check engine light ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3691 of 6020

Powertrain Interface Module – V6 Page 6E1–30

Checks Actions

Temperature Related The Tech 2 Freeze Frame / Failure Records or Snapshot data may be used if applicable

to the fault condition. Refer to 4.1 Diagnostic General Descriptions for information on

Tech 2 ECU diagnostic tests.

• If the intermittent fault is heat related, review the Tech 2 data in relationship to the

following:

• high ambient temperature,

• underhood / engine generated heat,

• circuit generated heat due to a poor electrical connection or high electrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review the

Tech 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests

• Check for incorrect installation of aftermarket electrical equipment such as the

following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Check for electromagnetic Interference (EMI) caused by a faulty relay, ECM

controlled solenoid or switch. The fault is triggered when the relay or solenoid is

activated.

• Check the A/C compressor clutch and some relays that contain a clamping diode

or resistor for an open circuit.

• Check the generator for a faulty rectifier bridge that may allow A/C noise into the

PIM electrical circuit.

When all diagnosis and repairs are completed, check the engine management system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3785 of 6020

Automatic Transmission – 4L60E – General Information Page 7C1–25

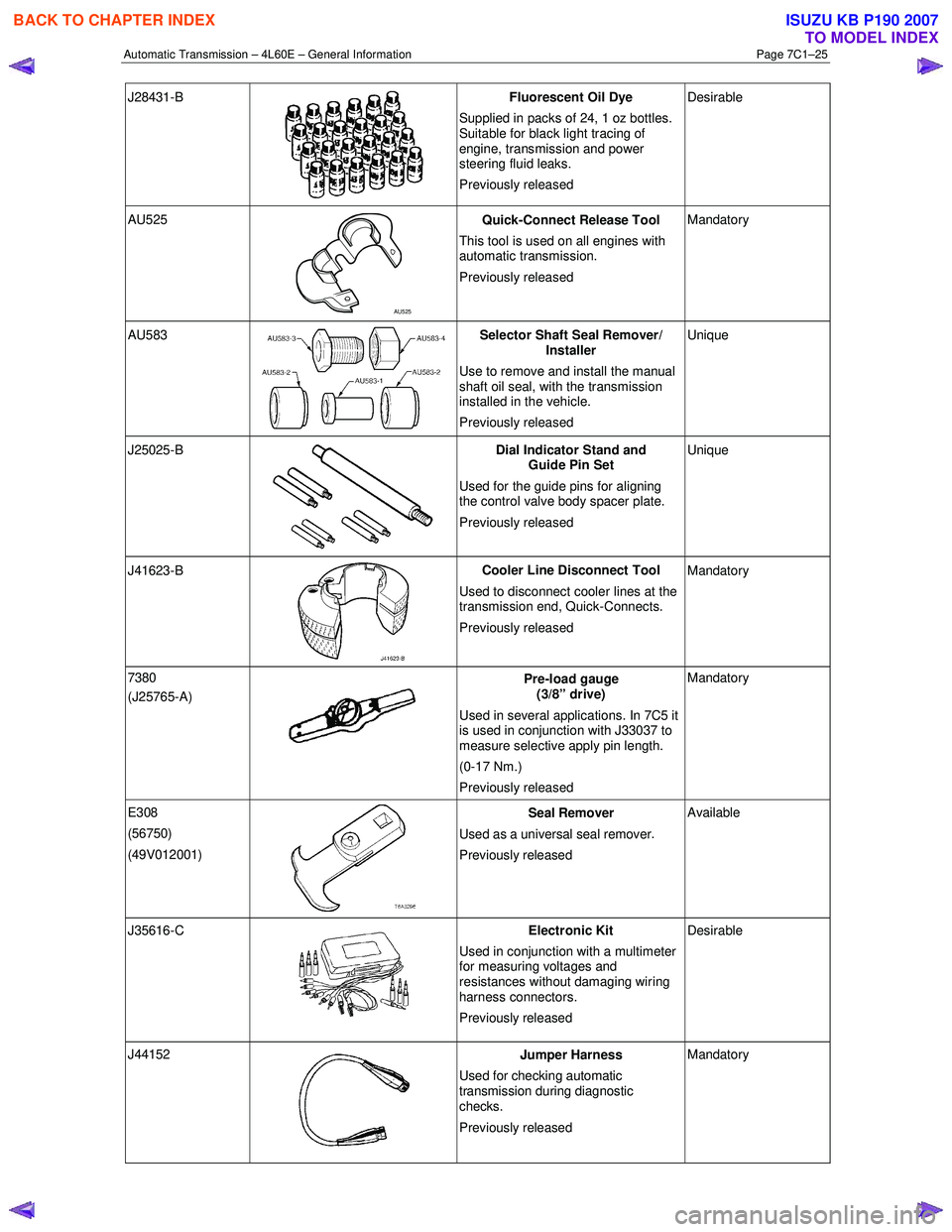

J28431-B

Fluorescent Oil Dye

Supplied in packs of 24, 1 oz bottles.

Suitable for black light tracing of

engine, transmission and power

steering fluid leaks.

Previously released Desirable

AU525

AU525 Quick-Connect Release Tool

This tool is used on all engines with

automatic transmission.

Previously released Mandatory

AU583 Selector Shaft Seal Remover/

Installer

Use to remove and install the manual

shaft oil seal, with the transmission

installed in the vehicle.

Previously released Unique

J25025-B

Dial Indicator Stand and

Guide Pin Set

Used for the guide pins for aligning

the control valve body spacer plate.

Previously released Unique

J41623-B

Cooler Line Disconnect Tool

Used to disconnect cooler lines at the

transmission end, Quick-Connects.

Previously released Mandatory

7380

(J25765-A)

Pre-load gauge

(3/8” drive)

Used in several applications. In 7C5 it

is used in conjunction with J33037 to

measure selective apply pin length.

(0-17 Nm.)

Previously released Mandatory

E308

(56750)

(49V012001)

Seal Remover

