check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4313 of 6020

![ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental r ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental r](/img/61/57177/w960_57177-4312.png)

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental restraint system

(SRS) control module all communicate with the scan

tool over the Keyword serial data link.

Diagnostic Aids

The following conditions will cause a loss of Keyword

serial data communication between the scan tool and

the TCM.

• A Keyword serial data circuit open • A Keyword serial data circuit shorted to ground

• A Keyword serial data circuit shorted to voltage

• An internal condition within a module or connector on the Keyword serial data circuit, that causes a

short to voltage or ground to the Keyword serial

data circuit

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Scan Tool Does Not Communicate with Keyward Device

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Attempt to establish communication with the listed control modules.

•TCM

• Electronic hydraulic control unit (EHCU) [ABS module] (If so equipped)

• Supplemental restraint system (SRS) control module (If so equipped)

Does the scan tool communicate with any of the

listed control modules? —

Go to Step 3 Go to Step 7

3 Does the scan tool communicate with the TCM?

—Go to Step 4 Go to Lost

Communication with

The Transmission Control Module (TCM)

4 Notice:

If no ABS is installed, skip to Step 5.

Does the scan tool communicate with the EHCU? —

Go to Step 5 Go to Diagnostic

System Check - Anti-lock Brake Controls

5 Notice:

If no SRS is installed, skip to Step 6.

Does the scan tool communicate with the SRS

control module? —

Go to Step 6 Go to Diagnostic

System Check -SRS Controls

6 Test the Keyword serial data circuit for an

intermittently short to ground or intermittently short

to voltage. Then, test the Keyword serial data

circuit for an intermittently open (based on which

control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition? —

Go to Step 15 System OK

7 1. Inspect for an intermittent, for a poor

connection and for corrosion at the data link

connector (DLC) (pin 7 of B-58).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4315 of 6020

![ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup](/img/61/57177/w960_57177-4314.png)

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental restraint system

(SRS) control module all communicate with the scan

tool over the Keyword serial data link. Schematic Reference:

Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Lost Communication with The Transmission Control Module (TCM)

Step Action ActionYes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission

Controls

2 Attempt to establish communication with the TCM.

Does the scan tool communicate with the TCM? —

Go to Intermittent

Conditions Go to Step 3

3 1. Inspect for an intermittent, for poor

connections and for corrosion at the TCM C-

94 and C-95 harness connectors.

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 4

4 1. Check the TCM (15A) in the cabin fuse block.

Replace and retest if open. If any fuse

continues to open, repair the short to ground

on each circuit fed by that fuse.

2. Turn OFF the ignition.

3. Disconnect the TCM C-95 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at

the TCM (pins 18 and 24 of C-95).

Does the test lamp illuminate? —

Go to Step 6 Go to Step 5

5 Repair the open in the ignition voltage circuit to the

TCM.

Did you complete the repair? —

Go to Step 9 —

6 1. Turn OFF the ignition.

2. Disconnect the TCM C-94 harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the TCM (pin 5 of C-94).

4. Test the Keyword serial data circuit between the TCM (pin 5 of C-94) and the DLC (pin 7 of

B-58) for an open circuit or high resistance.

