dimensions ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2099 of 6020

ENGINE MECHANICAL (C24SE) 6A-85

Piston Pins

Dimensions

Length mm

Diameter mm

61.5 21

Type Shank-fit in con-rod

Clearance

In piston mm

In con-rod mm 2.4L

0.010 to 0.015 0

Installation See operation “Con-rod, Replace”

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2100 of 6020

6A-86 ENGINE MECHANICAL (C24SE)

Con-rod

Permissible, weight variation of con-rods without pistons and bearing shells within an engine 8 g.

As the con-rods have no counterweights, re-working is not possible.

Con-rods must be replaced only as a set.

Crankshaft Grinding Dimensions

Crankshaft

bearing journals

I, II, III, IV, V Guide bearings

III

Con-Rod bearing journals

1 to 4

Con-rod

diameter

in

mm/colour code width

in mm diameter

in mm width

in mm width

in mm

Standard Size for Production and Service

from 57.974

white

to 57.981

over 57.981 green

to 57.988

over 57.988 brown

to 57.995 26.002

25.950

48.988

48.970

26.580

26.450

26.390

26.338

Crankshaft, Cylinder Block (continued)

Crankshaft and con-rod journal Permissible out-of-round:

0.04mm

Out-of-round Permissible variation of

middle crankshaft bearing

journal when seating shaft into

cylinder block: 0.03mm

Permissible end play 0.05 to 0.152mm

Permissible main bearing play Bearing I to V0.015 to 0.04mm

Permissible con-rod play 0.006 to 0.031mm

Permissible con-rod and play 0.07 to 0.24mm

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2446 of 6020

6E–276 ENGINE DRIVEABILITY AND EMISSIONS

• Oil in the combustion chamber.

• The spark plug gap is not set correctly.

If spark plug fouling is excessive, check the fuel and al

system for possible causes of trouble. If fuel and al

system are normal, install spark plugs of a higher heat

range which have the same physical dimensions as the

original equipment spark plugs.

The following symptoms are characteristics of spark

plugs that are running too hot:

• Fuel mixture is too lean.

• Heat range is incorrect.

If vehicle usage does not conform to normal driving

conditions, a more suitable spark plug may be

substituted.

If fuel and al system are normal, in most cases of this

sort, the problem can be corrected by using a colder

type spark plug with the same physical dimensions as

the original equipment spark plug.

3. Check the gaskets for damage and replace if necessary.

4. Measure the spark plug gap. The specification is 1.0 to 1.1mm (0.039 to 0.043").

5. Adjust the spark gap by bending the grounded electrode. Installation

1. Tighten the spark plug to the 25N·m (2.5kgf·m).

2. Push the spark plug cable in until it snaps in.

Installation Procedure 1. Install the spark plug to the cylinder head.

2. Tighten the spark plug with specified tightening torque.

Tightening Torque

• Bolt: 25N·m (2.5kgf·m) 3. Connect the spark plug cable to the spark plug.

4. Connect the negative battery cable.

NOTE: Verify any DTCs (diagnosis Trouble Code) are

not stored after replacement.

Verify proper connection of spark plug cables for each

cylinders.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2693 of 6020

Engine Mechanical – V6 Page 6A1–214

3 Using an inside micrometer, measure the piston pin

bore (1). Compare the result with the piston pin

diameter and piston pin to piston pin bore clearance

listed in the specifications, refer to 5 Specifications.

4 If the clearance is excessive, determine which piece is out of specification and replace as required.

5 Replace the piston if any of its dimensions are out of specification.

6 If the new piston does not meet clearance specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 387

Piston Ring Measurement

1 Measure the piston ring end gap using the following procedure:

a Place the piston ring (1) in the area of the bore where the piston ring will travel, approximately 25 mm below

the deck surface. Ensure the ring is square with the

cylinder bore by positioning the ring with the piston

head.

b Measure the end gap of the piston ring with feeler gauges (2), refer to 5 Specifications.

c If the clearance exceeds the provided specifications, the piston rings must be replaced.

d Repeat the procedure for all piston rings.

Figure 6A1 – 388

2 Measure the piston ring side clearance using the following procedure:

a Roll the piston ring (1) entirely around the piston ring groove. If any binding is caused by the ring groove,

dress the groove with a fine file. If any binding is

caused by a distorted piston ring, replace the ring.

b W ith the piston ring on the piston, use feeler gauges (2) to check clearance at multiple locations.

c Compare the measurements with piston ring side clearance listed in the specifications, refer to 5

Specifications.

d If the clearance is greater than specifications, replace the piston rings.

Figure 6A1 – 389

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2718 of 6020

Engine Mechanical – V6 Page 6A1–239

Inspect

Visual Inspection

NOTE

The following procedure assumes the engine has

been disassembled and cleaned, as described

above.

