light ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2065 of 6020

ENGINE MECHANICAL (C24SE) 6A-51

OPERATIONS ON CRANK DRIVE

Con-Rod Bearing

Removal

1. Remove oil pan and bearing bridge according to the corresponding operation.

2. Remove con-rod bearing cap and con-rod bearing after marking both sides.

Clean

Con-rod journal, con-rod bearing cap

Installation

1. Install new bearing shafts lightly coated with engine oil.

2. Install con-rod bearing cap.

Torque-Angle Method

Con-rod bearing cap to con-rod - 35N ⋅m (3.5 kgf ⋅m) +45 ° to

60 °

Important!

Use new bolts.

3. Install oil pan and bearing bridge according to the corresponding operation.

Piston with Con-Rod

Removal

1. Remove cylinder head and oil pan according to the corresponding operations.

2. Remove piston with con-rod after marking con-rod bearing cap.

Inspection

Remove and install all parts, if applicable.

Important!

Ring gap offset:

Piston rings - 180 °.

Oil scraper rings - 25 to 50 mm/1 to 2 in. from gap of

intermediate ring to the left and to the right.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2069 of 6020

ENGINE MECHANICAL (C24SE) 6A-55

OPERATIONS ON REMOVED ENGINE

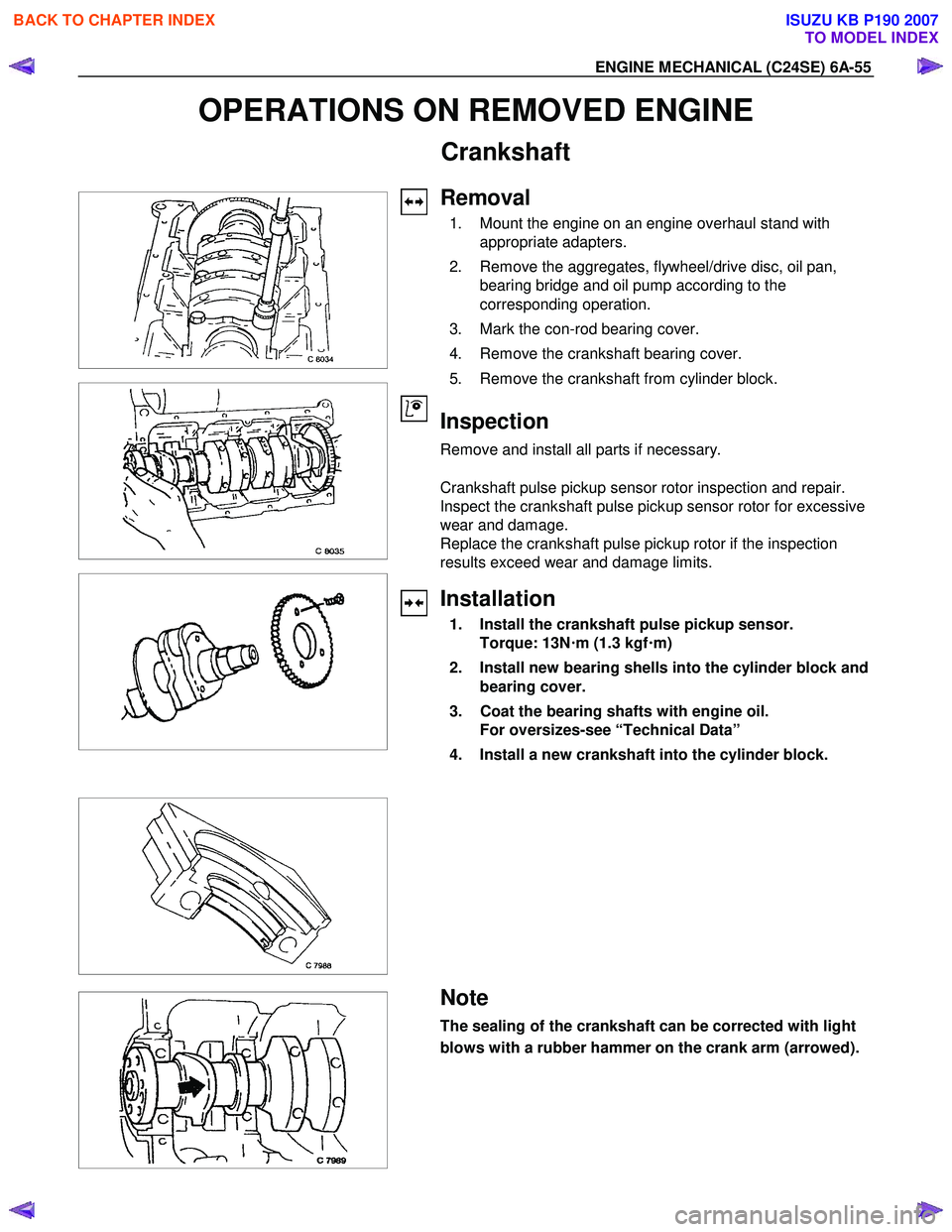

Crankshaft

Removal

1. Mount the engine on an engine overhaul stand with appropriate adapters.

2. Remove the aggregates, flywheel/drive disc, oil pan, bearing bridge and oil pump according to the

corresponding operation.

3. Mark the con-rod bearing cover.

4. Remove the crankshaft bearing cover.

5. Remove the crankshaft from cylinder block.

Inspection

Remove and install all parts if necessary.

Crankshaft pulse pickup sensor rotor inspection and repair.

Inspect the crankshaft pulse pickup sensor rotor for excessive

wear and damage.

Replace the crankshaft pulse pickup rotor if the inspection

results exceed wear and damage limits.

Installation

1. Install the crankshaft pulse pickup sensor. Torque: 13N !

!!

!

m (1.3 kgf !

!!

!

m)

2. Install new bearing shells into the cylinder block and bearing cover.

3. Coat the bearing shafts with engine oil. For oversizes-see “Technical Data”

4. Install a new crankshaft into the cylinder block.

Note

The sealing of the crankshaft can be corrected with light

blows with a rubber hammer on the crank arm (arrowed).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2070 of 6020

6A-56 ENGINE MECHANICAL (C24SE)

