indicator ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2843 of 6020

Engine Mechanical – V6 Page 6A1–66

Page 6A1–66

3 Minor Service Operations

ATTENTION

The V6 engine is a combination of numerous components, containing machined, honed, polished and lapped

surfaces manufactured on the latest, high technology production equipment. Many of the components

contain tolerances measured in thousa ndths of a millimetre. Consequently, when any e ngine component is to

be serviced, care and cleanliness are extremely important.

Prior to re-assembly of the engine, all components mu st be cleaned and inspected in accordance with the

relevant clean and inspect procedur es throughout this Section, and repl aced or repaired where required.

In addition to cleaning and inspecting components, a liberal coating of engine oil should be applied to friction

surfaces during assembly to protect and lubr icate the surfaces on initial operation.

When performing any service operation, it should be understood that correct cleaning and protection of

machined surfaces and friction areas is part of the repair procedure. This is considered standard workshop

practice, even if not specifically stated. Torque va lues must be used as specified during reassembly to

ensure correct retention of all components.

Through out this section, fastener torque wrench sp ecifications may be accompanied with the following

identification marks:

■ Fasteners must be replaced after loosening.

Fasteners either have micro encapsulated sealant a pplied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongs ide a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

3.1 Engine Oil

The procedure outlined below is typically the same for both rear wheel drive and all wheel drive vehicles.

Check

The following procedure is applicable to both rear wheel and all wheel drive vehicles

1 Run the engine to bring it to normal operating temperature.

2 Park the vehicle on a level surface. A vehicle that is not level will affect the accuracy of the level reading.

3 Stop the engine and wait 5 to 10 minutes to a llow the oil to drain back into the oil pan.

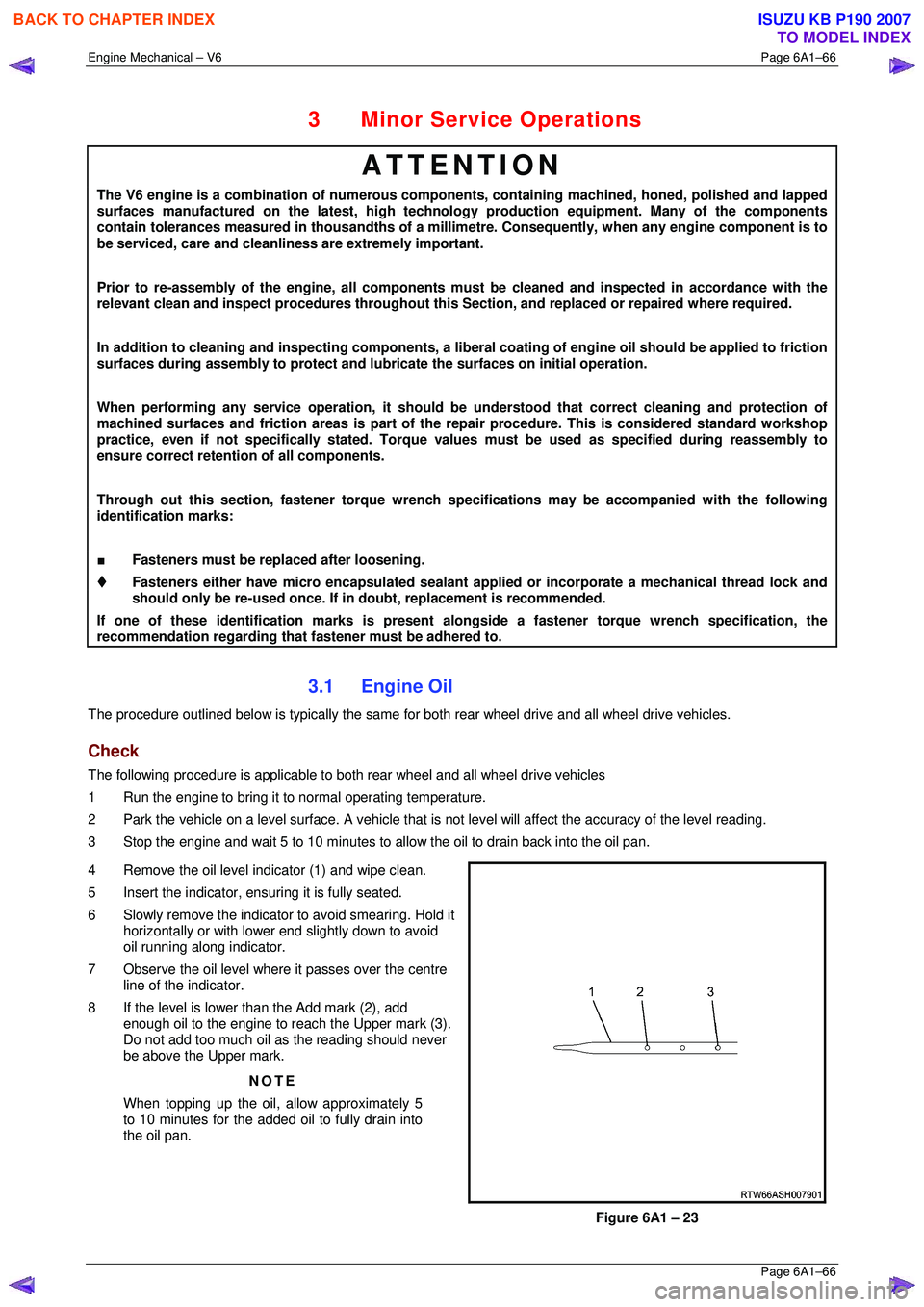

4 Remove the oil level indicator (1) and wipe clean.

5 Insert the indicator, ens uring it is fully seated.

6 Slowly remove the indicator to avoid smearing. Hold it horizontally or with lower end slightly down to avoid

oil running along indicator.

7 Observe the oil level where it passes over the centre

line of the indicator.