Used as a universal seal remover .

Previously released Available

J35616-C

Electronic Kit

Used in conjunction with a multimeter

for measuring voltages and

resistances without damaging wiring

harness connectors.

Previously released Desirable

J44152

Jumper Harness

Used for checking automatic

transmission during diagnostic

checks.

Previously released Mandatory

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3814 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–28

7 Ensure that all wiring harness connectors are fitted correctly and secure.

8 W hen steam or pressure cleaning vehicle components, such as engines, transmissions, etc., do not direct the cleaning nozzle at any system electrical wiring harness connectors or components.

9 Do not clear any DTCs unless instructed.

10 The fault must be present when using the Diagnostic Trouble Code (DTC) Diagnostic Tables. Otherwise, misdiagnosis or replacement of good parts may occur.

11 Do not touch any electronic control module connector pins or soldered components on the circuit board. This is required to avoid the possibility of electrostatic discharge damage.

12 Use only the test equipment specified in the diagnostic tables, as other test equipment may give incorrect results or damage good components.

13 Electronic control modules are designed to withstand normal current draws associated with vehicle operation. However, the following fault conditions or incorrect test procedure may overload internal control module circuits and

irreparably damage the control module:

• A short to voltage fault condition in any of the control module low reference circuits may cause internal and/or

sensor damage. Therefore, any short to voltage fault condition in the control module low reference circuits

must be rectified before replacing a faulty component.

• A short to ground fault condition in any of the control module 5 volts reference circuits may cause internal

control module and/or sensor damage. Therefore, any short to ground fault condition in the control module 5

volt reference circuits must be rectified before replacing a faulty component.

• W hen using a test light to test an electrical circuit, do not use any of the control module low reference circuits

or 5 volts reference circuits as a reference point. Otherwise, excessive current draw from the test light may

damage the control module.

14 Disregard DTCs that set while performing the following diagnostic Steps:

• Using the Tech 2 output control function, or

• Disconnecting a control module system sensor connector then switching the ignition ON.

