fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2360 of 6020

6E–190 ENGINE DRIVEABILITY AND EMISSIONS

8 Using the DVM and check the ignition coil modulepower supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the ignition coil module connector.

3. Check the circuit for open circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 10Go to Step 9

9 Repair the open or short to ground circuit between the “IGN. Coil” fuse (15A) and ignition coil module.

Is the action complete? — Verify repair —

10 Replace the ignition coil module. Was the problem solved? — Verify repair Go to Step 11

11 Is the ECM programmed with the latest software release?

If not, download the latest software to the ECM using

the “SPS (Service Programming System)”.

Was the problem solved? — Verify repair Go to Step 12

12 Replace the ECM. Is the action complete?

IMPORTANT: The replacement ECM must be

programmed. Refer to section of the Service

Programming System (SPS) in this manual.

Following ECM programming, the immobilizer system

(if equipped) must be linked to the ECM. Refer to

section 11 “Immobilizer System-ECM replacement” for

the ECM/Immobilizer linking procedure. — Verify repair —

Step

Action Value(s) Yes No

V

E-18

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2363 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–193

6 Using the DVM and check the purge solenoid valvepower supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the purge solenoid valve connector.

3. Check the circuit for open circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 8Go to Step 7

7 Repair the open or short to ground circuit between the “Engine” fuse (15A) and purge solenoid valve.

Is the action complete? — Verify repair -

8 Using the DVM and check the purge solenoid valve solenoid signal circuit.

Breaker box is available:

1. Ignition “Off”, engine “Off”.

2. Install the breaker box as type A. (ECM disconnected) Refer to 6E-88 page.

3. Disconnect the purge solenoid valve connector.

4. Check the circuit for open or short to ground circuit.

Was the problem found?

Breaker box is not available:

1. Ignition “Off”, engine “Off”.

2. Disconnect the purge solenoid valve connector and ECM connector.

3. Check the circuit for open or short to ground circuit.

Was the problem found?

—Repair faulty

harness and verify repair Go to Step 9

Step Action Value(s) Yes No

V

E-66

2

J1-5Breaker BoxE-66

Ω

1

E-66

E-60(J1)

51

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2365 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–195

DIAGNOSTIC TROUBLE CODE (DTC) P0502 VEHICLE SPEED SENSOR (VSS) CIRCUIT LOW INPUT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The vehicle speed sensor has a magnet rotated by the

transmission output shaft. Attached to the sensor is a

hall effect circuit that interacts with the magnetic field

created by the rotating magnet. A 12-volt operating

supply for the speed sensor hall circuit is supplied from

the meter fuse.

Diagnostic Aids

• Poor connection at ECM: Inspect harness connectors for backed out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal to wire connection.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0502 B Vehicle Speed Sensor Circuit Low Input 1. No DTC relating to MAP sensor, TPS, ECT

sensor, injector control circuit and ignition

control circuit.

2. Engine is running.

3. Vehicle speed is below 3km/h in power condition or 2km/h in deceleration condi-

tion. ECM uses 0km/h condition as substitute.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2367 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–197

