immobilizer ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1662 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-45

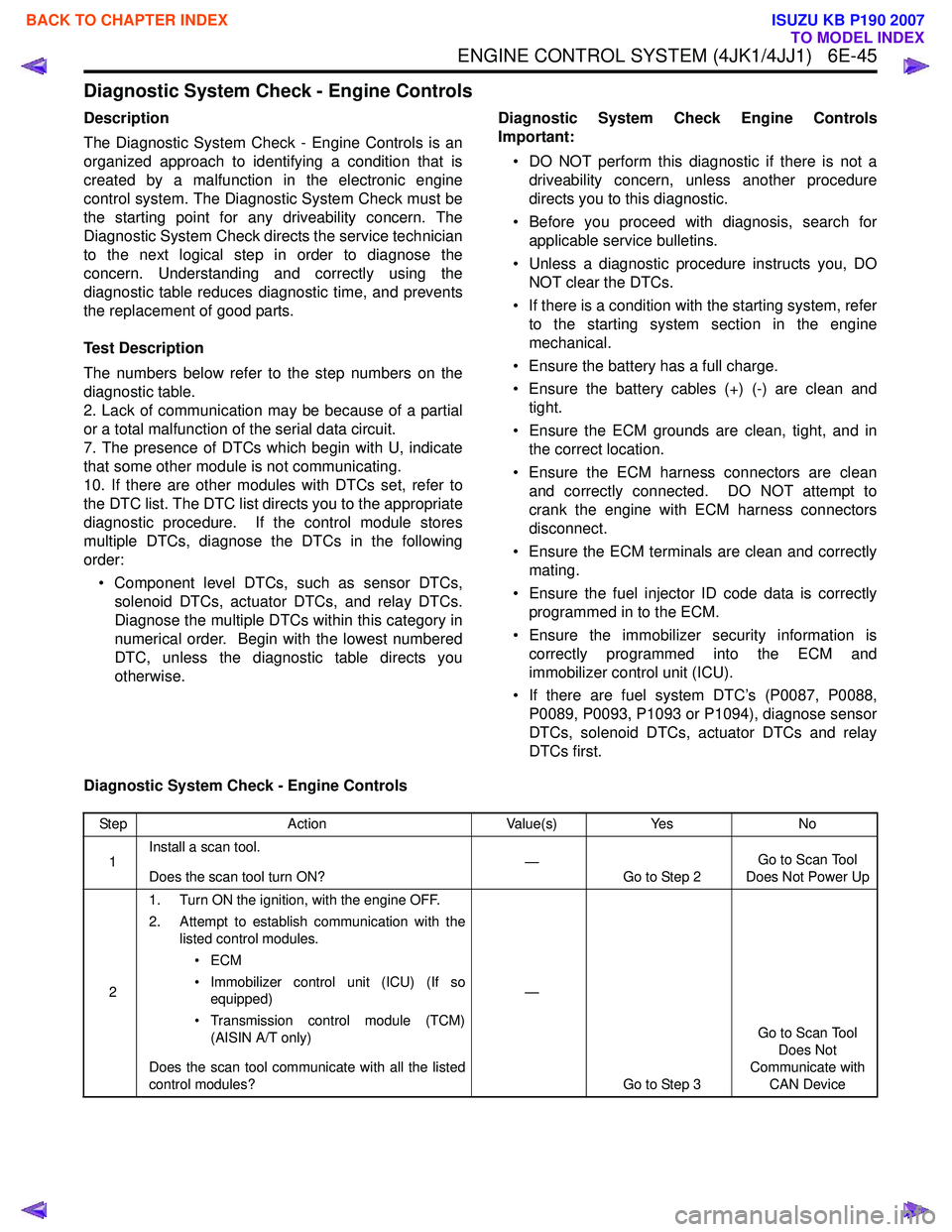

Diagnostic System Check - Engine Controls

Description

The Diagnostic System Check - Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine

control system. The Diagnostic System Check must be

the starting point for any driveability concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the

concern. Understanding and correctly using the

diagnostic table reduces diagnostic time, and prevents

the replacement of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

7. The presence of DTCs which begin with U, indicate

that some other module is not communicating.

10. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

• Component level DTCs, such as sensor DTCs, solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise. Diagnostic System Check Engine Controls

Important:

• DO NOT perform this diagnostic if there is not a driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• If there is a condition with the starting system, refer to the starting system section in the engine

mechanical.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the ECM grounds are clean, tight, and in the correct location.