15 After completing the required diagnostics and service operations, road test the vehicle to ensure correct system operation.

4.4 Preliminary Checks

The Preliminary Checks is a set of visual and physical checks or inspections that may quickly identify a control module

system fault condition:

1 Refer to relevant Service Techlines for information regarding the fault condition.

2 Ensure that the battery is fully charged.

3 Inspect the battery connections for corrosion or a loose terminal.

4 Ensure that all relevant control module system related fuses are serviceable.

5 Inspect for incorrect aftermarket theft deterrent devices, lights or mobile phone installation.

6 Ensure that there is no speaker magnet positioned too close to any electronic module that contains relays.

7 Inspect the system wiring harness for proper connections, pinches or cuts.

8 Ensure that all control module related electrical wiring connectors are fitted correctly.

9 Inspect the control module ground connections for corrosion, loose terminal or incorrect position.

10 Ensure that the resistance between the control module housing and the battery ground cable is less than 0.5 ohms.

11 Check that the control module and its mounting bracket is secure.

12 Check all control module related components for correct installation.

13 Check the control module and related wiring harness routing to ensure that no rubbing or cutting of the wiring harness by sharp body components can occur.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3920 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–7

NOTE

This will also flush the cooler hose/line

assemblies and cooler with transmission fluid.

7 If the flow rate is satisfactory, reconnect the cooler inlet line to the transmission, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

8 Lower the vehicle, check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

Flow Rate Test

Do not run the engine any longer than

absolutely necessary, as a fluid level too low

can cause aeration and foaming.

1 Ensure the transmission fluid is at the recommended level or slightly above, refer to 2.1 Transmission Fluid.

2 Disconnect the cooler inlet line at the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

3 Place a suitable size container underneath the disconnected cooler inlet line.

4 W ith the selector lever in the P position, start the engine and observe the fluid flow into the container after all the air bubbles have ceased and a steady flow is evident. Measure the flow rate over 20 seconds and ensure it is within

the specification.

Transmission fluid flow rate specification per 20 Seconds:

Temperature: Ambient ............................................................ 0.7 Litres 86° – 93° C ...................................................... 1.2 Litres

5 If the flow rate is less than the specification, the cause of the low flow rate must be located and rectified. Possible cause could include:

• restricted cooler within the radiator tank,

• kinked or damaged transmission cooler hose/line assemblies, or

• internal transmission fault such as a faulty pump.

6 Reinstall the cooler inlet line to the transmission quick-connect fitting, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3979 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-13

Item Description

Reverse lock out control If the select lever is moved to "R" position during forward driving, the TCM prohibits

reverse driving by turn off the S1 and turn on the S2 for prevention of danger and

protection of the automatic transmission.

1. Enable condition a) Vehicle speed is more than 11km/h (7mph).

2. Disable condition a) Vehicle speed is less than 9km/h (6mph).

b) W hen except "R" position is detected.

Auto cruise mode control If the auto cruise control can’t keep the setting speed like a uphill driving, the TCM selects the auto cruise mode shift pattern for downshifting, thus keeping the vehicle

speed.

W arm-up mode control TCM selects the warm-up mode shift pattern in engine cold condition for improvement of drivability and facilitation of warm-up.

Squat control W hen the TCM detects N→D garage shift, the TCM controls 1-3-1 shift by setting

timer, in order to improve the shift feel at N →D.

Coast down control The TCM switches to the coast down control at the coasting, in order to reduce the

roughness of shifting.

Uphill control W hen the TCM detected uphill, the TCM automatically switches to the uphill mode

in two-stage in proportion to inclination pitch to prevent the busy shifting and to

obtain an enough torque.

Downhill control W hen the TCM detected downhill, the TCM automatically switches to the downhill

mode, and shifts to the 3rd or keeps in the 3rd in order to prevent the vehicle

acceleration. Then, the brake load is reduced by a moderate engine brake and fuel

consumption is improved by the fuel cut.