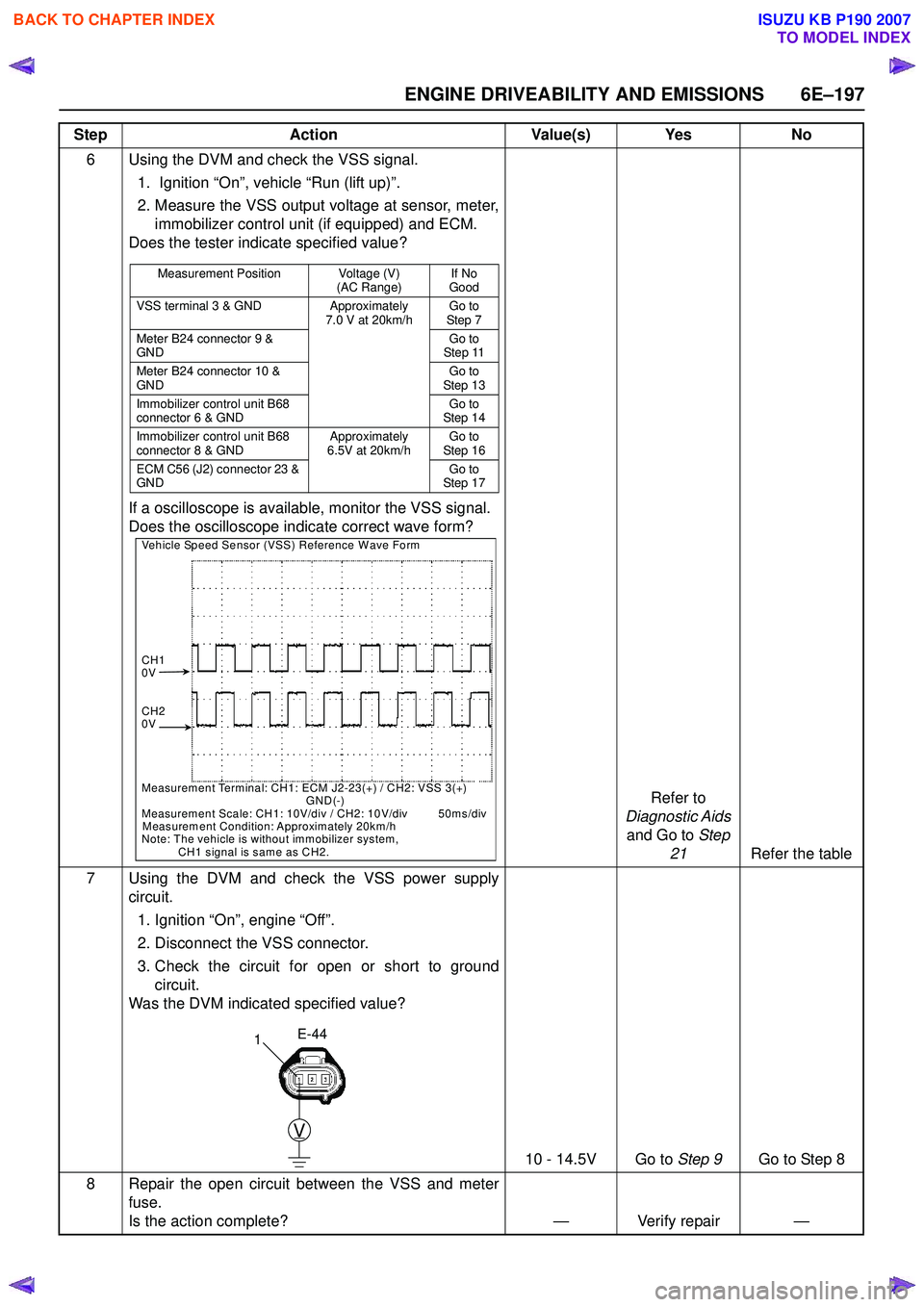

6 Using the DVM and check the VSS signal.1. Ignition “On”, vehicle “Run (lift up)”.

2. Measure the VSS output voltage at sensor, meter, immobilizer control unit (if equipped) and ECM.

Does the tester indicate specified value?

If a oscilloscope is available, monitor the VSS signal.

Does the oscilloscope indicate correct wave form?

Refer to

Diagnostic Aids

and Go to Step

21 Refer the table

7 Using the DVM and check the VSS power supply circuit.

1. Ignition “On”, engine “Off”.

2. Disconnect the VSS connector.

3. Check the circuit for open or short to ground circuit.

Was the DVM indicated specified value?

10 - 14.5V Go to Step 9Go to Step 8

8 Repair the open circuit between the VSS and meter fuse.

Is the action complete? — Verify repair —

Step

Action Value(s) Yes No

Measurement Position Voltage (V)

(AC Range)If No

Good

VSS terminal 3 & GND Approximately 7.0 V at 20km/hGo to

Step 7

Meter B24 connector 9 &

GND Go to

Step 11

Meter B24 connector 10 &

GND Go to

Step 13

Immobilizer control unit B68

connector 6 & GND Go to

Step 14

Immobilizer control unit B68

connector 8 & GND Approximately

6.5V at 20km/h Go to

Step 16

ECM C56 (J2) connector 23 &

GND Go to

Step 17

Vehicle Speed Sensor (VSS) Reference Wave Form

CH1

0V

CH2

0V

Measurement Terminal: CH1: ECM J2-23(+) / CH2: VSS 3(+)

GND(-)

Measurement Scale: CH1: 10V/div / CH2: 10V/div 50ms/div

Measurement Condition: Approximately 20km/h

Note: The vehicle is without immobilizer system,

CH1 signal is same as CH2.

V

E-44

1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2403 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–233

ENGINE CRANKS BUT WILL NOT RUN

DEFINITIONS: Engine cranks, but will not run. (The engine never start.)