• Ensure the ECM harness connectors are clean and correctly connected. DO NOT attempt to

crank the engine with ECM harness connectors

disconnect.

• Ensure the ECM terminals are clean and correctly mating.

• Ensure the fuel injector ID code data is correctly programmed in to the ECM.

• Ensure the immobilizer security information is correctly programmed into the ECM and

immobilizer control unit (ICU).

• If there are fuel system DTC’s (P0087, P0088, P0089, P0093, P1093 or P1094), diagnose sensor

DTCs, solenoid DTCs, actuator DTCs and relay

DTCs first.

Diagnostic System Check - Engine Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•ECM

• Immobilizer control unit (ICU) (If so equipped)

• Transmission control module (TCM) (AISIN A/T only)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with CAN Device

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1663 of 6020

6E-46 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

3Notice:

If an immobilizer system is active the ECM

will disable the fuel injection causing the engine to

stall immediately after starting and energize the

starter cut relay to disable cranking.

Attempt to crank the engine.

Does the engine crank? —

Go to Step 4 Go to Step 5

4 Attempt to start the engine.

Does the engine start and idle? —

Go to Step 6 Go to Engine

Cranks but Does

Not Run

5 Does the scan tool display ECM DTCs P0615,

P0633, P161B or U0167?

—

Go to Applicable DTC Problem is relating

to starting system. Refer to the

applicable

diagnostic chart in starting system

6 Select the DTC display function for the following

control modules: •ECM

• ICU (If so equipped)

• TCM (AISIN A/T only)

Does the scan tool display any DTCs? —

Go to Step 7 Go to Step 11

7 Does the scan tool display DTCs which begin with

U or other control module communication fault

DTCs? —

Go to Applicable

DTC Go to Step 8

8 Does the scan tool display ECM DTCs P0601,

P0602, P0604, P0606 or P1621? —Go to Applicable

DTC Go to Step 9

9 Does the scan tool display ECM DTCs P0562 or

P0563, P156A or P156B? —

Go to Applicable

DTC Go to Step 10

10 Is there any other code in any controller that has

not been diagnosed? —Go to Applicable

DTC Go to Step 11

11 Is the customer’s concern with the automatic

transmission? —Go to Diagnostic

System Check - Transmission

Controls Go to Step 12

12 Is the customer’s concern with the immobilizer

system? —Go to Diagnostic

System Check - Immobilizer

Controls Go to Step 13

13 1. Review the following symptoms.

2. Refer to the applicable symptom diagnostic table:

• Hard Start

• Rough, Unstable, or Incorrect Idle and Stalling

• High Idle Speed

•Cuts Out

• Surges

• Lack of Power, Sluggishness, or Sponginess

• Hesitation, Sag, Stumble

• Abnormal Combustion Noise

• Poor Fuel Economy

• Excessive Smoke (Black Smoke)

• Excessive Smoke (White Smoke)

Did you find and correct the condition? —

System OK Go to Intermittent

Conditions

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1666 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-49

