fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1831 of 6020

6E-214 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Connect a test lamp between the control

circuit (pin 1 of E-67) and battery voltage.

2. Perform the Swirl Control Solenoid Test with a scan tool.

3. Command the solenoid valve ON and OFF.

Does the test lamp turn ON and OFF with each

command (if test is aborted, go to Step 5)? —

Go to Step 9 Go to Step 5

5 Does the test lamp remain illuminated with each

command? —

Go to Step 8 Go to Step 7

6 Repair the open circuit or high resistance between

the Engine (10A) fuse and the solenoid valve (pin 2

of E-67). Check the Engine (10A) fuse first.

Did you complete the repair? —

Go to Step 13

—

71. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 10

8 1. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for a short to ground.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

9 1. Inspect for an intermittent and for poor

connections at the harness connector of the

solenoid valve (pins 1 and 2 of E-67).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 11

10 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor connection at harness connector of the ECM

(pin 67 of E-90).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 13 Go to Step 12

11 Replace the swirl control solenoid valve.

Did you complete the replacement? —

Go to Step 13

—

12Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 13

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1832 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-215

Circuit/ System Testing DTC P0662

131. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Turn ON the ignition, with the engine OFF.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 14

14 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step Action Value(s) Yes No

Step

Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition.

2. Disconnect the swirl control solenoid valve harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Is DTC P0661 set, but not P0662? —

Go to Step 5 Go to Step 4

4 1. Test the control circuit between the ECM (pin

67 of E-90) and the solenoid valve (pin 1 of E-

67) for a short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Step 6

5 Replace the swirl control solenoid valve.

Did you complete the replacement? —

Go to Step 7

—

6Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 7

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1874 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-257