8 If the level is lower than the Add mark (2), add enough oil to the engine to reach the Upper mark (3).

Do not add too much oil as the reading should never

be above the Upper mark.

NOTE

When topping up the oil, allow approximately 5

to 10 minutes for the added oil to fully drain into

the oil pan.

Figure 6A1 – 23

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2848 of 6020

Engine Mechanical – V6 Page 6A1–71

Page 6A1–71

3.4 Oil Level Indicator Tube

Remove

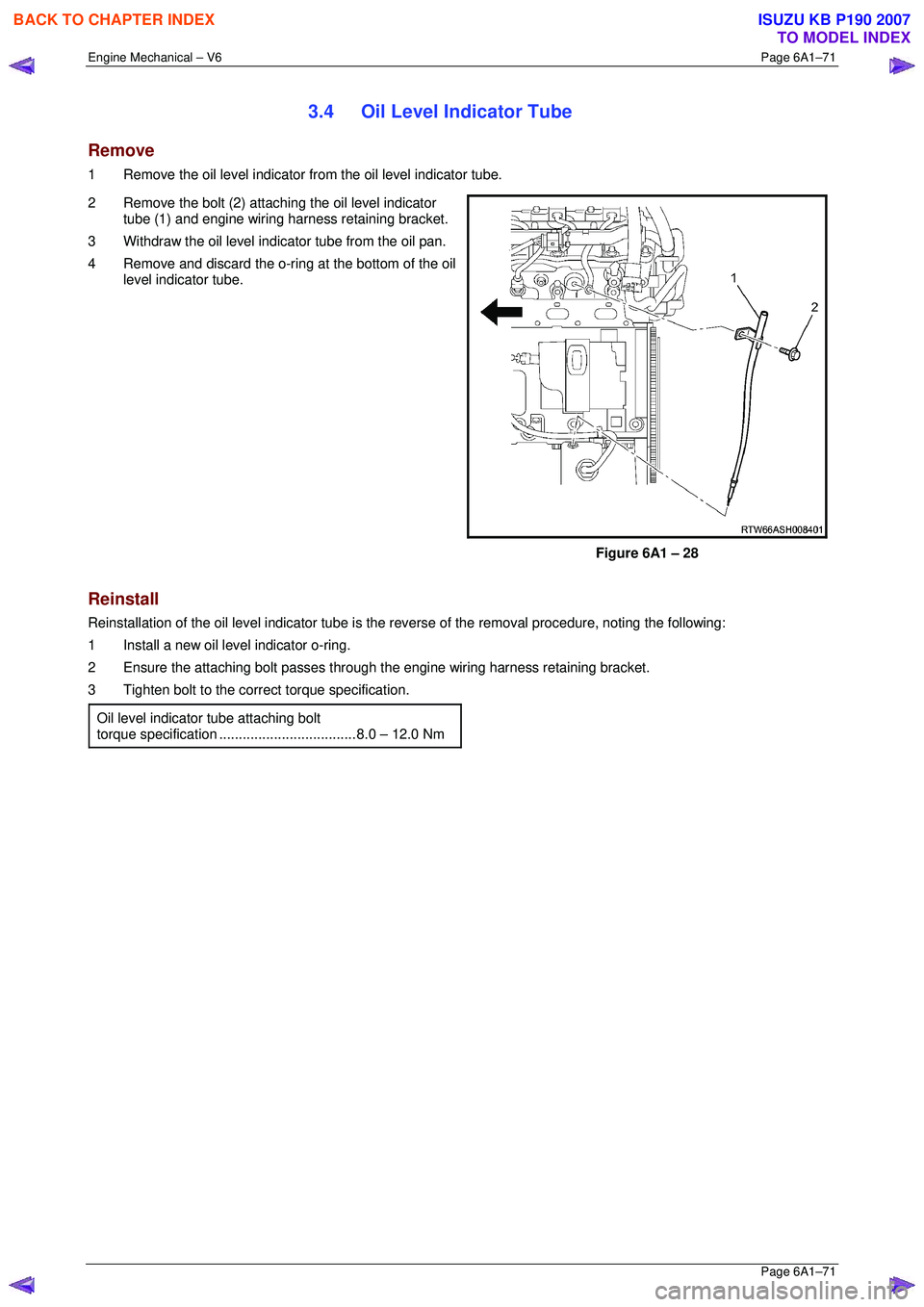

1 Remove the oil level indicator from the oil level indicator tube.

2 Remove the bolt (2) attaching the oil level indicator tube (1) and engine wiring harness retaining bracket.

3 Withdraw the oil level indi cator tube from the oil pan.

4 Remove and discard the o-ring at the bottom of the oil level indicator tube.

Figure 6A1 – 28

Reinstall

Reinstallation of the oil level indicator tube is the reverse of the removal procedure, noting the following:

1 Install a new oil level indicator o-ring.

2 Ensure the attaching bolt passes through the engine wiring harness retaining bracket.

3 Tighten bolt to the correct torque specification.

Oil level indicator tube attaching bolt

torque specificatio n ................................... 8. 0 – 12.0 Nm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2868 of 6020

Engine Mechanical – V6 Page 6A1–91

Page 6A1–91

3.11 Exhaust Manifold Assembly

Remove

Allow the engine to cool before commencing.

Disconnection of the battery affects

certain vehicle electronic systems, refer to

1.1 WARNING, CAUTION and NOTES before

disconnecting the battery.

1 Disconnect the battery negative terminal.

2 Remove the oxygen sensor harness connector (1) from the retaining bracket.

3 Disconnect the oxygen sensor wiring harness connector from the engine wiring harness connector

(2).

4 Unclip the oxygen sensor wiring harness retaining clip and move aside.

5 For the left-hand side: Remove the oil level indicator tube.

6 Raise the front of the vehicle and place on stands,

refer to Section 0A General Information .

