fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3437 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–159

Conditions for Running the DTC

DTCs P0685, P0686 and P0687 run continuously once the following conditions are met:

• The ignition is switched on

• The ignition voltage is 10.0 – 16.0 V.

Conditions for Setting the DTC

The ECM detects a condition that is incorrect for the engine control relay commanded state.

Conditions for Clearing the DTC

The engine control relay control circuit DTCs are Type C DTCs. Refer to 1.4 Diagnostic Trouble Codes in this

Section, for action taken when Type C DTCs set and conditions for clearing Type C DTCs.

Additional Information

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following number refers to the step number in the diagnostic table:

4 Removal of the ECM Fuse 29 enables the ECM to power down completely prior to the test procedure.

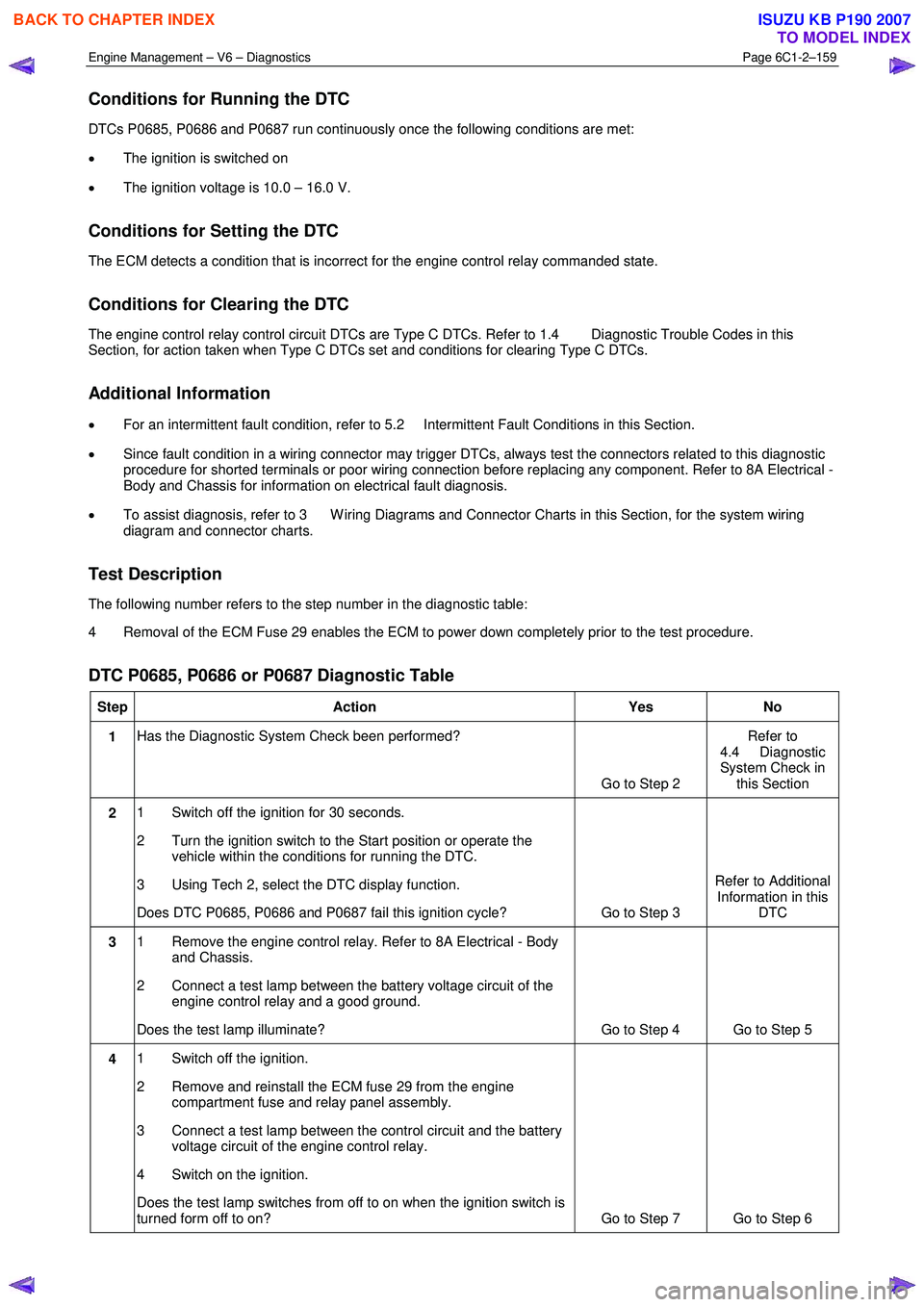

DTC P0685, P0686 or P0687 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Turn the ignition switch to the Start position or operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P0685, P0686 and P0687 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Remove the engine control relay. Refer to 8A Electrical - Body

and Chassis.