Line pressure control The TCM controls the impressed current of the pressure control solenoid based on the throttle opening, and regulates suitable throttle pressure.

Engine truque management

control The TCM controls engine torque for improvement of shift quality or durability under

the following conditions.

• Upshift and downshift

• Garageshift

Indicate driving mode function The TCM indicates the following driving mode on instrument panel.

• Power mode

• 3rd start mode

Indicate oil temperature

warning function If the transmission oil temperature sensor senses that transmission oil temperature

is greater than 146 °C (295 °F) , the TCM turns on ATF warning lamp. (The warning

lamp is turned off, if oil temperature is less than 126 °C/ 259 °F .)

Fail-safe function W hen trouble occurs to vehicle sensor and each solenoid, TCM automatically exerts

fail-safe control not to spoil driveability.

• This control is exerted when sensor or actuator is in trouble, while TCM works

normally.

• The "CHECK TRANS" light flashes to alert the driver, and the transmission

must be manually shifted as follows.

Select lever position Gear position

D 4 (Fourth)

3 4 (Fourth)

2 3 (Third)

L 3 (Third)

R Reverse

Shift are firmer to prevent clutch slip and consequent wear. The fault should be

corrected as soon as possible.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3989 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-23

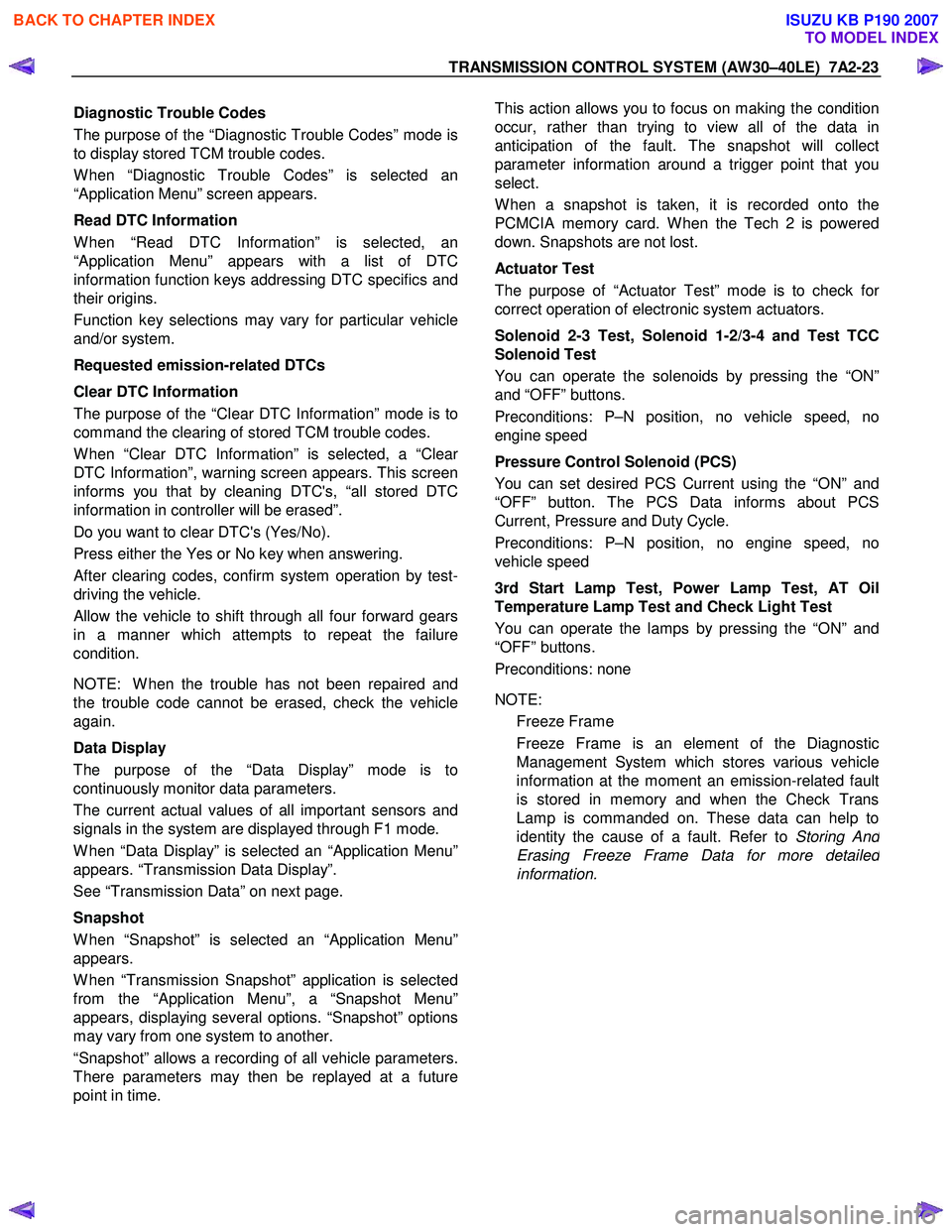

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes” mode is

to display stored TCM trouble codes.

W hen “Diagnostic Trouble Codes” is selected an

“Application Menu” screen appears.

Read DTC Information

W hen “Read DTC Information” is selected, an

“Application Menu” appears with a list of DTC

information function keys addressing DTC specifics and

their origins.

Function key selections may vary for particular vehicle

and/or system.

Requested emission-related DTCs

Clear DTC Information

The purpose of the “Clear DTC Information” mode is to

command the clearing of stored TCM trouble codes.