7 Working from under the vehicle, remove the two exhaust manifold to exhaust pipe flange nuts, refer to

Section 6F Exhaust System - V6 .

Figure 6A1 – 56

8 Remove the three bolts attaching the exhaust manifold outer heat shield (1) to the exhaust manifold

(2).

Figure 6A1 – 57

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2983 of 6020

Engine Mechanical – V6 Page 6A1–206

Page 6A1–206

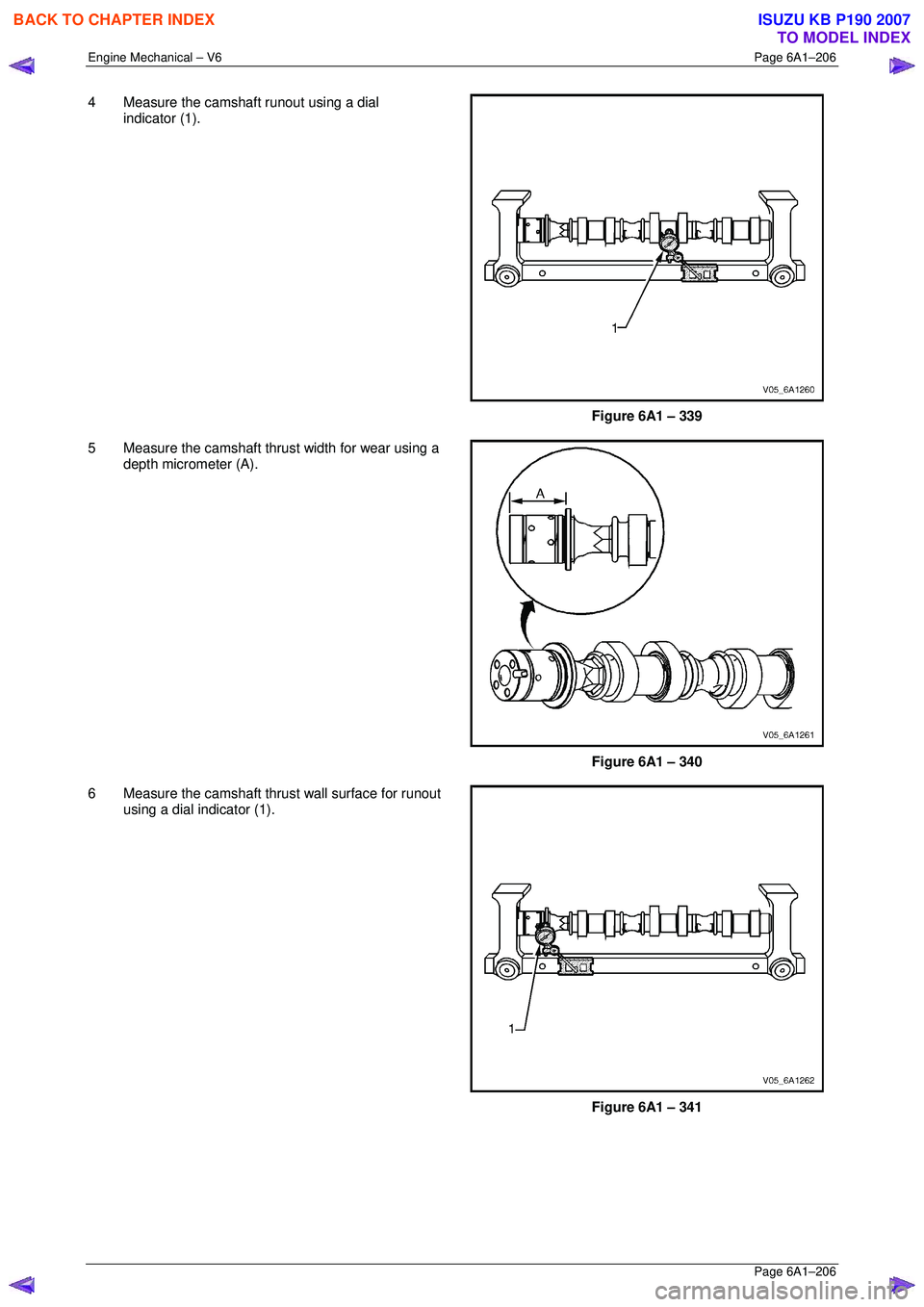

4 Measure the camshaft runout using a dial

indicator (1).