1 Inspect the crankshaft bearing journals for damage or spun bearings. The crankshaft bearing journals are not repairable and if damage is found, the cylinder block assembly must be replaced.

2 Inspect the primary camshaft chain tensioner mounting surface on the engine block for burrs or any defects that would affect the sealing of the new primary camshaft chain tensioner gasket.

3 Inspect all sealing and mating surfaces for damage, repair or replace the cylinder block assembly if required.

4 Inspect all threaded and through holes for damage or excessive debris.

5 Inspect all bolts for damage, if damaged replace with new bolts only.

6 Inspect the cylinder walls for cracks or damage. The cylinder sleeves are not serviced separately, if the cylinders are damaged the cylinder block assembly must be replaced.

7 Inspect the engine block for cracks. Do not repair any cracks. If cracks are found, the cylinder block assembly must be replaced. Repair any damaged threaded holes, refer to 4.9 Thread Repair Specifications.

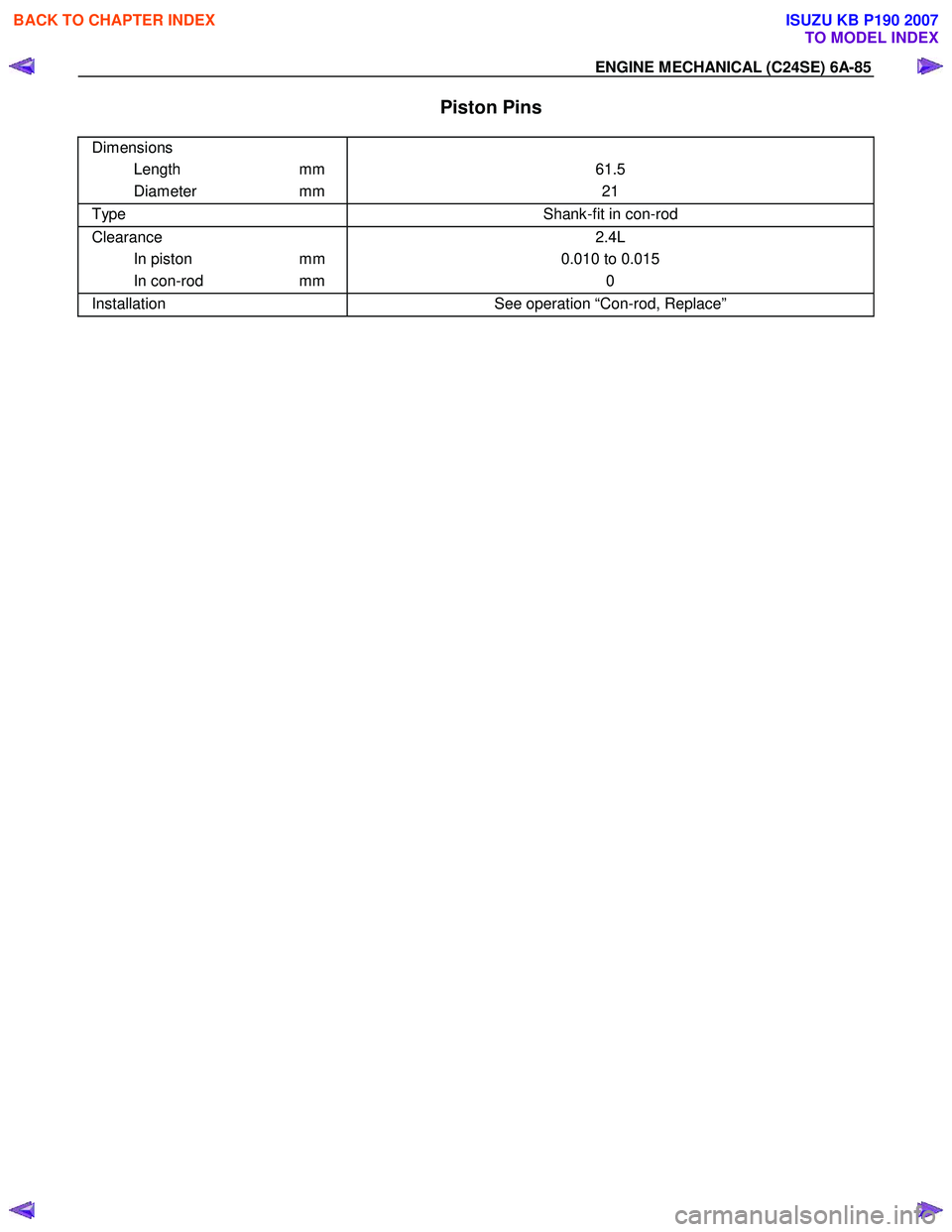

Measuring Cylinder Bore Diameter

1 Measure the cylinder bore diameter 37 mm from the deck face (1) using a commercially available bore

gauge or Tool No. J-8087 (2).