2 Connect a test lamp between the battery voltage circuit of the engine control relay and a good ground.

Does the test lamp illuminate? Go to Step 4 Go to Step 5

4 1 Switch off the ignition.

2 Remove and reinstall the ECM fuse 29 from the engine compartment fuse and relay panel assembly.

3 Connect a test lamp between the control circuit and the battery voltage circuit of the engine control relay.

4 Switch on the ignition.

Does the test lamp switches from off to on when the ignition switch is

turned form off to on? Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3457 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–179

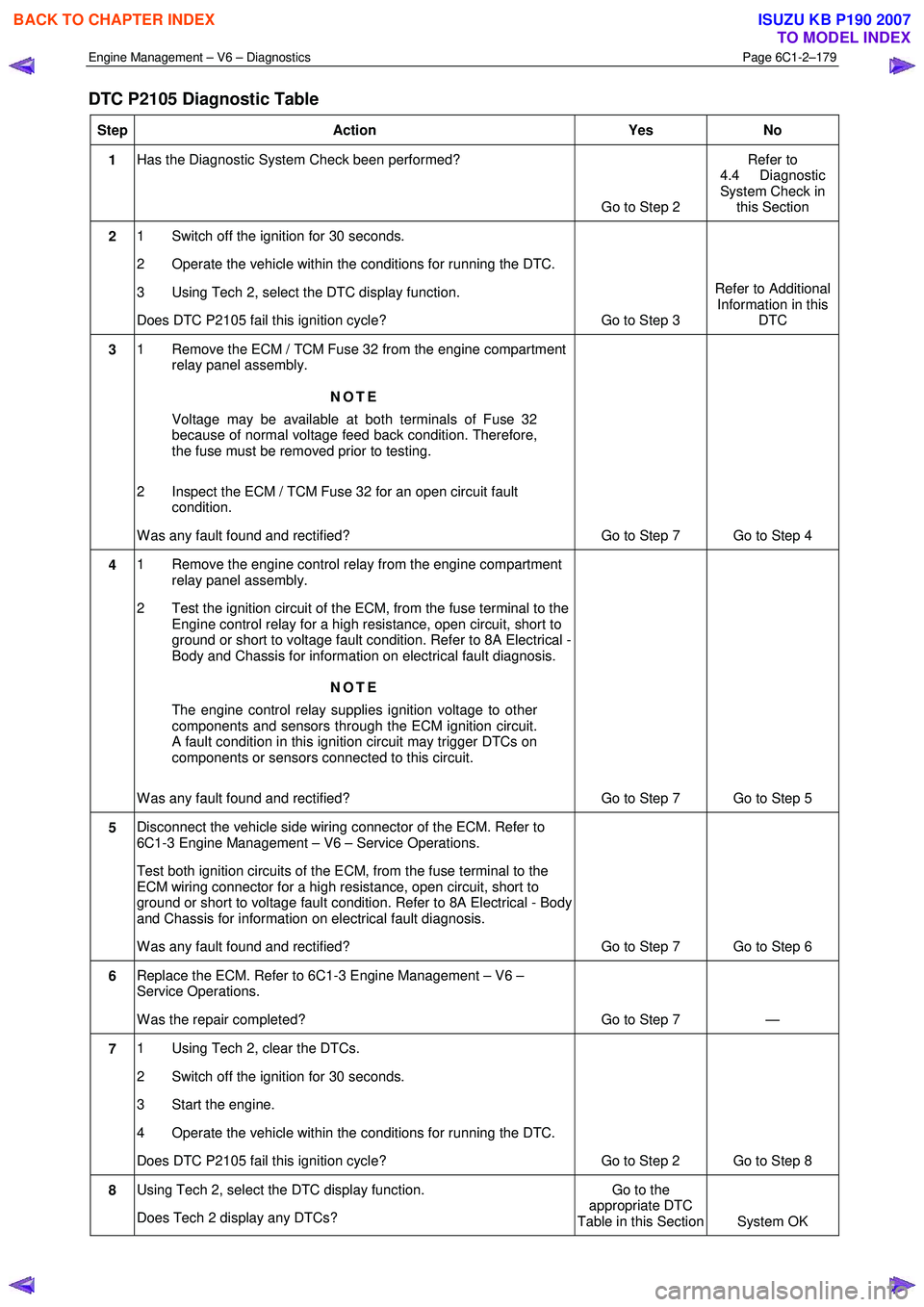

DTC P2105 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P2105 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Remove the ECM / TCM Fuse 32 from the engine compartment

relay panel assembly.