Figure 6A1 – 339

5 Measure the camshaft thrust width for wear using a depth micrometer (A).

Figure 6A1 – 340

6 Measure the camshaft thrust wall surface for runout using a dial indicator (1).

Figure 6A1 – 341

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2984 of 6020

Engine Mechanical – V6 Page 6A1–207

Page 6A1–207

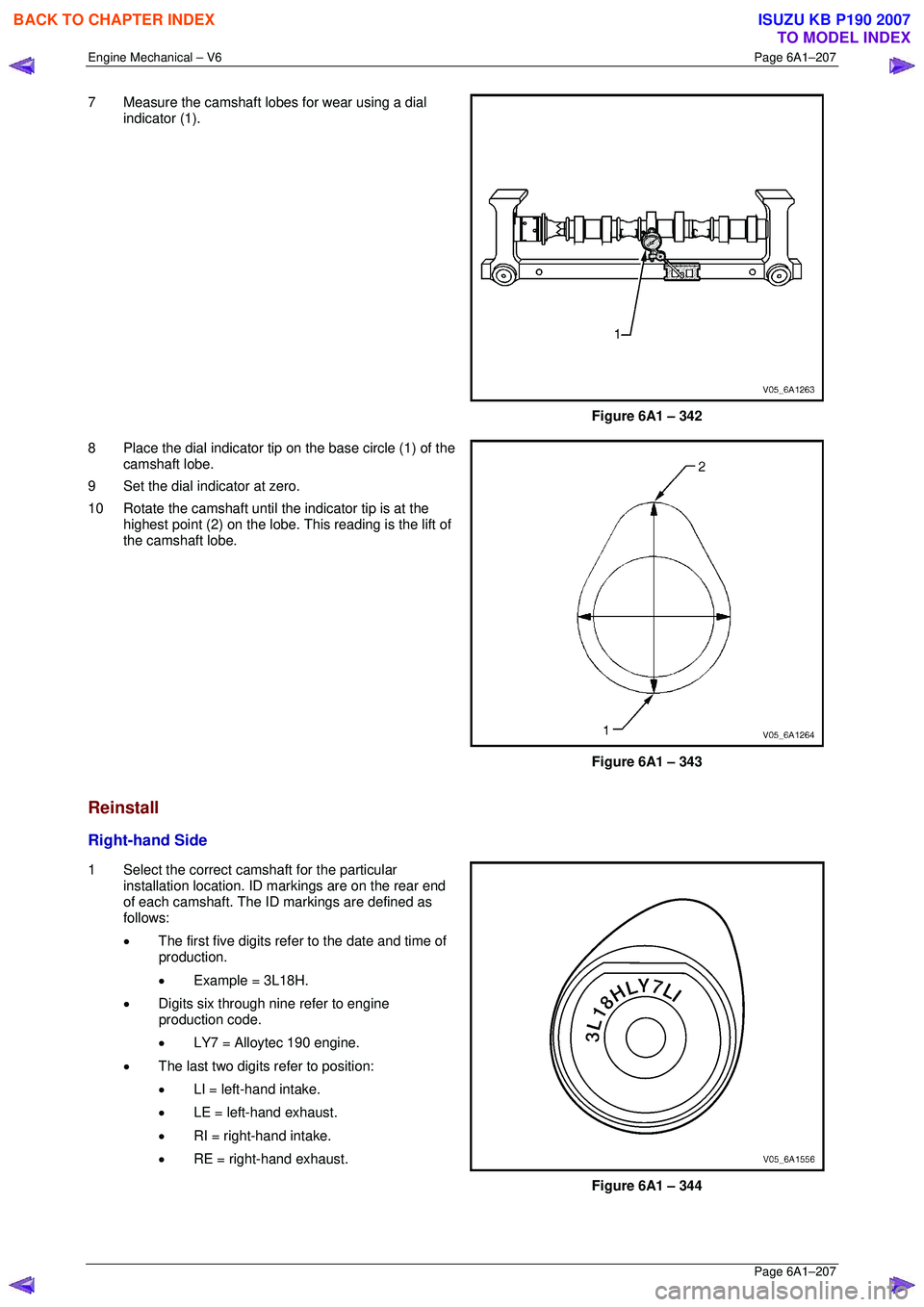

7 Measure the camshaft lobes for wear using a dial

indicator (1).

Figure 6A1 – 342

8 Place the dial indicator tip on the base circle (1) of the camshaft lobe.

9 Set the dial indicator at zero.

10 Rotate the camshaft until the indicator tip is at the highest point (2) on the lobe. This reading is the lift of

the camshaft lobe.

Figure 6A1 – 343

Reinstall

Right-hand Side

1 Select the correct camshaft for the particular installation location. ID markings are on the rear end

of each camshaft. The ID markings are defined as

follows:

• The first five digits refer to the date and time of

production.

• Example = 3L18H.

• Digits six through nine refer to engine

production code.

• LY7 = Alloytec 190 engine.

• The last two digits refer to position:

• LI = left-hand intake.

• LE = left-hand exhaust.

• RI = right-hand intake.

• RE = right-hand exhaust.