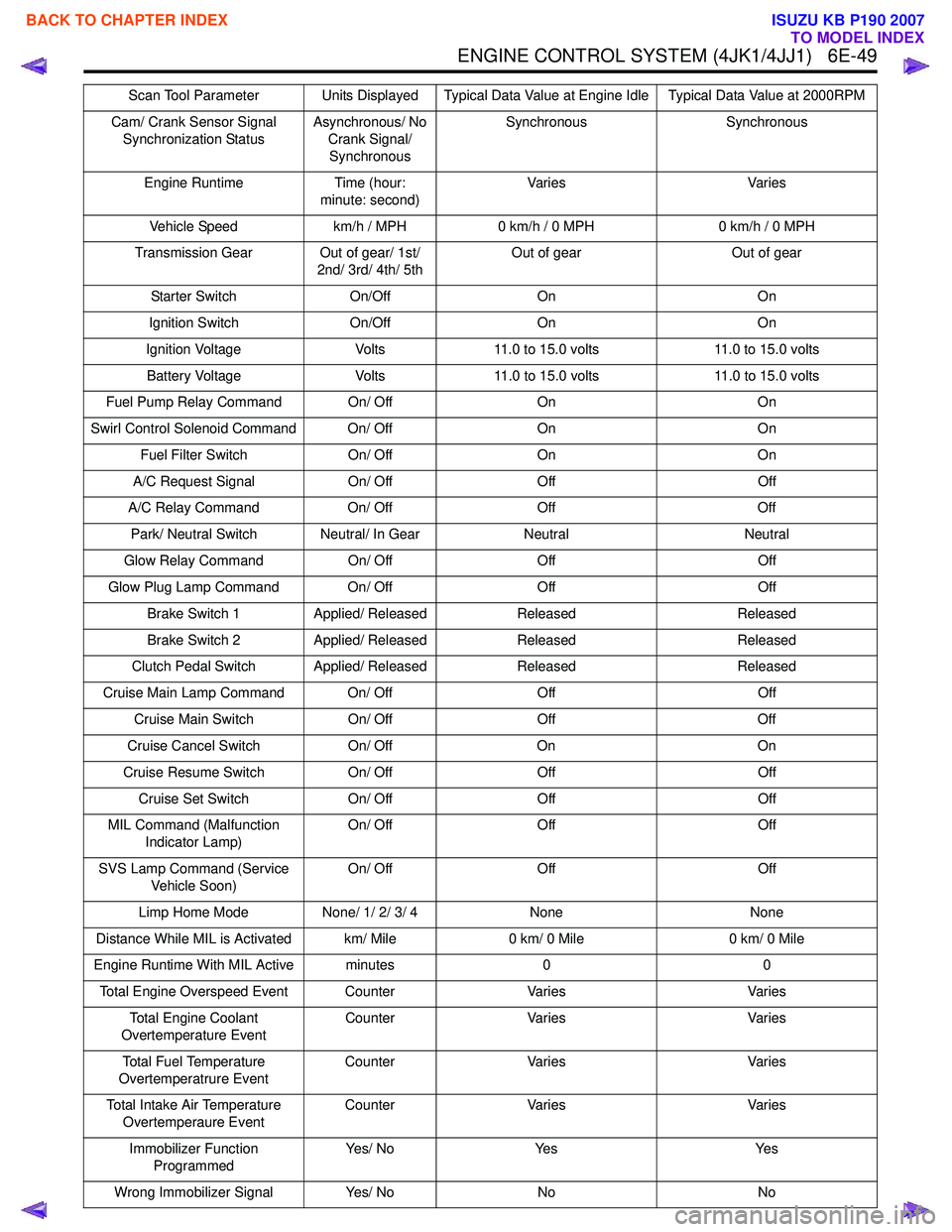

Cam/ Crank Sensor Signal Synchronization Status Asynchronous/ No

Crank Signal/ Synchronous Synchronous Synchronous

Engine Runtime Time (hour: minute: second) Va r i e s

Va r i e s

Vehicle Speed km/h / MPH0 km/h / 0 MPH 0 km/h / 0 MPH

Transmission Gear Out of gear/ 1st/ 2nd/ 3rd/ 4th/ 5th Out of gear

Out of gear

Starter Switch On/OffOn On

Ignition Switch On/OffOn On

Ignition Voltage Volts11.0 to 15.0 volts 11.0 to 15.0 volts

Battery Voltage Volts11.0 to 15.0 volts 11.0 to 15.0 volts

Fuel Pump Relay Command On/ Off OnOn

Swirl Control Solenoid Command On/ Off OnOn

Fuel Filter Switch On/ OffOn On

A/C Request Signal On/ OffOff Off

A/C Relay Command On/ OffOff Off

Park/ Neutral Switch Neutral/ In Gear NeutralNeutral

Glow Relay Command On/ OffOff Off

Glow Plug Lamp Command On/ Off OffOff

Brake Switch 1 Applied/ Released Released Released

Brake Switch 2 Applied/ Released Released Released

Clutch Pedal Switch Applied/ Released ReleasedReleased

Cruise Main Lamp Command On/ Off OffOff

Cruise Main Switch On/ OffOff Off

Cruise Cancel Switch On/ OffOn On

Cruise Resume Switch On/ OffOff Off

Cruise Set Switch On/ OffOff Off

MIL Command (Malfunction Indicator Lamp) On/ Off

Off Off

SVS Lamp Command (Service Vehicle Soon) On/ Off

Off Off

Limp Home Mode None/ 1/ 2/ 3/ 4 None None

Distance While MIL is Activated km/ Mile 0 km/ 0 Mile0 km/ 0 Mile

Engine Runtime With MIL Active minutes 00

Total Engine Overspeed Event Counter VariesVaries

Total Engine Coolant

Overtemperature Event Counter

Varies Varies

Total Fuel Temperature

Overtemperatrure Event Counter

Varies Varies

Total Intake Air Temperature Overtemperaure Event Counter

Varies Varies

Immobilizer Function Programmed Ye s / N o

Ye s Ye s

Wrong Immobilizer Signal Yes/ NoNo No

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1667 of 6020

6E-50 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Scan Tool Data Definitions

This information will assist in emission or driveability

problems. The displays can be viewed while the vehicle

is being driven. Always perform the Diagnostic System

Check - Engine Controls first. The Diagnostic System

Check will confirm proper system operation.