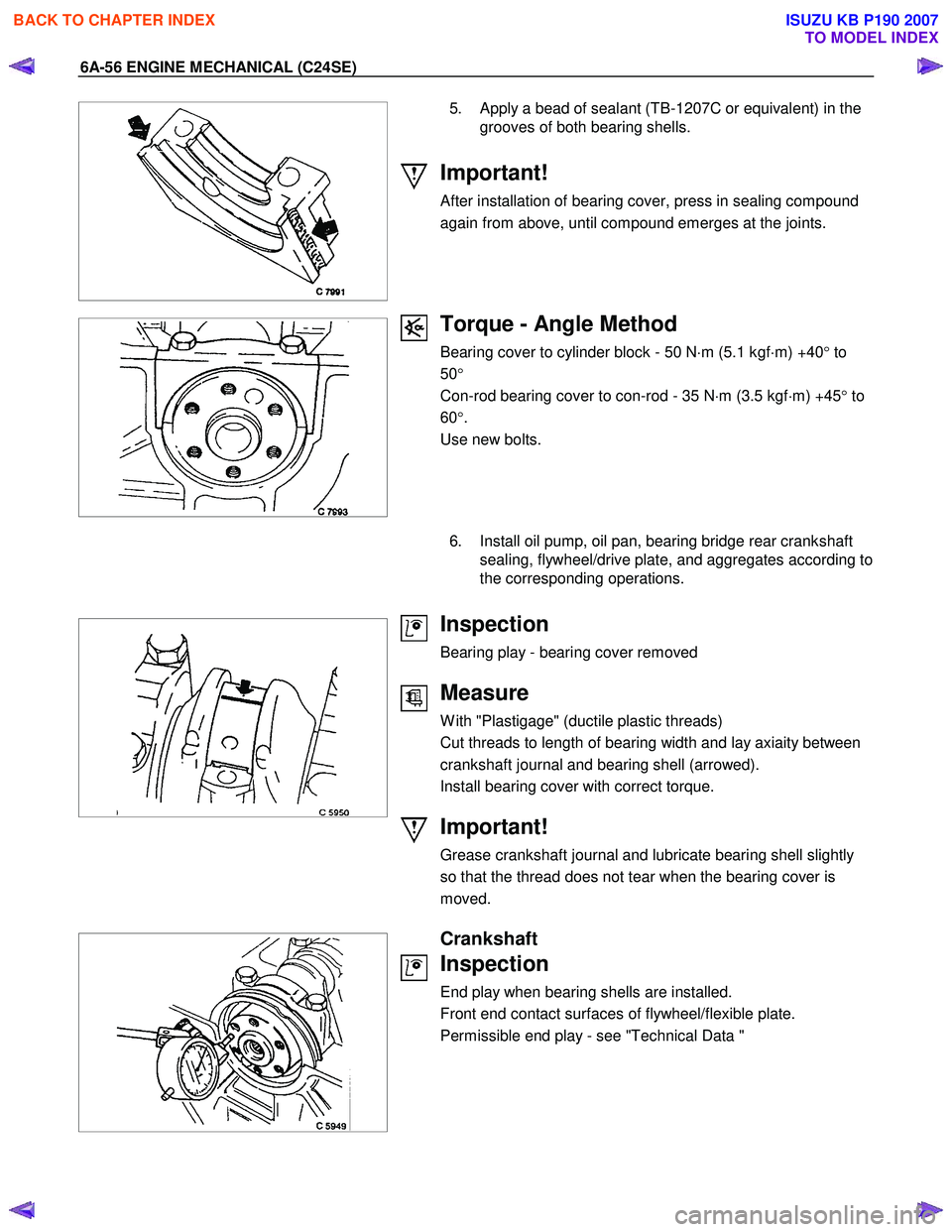

5. Apply a bead of sealant (TB-1207C or equivalent) in the grooves of both bearing shells.

Important!

After installation of bearing cover, press in sealing compound

again from above, until compound emerges at the joints.

Torque - Angle Method

Bearing cover to cylinder block - 50 N ⋅m (5.1 kgf ⋅m) +40 ° to

50 °

Con-rod bearing cover to con-rod - 35 N ⋅m (3.5 kgf ⋅m) +45 ° to

60 °.

Use new bolts.

6. Install oil pump, oil pan, bearing bridge rear crankshaft

sealing, flywheel/drive plate, and aggregates according to

the corresponding operations.

Inspection

Bearing play - bearing cover removed

Measure

W ith "Plastigage" (ductile plastic threads)

Cut threads to length of bearing width and lay axiaity between

crankshaft journal and bearing shell (arrowed).

Install bearing cover with correct torque.

Important!

Grease crankshaft journal and lubricate bearing shell slightly

so that the thread does not tear when the bearing cover is

moved.

Crankshaft

Inspection

End play when bearing shells are installed.

Front end contact surfaces of flywheel/flexible plate.

Permissible end play - see "Technical Data "

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2071 of 6020

ENGINE MECHANICAL (C24SE) 6A-57

Inspection

Out-of-round (run-out)-middle bearing shell removed when

mounting on front and rear bearing.

Permissible out-of-round - see "Technical Data"

Bearing Free Play Measurement

Two methods for measuring bearing free play are described -

1. Plastigage method and 2. micrometer and gauge method.

The two procedures are suitable for measuring both con-rod

and main bearing free play.

For both methods ensure con-rod and main bearing caps are

identified (1) prior to removal as they are machine matched.

1.Plastigage Method

Removal

1. Remove bearing cap and shell.

2. Lightly coat journals and bearings with engine oil to prevent Plastigage from tearing when cap is removed.

Installation

1. Lay a length of Plastigage across width of crank pin and fit bearing cap and shell using old bolts at this stage.

Important!

Do not allow crankshaft to rotate.

Torque - Angle Method

Main bearing cap bolt - 60 N ⋅m (6.1 kgf ⋅m) +40 ° + to 50 °.

Con-rod bearing cap bolts - 35 N ⋅m (3.6 kgf ⋅m) +45 °.

Removal

1. Remove bearing cap and shell.

Measure

W idth of Plastigage -use scale supplied with Plastigage.