Figure 6A1 – 344

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3001 of 6020

Engine Mechanical – V6 Page 6A1–224

Page 6A1–224

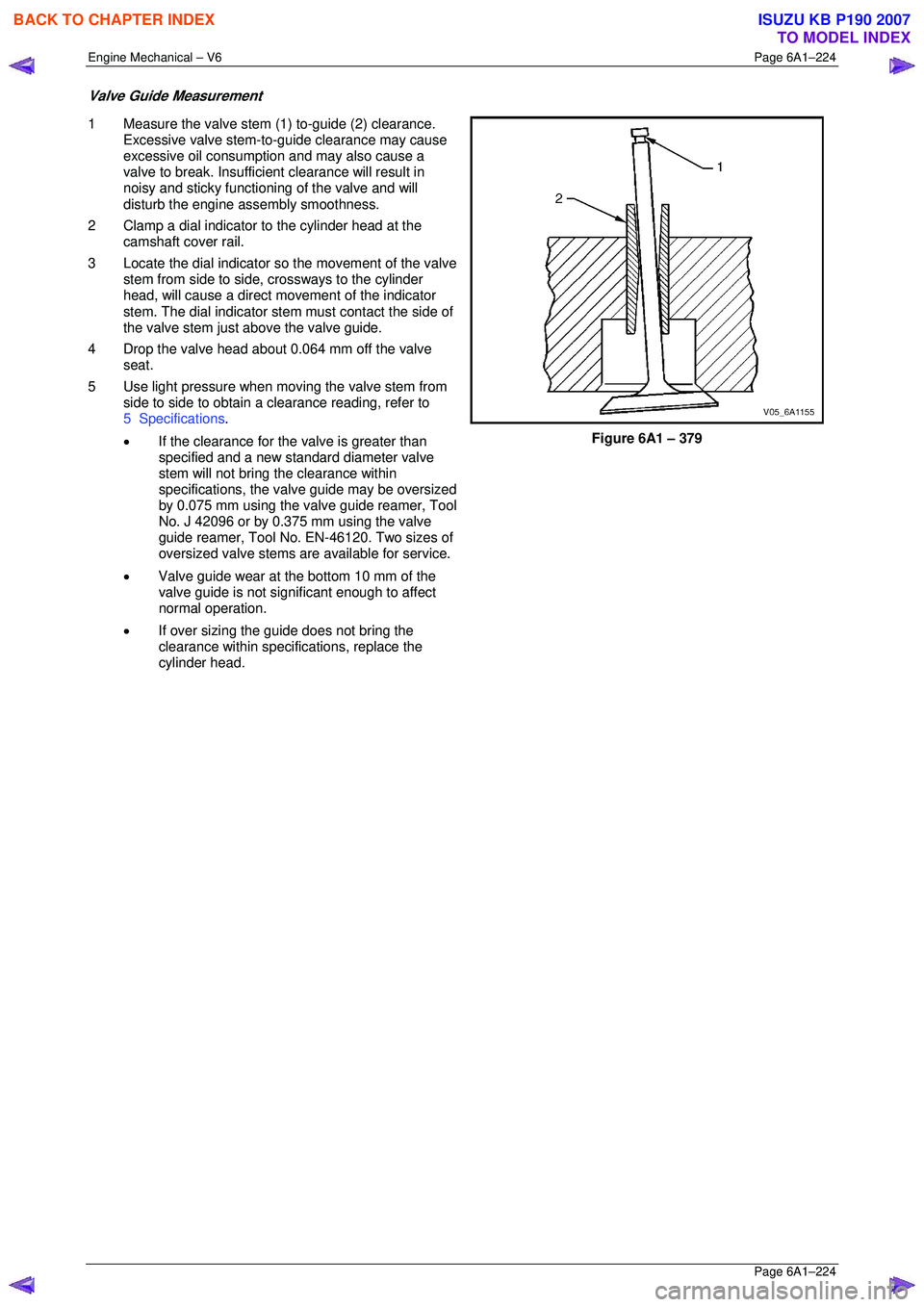

Valve Guide Measurement

1 Measure the valve stem (1) to-guide (2) clearance.

Excessive valve stem-to-guide clearance may cause

excessive oil consumption and may also cause a

valve to break. Insufficient clearance will result in

noisy and sticky functioning of the valve and will

disturb the engine assembly smoothness.

2 Clamp a dial indicator to the cylinder head at the camshaft cover rail.

3 Locate the dial indicator so the movement of the valve

stem from side to side, crossways to the cylinder

head, will cause a direct mo vement of the indicator

stem. The dial indicator stem must contact the side of

the valve stem just above the valve guide.

4 Drop the valve head about 0.064 mm off the valve seat.

5 Use light pressure when moving the valve stem from side to side to obtain a clearance reading, refer to

5 Specifications .

• If the clearance for the valve is greater than

specified and a new st andard diameter valve

stem will not bring the clearance within

specifications, the valv e guide may be oversized

by 0.075 mm using the valve guide reamer, Tool

No. J 42096 or by 0.375 mm using the valve

guide reamer, Tool No. EN-46120. Two sizes of

oversized valve stems are available for service.

• Valve guide wear at the bottom 10 mm of the

valve guide is not significant enough to affect

normal operation.

• If over sizing the guide does not bring the

clearance within specif ications, replace the

cylinder head.