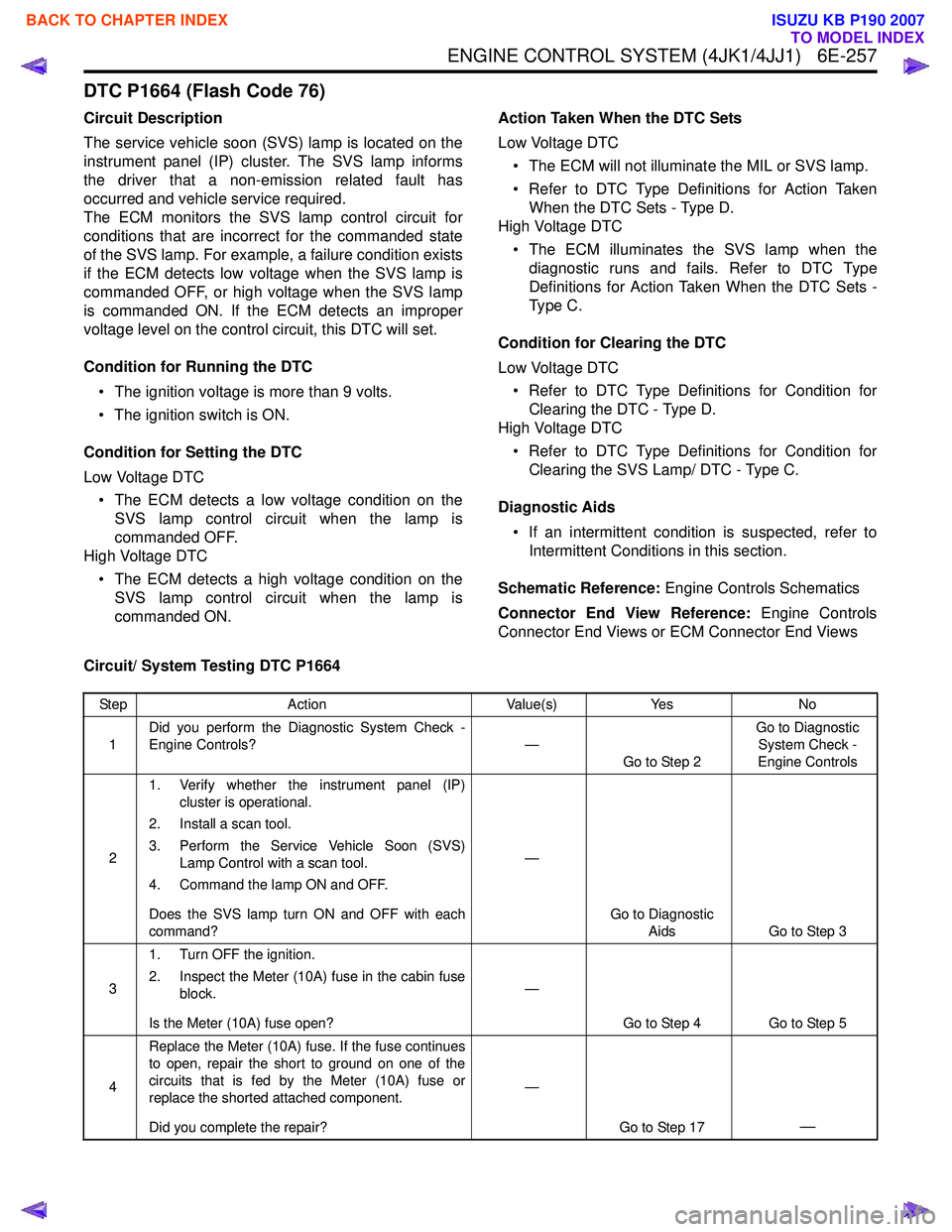

DTC P1664 (Flash Code 76)

Circuit Description

The service vehicle soon (SVS) lamp is located on the

instrument panel (IP) cluster. The SVS lamp informs

the driver that a non-emission related fault has

occurred and vehicle service required.

The ECM monitors the SVS lamp control circuit for

conditions that are incorrect for the commanded state

of the SVS lamp. For example, a failure condition exists

if the ECM detects low voltage when the SVS lamp is

commanded OFF, or high voltage when the SVS lamp

is commanded ON. If the ECM detects an improper

voltage level on the control circuit, this DTC will set.

Condition for Running the DTC • The ignition voltage is more than 9 volts.

• The ignition switch is ON.

Condition for Setting the DTC

Low Voltage DTC • The ECM detects a low voltage condition on the SVS lamp control circuit when the lamp is

commanded OFF.

High Voltage DTC

• The ECM detects a high voltage condition on the SVS lamp control circuit when the lamp is

commanded ON. Action Taken When the DTC Sets

Low Voltage DTC • The ECM will not illuminate the MIL or SVS lamp.

• Refer to DTC Type Definitions for Action Taken When the DTC Sets - Type D.

High Voltage DTC

• The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C.

Condition for Clearing the DTC

Low Voltage DTC • Refer to DTC Type Definitions for Condition for Clearing the DTC - Type D.

High Voltage DTC

• Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P1664

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Verify whether the instrument panel (IP)

cluster is operational.

2. Install a scan tool.

3. Perform the Service Vehicle Soon (SVS) Lamp Control with a scan tool.

4. Command the lamp ON and OFF.

Does the SVS lamp turn ON and OFF with each

command? —

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition.

2. Inspect the Meter (10A) fuse in the cabin fuse block.

Is the Meter (10A) fuse open? —

Go to Step 4 Go to Step 5

4 Replace the Meter (10A) fuse. If the fuse continues

to open, repair the short to ground on one of the

circuits that is fed by the Meter (10A) fuse or

replace the shorted attached component.

Did you complete the repair? —

Go to Step 17

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1875 of 6020

6E-258 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

51. Turn OFF the ignition.

2. Disconnect the ECM J-2 (C-58) harness connector.

3. Turn ON the ignition, with the engine OFF.

Is the SVS lamp OFF? —

Go to Sep 6 Go to Step 12

6 1. Remove the Meter (10A) fuse that supplies

voltage to the SVS lamp.

2. Turn ON the ignition, with the engine OFF.

3. Measure the voltage from the SVS lamp control circuit in the ECM harness connector

(pin 71 of C-58) to a known good ground.

Is the voltage less than the specified value? 1 volt

Go to Step 7 Go to Step 13

7 1. Turn OFF the ignition.

2. Reinstall the Meter (10A) fuse.

3. Turn ON the ignition, with the engine OFF.

4. Connect a 3-amp fused jumper wire between the ECM harness connector (pin 71 of C-58)

and a known good ground.

Is the SVS lamp illuminated? —

Go to Step 11 Go to Step 8

8 1. Turn OFF the ignition.