Engine Speed

This parameter displays the rotational speed of the

crankshaft as calculated by the ECM based on inputs

from the crankshaft position (CKP) sensor or camshaft

position (CMP) sensor.

Desired Idle Speed

This parameter displays the idle speed requested by

the ECM. The ECM will change desired idle speed

based on engine coolant temperature and other inputs.

Calculate Engine Load

This parameter displays the engine load in percent

based on inputs to the ECM from various engine

sensors. The scan tool will display a lower percentage

when the engine is at idle with little or no load. The

scan tool will display a higher percentage when the

engine is running at high engine speed under a heavy

load.

Coolant Temperature

This parameter displays the temperature of the engine

coolant as calculated by the ECM using the signal from

the engine coolant temperature (ECT) sensor. The

scan tool will display a low temperature when the ECT

sensor signal voltage is high, and a high temperature

when the ECT sensor signal voltage is low.

Engine Coolant Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the engine coolant temperature (ECT)

sensor. ECT sensor is a range of value indicating a low

voltage when the temperature is high, and a high

voltage when the temperature is low.

Intake Air Temperature

This parameter displays the temperature of the intake

air as calculated by the ECM using the signal from the

intake air temperature (IAT) sensor. The scan tool will

display a low temperature when the IAT sensor signal

voltage is high, and a high temperature when the IAT

sensor signal voltage is low. Intake Air Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the intake air temperature (IAT) sensor. IAT

sensor is a range of value indicating a low voltage

when the temperature is high, and a high voltage when

the temperature is low.

Fuel Temperature

This parameter displays the temperature of the fuel as

calculated by the ECM using the signal from the fuel

temperature (FT) sensor. The scan tool will display a

low temperature when the FT sensor signal voltage is

high, and a high temperature when the FT sensor

signal voltage is low.

Fuel Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the fuel temperature (FT) sensor. FT sensor

is a range of value indicating a low voltage when the

temperature is high, and a high voltage when the

temperature is low.

MAF (Mass Air Flow)

This parameter displays the air flow into the engine as

calculated by the ECM based on the mass air flow

(MAF) sensor input. The scan tool will display a high

value at higher engine speeds, and a low value at lower

engine speed.

MAF Sensor (Mass Air Flow)

This parameter displays the voltage signal sent to the

ECM from the mass air flow (MAF) sensor. MAF sensor

is a range of value indicating a low voltage at lower

engine speed, and a high voltage at a higher engine

speeds.

Barometric Pressure

This parameter displays the barometric pressure

(BARO) as calculated by the ECM using the signal from

the BARO sensor. The scan tool will display a low

barometric pressure in high altitude area.

Barometric Pressure Sensor

This parameter displays the voltage signal sent to the

ECM from the barometric pressure (BARO) sensor.

BARO sensor is a range of value indicating a low

voltage in high altitude area, and a middle voltage in

sea level.