Figure 6A1 – 379

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3004 of 6020

Engine Mechanical – V6 Page 6A1–227

Page 6A1–227

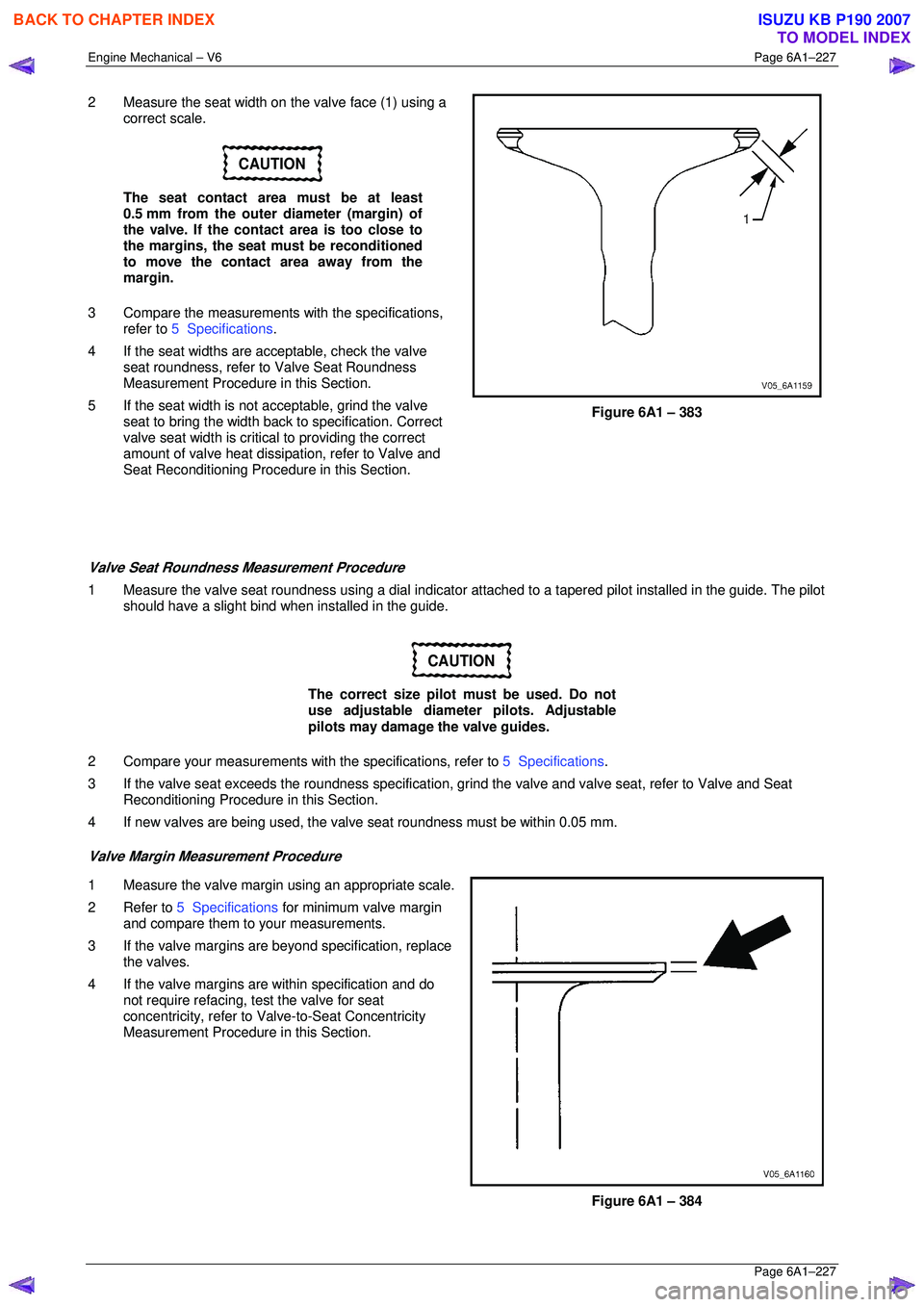

2 Measure the seat width on the valve face (1) using a

correct scale.

CAUTION

The seat contact area must be at least

0.5 mm from the outer diameter (margin) of

the valve. If the contact area is too close to

the margins, the seat must be reconditioned

to move the contact area away from the

margin.

3 Compare the measurements with the specifications,

refer to 5 Specifications .

4 If the seat widths are a cceptable, check the valve

seat roundness, refer to Valve Seat Roundness

Measurement Procedure in this Section.

5 If the seat width is not acceptable, grind the valve

seat to bring the width back to specification. Correct

valve seat width is critical to providing the correct

amount of valve heat dissipat ion, refer to Valve and

Seat Reconditioning Procedure in this Section.

Figure 6A1 – 383

Valve Seat Roundness Measurement Procedure

1 Measure the valve seat roundness using a dial indicator a ttached to a tapered pilot installed in the guide. The pilot

should have a slight bind w hen installed in the guide.

CAUTION

The correct size pilot must be used. Do not

use adjustable diameter pilots. Adjustable

pilots may damage the valve guides.

2 Compare your measurements with the specifications, refer to 5 Specifications.

3 If the valve seat exceeds the roundne ss specification, grind the valve and valve seat, refer to Valve and Seat

Reconditioning Procedure in this Section.

4 If new valves are being used, the valv e seat roundness must be within 0.05 mm.

Valve Margin Measurement Procedure

1 Measure the valve margin using an appropriate scale.

2 Refer to 5 Specifications for minimum valve margin

and compare them to your measurements.

3 If the valve margins are beyond specification, replace the valves.

4 If the valve margins are within specification and do not require refacing, test the valve for seat

concentricity, refer to Valve-to-Seat Concentricity

Measurement Procedure in this Section.

Figure 6A1 – 384

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3022 of 6020

Engine Mechanical – V6 Page 6A1–245

Page 6A1–245

35 Disconnect the harness connector from the transmission, refer to Section 7B1 Manual Transmission – V6 or

Section 7C1, Section 7C2, Section 7C3 or Section 7C4 for automatic transmission.