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 7

7 1. Check TCM ground for corrosion and

tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4317 of 6020

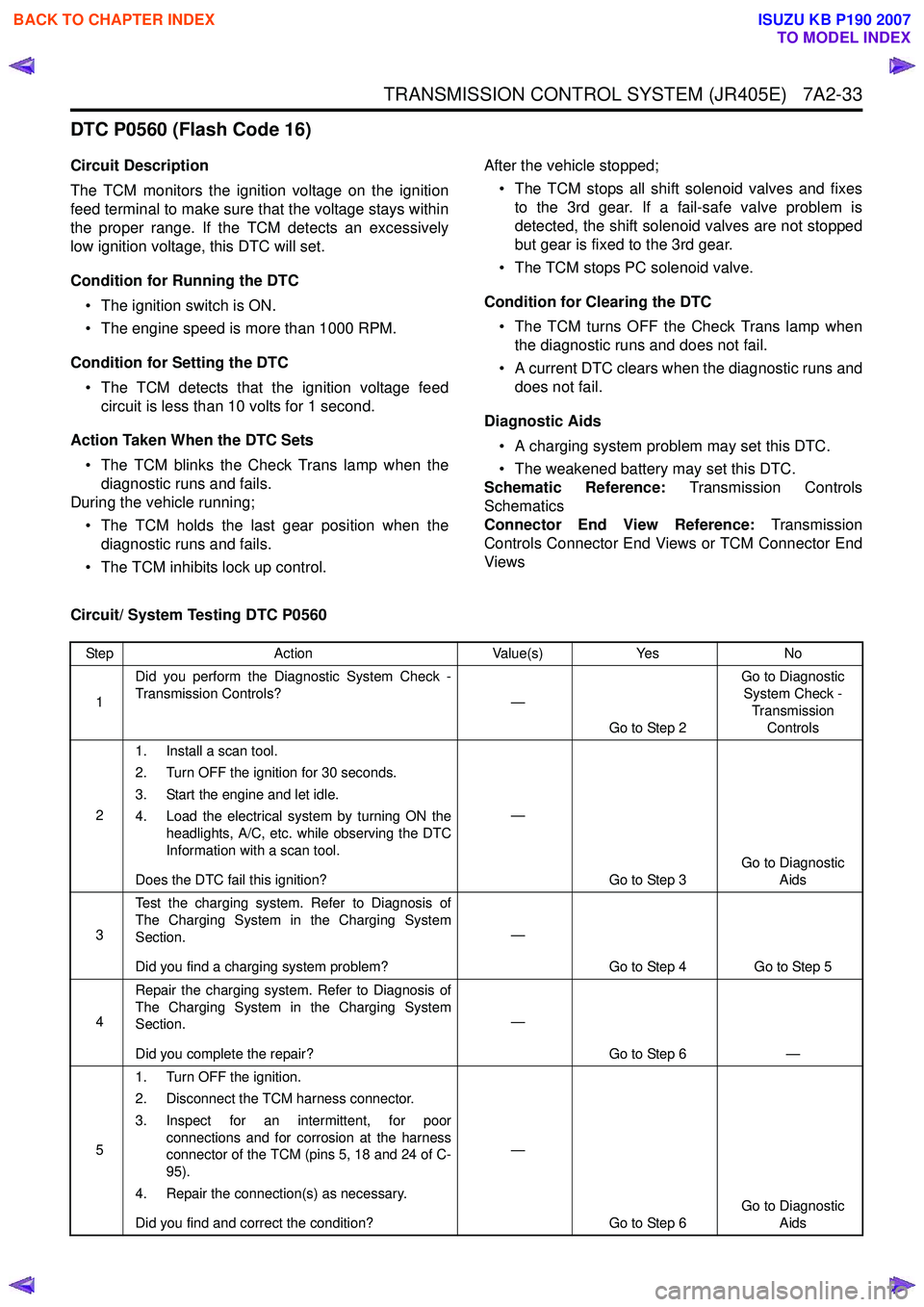

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-33

DTC P0560 (Flash Code 16)

Circuit Description

The TCM monitors the ignition voltage on the ignition

feed terminal to make sure that the voltage stays within

the proper range. If the TCM detects an excessively

low ignition voltage, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is more than 1000 RPM.

Condition for Setting the DTC • The TCM detects that the ignition voltage feed circuit is less than 10 volts for 1 second.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control. After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • A charging system problem may set this DTC.

• The weakened battery may set this DTC.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0560

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle.

4. Load the electrical system by turning ON the headlights, A/C, etc. while observing the DTC

Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 4 Go to Step 5

4 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6 —

5 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent, for poor connections and for corrosion at the harness

connector of the TCM (pins 5, 18 and 24 of C-

95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4319 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-35

DTC P0602

Description

The TCM has the ability to set a diagnostic trouble

code (DTC) if it detects that there is no vehicle

identification number (VIN) stored. In order for the

software to be locked, the mechanization counter used

at time of production must be set to zero. If the counter

is anything other than zero AND there is no VIN stored,

this DTC will set. Condition for Setting the DTC

• VIN in TCM is not programmed (blank) and TCM is unlocked.

Action Taken When the DTC Sets • The TCM does not blink the Check Trans lamp.

Notice: • Clear the DTC with a scan tool after programming the VIN.

Circuit/ System Testing DTC P0602

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Step 5

3 1. Verify the correct VIN is entered into the TCM

with a scan tool. Refer to TCM Replacement.