2 Record the results and compare with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of

oversized pistons and rings are available for

service. If the cylinder bore diameter exceeds

specification by more than 0.25 mm, the

cylinder block must be replaced.

Figure 6A1 – 448

Measuring Cylinder Bore Taper

1 Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 10 mm below the deck surface and record the measurement.

2 Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 100 mm below the deck surface and record the measurement.

3 Calculate the difference between the two measurements. The result will be the cylinder taper.

4 Compare the results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter exceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Measuring Cylinder Bore Out-of-Round

1 Measure both the thrust and non-thrust cylinder diameter at 10 mm below the deck. Record your measurements.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2719 of 6020

Engine Mechanical – V6 Page 6A1–240

2 Calculate the difference between the two measurements. The result will indicate out-of-round at the upper end of

the cylinder.

3 Measure both the thrust and non-thrust cylinder diameter at 100 mm below the deck surface. Record your measurements.

4 Calculate the difference between the two measurements. The result will indicate out-of-round at the lower end of the cylinder.

5 Compare your results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter exceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

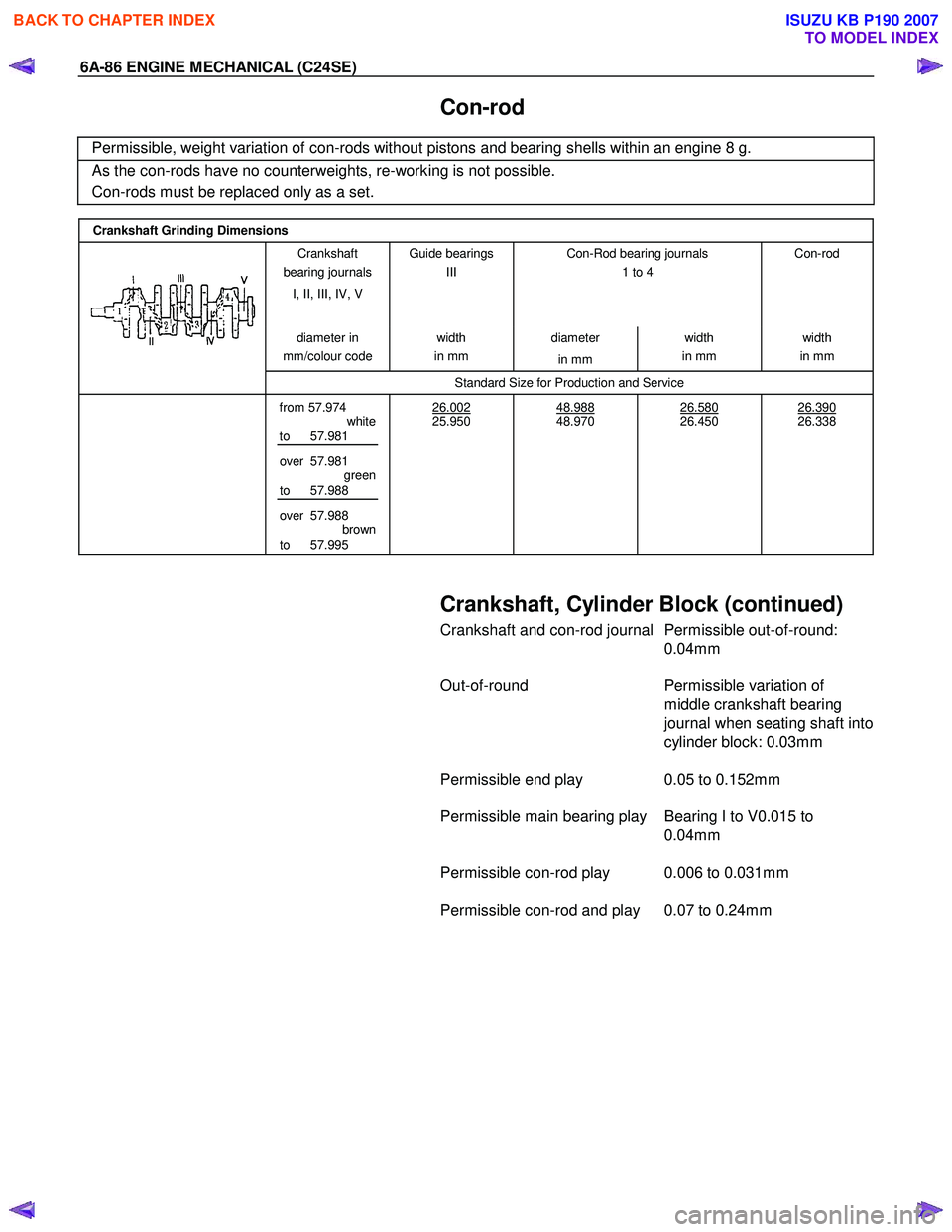

Deck Flatness Inspection

1 Ensure the engine block decks are clean and free of gasket material.

2 Inspect the surface for any imperfections or scratches that could inhibit correct cylinder head gasket sealing.

3 Place a straight-edge diagonally across the cylinder block deck face surface.

4 Measure the clearance between the straight-edge and the cylinder block deck face using a feeler gauge

at 4 points along the straight-edge.

5 If the warpage is less than 0.05 mm, the cylinder block deck surface does not require resurfacing.

6 If the warpage is between 0.05 ±0.20 mm or any imperfections or scratches that could inhibit correct

cylinder head gasket sealing are present, the cylinder

block deck surface requires resurfacing.

7 If resurfacing is required the maximum amount that can be removed is 0.25 mm.

8 If the cylinder block deck surface requires more than 0.25 mm material removal the block must be

replaced.

Figure 6A1 – 449

Reassemble

1 Install the cylinder block-to-cylinder head alignment

dowels (1).