If con-rod bearing clearance exceeds 0.031mm/0.001in or

main journal bearing clearance exceeds 0.04mm/0.02in. -

check crankshaft journal diameters - see corresponding

operation.

Replace bearing if crankshaft is within specification - see

"Technical Data"

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2072 of 6020

6A-58 ENGINE MECHANICAL (C24SE)

Clean

Plastigage from journals.

Lightly coat journals and bearings with engine oil.

Installation

Install bearing cap and shell using new bolts.

Torque - Angle Method

Main bearing cap bolt - 60 N ⋅m (6.1 kgf ⋅m) +40 ° to 50 °.

Con-rod bearing cap bolts - 35 N ⋅m (3.9 kgf ⋅m) +45 °.

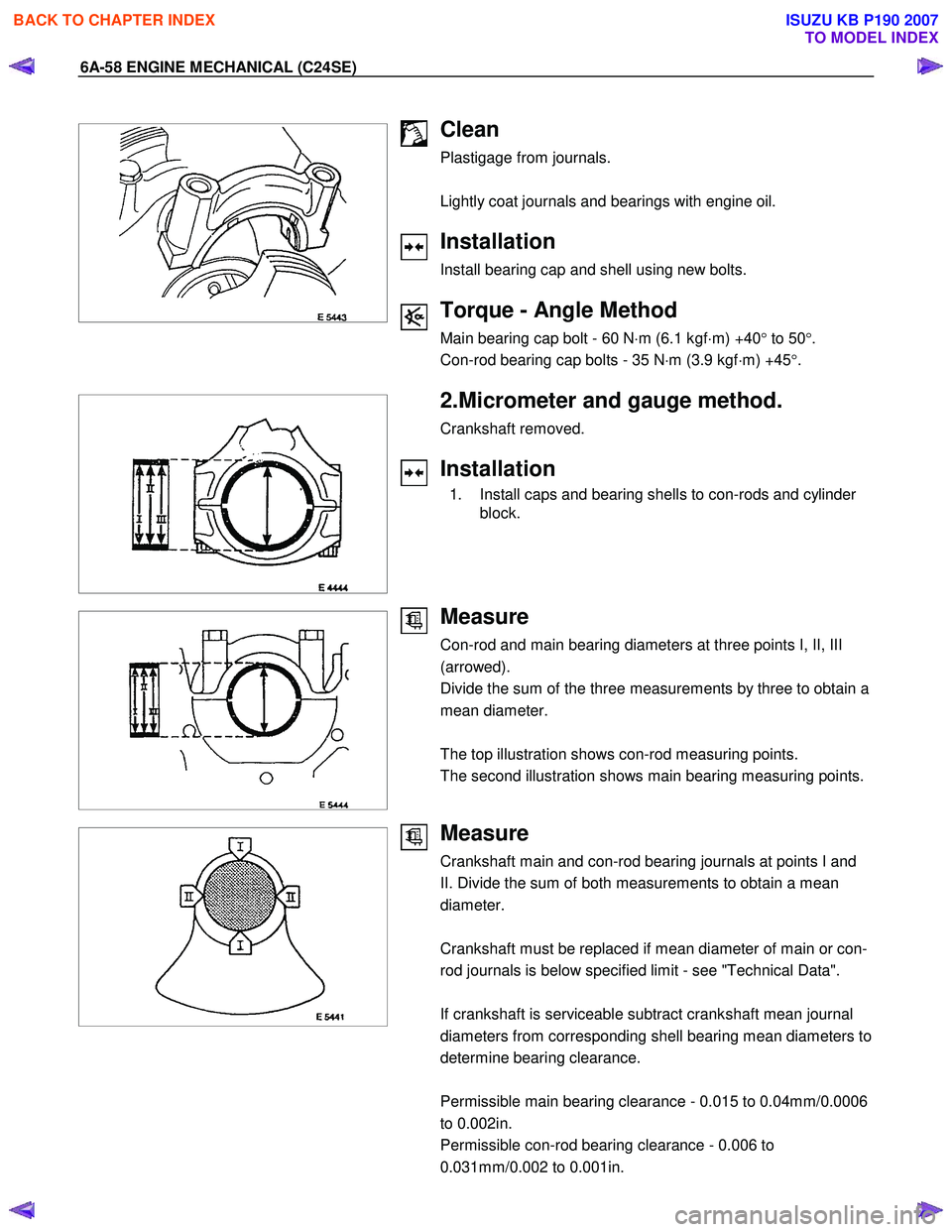

2.Micrometer and gauge method.