If the VIN is correctly entered, clear the DTC

with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

Does the DTC fail this ignition? —

Go to Step 4 Go to Step 5

4 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 5 —

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4320 of 6020

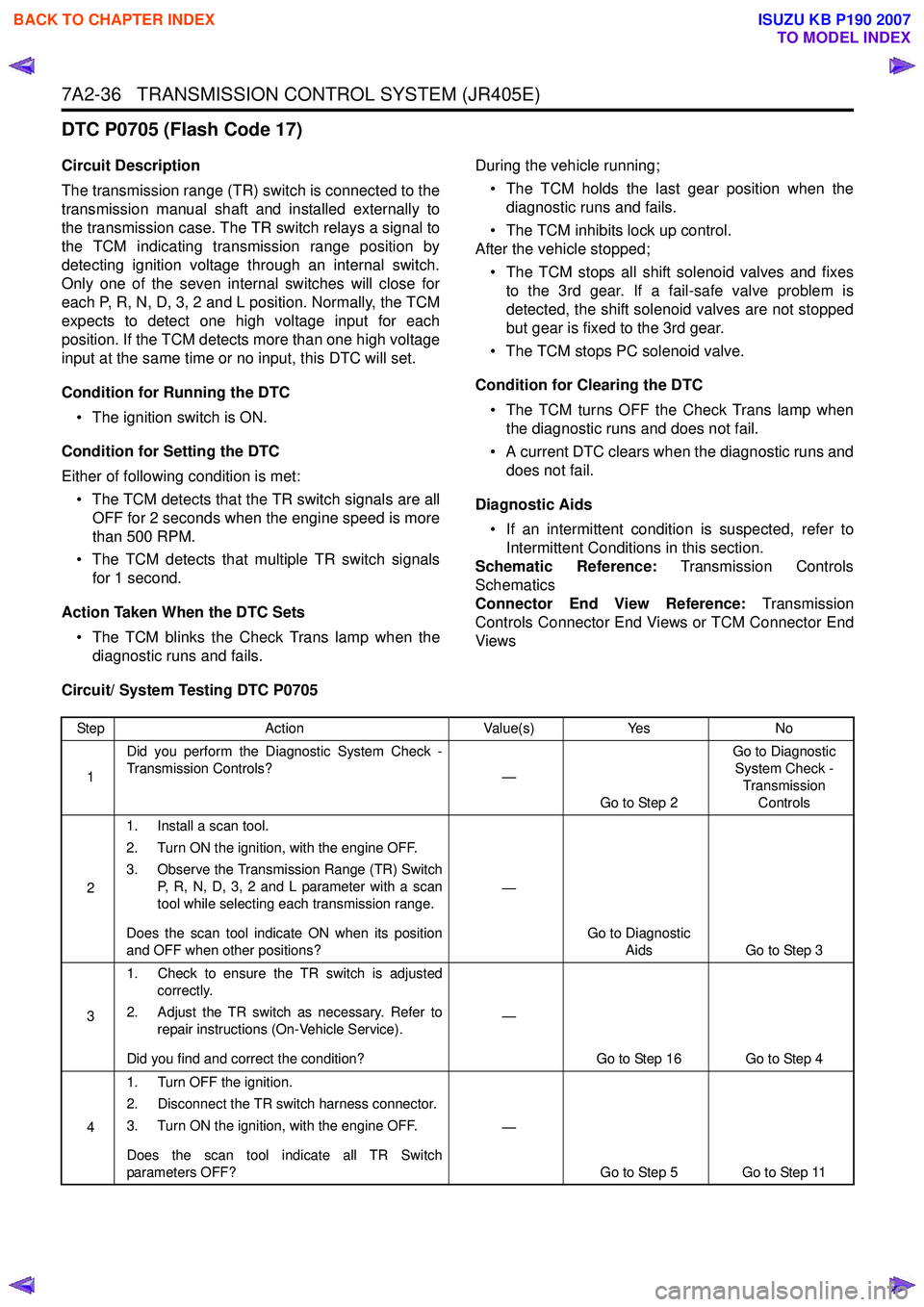

7A2-36 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0705 (Flash Code 17)

Circuit Description

The transmission range (TR) switch is connected to the

transmission manual shaft and installed externally to

the transmission case. The TR switch relays a signal to

the TCM indicating transmission range position by

detecting ignition voltage through an internal switch.

Only one of the seven internal switches will close for

each P, R, N, D, 3, 2 and L position. Normally, the TCM

expects to detect one high voltage input for each

position. If the TCM detects more than one high voltage

input at the same time or no input, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The TCM detects that the TR switch signals are all OFF for 2 seconds when the engine speed is more

than 500 RPM.

• The TCM detects that multiple TR switch signals for 1 second.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails. During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control.