Immobilizer Signal Yes/ NoYes Yes

Security Wait Time Inactive/ Time

(hour: minute: second) Inactive

Inactive

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1671 of 6020

6E-54 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

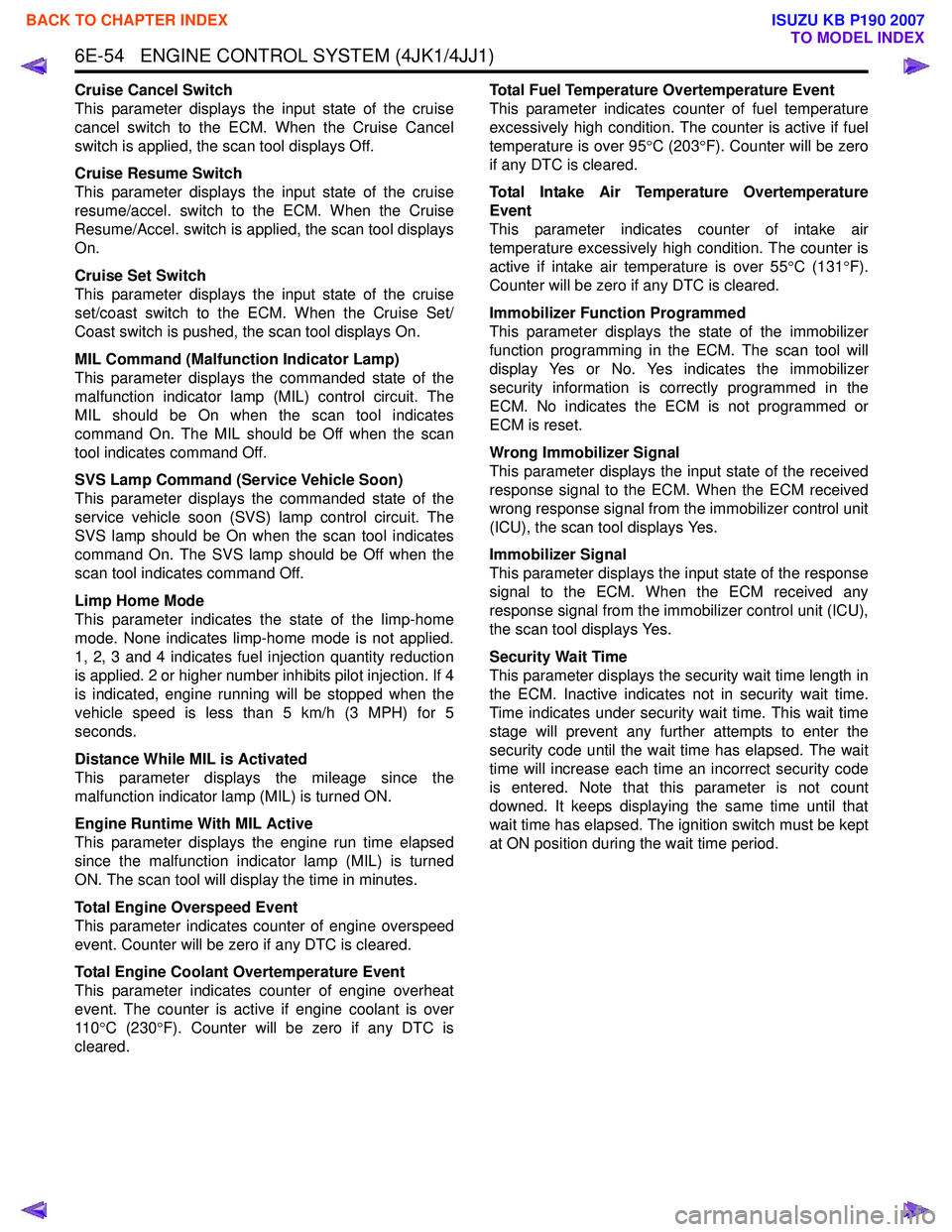

Cruise Cancel Switch

This parameter displays the input state of the cruise

cancel switch to the ECM. When the Cruise Cancel

switch is applied, the scan tool displays Off.

Cruise Resume Switch

This parameter displays the input state of the cruise

resume/accel. switch to the ECM. When the Cruise

Resume/Accel. switch is applied, the scan tool displays

On.

Cruise Set Switch

This parameter displays the input state of the cruise

set/coast switch to the ECM. When the Cruise Set/

Coast switch is pushed, the scan tool displays On.

MIL Command (Malfunction Indicator Lamp)

This parameter displays the commanded state of the

malfunction indicator lamp (MIL) control circuit. The

MIL should be On when the scan tool indicates

command On. The MIL should be Off when the scan

tool indicates command Off.

SVS Lamp Command (Service Vehicle Soon)

This parameter displays the commanded state of the

service vehicle soon (SVS) lamp control circuit. The

SVS lamp should be On when the scan tool indicates

command On. The SVS lamp should be Off when the

scan tool indicates command Off.

Limp Home Mode

This parameter indicates the state of the limp-home

mode. None indicates limp-home mode is not applied.

1, 2, 3 and 4 indicates fuel injection quantity reduction

is applied. 2 or higher number inhibits pilot injection. If 4

is indicated, engine running will be stopped when the

vehicle speed is less than 5 km/h (3 MPH) for 5

seconds.

Distance While MIL is Activated

This parameter displays the mileage since the

malfunction indicator lamp (MIL) is turned ON.

Engine Runtime With MIL Active

This parameter displays the engine run time elapsed

since the malfunction indicator lamp (MIL) is turned

ON. The scan tool will display the time in minutes.