Crankshaft removed.

Installation

1. Install caps and bearing shells to con-rods and cylinder block.

Measure

Con-rod and main bearing diameters at three points I, II, III

(arrowed).

Divide the sum of the three measurements by three to obtain a

mean diameter.

The top illustration shows con-rod measuring points.

The second illustration shows main bearing measuring points.

Measure

Crankshaft main and con-rod bearing journals at points I and

II. Divide the sum of both measurements to obtain a mean

diameter.

Crankshaft must be replaced if mean diameter of main or con-

rod journals is below specified limit - see "Technical Data".

If crankshaft is serviceable subtract crankshaft mean journal

diameters from corresponding shell bearing mean diameters to

determine bearing clearance.

Permissible main bearing clearance - 0.015 to 0.04mm/0.0006

to 0.002in.

Permissible con-rod bearing clearance - 0.006 to

0.031mm/0.002 to 0.001in.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2128 of 6020

6C-10 ENGINE FUEL (C24SE)

Fuel Tube / Quick – Connector Fittings

Precautions

• Do not light a match or create a flame.

• Keep flames away from your work area to prevent

flammable materials from catching fire.

• Disconnect battery ground cable to prevent

electrical shorts.

• Pre-treat piping system or associated parts from

thermal damage or from spattering when welding

or similar heat-generating work.