Figure 6A1 – 450

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3047 of 6020

Engine Mechanical – V6 Page 6A1–270

Page 6A1–270

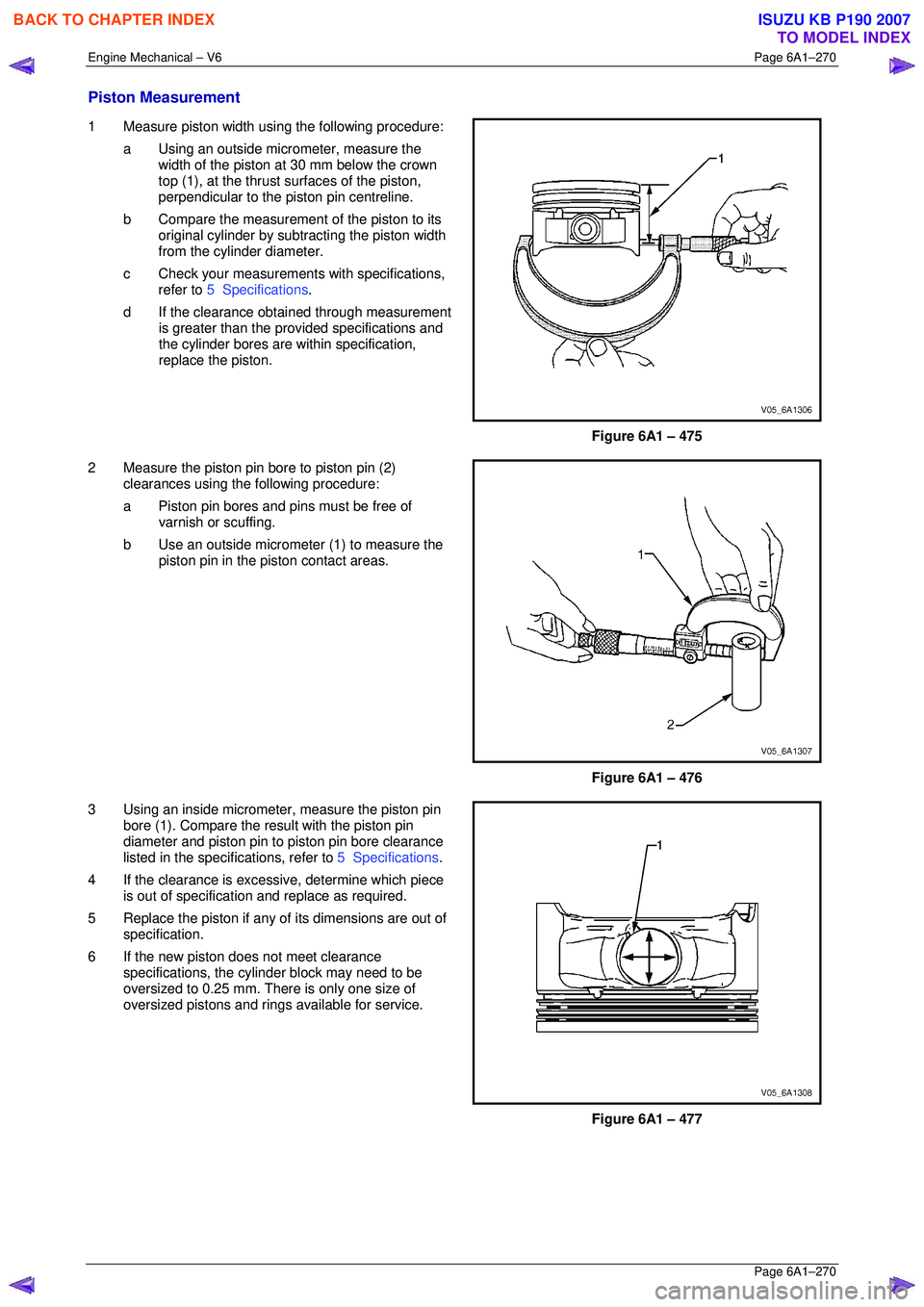

Piston Measurement

1 Measure piston width using the following procedure:

a Using an outside micr ometer, measure the

width of the piston at 30 mm below the crown

top (1), at the thrust surfaces of the piston,

perpendicular to the piston pin centreline.

b Compare the measurement of the piston to its

original cylinder by subtracting the piston width