W hen “Clear DTC Information” is selected, a “Clea

r

DTC Information”, warning screen appears. This screen

informs you that by cleaning DTC's, “all stored DTC

information in controller will be erased”.

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test-

driving the vehicle.

Allow the vehicle to shift through all four forward gears

in a manner which attempts to repeat the failure

condition.

NOTE: W hen the trouble has not been repaired and

the trouble code cannot be erased, check the vehicle

again.

Data Display

The purpose of the “Data Display” mode is to

continuously monitor data parameters.

The current actual values of all important sensors and

signals in the system are displayed through F1 mode.

W hen “Data Display” is selected an “Application Menu”

appears. “Transmission Data Display”.

See “Transmission Data” on next page.

Snapshot

W hen “Snapshot” is selected an “Application Menu”

appears.

W hen “Transmission Snapshot” application is selected

from the “Application Menu”, a “Snapshot Menu”

appears, displaying several options. “Snapshot” options

may vary from one system to another.

“Snapshot” allows a recording of all vehicle parameters.

There parameters may then be replayed at a future

point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

W hen a snapshot is taken, it is recorded onto the

PCMCIA memory card. W hen the Tech 2 is powered

down. Snapshots are not lost.

Actuator Test

The purpose of “Actuator Test” mode is to check fo

r

correct operation of electronic system actuators.

Solenoid 2-3 Test, Solenoid 1-2/3-4 and Test TCC

Solenoid Test

You can operate the solenoids by pressing the “ON”

and “OFF” buttons.

Preconditions: P–N position, no vehicle speed, no

engine speed

Pressure Control Solenoid (PCS)

You can set desired PCS Current using the “ON” and

“OFF” button. The PCS Data informs about PCS

Current, Pressure and Duty Cycle.

Preconditions: P–N position, no engine speed, no

vehicle speed

3rd Start Lamp Test, Power Lamp Test, AT Oil

Temperature Lamp Test and Check Light Test

You can operate the lamps by pressing the “ON” and

“OFF” buttons.