Cautions During Work

140R100032

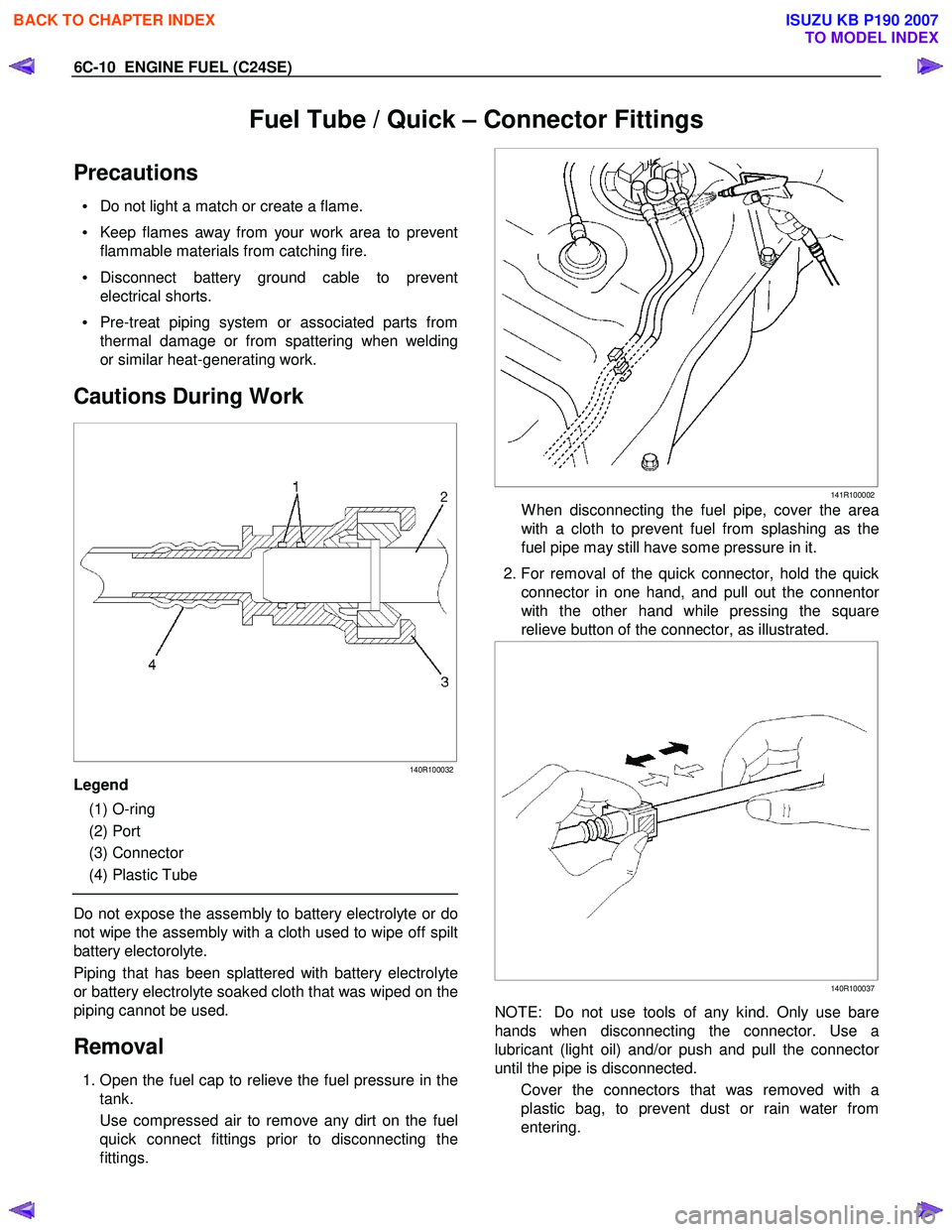

Legend

(1) O-ring

(2) Port

(3) Connector

(4) Plastic Tube

Do not expose the assembly to battery electrolyte or do

not wipe the assembly with a cloth used to wipe off spilt

battery electorolyte.

Piping that has been splattered with battery electrolyte

or battery electrolyte soaked cloth that was wiped on the

piping cannot be used.

Removal

1. Open the fuel cap to relieve the fuel pressure in the

tank.

Use compressed air to remove any dirt on the fuel

quick connect fittings prior to disconnecting the

fittings.

141R100002

W hen disconnecting the fuel pipe, cover the area

with a cloth to prevent fuel from splashing as the

fuel pipe may still have some pressure in it.