NOTE

Voltage may be available at both terminals of Fuse 32

because of normal voltage feed back condition. Therefore,

the fuse must be removed prior to testing.

2 Inspect the ECM / TCM Fuse 32 for an open circuit fault condition.

W as any fault found and rectified? Go to Step 7 Go to Step 4

4 1 Remove the engine control relay from the engine compartment

relay panel assembly.

2 Test the ignition circuit of the ECM, from the fuse terminal to the Engine control relay for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

NOTE

The engine control relay supplies ignition voltage to other

components and sensors through the ECM ignition circuit.

A fault condition in this ignition circuit may trigger DTCs on

components or sensors connected to this circuit.

W as any fault found and rectified? Go to Step 7 Go to Step 5

5 Disconnect the vehicle side wiring connector of the ECM. Refer to

6C1-3 Engine Management – V6 – Service Operations.

Test both ignition circuits of the ECM, from the fuse terminal to the

ECM wiring connector for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 7 Go to Step 6

6 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 7 —

7 1 Using Tech 2, clear the DTCs.

2 Switch off the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the conditions for running the DTC.

Does DTC P2105 fail this ignition cycle? Go to Step 2 Go to Step 8

8 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs? Go to the

appropriate DTC

Table in this Section System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3460 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–182

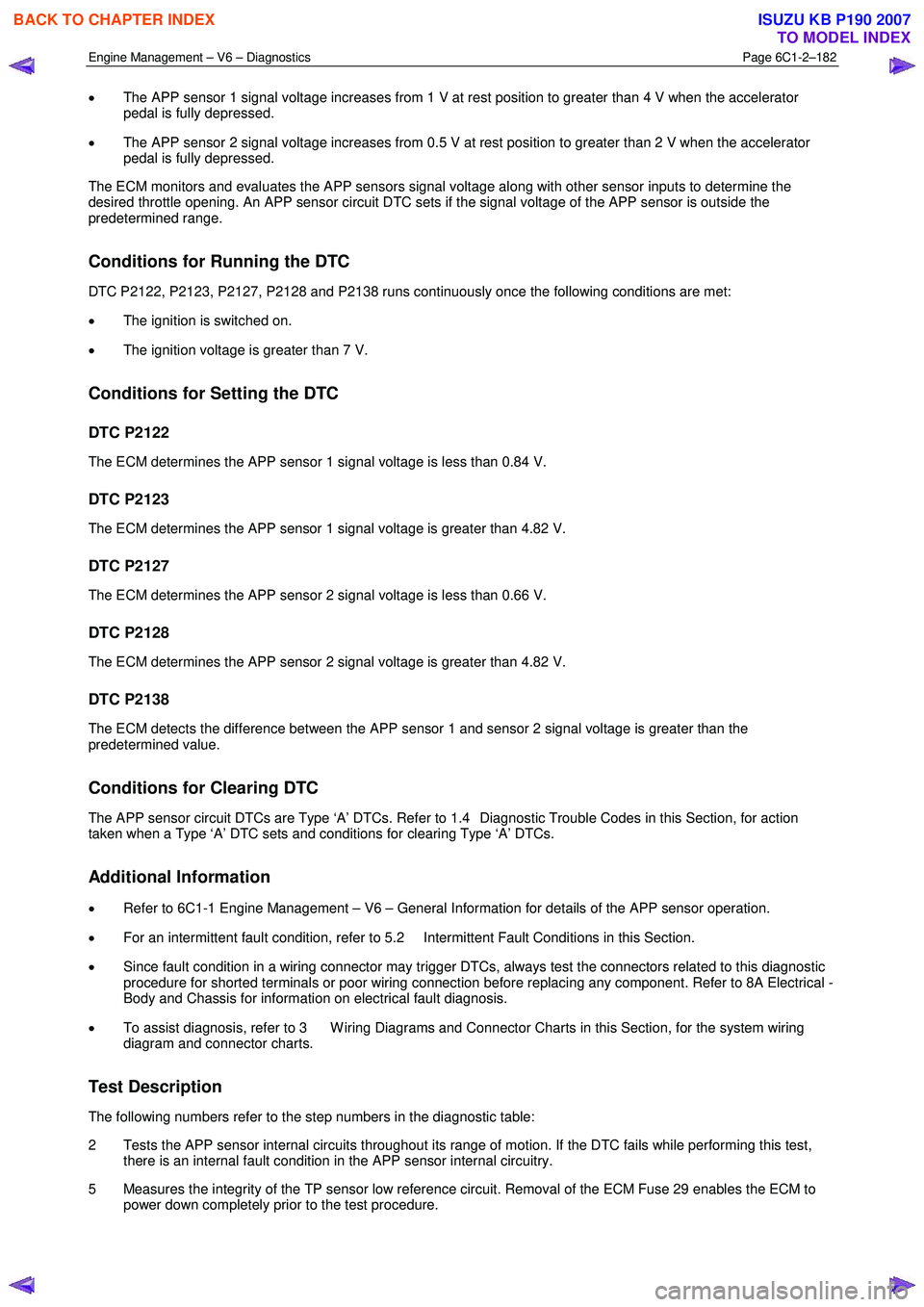

• The APP sensor 1 signal voltage increases from 1 V at rest position to greater than 4 V when the accelerator

pedal is fully depressed.