from the cylinder diameter.

c Check your measurements with specifications, refer to 5 Specifications .

d If the clearance obtai ned through measurement

is greater than the prov ided specifications and

the cylinder bores are wi thin specification,

replace the piston.

Figure 6A1 – 475

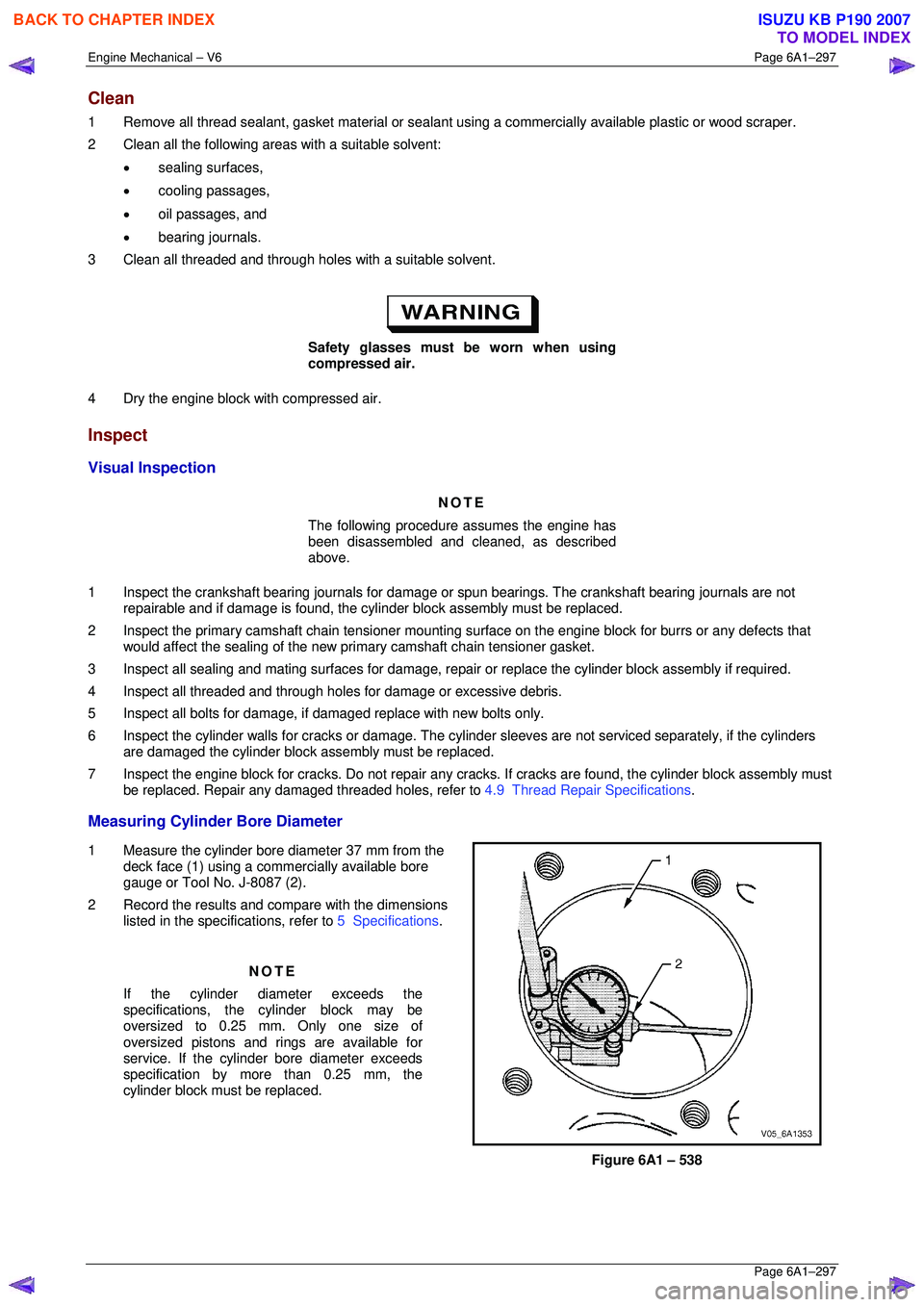

2 Measure the piston pin bore to piston pin (2) clearances using the following procedure:

a Piston pin bores and pins must be free of varnish or scuffing.