NOTE: The replacement ECM must be programmed. Refer to section of the Service Programming System (SPS) in

this manual. Following ECM programming, the immobilizer system (if equipped) must be linked to the ECM.

Refer to section 11 “Immobilizer System-ECM replacement” for the ECM/Immobilizer linking procedure.

NOTE: The vehicle with immobilizer system, this system may be activated. Check the immobilizer system diagosis.

Step Action Value(s) Yes No

1 Was the “ On-Board Diagnostic (OBD) System Check ”

performed? — Go to Step 2Go to

OBD

System Check

2 1. Perform a bulletin search. 2. If a bulletin that addresses the symptom is found,correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom? — Verify repair Go to Step 3

3 Was a visually/physical check performed? —Go to Step 4Go to

Visual /

physical Check.

4 Check the “Ignition coil” fuse (15A) and “ECM” fuse (15A).

Was a fuse blown? — Verify repair Go to Step 5

5 1. Ignition ON 2. Use a DVM to verify that battery voltage at theignition coil fuse, and the ECM fuse.

Was battery voltage presented at the fuses? — Go to Step 6Verify & repair

6 1. Visually/physically inspect for the following conditions:

• Restriction of air intake system. Check for a restricted air filter element, or foreign objects

blocking the air intake system.

• Check for objects blocking the IAC passage or throttle bore, excessive deposits in the throttle

bore and on the throttle plate.

• Check for a condition that causes a large vacuum leak, such as an incorrectly installed or

faulty crankcase ventilation hose/brake booster

hose.

Was a problem found? — Verify repair Go to Step 7

7 1. Using a Tech 2, display the IAC value. 2. Check for a faulty, plugged, or sticking IACoperation.

Was the problem found? — Verify repair Go to Step 8

8 1. Using a Tech 2, display the MAP sensor value. 2. Check for a faulty, plugged, or incorrectly installedMAP sensor.

Was the problem found? — Verify repair Go to Step 9

9 If oscilloscope is available, check the wave form of the CKP signal.

Was the correct wave form found? — Go to Step 12Go to Step 10

10 Check the CKP sensor wire for open or short circuit. Was a problem found? — Verify repair Go to Step 11

11 Replace CKP sensor. Is there still problem? —Replace pulsar

ring. Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2517 of 6020

Engine Mechanical – V6 Page 6A1–38

2.15 Engine Compression Test

A compression pressure test of the engine cylinders determines the condition of the rings, the valves and the head

gasket.

Preliminary Steps

1 Ensure the battery is fully charged.

2 Remove the spark plugs from all cylinders, refer to 6C1-3 Engine Management – V6 – Service Operations.

NOTE

DTCs will set when the fuel system or the ignition

system is disabled and the engine is cranked.

Disregard DTCs that set under this condition.

3 Disable the fuel system by removing the fuel pump relay, refer to 8A Electrical Body & Chassis.

4 Start the engine to use any residual fuel from the fuel lines.

4 Disable the ignition coils by removing fuses 34 and 35, refer to 8A Electrical Body & Chassis .

5 Using Tech 2, command the throttle plate to wide open throttle.

Engine Cylinder Compression Test

1 Install the compression tester to cylinder number 1.

2 W hile observing the compression tester reading, turn the ignition to the START position for several seconds and then allow the ignition to return to the ON position.

3 Record the highest compression reading obtained.

4 Repeat the engine compression test for each cylinder.

Test Result Evaluation

Normal engine compression pressure builds quickly and evenly to over 965 kPa. In addition, the lowest reading of an

engine cylinder should not be less than 70 percent of the highest reading. If any cylinder fails the compression test,

adding 15 ml of engine oil to the suspected cylinder may help isolate the following fault condition.

1 A fault condition in the piston rings will produce the following result:

• A low compression on the first engine cycle

• The compression tends to build-up with the succeeding engine rotation.

• The compression improves with the addition of engine oil.

2 A fault condition in an intake or exhaust valve will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

3 A fault condition in the cylinder head gasket will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

• The suspected cylinders are positioned adjacent to each other.

• The engine oil may be contaminated with engine coolant.

• The engine coolant may be contaminated with engine oil.

Once the fault has been identified, refer to the relevant service procedure and reinstall the removed components.

Using Tech 2, clear DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2527 of 6020

Engine Mechanical – V6 Page 6A1–48

NOTE

Pilling is the small balls (pills) or strings of rubber

in the belt grooves caused by the accumulation of

rubber dust.