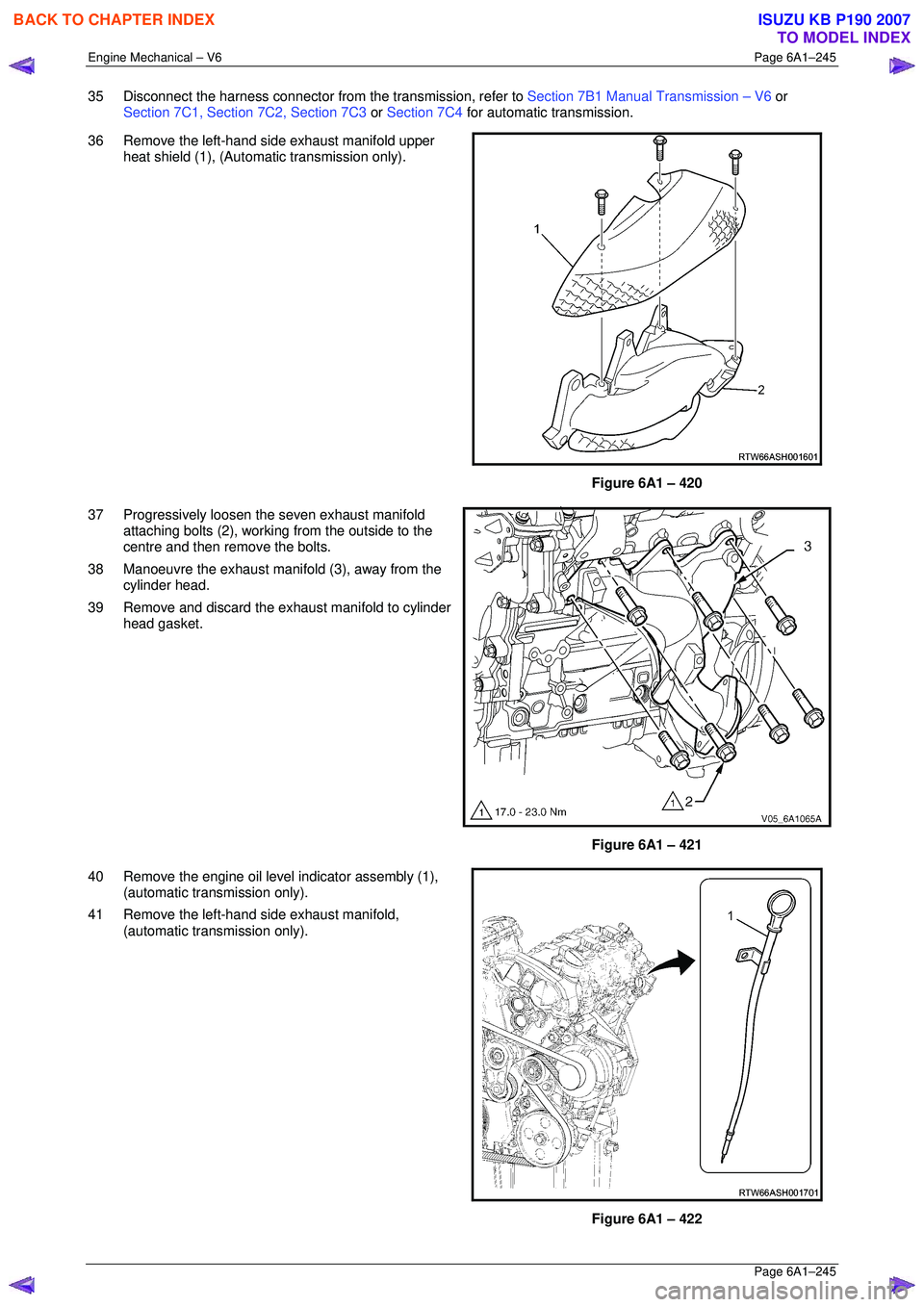

36 Remove the left-hand side exhaust manifold upper heat shield (1), (Automatic transmission only).

Figure 6A1 – 420

37 Progressively loosen the seven exhaust manifold attaching bolts (2), working from the outside to the

centre and then remove the bolts.

38 Manoeuvre the exhaust manifold (3), away from the cylinder head.

39 Remove and discard the exhaust manifold to cylinder head gasket.

Figure 6A1 – 421

40 Remove the engine oil level indicator assembly (1), (automatic transmission only).

41 Remove the left-hand side exhaust manifold, (automatic transmission only).

Figure 6A1 – 422

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3058 of 6020

Engine Mechanical – V6 Page 6A1–281

Page 6A1–281

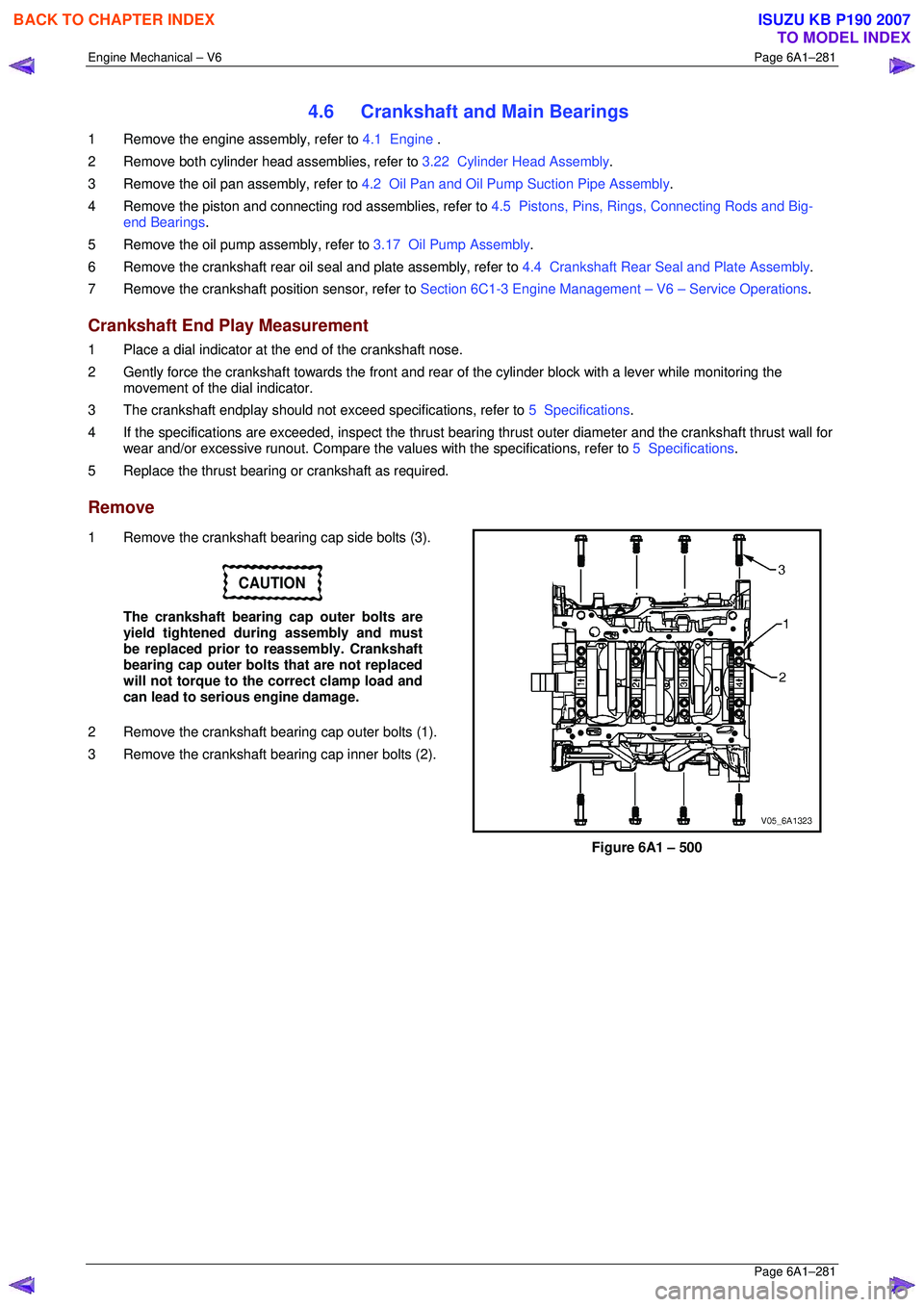

4.6 Crankshaft and Main Bearings

1 Remove the engine assembly, refer to 4.1 Engine .

2 Remove both cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

3 Remove the oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly .

4 Remove the piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-

end Bearings .