Preconditions: none

NOTE: Freeze Frame

Freeze Frame is an element of the Diagnostic

Management System which stores various vehicle

information at the moment an emission-related fault

is stored in memory and when the Check Trans

Lamp is commanded on. These data can help to

identity the cause of a fault. Refer to Storing An

d

Erasing Freeze Frame Data for more detaile

d

information.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3990 of 6020

7A2-24 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

TRANSMISSION DATA

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle

Operating Conditions: Engine idling/ Engine coolant temperature is between 75 to 85 °C(167 to 185 °F)/

Accelerator pedal is constant/ Neutral or Park/ Accessories OFF/ Vehicle located at sea level

Engine Coolant temperature °C/ °F 75 to 85°C (167 to 185 °F)

Engine Speed RPM 700

Vehicle Speed Km/h / MPH 0

Ignition Voltage V 13.6

Accelerator Pedal Position Signal % 0

Throttle Position % 0

Accelerator Pedal Position Signal

During Cruise Control % 0

Cruise Control

Inactive / Active Inactive

Cruise Control OD Cancel Request ON / OFF OFF

Engine W arm Up Cycle Achieved FALSE / TRUE FALSE

Transmission Shift in Progress Inactive / Active Inactive

Garage Shift Control Inactive / Active Inactive

MIL Request Command ON / OFF OFF

Transmission Check Light ON / OFF OFF

Transmission Oil Temperature Lamp ON / OFF OFF

Power Drive Lamp ON / OFF OFF

3rd Start Lamp ON / OFF OFF

Transmission Fluid Temperature

°C/ °F 70 to 80°C (158 to 176 °F)

AT Input Speed RPM 625

AT Output Speed RPM 0

Transmission Range Park / Reverse /

Neutral / Drive 4 / Drive 3 / Drive 2 / Drive 1 Park

TR Switch P

ON / OFF ON

TR Switch R ON / OFF OFF

TR Switch N ON / OFF OFF

TR Switch D ON / OFF OFF

TR Switch 3 ON / OFF OFF

TR Switch 2 ON / OFF OFF

TR Switch L ON / OFF OFF

Diagnostic Switch Open / Close Open

Brake Pedal Switch ON / OFF OFF

Power Drive Switch ON / OFF OFF

3rd Start Switch ON / OFF OFF

4 W heel Drive Low ON / OFF OFF

Shift Solenoid 1 Command ON / OFF ON

Shift Solenoid 2 Command ON / OFF OFF

TCC Solenoid Engaged / Disengaged Disengaged

Downhill Mode Inactive / Active Inactive

Active Shift Mode Normal Mode /

Power Mode /

3rd Gear Start /

Transfer 4L MODE Hot 1 / Hot 2 /

UPHILL MODE 1 /

UPHILL MODE 2 / Cruise MODE /

W arm Up MODE Normal Mode

Estimated Gear Ratio

:1 7.97 : 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4007 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-41