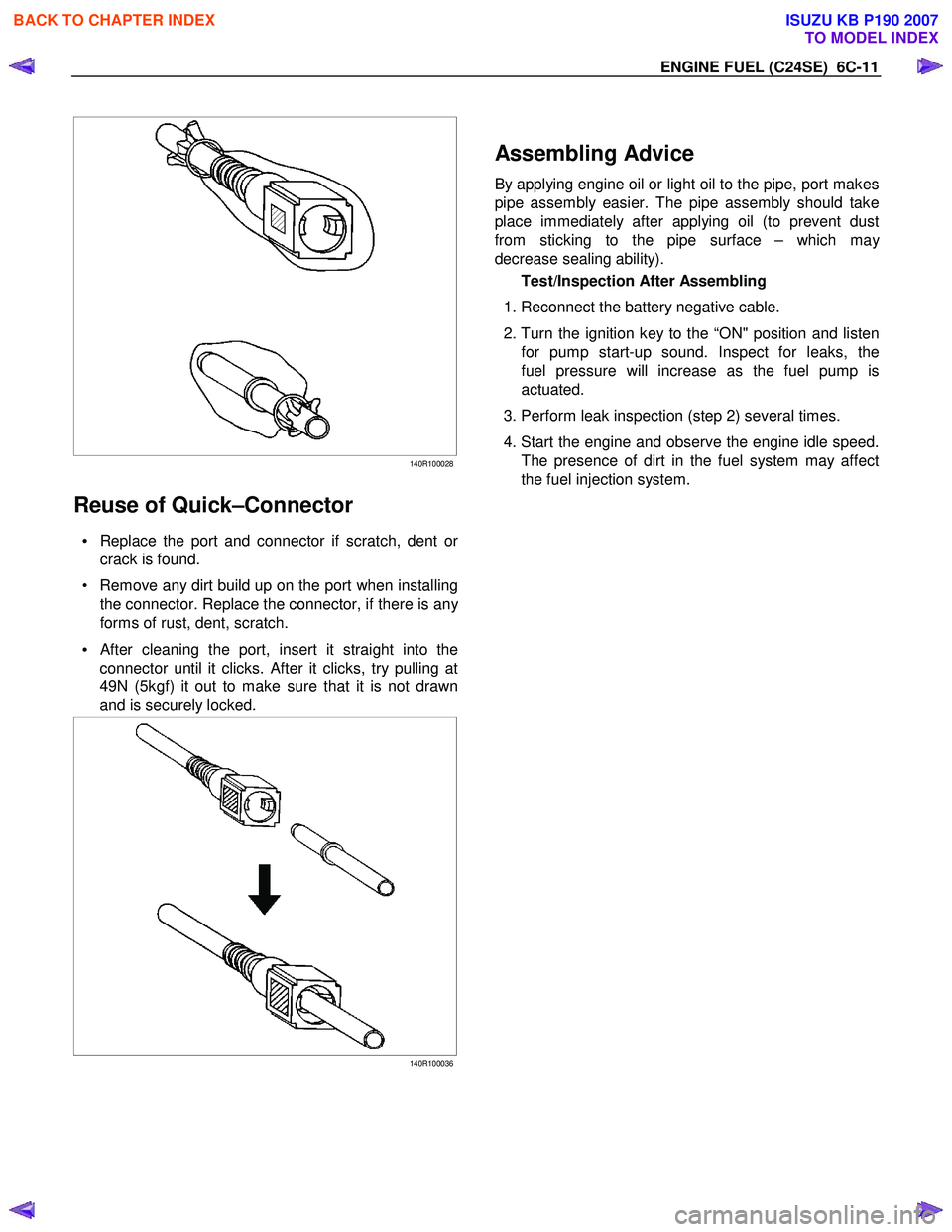

2. For removal of the quick connector, hold the quick

connector in one hand, and pull out the connento

r

with the other hand while pressing the square

relieve button of the connector, as illustrated.

140R100037

NOTE: Do not use tools of any kind. Only use bare

hands when disconnecting the connector. Use a

lubricant (light oil) and/or push and pull the connecto

r

until the pipe is disconnected.

Cover the connectors that was removed with a

plastic bag, to prevent dust or rain water from

entering.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2129 of 6020

ENGINE FUEL (C24SE) 6C-11

140R100028

Reuse of Quick–Connector

• Replace the port and connector if scratch, dent or

crack is found.

• Remove any dirt build up on the port when installing the connector. Replace the connector, if there is an

y

forms of rust, dent, scratch.

•

After cleaning the port, insert it straight into the

connector until it clicks. After it clicks, try pulling at

49N (5kgf) it out to make sure that it is not drawn

and is securely locked.

140R100036

Assembling Advice

By applying engine oil or light oil to the pipe, port makes

pipe assembly easier. The pipe assembly should take

place immediately after applying oil (to prevent dust

from sticking to the pipe surface – which ma

y

decrease sealing ability).

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Turn the ignition key to the “ON" position and listen

for pump start-up sound. Inspect for leaks, the

fuel pressure will increase as the fuel pump is

actuated.

3. Perform leak inspection (step 2) several times.

4. Start the engine and observe the engine idle speed.

The presence of dirt in the fuel system may affect

the fuel injection system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2142 of 6020

ENGINE ELECTRICAL 6D1-5

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly rinse

the affected area with clean tap water.

Never allow metal tools or jumper cables to come in contact

with the positive battery terminal, or any other metal surface of

the vahicle. This will protect against a short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake and place the shift lever in the

"NEUTRAL" position.

Turn "OFF" the ignition.

Turn "OFF" all lights and any other accessory requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is completel

y

clear, do not try to jump start.

3.

Attach the end of one jumper cable to the positive terminal

of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will cause a ground connection, effectively neutralizing the

charging procedure.

Be sure that the booster battery has a 12 volt rating.

4.

Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid engine ground (such as the air conditioning compressor bracket o

r

the generator mounting bracket) of the vehicle with the

discharged battery.

The ground connection must be at least 450 mm (18 in.) from the battery of the vehicle whose battery is being

charged.