Total Engine Overspeed Event

This parameter indicates counter of engine overspeed

event. Counter will be zero if any DTC is cleared.

Total Engine Coolant Overtemperature Event

This parameter indicates counter of engine overheat

event. The counter is active if engine coolant is over

11 0 °C (230 °F). Counter will be zero if any DTC is

cleared. Total Fuel Temperature Overtemperature Event

This parameter indicates counter of fuel temperature

excessively high condition. The counter is active if fuel

temperature is over 95 °C (203 °F). Counter will be zero

if any DTC is cleared.

Total Intake Air Temperature Overtemperature

Event

This parameter indicates counter of intake air

temperature excessively high condition. The counter is

active if intake air temperature is over 55 °C (131 °F).

Counter will be zero if any DTC is cleared.

Immobilizer Function Programmed

This parameter displays the state of the immobilizer

function programming in the ECM. The scan tool will

display Yes or No. Yes indicates the immobilizer

security information is correctly programmed in the

ECM. No indicates the ECM is not programmed or

ECM is reset.

Wrong Immobilizer Signal

This parameter displays the input state of the received

response signal to the ECM. When the ECM received

wrong response signal from the immobilizer control unit

(ICU), the scan tool displays Yes.

Immobilizer Signal

This parameter displays the input state of the response

signal to the ECM. When the ECM received any

response signal from the immobilizer control unit (ICU),

the scan tool displays Yes.

Security Wait Time

This parameter displays the security wait time length in

the ECM. Inactive indicates not in security wait time.

Time indicates under security wait time. This wait time

stage will prevent any further attempts to enter the

security code until the wait time has elapsed. The wait

time will increase each time an incorrect security code

is entered. Note that this parameter is not count

downed. It keeps displaying the same time until that

wait time has elapsed. The ignition switch must be kept

at ON position during the wait time period.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1674 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-57