Diagnostic Aids

Vibration from the engine may cause a body component or other parts to emit a rumbling noise.

The drive belt may have a condition that cannot be seen or felt. Sometimes the replacement of the belt may be the only

way to confirm the belt is faulty.

If the drive belt has been replaced and the diagnostic table completed, but the rumble is still present only when the drive

belt is installed, an accessory drive component such as the A/C compressor may be the cause. Varying the load to each

accessory drive component in turn, should help isolate which component is causing the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2 Confirms the symptom exists at the time of diagnosis. Other vehicle components may be causing the noise.

3 Confirms the accessory drive belt is the cause of the noise. Drive belt rumbling is often confused with an internal engine noise due to the similarity in the description. Removing the drive belt and operating the engine briefly will

confirm whether or not the noise is related to the drive belt.

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 Inspecting the drive belt is to ensure that it is not causing the noise. Small cracks across the ribs of the drive belt will not cause the noise and are not justification alone to replace the belt. Belt separation can be identified by the

ply of the belt separating and may be seen at the edge of the belt or felt as lumps under the belt.

5 Small amounts of pilling is a normal condition and is deemed acceptable. W hen the pilling is severe (33% of the belt groove depth), the belt does not have a smooth surface to run on and should be replaced.

Diagnostic Table

Step Action Yes No

1 Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to 2.2

Symptoms

2 Confirm the customer complaint. Is there a rumbling noise? Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the rumbling noise still exist? Accessory drive

system OK

Go to 2.2

Symptoms,

and restart the diagnosis Go to Step 4

4 Inspect the accessory drive belt for damage, separation or sections of missing ribs.

Did you find any damaged, separated or missing ribs? Go to Step 7 Go to Step 5

5 Inspect the accessory drive belt for severe pilling (exceeding 33% of the belt groove depth).

Did you find sever pilling? Go to Step 6 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2528 of 6020

Engine Mechanical – V6 Page 6A1–49

Step Action Yes No

6 Clean the drive belt using a suitable wire brush and reinstall to the

engine, refer to 3.5 Accessory Drive Belt.

Did you complete the repairs? Go to Step 8 —

7 Install a new accessory drive belt, refer to 3.5 Accessory Drive Belt.

Did you replace the accessory drive belt? Go to Step 8

—

8 If required, reinstall the accessory drive belt and operate the system to

confirm the repair.

Did you correct the rumbling noise? Accessory drive

system OK Refer to Diagnostic

Aids in this Section

Drive Belt Vibration

Definition

Accessory drive belt vibration can be defined as a drive belt that jumps, shakes or rattles. Accessory drive belt vibration

is usually indicated by one of the following:

• the vibration is engine speed related, or

• the vibration is sensitive to accessory drive system load.

Diagnostic Aids

The accessory drive components such as the A/C compressor or generator can have an affect on engine vibration.

To aid in locating which component is causing the vibration, vary the load to each accessory drive component in turn and

note the effect it has on the vibration if any.

Test Description

The numbers below refer to steps in the diagnostic table.

2 Confirms the symptom exists at the time of diagnosis. Other vehicle components may be causing the noise.

3 Confirms the accessory drive belt is the cause of the noise. Drive belt rumbling is often confused with an internal engine noise due to the similarity in the description. Removing the drive belt and operating the engine briefly will

confirm whether or not the noise is related to the drive belt.

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 The drive belt may cause a vibration. Inspecting the drive belt is considerably easier while the drive belt is removed.

6 Inspecting the fasteners can eliminate the possibility that an incorrect fastener has been installed.

8 This step should only be performed if the coolant pump is driven by the drive belt. Inspect the coolant pump for a bent shaft. Also inspect the coolant pump bearings for smooth operation and excessive play. Compare the coolant

pump with a known good pump.

9 Accessory drive component brackets that are bent, cracked or loose may put extra strain on the accessory component causing it to vibrate.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2822 of 6020

Engine Mechanical – V6 Page 6A1–45

Page 6A1–45

2.15 Engine Compression Test

A compression pressure test of the engine cylinders determines the condition of the rings, the valves and the head

gasket.

Preliminary Steps

1 Ensure the battery is fully charged.

2 Remove the spark plugs from all cylinders, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

NOTE

DTCs will set when the fuel system or the ignition

system is disabled and the engine is cranked.

Disregard DTCs that set under this condition.