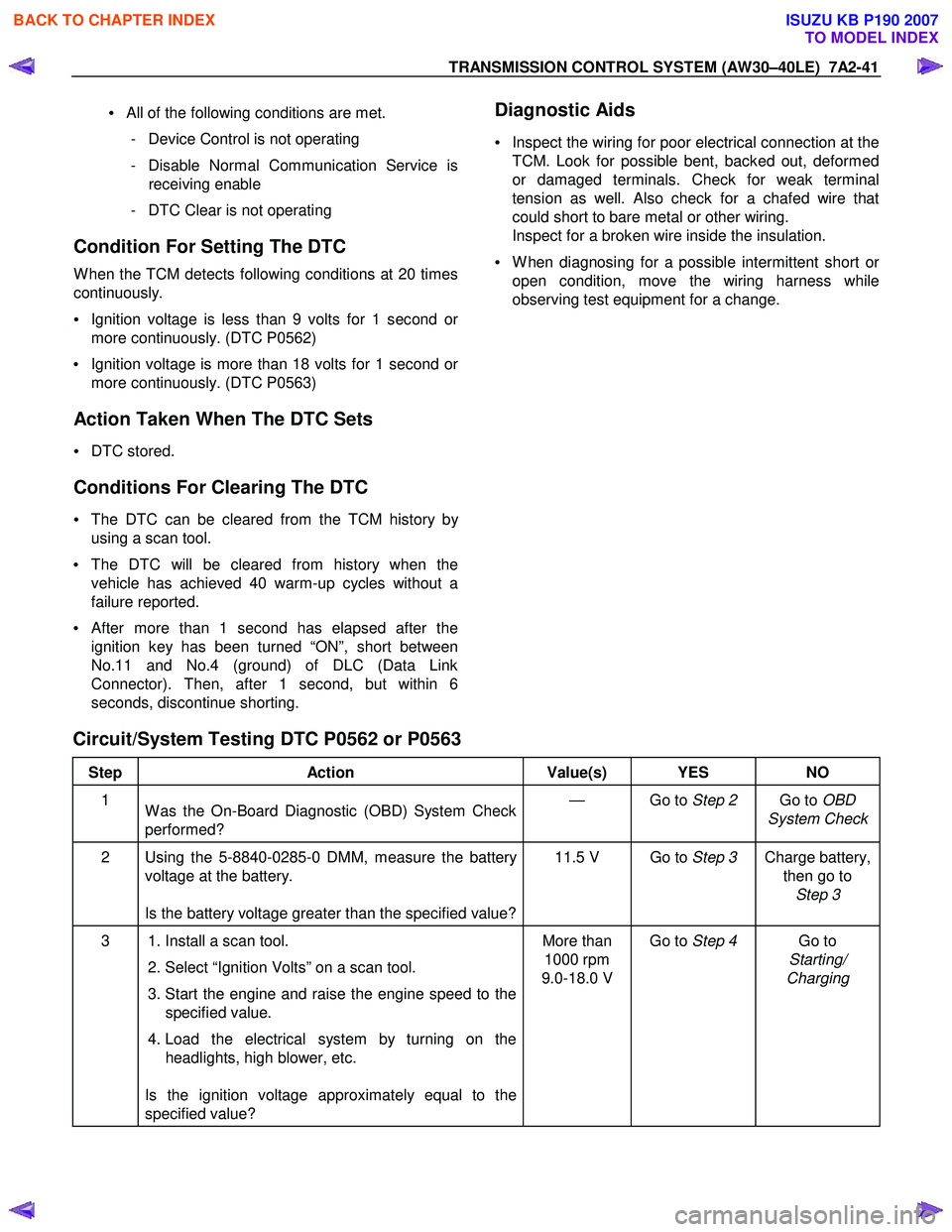

• All of the following conditions are met.

- Device Control is not operating

- Disable Normal Communication Service is receiving enable

- DTC Clear is not operating

Condition For Setting The DTC

W hen the TCM detects following conditions at 20 times

continuously.

• Ignition voltage is less than 9 volts for 1 second o

r

more continuously. (DTC P0562)

• Ignition voltage is more than 18 volts for 1 second o

r

more continuously. (DTC P0563)

Action Taken When The DTC Sets

• DTC stored.

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring.

Inspect for a broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

Circuit/System Testing DTC P0562 or P0563

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed? — Go to

Step 2 Go to OBD

System Check

2 Using the 5-8840-0285-0 DMM, measure the battery voltage at the battery.

Is the battery voltage greater than the specified value? 11.5 V Go to

Step 3 Charge battery,

then go to Step 3

3 1. Install a scan tool.

2. Select “Ignition Volts” on a scan tool.

3. Start the engine and raise the engine speed to the specified value.

4. Load the electrical system by turning on the headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value? More than

1000 rpm

9.0-18.0 V Go to

Step 4 Go to

Starting/

Charging

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4317 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-33