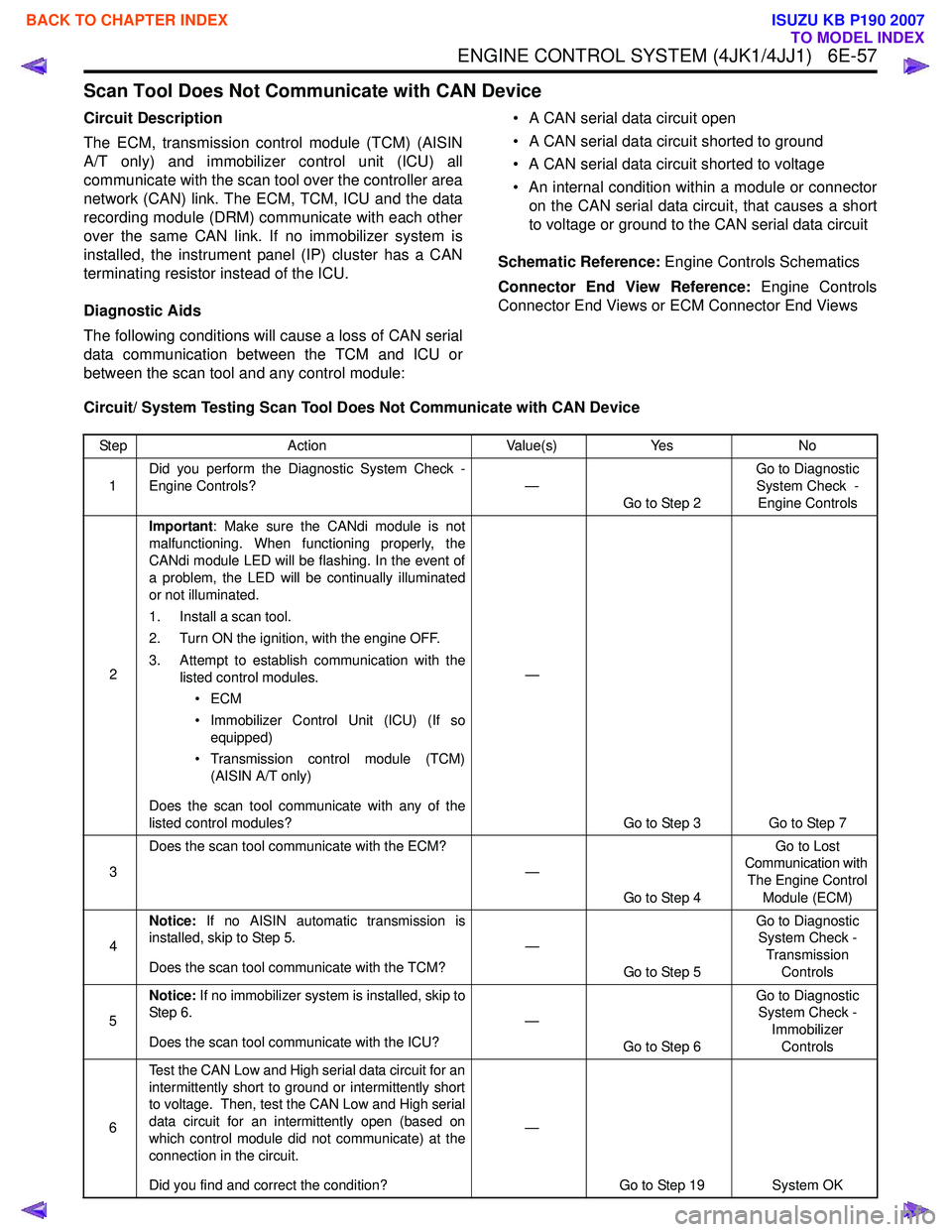

Scan Tool Does Not Communicate with CAN Device

Circuit Description

The ECM, transmission control module (TCM) (AISIN

A/T only) and immobilizer control unit (ICU) all

communicate with the scan tool over the controller area

network (CAN) link. The ECM, TCM, ICU and the data

recording module (DRM) communicate with each other

over the same CAN link. If no immobilizer system is

installed, the instrument panel (IP) cluster has a CAN

terminating resistor instead of the ICU.

Diagnostic Aids

The following conditions will cause a loss of CAN serial

data communication between the TCM and ICU or

between the scan tool and any control module: • A CAN serial data circuit open

• A CAN serial data circuit shorted to ground

• A CAN serial data circuit shorted to voltage

• An internal condition within a module or connector on the CAN serial data circuit, that causes a short

to voltage or ground to the CAN serial data circuit

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Scan Tool Does Not Communicate with CAN Device

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Engine Controls

2 Important

: Make sure the CANdi module is not

malfunctioning. When functioning properly, the

CANdi module LED will be flashing. In the event of

a problem, the LED will be continually illuminated

or not illuminated.

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Attempt to establish communication with the listed control modules.

•ECM

• Immobilizer Control Unit (ICU) (If so equipped)

• Transmission control module (TCM) (AISIN A/T only)

Does the scan tool communicate with any of the

listed control modules? —

Go to Step 3 Go to Step 7

3 Does the scan tool communicate with the ECM?

—

Go to Step 4 Go to Lost

Communication with

The Engine Control Module (ECM)

4 Notice:

If no AISIN automatic transmission is

installed, skip to Step 5.

Does the scan tool communicate with the TCM? —

Go to Step 5 Go to Diagnostic

System Check -

Transmission Controls

5 Notice:

If no immobilizer system is installed, skip to

Step 6.

Does the scan tool communicate with the ICU? —

Go to Step 6 Go to Diagnostic

System Check -

Immobilizer Controls

6 Test the CAN Low and High serial data circuit for an

intermittently short to ground or intermittently short

to voltage. Then, test the CAN Low and High serial

data circuit for an intermittently open (based on

which control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition? —

Go to Step 19 System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1675 of 6020