2. Remove the IP cluster.

3. Connect a test lamp between the ignition voltage feed circuit of the IP cluster harness

connector (pin 8 of B-24) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 9 Go to Step 14

9 1. Test the control circuit between the ECM (pin

71 of C-58) and the IP cluster (pin 26 of B-23)

for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 17 Go to Step 10

10 1. Inspect for an intermittent and for poor

connections at the harness connector of the

IP cluster (pin 8 of B-24 and pin 26 of B-23).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 17 Go to Step 15

11 1. Inspect for an intermittent and for a poor

connection at the harness connector of the

ECM (pin 71 of C-58).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 17 Go to Step 16

12 Repair the short to ground between the ECM (pin

71 of C-58) and the IP cluster (pin 26 of B-23).

Did you complete the repair? —

Go to Step 17

—

13Repair the short to battery or ignition voltage

between the ECM (pin 71 of C-58) and the IP

cluster (pin 26 of B-23).

Did you complete the repair? —

Go to Step 17

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1876 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-259

14Repair the open circuit or high resistance on the

ignition voltage feed circuit between the Meter

(10A) fuse and the IP cluster (pin 8 of B-24).

Did you complete the repair? —

Go to Step 17

—

15Repair or replace the IP cluster.

Did you complete the repair or replacement? —

Go to Step 17—

16Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 17

—

171. Reconnect all previously disconnected fuse or

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Perform the SVS Lamp Control with a scan tool.

5. Command the lamp ON and OFF.

Does the SVS lamp turn ON and OFF with each

command? —

Go to Step 18 Go to Step 3

18 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1881 of 6020

6E-264 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

41. Turn OFF the ignition.

2. Disconnect the APP sensor harness connector.

3. Connect a DMM between the 5 volts reference circuit (pin 10 of C-40) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 5 Go to Step 6

5 Connect a 3-amp fused jumper wire between the 5

volts reference circuit and the signal circuit (pins 5

and 10 of C-40).

Is the APP Sensor 1 parameter more than the

specified value? 4.7 volts

Go to Step 8 Go to Step 7

6 1. Test the 5 volts reference circuit between the

ECM (pin 11 of C-58) and the APP sensor (pin

10 of C-40) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

7 1. Test the signal circuit between the ECM (pin

12 of C-58) and the APP sensor (pin 5 of C-

40) for the following conditions:

• An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

8 1. Inspect for an intermittent and for poor

connections at the harness connector of the

APP sensor (pins 5 and 10 of C-40).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 10

9 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the

ECM (pins 11 and 12 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

10 Replace the APP sensor. Refer to APP Sensor

Replacement.

Did you complete the replacement? —

Go to Step 12

—

11Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 12

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1886 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-269

Circuit/ System Testing DTC P2128

StepAction Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0653 also set? —

Go to DTC P0653 Go to Step 3

3 Fully depress and release the accelerator pedal

while observing the Accelerator Pedal Position

(APP) Sensor 2 parameter with a scan tool.

Does the scan tool indicate more than the specified

value during depressing or releasing the pedal? 4.8 volts

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Disconnect the APP sensor harness connector.

3. Connect a DMM between the signal circuit (pin 9 of C-40) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 5.3 volts

Go to Step 10 Go to Step 5

5 1. Connect a test lamp between the signal circuit

of the sensor 2 harness (pin 9 of C-40) and a

known good ground.

2. Connect a DMM between the probe of the test lamp and a known good ground.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 9 Go to Step 6

6 Connect a 3-amp fused jumper wire between the

signal circuit and the low reference circuit of the

sensor 2 harness (pins 3 and 9 of C-40).

Is the APP Sensor 2 parameter less than the

specified value? 0.2 volts

Go to Step 11 Go to Step 7

7 1. Test the low reference circuit between the

ECM (pin 25 of C-58) and the APP sensor (pin

3 of C-40) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 8

8 1. Test the signal circuit between the ECM (pin

10 of C-58) and the APP sensor (pin 9 of C-

40) for an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 12

9 1. Test the signal circuit between the ECM (pin

10 of C-58) and the APP sensor (pin 9 of C-

40) for short to any 5 volts reference circuit.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1890 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-273

Circuit/ System Testing DTC P2133

121. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Fully depress and release the accelerator pedal while observing the APP Sensor 3

parameter with the scan tool.