After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0705

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Observe the Transmission Range (TR) Switch P, R, N, D, 3, 2 and L parameter with a scan

tool while selecting each transmission range.

Does the scan tool indicate ON when its position

and OFF when other positions? —

Go to Diagnostic Aids Go to Step 3

3 1. Check to ensure the TR switch is adjusted

correctly.

2. Adjust the TR switch as necessary. Refer to repair instructions (On-Vehicle Service).

Did you find and correct the condition? —

Go to Step 16 Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the TR switch harness connector.

3. Turn ON the ignition, with the engine OFF.

Does the scan tool indicate all TR Switch

parameters OFF? —

Go to Step 5 Go to Step 11

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4324 of 6020

7A2-40 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0710 (Flash Code 15)

Circuit Description

The transmission fluid temperature (TFT) sensor is

attached to the lower part of the valve body assembly.

The TFT sensor is a variable resistor and it measures

the temperature of the transmission fluid. The sensor

has a signal circuit and a low reference circuit. The

TCM supplies 2.5 volts to the signal circuit and a

ground for the low reference circuit. When the TFT

sensor is cold, the sensor resistance is high. When the

transmission fluid temperature increases, the sensor

resistance decreases. With high sensor resistance, the

TCM detects a high voltage on the signal circuit. With

lower sensor resistance, the TCM detects a lower

voltage on the signal circuit. If the TCM detects an

excessively low or high signal voltage, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The TCM detects that the TFT sensor signal voltage is less than 0.1 volts (more than 146 °C

[295 °F]) when the selector lever is P or N range for

longer than 5 minutes.

• The TCM detects that the TFT sensor signal voltage is more than 2.43 volts (less than -40 °C [-

40 °F]) for 10 seconds when the vehicle speed is

more than 20 km/h (12 MPH).

Action Taken When the DTC Sets • The TCM does not blink the Check Trans lamp. • The TCM inhibits 4th gear. (If the engine speed is

more than 470 PRM for 10 minutes, shifting to 4th

gear is allowed.)

• The TCM inhibits lock up control. (If the engine speed is more than 470 RPM for 10 minutes, lock

up control is allowed.)

• The TCM uses a TFT substitution of 80 °C (176 °F)

for transmission control.

Condition for Clearing the DTC • current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Use the Temperature vs. Resistance table to test the TFT sensor at various temperature levels to

evaluate the possibility of a skewed sensor. A

skewed sensor could result in poor driveability

(poor shift quality) concerns.

Test Description

The numbers below refer to the step number on the

Circuit/ System Testing.

5. If the TFT sensor signal circuit is shorted to ground,

A/T Oil Temp lamp turns ON and the TCM switches

shift map to the high temperature mode until this DTC

is set.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0710

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Observe the Transmission Fluid Temperature (TFT) parameter with a scan tool within 5

minutes from the ignition switch is ON.

Is the TFT parameter more than the specified

value? 146

°C (295 °F)

Go to Step 4 Go to Step 3

3 Is the TFT parameter less than the specified value

at Step 2? -40

°C (-40 °F)

Go to Step 7 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4328 of 6020

7A2-44 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0717 (Flash Code 14)

Circuit Description

The input shaft speed (ISS) sensor is located on right-

hand of the transmission case. The ISS sensor is a hall

effect element type sensor, which generates a square

wave signal pulse based on the reverse & high clutch

drum rotational speed (32 pulses per a rotation of the

reverse & high clutch drum). The sensor has the

following circuits.

• Ignition voltage feed circuit

• Low reference circuit

• ISS sensor signal circuit

The TCM calculates the turbine speed by the ISS

sensor signal, and uses it to calculate torque converter

slip speed and gear ratio. If the TCM detects

excessively low input shaft speed during the vehicle

running, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is more than 1500 RPM.

• The vehicle speed is more than 40 km/h (24 MPH).

• The selector lever is forward range.

Condition for Setting the DTC • The TCM detects that the input shaft speed is less than 300 RPM for 2 seconds.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails. During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control.

After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the ISS sensor circuits may set this DTC.

• An intermittent ISS sensor signal pulse may set this DTC.

• Ensure the ISS sensor is tight.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0717

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Lift the driving wheels or drive the vehicle.

4. Operate the vehicle within the Conditions for Running the DTC.

5. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the input shaft speed (ISS) sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the ignition voltage feed circuit (pin 2 of E-31) and a

known good ground.