3 Disable the fuel system by removi ng the fuel pump relay, refer to Section 8A Electrical Body & Chassis .

4 Start the engine to use any resi dual fuel from the fuel lines.

4 Disable the ignition coils by removing fuses 34 and 35, refer to Section 8A Electrical Body & Chassis .

5 Using Tech 2, command the throttle plate to wide open throttle.

Engine Cylinder Compression Test

1 Install the compression tester to cylinder number 1.

2 While observing the compression tester reading, turn t he ignition to the START position for several seconds and

then allow the ignition to return to the ON position.

3 Record the highest compression reading obtained.

4 Repeat the engine compression test for each cylinder.

Test Result Evaluation

Normal engine compression pressure builds quickly and evenly to over 965 kPa. In addition, the lowest reading of an

engine cylinder should not be less than 70 per cent of the highest reading. If any cylinder fails the compression test,

adding 15 ml of engine oil to the suspected cylinder may help isolate the following fault condition.

1 A fault condition in the piston rings will produce the following result:

• A low compression on the first engine cycle

• The compression tends to build-up with the succeeding engine rotation.

• The compression improves with the addition of engine oil.

2 A fault condition in an intake or exhaus t valve will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

3 A fault condition in the cylinder head gasket will produce the following result:

• A low compression on the first engine cycle

• The compression does not build with the succeeding engine rotation.

• The compression does not improve with the addition of engine oil.

• The suspected cylinders are pos itioned adjacent to each other.

• The engine oil may be contaminated with engine coolant.

• The engine coolant may be cont aminated with engine oil.

Once the fault has been identified, refe r to the relevant service procedure and reinstall the removed components.

Using Tech 2, clear DTCs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2835 of 6020

Engine Mechanical – V6 Page 6A1–58

Page 6A1–58

Drive Belt Rumble

Definition

Accessory drive belt rumble can be defined as a low pitch tapping, knocking or thumping noise heard at or just above

idle, once per rotation of the drive belt or a specific co mponent. Drive belt rumble is generally caused by one of the

following:

• pilling or strings in the drive belt grooves,

• separation of the drive belt, or

• a damaged or faulty drive belt.

NOTE

Pilling is the small balls (p ills) or strings of rubber

in the belt grooves caused by the accumulation of

rubber dust.

Diagnostic Aids

Vibration from the engine may cause a body component or other parts to emit a rumbling noise.

The drive belt may have a condition that cannot be seen or felt. Sometimes the replacement of the belt may be the only

way to confirm the belt is faulty.

If the drive belt has been replaced and the di agnostic table completed, but the rumble is still present only when the drive

belt is installed, an accessory drive component such as t he A/C compressor may be the cause. Varying the load to each

accessory drive component in turn, should help isolate which component is causing the noise.

Test Description

The numbers below refer to steps in the diagnostic table.

2 Confirms the symptom exists at the time of di agnosis. Other vehicle components may be causing the noise.

3 Confirms the accessory drive belt is the cause of the noise. Drive belt rumbling is often confused with an internal

engine noise due to the similarity in the description. Removing the drive belt and operating the engine briefly will

confirm whether or not the noise is related to the drive belt.

CAUTION

When running the engine with the accessory

drive belt removed, the coolant pump will not

be operating and the engine may overheat if

left unsupervised even for a short period.

NOTE

There may also be a number of DTCs set when

running the engine with the accessory drive belt

removed.

4 Inspecting the drive belt is to ensure t hat it is not causing the noise. Small cracks across the ribs of the drive belt

will not cause the noise and are not just ification alone to replace the belt. Belt separation can be identified by the

ply of the belt separating and may be seen at the edge of the belt or felt as lumps under the belt.

5 Small amounts of pilling is a normal condition and is deemed acceptable. When the pilling is severe (33% of the

belt groove depth), the belt does not have a smoot h surface to run on and should be replaced.

Diagnostic Table

Step Action Yes No

1

Did you review the information provided in 2.2 Symptoms, and

perform the required inspections. Go to Step 2 Go to

2.2 Symptoms

2 Confirm the customer compla int. Is there a rumbling noise?

Go to Step 3 Refer to Diagnostic

Aids in this Section

3 1 Remove the drive belt, refer to 3.5 Accessory Drive Belt.

2 Operate the engine for no more than 40 seconds.

Does the rumbling noise still exist? Accessory drive

system OK

Go to 2.2

Symptoms, and

restart the diagnosis Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007