Does the scan tool indicate less than the specified

value during depressing or releasing the pedal? 1.2 volts

Go to Step 3 Go to Step 13

13 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step Action Value(s) Yes No

Step

Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0699 also set? —

Go to DTC P0653 Go to Step 3

3 Fully depress and release the accelerator pedal

while observing the Accelerator Pedal Position

(APP) Sensor 3 parameter with a scan tool.

Does the scan tool indicate more than the specified

value during depressing or releasing the pedal? 4.8 volts

Go to Step 4 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Disconnect the APP sensor harness connector.

3. Connect a DMM between the signal circuit (pin 6 of C-40) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value? 5.3 volts

Go to Step 10 Go to Step 5

5 1. Connect a test lamp between the signal circuit

(pin 6 of C-40) and a known good ground.

2. Connect a DMM between the probe of the test lamp and a known good ground.

Is the DMM voltage more than the specified value? 4.7 volts

Go to Step 9 Go to Step 6

6 Connect a 3-amp fused jumper wire between the

signal circuit and the low reference circuit of the

sensor 3 harness (pins 6 and 7 of C-40).

Is the APP Sensor 3 parameter less than the

specified value? 0.2 volts

Go to Step 11 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1911 of 6020

6E-294 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

5Connect a 3-amp fused jumper wire between the 5

volts reference circuit and the signal circuit (pins 2

and 3 of E-40).

Is the BARO Sensor parameter more than the

specified value? 4.7 volts

Go to Step 8 Go to Step 7

6 1. Test the 5 volts reference circuit between the

ECM (pin 19 of E-90) and the BARO sensor

(pin 3 of E-40) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

7 1. Test the signal circuit between the ECM (pin

18 of E-90) and the BARO sensor (pin 2 of E-

40) for the following conditions:

• An open circuit

• A short to ground

• A short to the low reference circuit

• High resistance

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 9

8 1. Inspect for an intermittent and for poor

connections at the harness connector of the

BARO sensor (pins 2 and 3 of E-40).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 10

9 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for poor connections at the harness connector of the

ECM (pins 18 and 19 of E-90).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 12 Go to Step 11

10 Replace the BARO sensor. Refer to BARO Sensor

Replacement.

Did you complete the replacement? —

Go to Step 12

—

11Important:

Replacement ECM must be

programmed and learned.

Replace the ECM. Refer to ECM Replacement.

Did you complete the replacement? —

Go to Step 12

—

121. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 13

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1924 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-307

51. Turn OFF the ignition.

2. Remove the metal bus bar from the glow plugs.

3. Measure resistance of each glow plug between the glow plug terminals and a known

good ground. Make sure to record all

measurements and take them quickly as to

not allow engine temperature changes

between measurements.

Are the resistances within the specified value each

other? 1

Ω

System OK Go to Step 16

6 1. Turn OFF the ignition.

2. Replace the glow relay with the starter relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

4. Connect a test lamp between the metal bus bar (glow plug power supply E-49 connector)

and a known good ground.

5. Perform the Glow Relay Control with a scan tool.

6. Command the relay ON while observing the test lamp.

Does the test lamp turn ON only when commanded

ON? —

Go to Step 14 Go to Step 7

7 Inspect the Glow (60A) slow blow fuse in the

engine room fuse block.

Is the Glow (60A) slow blow fuse open? —

Go to Step 8 Go to Step 9

8 Replace the Glow (60A) slow blow fuse. If the slow

blow fuse continues to open, repair the short to

ground on a circuit fed by the slow blow fuse or

check for a shorted attached component.

Did you complete the repair? —

Go to Step 17

—

91. Turn OFF the ignition.

2. Remove the glow relay.

3. Probe the battery voltage feed circuit of the relay (pin 4 of X-5) with a test lamp that is

connected to a known good ground.

Does the test lamp illuminate? —

Go to Step 10 Go to Step 11

10 1. Probe the voltage supply circuit of glow plugs

(pin 1 of X-5) with a test lamp that is

connected to a known good ground.

2. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate? —

Go to Step 13 Go to Step 12

11 Repair the open circuit or high resistance between

the Glow (60A) slow blow fuse and the glow relay

(pin 4 of X-5).

Did you complete the repair? —

Go to Step 17

—

12Repair the open circuit or high resistance between

the glow relay (pin 1 of X-5) and the glow plugs (E-

49 terminal).

Did you complete the repair? —

Go to Step 17

—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007