b Use an outside micrometer (1) to measure the

piston pin in the piston contact areas.

Figure 6A1 – 476

3 Using an inside micrometer , measure the piston pin

bore (1). Compare the resu lt with the piston pin

diameter and piston pin to piston pin bore clearance

listed in the specifications, refer to 5 Specifications.

4 If the clearance is excessive, determine which piece is out of specification and replace as required.

5 Replace the piston if any of its dimensions are out of

specification.

6 If the new piston does not meet clearance specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 477

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3074 of 6020

Engine Mechanical – V6 Page 6A1–297

Page 6A1–297

Clean

1 Remove all thread sealant, gasket material or sealant using a commercially available plastic or wood scraper.

2 Clean all the following areas with a suitable solvent:

• sealing surfaces,

• cooling passages,

• oil passages, and

• bearing journals.

3 Clean all threaded and through holes with a suitable solvent.

Safety glasses must be worn when using

compressed air.

4 Dry the engine block with compressed air.

Inspect

Visual Inspection

NOTE

The following procedure assumes the engine has

been disassembled and cleaned, as described

above.

1 Inspect the crankshaft bearing journals for damage or spun bearings. The crankshaft bearing journals are not

repairable and if damage is f ound, the cylinder block assembly must be replaced.

2 Inspect the primary camshaft chain t ensioner mounting surface on the engine block for burrs or any defects that

would affect the sealing of the new primary camshaft chain tensioner gasket.

3 Inspect all sealing and mating surfaces for damage, repair or replace the cylinder block assembly if required.

4 Inspect all threaded and through holes for damage or excessive debris.

5 Inspect all bolts for damage, if damaged replace with new bolts only.

6 Inspect the cylinder walls for cracks or damage. The cyli nder sleeves are not serviced separately, if the cylinders

are damaged the cylinder block assembly must be replaced.

7 Inspect the engine block for cracks. Do not repair any cra cks. If cracks are found, the cylinder block assembly must

be replaced. Repair any damaged threaded holes, refer to 4.9 Thread Repair Specifications.