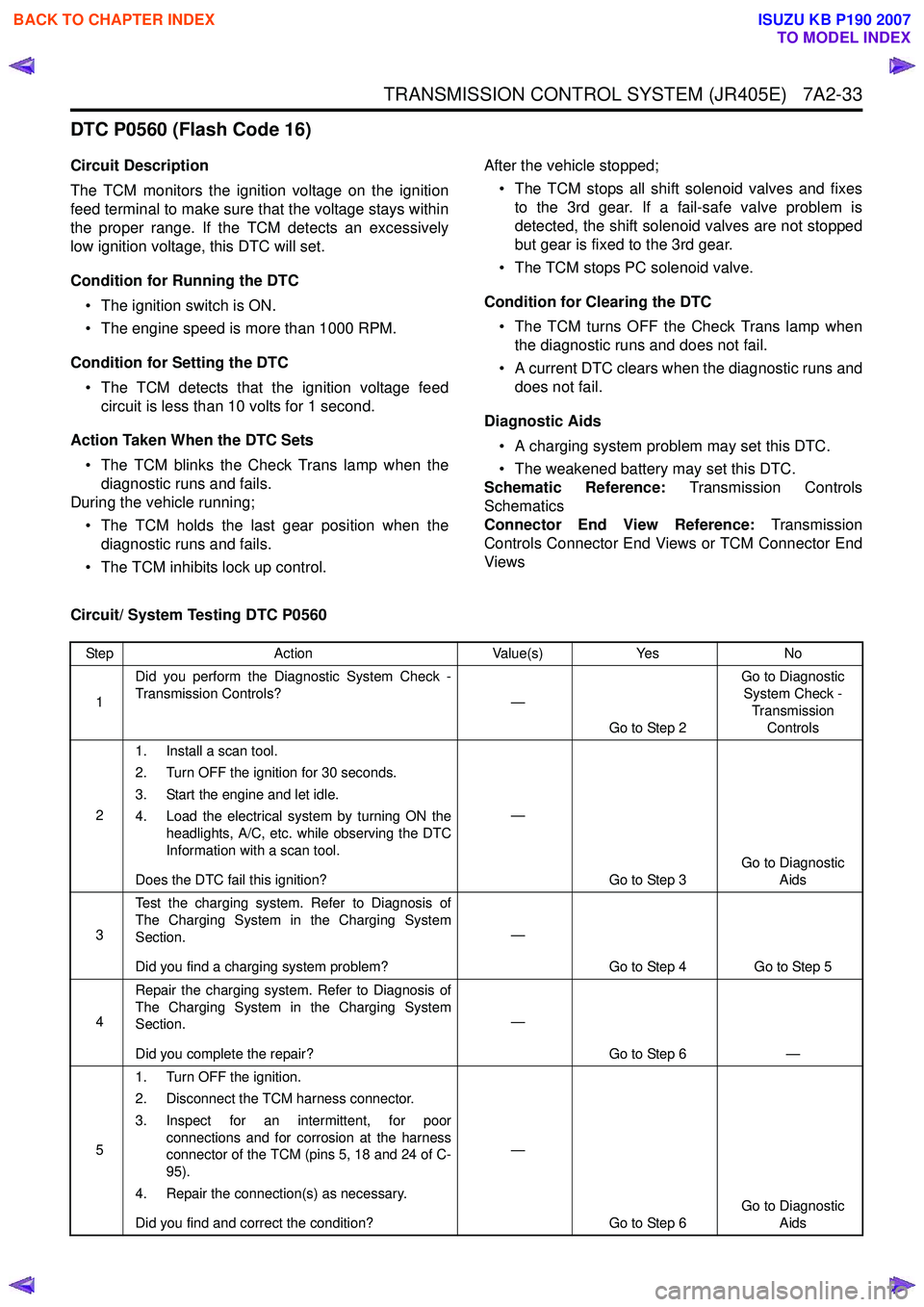

DTC P0560 (Flash Code 16)

Circuit Description

The TCM monitors the ignition voltage on the ignition

feed terminal to make sure that the voltage stays within

the proper range. If the TCM detects an excessively

low ignition voltage, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is more than 1000 RPM.

Condition for Setting the DTC • The TCM detects that the ignition voltage feed circuit is less than 10 volts for 1 second.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control. After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • A charging system problem may set this DTC.

• The weakened battery may set this DTC.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0560

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle.

4. Load the electrical system by turning ON the headlights, A/C, etc. while observing the DTC

Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 4 Go to Step 5

4 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6 —

5 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent, for poor connections and for corrosion at the harness

connector of the TCM (pins 5, 18 and 24 of C-

95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007