wall for rust, wear, cracks or damage.

CAUTION:

Always clean with new brake fluid. Never clean wit h mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage.

Pistons

Check the surface of the piston for rust, wear, cracks or damage.

CAUTION:

A piston sliding surface is plat ed. Never polish with sandpaper.

Sliding Pin and Sliding Pin Boot

Check the sliding pins and sliding pin boots for rust, wear, cracks or damage.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any dr ag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-34, "

BRAKE PAD : Removal and Installation".

JPFIA0032ZZ

JPFIA0782ZZ

JPFIA0034ZZ

Revision: 2010 May2011 QX56

Page 514 of 5598

BR-44

< REMOVAL AND INSTALLATION >

REAR DISC BRAKE

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and caliper assembly.

6. Remove disc rotor. Refer to RAX-7, "

Removal and Installation".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Install disc rotor. Refer to RAX-7, "

Removal and Installation".

2. Install the brake caliper assembly to the axle hous ing and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts. Wipe out any grease and moisture.

3. Install brake hose to brake caliper assembly. Refer to BR-26, "

REAR : Removal and Installation".

4. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

5. Check a drag of rear disc brake. If any drag is found, refer to BR-45, "

BRAKE CALIPER ASSEMBLY :

Inspection".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000006222500

DISASSEMBLY

NOTE:

Never remove the torque member, brake pads and pad retainers when disassembling and assembling the cyl-

inder body.

1. Remove the sliding pin bolt, and remove the cylinder body from the torque member.

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2. Remove sliding pin boots from torque member.

3. Remove bushing from sliding pin bolt.

4. Place a wooden block as shown in the figure, and blow air from brake hose mounting hole to remove piston and piston boot.

CAUTION:

Never get fingers caught in the piston.

MAA0272D

Revision: 2010 May2011 QX56