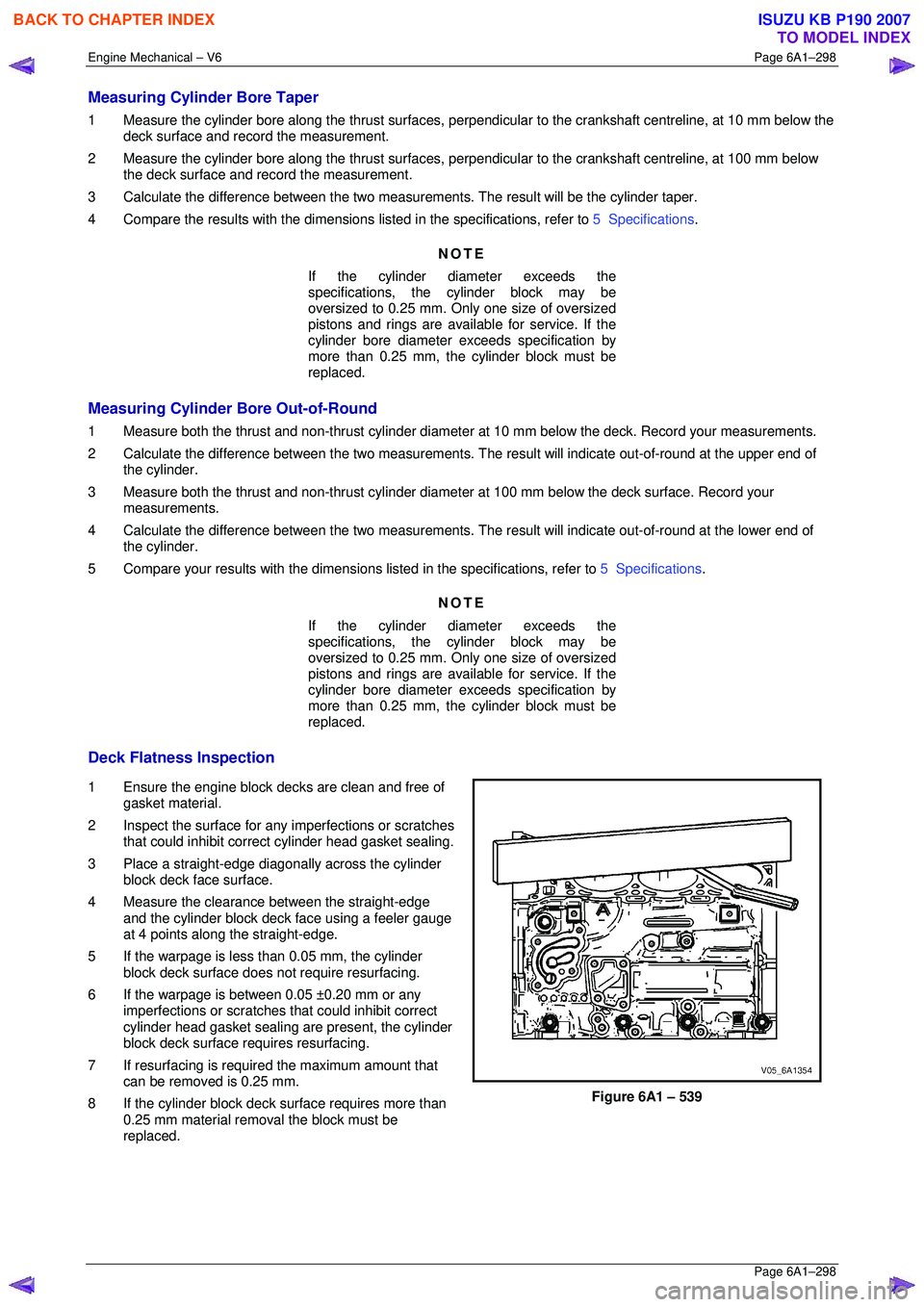

Measuring Cylinder Bore Diameter

1 Measure the cylinder bore diameter 37 mm from the

deck face (1) using a commercially available bore

gauge or Tool No. J-8087 (2).

2 Record the results and compare with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of

oversized pistons and rings are available for

service. If the cylinder bore diameter exceeds

specification by mo re than 0.25 mm, the

cylinder block must be replaced.

Figure 6A1 – 538

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3075 of 6020

Engine Mechanical – V6 Page 6A1–298

Page 6A1–298

Measuring Cylinder Bore Taper

1 Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 10 mm below the

deck surface and record the measurement.

2 Measure the cylinder bore along the th rust surfaces, perpendicular to the crankshaft centreline, at 100 mm below

the deck surface and record the measurement.

3 Calculate the difference betw een the two measurements. The re sult will be the cylinder taper.

4 Compare the results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Measuring Cylinder Bore Out-of-Round

1 Measure both the thrust and non-thrust cylinder diameter at 10 mm below the deck. Record your measurements.

2 Calculate the difference bet ween the two measurements. The result will indicate out-of-r ound at the upper end of

the cylinder.

3 Measure both the thrust and non-thru st cylinder diameter at 100 mm below the deck surface. Record your

measurements.

4 Calculate the difference between the tw o measurements. The result will indicate out-of-round at the lower end of

the cylinder.

5 Compare your results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Deck Flatness Inspection

1 Ensure the engine block decks are clean and free of gasket material.

2 Inspect the surface for any imperfections or scratches

that could inhibit correct cylinder head gasket sealing.

3 Place a straight-edge diagonally across the cylinder block deck face surface.

4 Measure the clearance between the straight-edge

and the cylinder block deck face using a feeler gauge

at 4 points along the straight-edge.

5 If the warpage is less t han 0.05 mm, the cylinder

block deck surface does not require resurfacing.

6 If the warpage is between 0.05 ±0.20 mm or any imperfections or scratches that could inhibit correct

cylinder head gasket sealing are present, the cylinder

block deck surface requires resurfacing.

7 If resurfacing is requir ed the maximum amount that

can be removed is 0.25 mm.

8 If the cylinder block deck surface requires more than 0.25 mm material removal the block must be

replaced.

Figure 6A1 – 539

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3944 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–31

Keep the control valve body level when

lowering it to prevent the loss of the

checkballs located in the body passages.

5 Carefully lower the control valve body (1) from the transmission case. As the valve body is being lowered,

rotate it slightly to disconnect the manual valve link (2)

from the manual valve (3) and remove the control

valve body.