• The APP sensor 2 signal voltage increases from 0.5 V at rest position to greater than 2 V when the accelerator

pedal is fully depressed.

The ECM monitors and evaluates the APP sensors signal voltage along with other sensor inputs to determine the

desired throttle opening. An APP sensor circuit DTC sets if the signal voltage of the APP sensor is outside the

predetermined range.

Conditions for Running the DTC

DTC P2122, P2123, P2127, P2128 and P2138 runs continuously once the following conditions are met:

• The ignition is switched on.

• The ignition voltage is greater than 7 V.

Conditions for Setting the DTC

DTC P2122

The ECM determines the APP sensor 1 signal voltage is less than 0.84 V.

DTC P2123

The ECM determines the APP sensor 1 signal voltage is greater than 4.82 V.

DTC P2127

The ECM determines the APP sensor 2 signal voltage is less than 0.66 V.

DTC P2128

The ECM determines the APP sensor 2 signal voltage is greater than 4.82 V.

DTC P2138

The ECM detects the difference between the APP sensor 1 and sensor 2 signal voltage is greater than the

predetermined value.

Conditions for Clearing DTC

The APP sensor circuit DTCs are Type ‘A’ DTCs. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when a Type ‘A’ DTC sets and conditions for clearing Type ‘A’ DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the APP sensor operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 Tests the APP sensor internal circuits throughout its range of motion. If the DTC fails while performing this test, there is an internal fault condition in the APP sensor internal circuitry.

5 Measures the integrity of the TP sensor low reference circuit. Removal of the ECM Fuse 29 enables the ECM to power down completely prior to the test procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3461 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–183