5 Remove the oil pump assembly, refer to 3.17 Oil Pump Assembly.

6 Remove the crankshaft rear oil seal and plate assembly, refer to 4.4 Crankshaft Rear Seal and Plate Assembly .

7 Remove the crankshaft position sensor, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

Crankshaft End Play Measurement

1 Place a dial indicator at the end of the crankshaft nose.

2 Gently force the crankshaft towards the front and rear of the cylinder block with a lever while monitoring the

movement of the dial indicator.

3 The crankshaft endplay should not exceed specifications, refer to 5 Specifications.

4 If the specifications are ex ceeded, inspect the thrust bearing thrust outer diameter and the crankshaft thrust wall for

wear and/or excessive runout. Compare the va lues with the specifications, refer to 5 Specifications.

5 Replace the thrust bearing or crankshaft as required.

Remove

1 Remove the crankshaft bearing cap side bolts (3).

CAUTION

The crankshaft bearing cap outer bolts are

yield tightened during assembly and must

be replaced prior to reassembly. Crankshaft

bearing cap outer bolts that are not replaced

will not torque to the correct clamp load and

can lead to serious engine damage.

2 Remove the crankshaft bearing cap outer bolts (1).

3 Remove the crankshaft bearing cap inner bolts (2).

Figure 6A1 – 500

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3063 of 6020

Engine Mechanical – V6 Page 6A1–286

Page 6A1–286

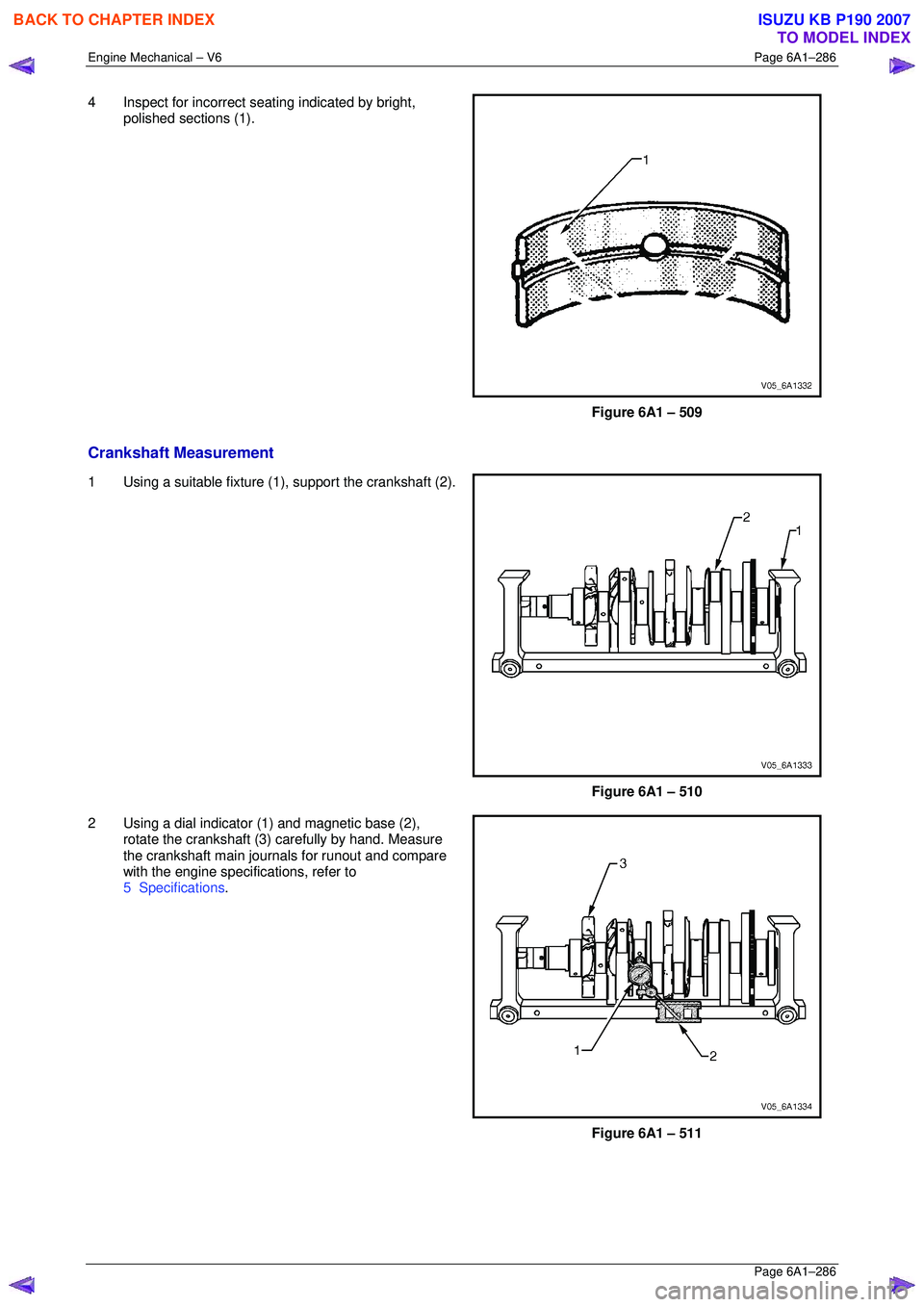

4 Inspect for incorrect seating indicated by bright,

polished sections (1).

Figure 6A1 – 509

Crankshaft Measurement

1 Using a suitable fixture (1 ), support the crankshaft (2).

Figure 6A1 – 510

2 Using a dial indicator (1) and magnetic base (2), rotate the crankshaft (3) carefully by hand. Measure

the crankshaft main journals for runout and compare

with the engine specifications, refer to

5 Specifications .

Figure 6A1 – 511

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007