WARNING: NEVER ATTACH THE END OF THE JUMPER

CABLE DIRECTLY TO THE NEGATIVE TERMINAL OF THE

DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories have been turned "OFF".

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above directions in reverse order.

Be sure to first disconnect the negative cable from the vehicle with the discharged battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2159 of 6020

STARTING AND CHARGING SYSTEM 6D3-11

Warning

Do not reverse S and L connections as this will destroy the

warning lamp circuit of the regulator.

Ensure good electrical contact beween generator earth and

battery negative,

Operation

W ith the Iginiton switch turnded "ON", current is supplied via

the warning lamp to the "L" terminal of the regulator. Base

current is fed to T15 causing it to turn on, current then flows

from B+ through the rotor winding via the regulator brushes

and the collector emitter junction of T15 to earth completing

the circuit. The current in the rotor causes a magnetic field

between adjacent poles to be created, this field is rotated and

cuts the windings of the stator at right angles inducing a

voltage into them.

As the speed is increased this induced voltage increases and

results in curent being rectified in the 3 phase diode bridge and

supplied as DC to the B+ output and hence to the battery.

W hen the voltage at the B+ terminal of the battery reaches

around 14.2 volts, this voltage is monitored by the "S" lead and

turns the regulator Hybrid base current to T15 OFF removing

rotor current, resulting in a decrease in output voltage to below

the regulating voltage, T15 base current turns ON and the

whole cycle is repeated very rapidly.

D38 protects T15 and the regulator against the back voltage

developed across the rotor winding when T15 turns OFF.

The new generated EP regulators incorporate current limiting

in the warning lamp circuit.

Backup Regulation

The EP regulator will limit the output voltage to a safe level

should either the main B+ cable or the battery sense wire

become decoupled, the output voltage will be slightly above the

normal setting(1-3 volts).

Start up phase

W hen the Iginition switch is turned on and the engine is not

running, the current to the rotor is reduced by switching it on

and off at a 50% duty cycle, the frequency is approximately 4

KHz and may be audible at times.

This is quite normal, once the engine is started normal

regulation commences.

Warning lamp failure

Should the warning lamp fail, the generator will self excite by

deriving a small current from the phase connecion allowing the

voltage to build up to regulating level.

Note: no filed current will flow when the engine is cranking.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2161 of 6020

STARTING AND CHARGING SYSTEM 6D3-13

5. During current output tests please make sure that the

ammeter is securely connceted into the charge circuit.

6. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Onl

y

disconnect or connect timing lights when the engine is

switched off.

7. Make sure the warning lamp circuit is functioning normall

y

before commencing tests.

8. Battery isolation switches must only be operated when the engine is stopped.

9. To protect the charging system when using 240 volt chargers it is recommeneded that the battery is

disconnected whilst charging.

10. Due to the very low resistance value of the stator winding it may not be possible to obtain accurate readings without

special equipment.

11. 12 volts must never be connected to the "L" terminal of the regulator as this will damage the lamp driver circuit.

12. No loads apart from the warning lamp can be connected to the "L" termainal. The "W " terminal is provided for this

purpose.

Disassembly

1. Mark the relative positions of the end housings in relation to the stator assembly to aid reassembly. Use a permanent

marking pen do not use centre punched as this can cause

misalignmnet of the housings.

2. Remove the EP regulator from the slipring end housing b

y

removing the two screws. Tilt the regulator slightly from the

plug connection until the regulator clears the housing, then

lift clear.

3. Remove the four through bolts.

4. Carefully remove the stator assembly along with the slipring end housing taking care not to put strain on the stator wires.

5. To disconnect the stator from the rectifier assembly, grasp the stator wires close to the wire loop with a pair of long

nosed pliers, heat the joint with a soldering iron, when the

point becomes plastic apply a slight twisting motion to the

wires, then pull upwards to release the wires. Remove the

stator.

This procedure opens the wire loop to release the stato

r

connections easily.

6. To remove the rectifier remove the three retaining scre

w

and the B+ terminal nut and washers.

Note: the B+ bolt and the positive heatsink retaining screw are

fitted with mica insulating washers.

These must be discarded and replaced with new washers and

heatsink compound.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007