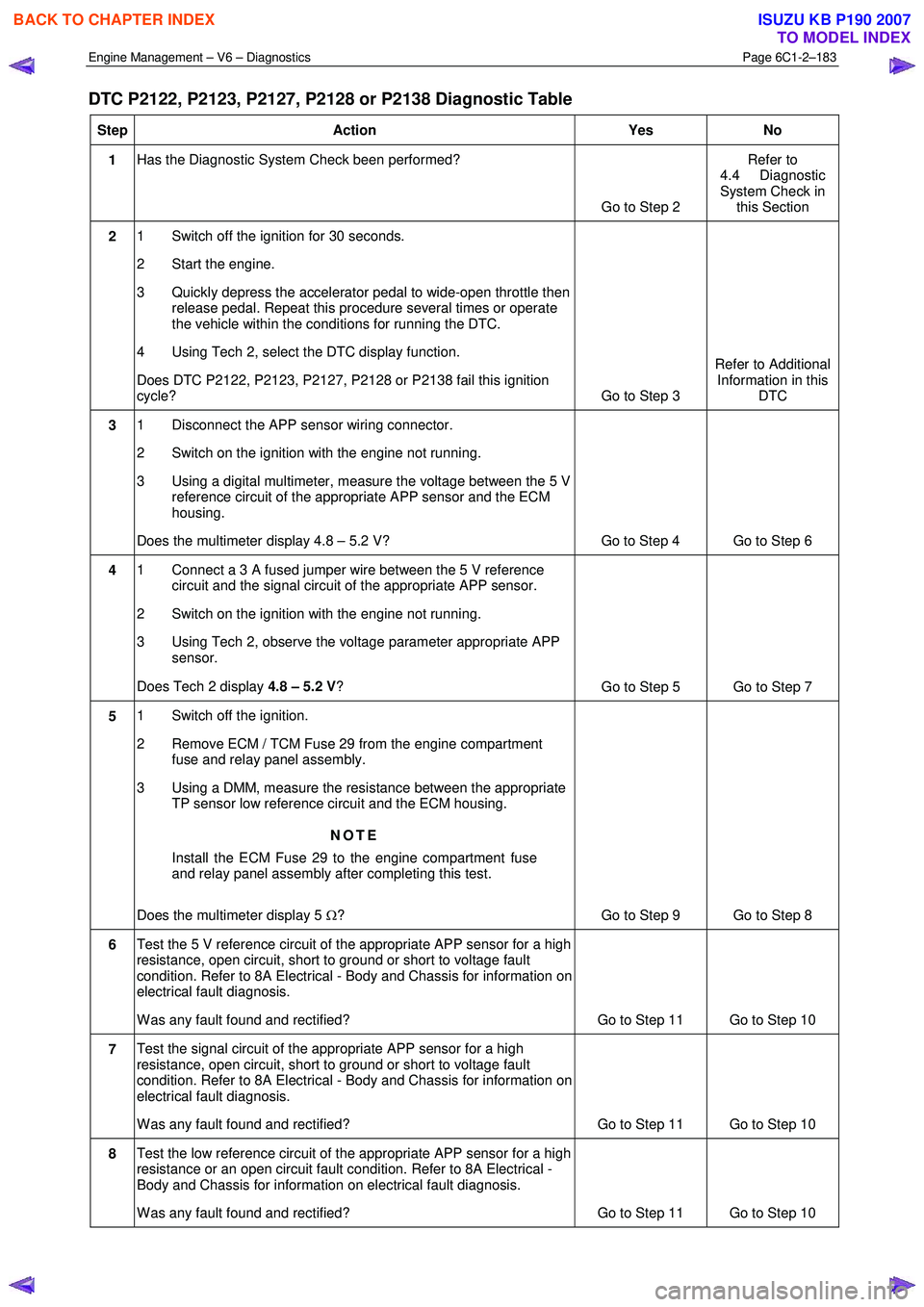

DTC P2122, P2123, P2127, P2128 or P2138 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Start the engine.

3 Quickly depress the accelerator pedal to wide-open throttle then release pedal. Repeat this procedure several times or operate

the vehicle within the conditions for running the DTC.

4 Using Tech 2, select the DTC display function.

Does DTC P2122, P2123, P2127, P2128 or P2138 fail this ignition

cycle? Go to Step 3 Refer to Additional

Information in this DTC

3 1 Disconnect the APP sensor wiring connector.

2 Switch on the ignition with the engine not running.

3 Using a digital multimeter, measure the voltage between the 5 V reference circuit of the appropriate APP sensor and the ECM

housing.

Does the multimeter display 4.8 – 5.2 V? Go to Step 4 Go to Step 6

4 1 Connect a 3 A fused jumper wire between the 5 V reference

circuit and the signal circuit of the appropriate APP sensor.

2 Switch on the ignition with the engine not running.

3 Using Tech 2, observe the voltage parameter appropriate APP sensor.

Does Tech 2 display 4.8 – 5.2 V ?

Go to Step 5 Go to Step 7

5 1 Switch off the ignition.

2 Remove ECM / TCM Fuse 29 from the engine compartment fuse and relay panel assembly.

3 Using a DMM, measure the resistance between the appropriate TP sensor low reference circuit and the ECM housing.

NOTE

Install the ECM Fuse 29 to the engine compartment fuse

and relay panel assembly after completing this test.

Does the multimeter display 5 Ω? Go to Step 9 Go to Step 8

6 Test the 5 V reference circuit of the appropriate APP sensor for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for information on

electrical fault diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

7 Test the signal circuit of the appropriate APP sensor for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for information on

electrical fault diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

8 Test the low reference circuit of the appropriate APP sensor for a high

resistance or an open circuit fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3484 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–206

• The engine is running.

Conditions for Setting the DTC

DTC P2227

The ECM detects the BARO pressure changed greater than 5 kPa within 20 seconds or the BARO pressure changed

greater than 30 kPa since the last ignition cycle.

DTC P2228

The ECM detects the BARO sensor signal voltage is less than 0.20 V.

DTC P2229

The ECM detects the BARO sensor signal voltage is greater than 4.8 V for longer than 2.0 seconds.

Conditions for Clearing DTC

The BARO pressure sensor circuit DTCs are Type ‘B’ DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for

action taken when a Type ‘B’ DTC sets and conditions for clearing Type ‘B’ DTCs.