Does the test lamp illuminate? —

Go to Step 4 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4329 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-45

4Intermittently jump the signal circuit (pin 1 of E-31)

with a test lamp that is connected to a known good

ground while observing the AT Input Speed

parameter with a scan tool.

Does the scan tool indicate any AT input speed

when the circuit is intermittently pulled to ground? —

Go to Step 5 Go to Step 8

5 Connect a test lamp between the ignition voltage

feed circuit and the low reference circuit (pins 2 and

3 of E-31).

Does the test lamp illuminate? —

Go to Step 9 Go to Step 7

6 Repair the open circuit or high resistance between

the Back Up (15A) fuse and the ISS sensor (pin 2

of E-31). Check the Back Up (15A) fuse first.

Did you complete the repair? —

Go to Step 14 —

7 Repair the open circuit or high resistance on the

low reference circuit between the ISS sensor (pin 3

of E-31) and the engine ground terminal (E-10).

Clean or tighten ground as necessary.

Did you complete the repair? —

Go to Step 14 —

8 1. Test the signal circuit between the TCM (pin 3

of C-95) and the ISS sensor (pin 1 of E-31) for

the following conditions

• An open circuit

• A short to ground

• A short to the low reference

• A short to battery or ignition voltage

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 10

9 1. Inspect for an intermittent and for poor

connections at the harness connector of the

ISS sensor (pin 1, 2 and 3 of E-31).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 11

10 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent and for a poor connection at the harness connector of the

TCM (pin 3 of C-95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 14 Go to Step 13

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4331 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-47

DTC P0722 (Flash Code 11)

Circuit Description

The output shaft speed (OSS) sensor is located on

right-hand of the transmission case near the

transmission range switch. The OSS sensor is a hall

effect element type sensor, which generates a square

wave signal pulse based on the parking gear rotational

speed that is connected to output shaft (16 pulses per a

rotation of the parking gear). The sensor has the

following circuits.

• Ignition voltage feed circuit

• Low reference circuit

• OSS sensor signal circuit

The TCM calculates the vehicle speed by the OSS

sensor signal, and uses it to determine appropriate shift

points and calculate gear ratio. The 2WD vehicle

outputs the vehicle speed signal from the TCM to the

engine control module (ECM) and the vehicle speed

meter via output signal line. If the TCM detects

excessively low output shaft speed during the vehicle

running, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The input shaft speed is more than 1000 RPM.

• The selector lever is forward range for longer than 25 seconds.

Condition for Setting the DTC • The TCM detects that the vehicle speed is less than 5 km/h (3 MPH) for 5 seconds.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails. During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control.

After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Electromagnetic interference in the OSS sensor circuits may set this DTC.

• An intermittent OSS sensor signal pulse may set this DTC.

• Ensure the OSS sensor is tight.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0722

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 Drive the vehicle while observing the Vehicle

Speed parameter with a scan tool.

Does the scan tool indicate correct vehicle speed? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the output shaft speed (OSS) sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the ignition voltage feed circuit (pin 2 of E-30) and a

known good ground.

Does the test lamp illuminate? —

Go to Step 4 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4334 of 6020

7A2-50 TRANSMISSION CONTROL SYSTEM (JR405E)

DTC P0727 (Flash Code 13)

Circuit Description

The engine speed signal to the TCM is sent from the

engine control module (ECM) via a signal circuit based

on inputs from the crankshaft position (CKP) sensor

and camshaft position (CMP) sensor. If the TCM

detects no engine speed signal from the ECM during

the vehicle running, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The vehicle speed is more than 40 km/h (24 MPH).

Condition for Setting the DTC • The TCM detects that the engine speed signal pulses from the ECM are not being received for 2

seconds. Action Taken When the DTC Sets

• The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

• The TCM inhibits lock up control.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0727

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine. If the engine does not start, crank over the engine for 10 seconds.

4. Monitor the ENGINE DTC Information with a scan tool.

Is DTC P0335, P0336, P0340 or P0341 set? —

Go to Applicable DTC in engine

control section Go to Step 3

3 Observe the Engine Speed parameter in the

transmission data display with a scan tool.

Does the scan tool indicate correct engine speed? —

Go to Diagnostic

Aids Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the engine control module (ECM) harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Intermittently jump the signal circuit (pin 33 of C-58) with a test lamp that is connected to a

known good ground while observing the

Engine Speed parameter with a scan tool.

Does the scan tool indicate any engine speed when

the circuit is intermittently pulled to ground? —

Go to Step 7 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007