6 Remove the manual valve link from the inner detent lever (4).

Figure 7C4 – 39

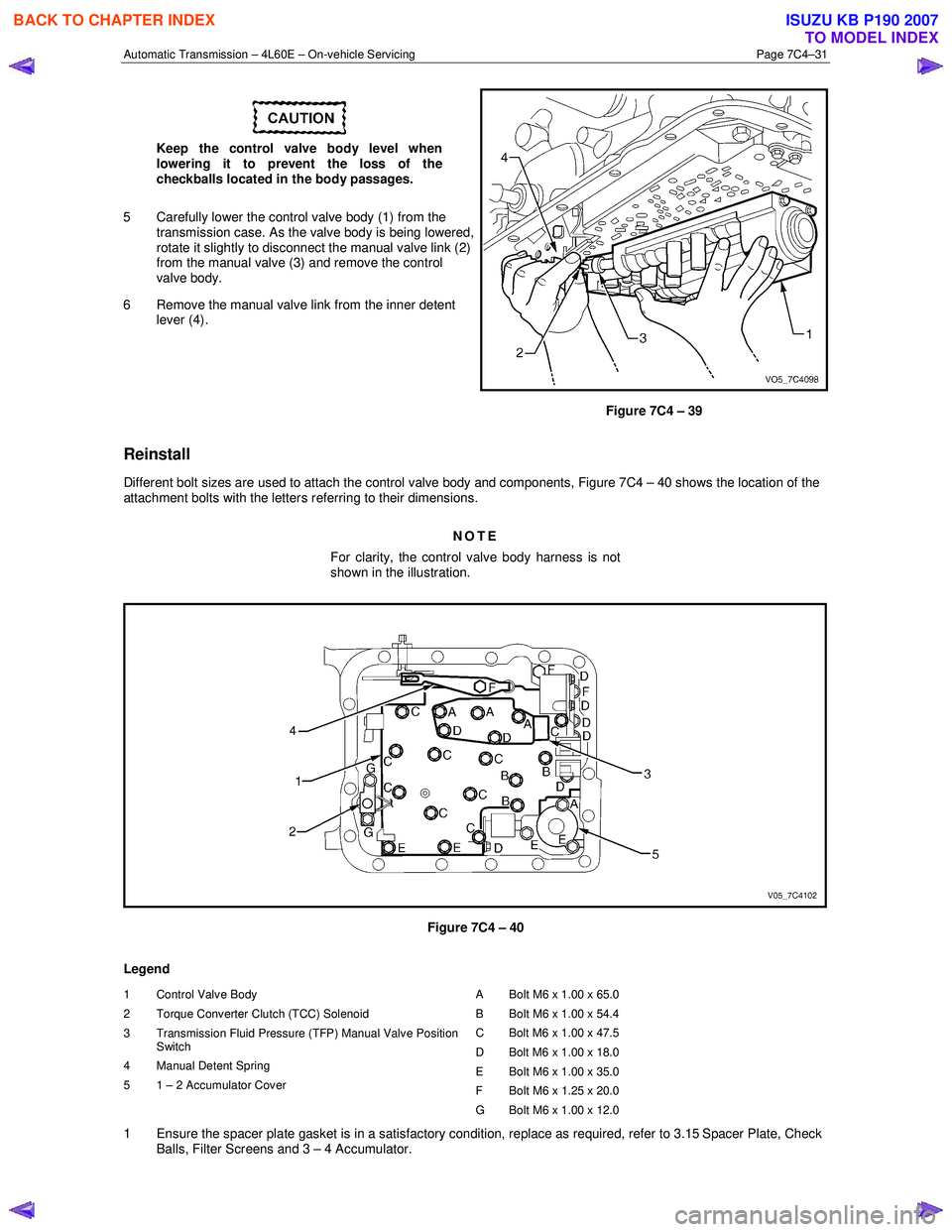

Reinstall

Different bolt sizes are used to attach the control valve body and components, Figure 7C4 – 40 shows the location of the

attachment bolts with the letters referring to their dimensions.

NOTE

For clarity, the control valve body harness is not

shown in the illustration.

Figure 7C4 – 40

Legend

1 Control Valve Body

2 Torque Converter Clutch (TCC) Solenoid

3 Transmission Fluid Pressure (TFP) Manual Valve Position Switch

4 Manual Detent Spring

5 1 – 2 Accumulator Cover A Bolt M6 x 1.00 x 65.0

B Bolt M6 x 1.00 x 54.4

C Bolt M6 x 1.00 x 47.5

D Bolt M6 x 1.00 x 18.0

E Bolt M6 x 1.00 x 35.0

F Bolt M6 x 1.25 x 20.0

G Bolt M6 x 1.00 x 12.0

1 Ensure the spacer plate gasket is in a satisfactory condition, replace as required, refer to 3.15 Spacer Plate, Check Balls, Filter Screens and 3 – 4 Accumulator.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007