Additional Information

• Refer to 6C1-1 Engine Management – V6 – General Information for details of the BARO Sensor operation.

• For an intermittent fault condition, refer to 5.2 Intermittent Fault Conditions in this Section.

• Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

• To assist diagnosis, refer to 3 W iring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

4 Test signal circuit of the BARO sensor. This circuit should display a voltage within the specified range.

5 Measures the integrity of the TP sensor low reference circuit. Removal of the ECM Fuse 29 enables the ECM to power down completely prior to the test procedure.

DTC P2227 P2228 or P2229 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.4 Diagnostic

System Check in this Section

2 1 Switch off the ignition for 30 seconds.

2 Operate the vehicle within the conditions for running the DTC.

3 Using Tech 2, select the DTC display function.

Does DTC P2227, P2228 or P2229 fail this ignition cycle? Go to Step 3 Refer to Additional

Information in this DTC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3485 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–207

Step Action Yes

No

3 1 Switch off the ignition.

2 Disconnect the BARO sensor wiring connector.

3 Switch on the ignition with the engine not running.

4 Using a digital multimeter, measure the voltage between the BARO sensor signal circuit and the ECM housing.

Does the multimeter display 4.5 – 5.5 V? Go to Step 4 Go to Step 6

4 1 Switch on the ignition with the engine not running.

2 Using a digital multimeter, measure the voltage between the BARO sensor 5 V reference circuit and the ECM housing.

Does the multimeter display 4.8 – 5.2 V? Go to Step 5 Go to Step 7

5 1 Switch off the ignition.

2 Remove ECM / TCM Fuse 29 from the engine compartment fuse and relay panel assembly.

3 Using a digital multimeter, measure the resistance between the BARO sensor low reference circuit and the ECM housing.

NOTE

Install the ECM Fuse 29 to the engine compartment fuse

and relay panel assembly after completing this test.

Does the multimeter display 5 Ω? Go to Step 9 Go to Step 8

6 Test BARO sensor signal circuit for a high resistance, open circuit,

short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

7 Test the BARO sensor 5 V reference circuit for an open, short to

ground or high resistance fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

NOTE

The BARO sensor shares the 5 V reference circuit with

other sensors. A fault condition in the 5 V reference circuit

may trigger DTCs on sensors that share this circuit. Refer

to 3 W iring Diagrams and Connector Charts in this

Section, to assist diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

8 1 Disconnect the ECM wiring connector.

2 Test the BARO sensor low reference circuit for a high resistance and open circuit fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

W as any fault found and rectified? Go to Step 11 Go to Step 10

9 Replace the BARO sensor. Refer to 6C1-3 Engine Management – V6

– Service Operations.

W as the repair completed? Go to Step 11 —

10 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

W as the repair completed? Go to Step 11 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3492 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–214

3 Are DTCs relating to the reference circuit of the HO2S

also set?

(e.g. 7.10 DTC P0130, P0131, P0132, P0135, P0137,

P0138, P0140, P0141, P0150 P0151, P0152, P0155,

P0157, P0158, P0160, P0161, P2243, P2247, P2270,

P2271, P2272, P2273, P2297 or P2298) —

Go to the

appropriate DTC Table in this Section Go to Step 4

4 1 Disconnect the appropriate HO2S wiring

connector.

2 Ignition ON, engine OFF.

3 Using a digital multimeter, measure the voltage between the input pump current circuit and a

good ground.

Is the voltage more than the specified value? 50 mV

Go to Step 8 Go to Step 5

5 1 Ignition ON, engine OFF.

2 Using a digital multimeter, measure the voltage between the pump current circuit and a good

ground.

is the voltage display more than the specified value? 50 mV

Go to Step 8 Go to Step 6

6 1 Connect a 3 A fused jumper wire between the

HO2S reference signal circuit and the low

reference circuit.

2 Ignition ON, engine OFF.

3 Using a digital multimeter, measure the voltage between the input pump current circuit and a

good ground.

Is the voltage reading within the specified range? 4.8 – 5.2 V

Go to Step 7 Go to Step 8

7 1 Connect a 3 A fused jumper wire between the

HO2S reference signal circuit and the low

reference circuit.

2 Ignition ON, engine OFF.

3 Using a digital multimeter, measure the voltage between the pump current circuit and a good

ground.

Is the voltage reading within the specified range? 4.8 – 5.2 V

Go to Step 9 Go to Step 10

8 1 Test the input pump current and the pump

current circuit of the HO2S for a high resistance,

open circuit, short to ground, short to voltage or

shorted together fault condition. Refer to 8A

Electrical-Body and Chassis for information on

electrical fault diagnosis.

W as any fault found and rectified? —

Go to Step 12 Go to Step 11

9 1 Test or inspect for the following conditions that

may cause the HO2S to detect an incorrect

air / fuel mixture:

• Lean or rich fuel injector fuel delivery,

• Contaminated fuel,

• Low fuel line pressure,

• Exhaust leak near the HO2S, and

• Leak in the crankcase or vacuum line.

W as any fault found and rectified? —

Go to Step 12 Go to Step 10

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3495 of 6020

Engine Management – V6 – Diagnostics Page 6C1-2–217

Low Reference 2.2 – 2.7 V

Pump Current Less than 0.5 A

Input Pump Current Less than 0.5 A

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2 This step determines if the condition exists. The HO2S lambda parameter should react immediately to the changes in throttle position when performing this test.

5 This step determines if there is a condition with the pumping current circuit. Connecting a jumper wire between the reference voltage and the low reference circuits causes the ECM to command the pumping current and the input

pumping current circuits.

DTC P2626, P2627, P2628, P2629, P2630 or P2631 Diagnostic Table

Step Action Value(s) Yes No

1

Has the Diagnostic System Check been completed? —

Go to Step 2 Refer to

4.4 Diagnostic System Check

2 1 Start engine and allow to reach operating

temperature.

2 Cycle the throttle from idle to wide open throttle (W OT), 3 times within 5 seconds.

3 Use Tech 2 to observe the affected HO2S lambda value

Does the affected HO2S lambda value react

immediately to the above action? —

Go to Step 3 Go to Step 4

3 1 Observe the Freeze Frame / Failure Records for

this DTC.

2 Turn OFF the ignition for 30 seconds.

3 Start the engine.

4 Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame / Failure Records.

Does P2626 P2627, P2628, P2629, P2630 or P2631

fail this ignition? —

Go to Step 4 Go to Additional

Information in this DTC

4

Is DTC P0131, P0132, P0151 or P0152 also set? —

Go to the

appropriate DTC Table in this Section Go to Step 5

5 1 Ignition OFF.

2 Disconnect the appropriate heated oxygen sensor (HO2S).

3 Ignition ON, engine OFF.

4 Connect a 3-amp fused jumper wire between the reference voltage circuit and the low reference

circuit of the HO2S.

5 Measure the voltage between the pump current circuit and a good ground.

Is the voltage more than the specified value? 1.0 V

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3530 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–6

Basic Diagnostic Tools Required

Use of incorrect electrical circuit diagnostic

tools when performing certain service

procedures could result in incorrect

diagnostic results or damage to components.

The following electrical circuit testing tools are required to perform the diagnostic procedures detailed in this Section:

• Test lamp, refer to 8A Electrical – Body and Chassis for further information.

• Digital multimeter with 10 M Ω ohms impedance, refer to 8A Electrical – Body and Chassis for further information.

• Connector test adapter kit Tool No. J35616-A.

1.3 Service Operations Not Covered In This

Section

There are situations where components and/or procedures related to the powertrain management system are covered in

other Sections of the service documentation. To aid technicians in locating the necessary service procedures for these

components and/or procedures, refer to the stated references.

Air-conditioning System

For A/C pressure switch replacement procedure, refer to 2A Heater and Air-conditioning.

Electrical Components

For the following electrical system component replacement procedures, refer to the appropriate Sections as follows:

• Extended brake pedal travel switch and stop lamp switch service operations, refer to 5C Brakes.

• Fuse and relay locations, refer to 8A Electrical-Body and Chassis.

• Cruise control switch assembly service operations, refer to 8C Cruise Control – HFV6.

• Powertrain interface module PIM removal and installation procedure, refer to 6E1 Powertrain Interface Module – V6.

• Neutral start and back-up lamp switch, refer to 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

• Vehicle speed sensor service operations, refer to:

− 7C4 Automatic Transmission – 4L60E – On-vehicle Servicing

− 7B1 Manual Transmission – V6

Fuel System

For the following fuel system component replacement procedures, refer to 6C Fuel System – V6.

• Fuel system cleaning,

• Fuel system leak and pressure test,

• Fuel feed hose to fuel rail replacement,

• Fuel line quick connect fittings,

• Evaporative emission control canister,

• Fuel filter,

• Fuel hose / pipes layout,

• Fuel pump motor assembly and fuel pressure regulator assembly,

• Fuel sender assembly service operations.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3551 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–27

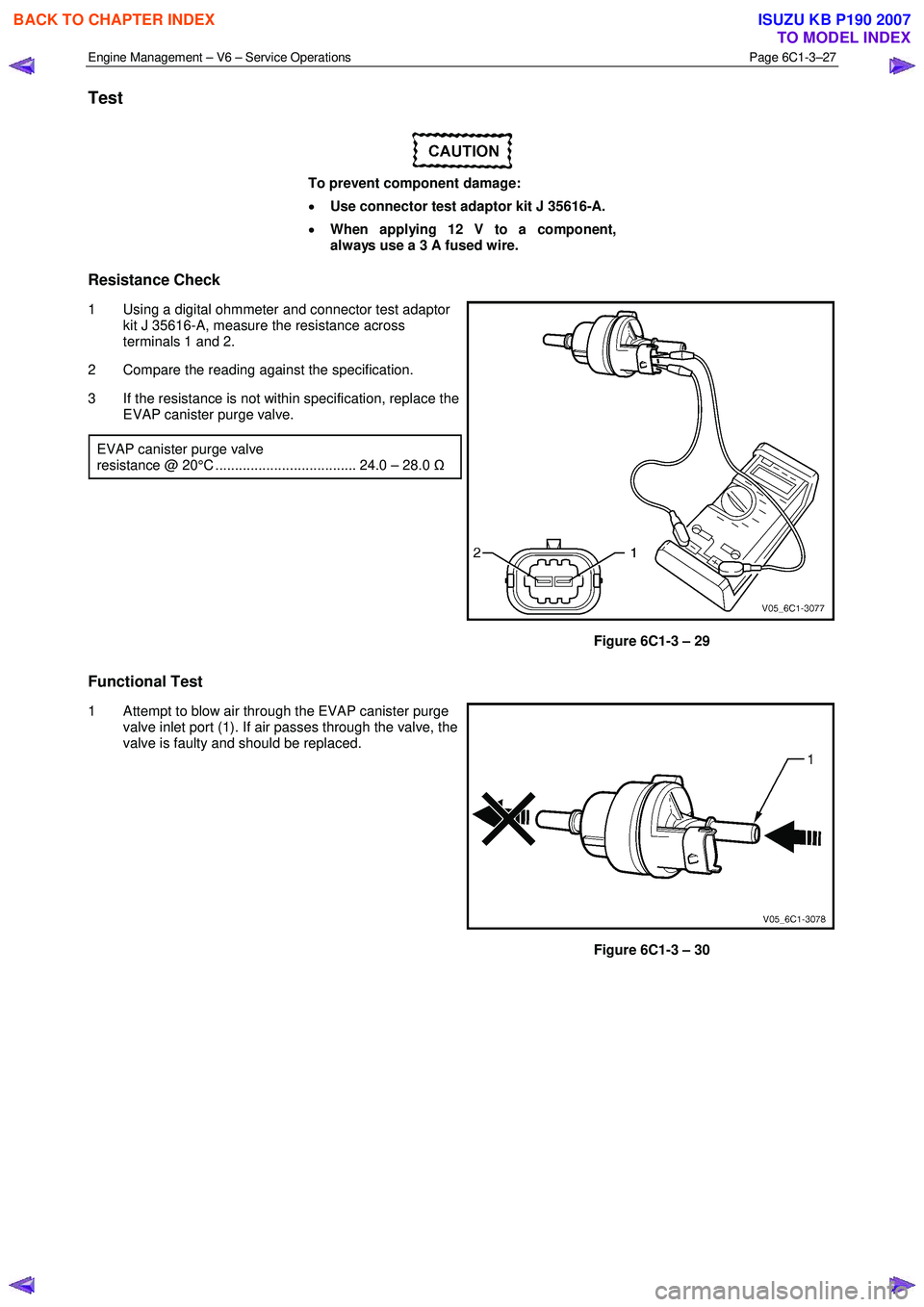

Test

To prevent component damage:

• Use connector test adaptor kit J 35616-A.

• When applying 12 V to a component,

always use a 3 A fused wire.

Resistance Check

1 Using a digital ohmmeter and connector test adaptor

kit J 35616-A, measure the resistance across

terminals 1 and 2.

2 Compare the reading against the specification.

3 If the resistance is not within specification, replace the EVAP canister purge valve.

EVAP canister purge valve

resistance @ 20°C .................................... 24.0 – 28.0 Ω

Figure 6C1-3 – 29

Functional Test

1 Attempt to blow air through the EVAP canister purge

valve inlet port (1). If air passes through the valve, the

valve is faulty and should be replaced.

Figure 6C1-3 – 30

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007