6E-58 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

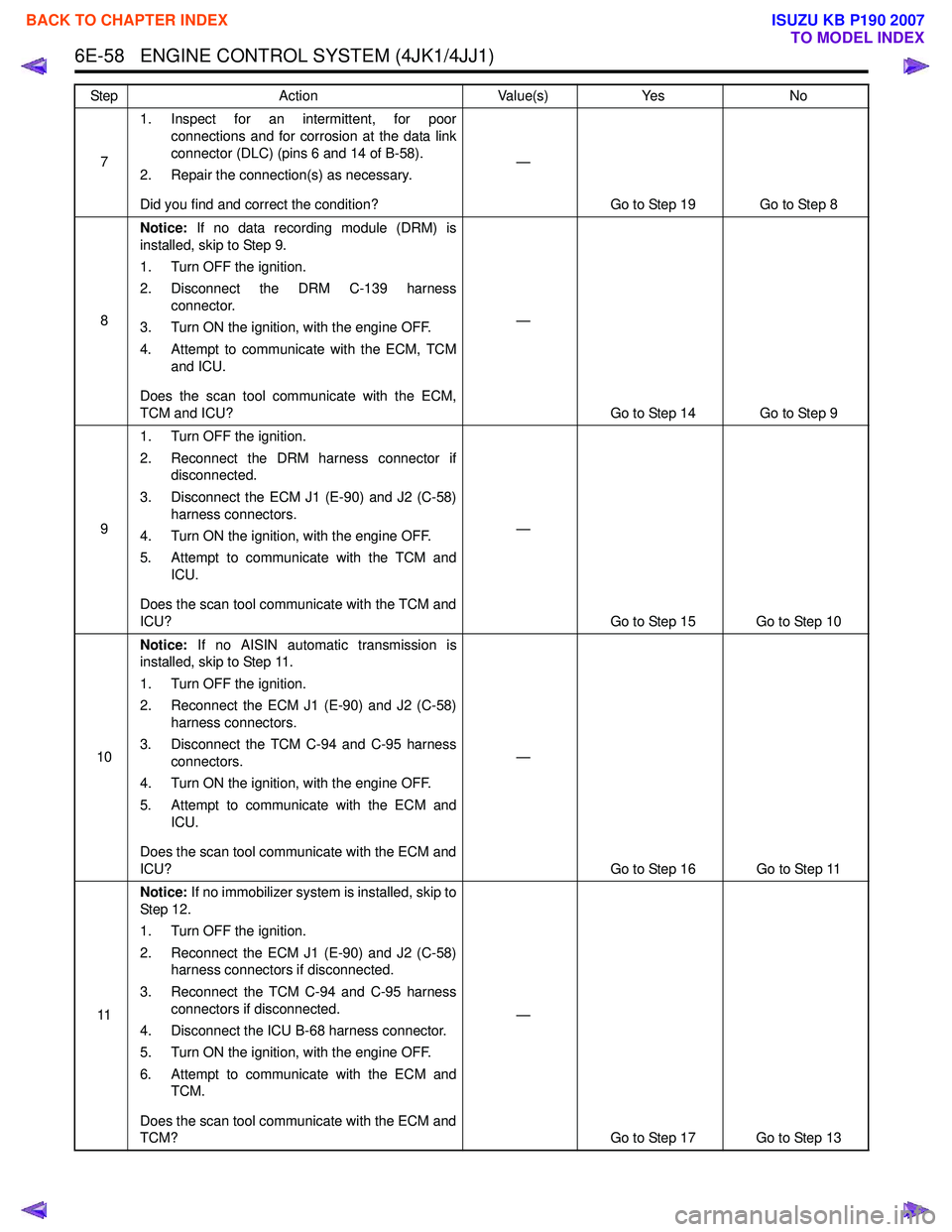

71. Inspect for an intermittent, for poor

connections and for corrosion at the data link

connector (DLC) (pins 6 and 14 of B-58).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 19 Go to Step 8

8 Notice:

If no data recording module (DRM) is

installed, skip to Step 9.

1. Turn OFF the ignition.

2. Disconnect the DRM C-139 harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Attempt to communicate with the ECM, TCM and ICU.

Does the scan tool communicate with the ECM,

TCM and ICU? —

Go to Step 14 Go to Step 9

9 1. Turn OFF the ignition.

2. Reconnect the DRM harness connector if disconnected.

3. Disconnect the ECM J1 (E-90) and J2 (C-58) harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the TCM and ICU.

Does the scan tool communicate with the TCM and

ICU? —

Go to Step 15 Go to Step 10

10 Notice:

If no AISIN automatic transmission is

installed, skip to Step 11.

1. Turn OFF the ignition.

2. Reconnect the ECM J1 (E-90) and J2 (C-58) harness connectors.

3. Disconnect the TCM C-94 and C-95 harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and ICU.

Does the scan tool communicate with the ECM and

ICU? —

Go to Step 16 Go to Step 11

11 Notice:

If no immobilizer system is installed, skip to

St ep 1 2.

1. Turn OFF the ignition.

2. Reconnect the ECM J1 (E-90) and J2 (C-58) harness connectors if disconnected.

3. Reconnect the TCM C-94 and C-95 harness connectors if disconnected.

4. Disconnect the ICU B-68 harness connector.

5. Turn ON the ignition, with the engine OFF.

6. Attempt to communicate with the ECM and TCM.

Does the scan tool communicate with the ECM and

TCM? —

Go to Step 17 Go to Step 13

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1677 of 6020

6E-60 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

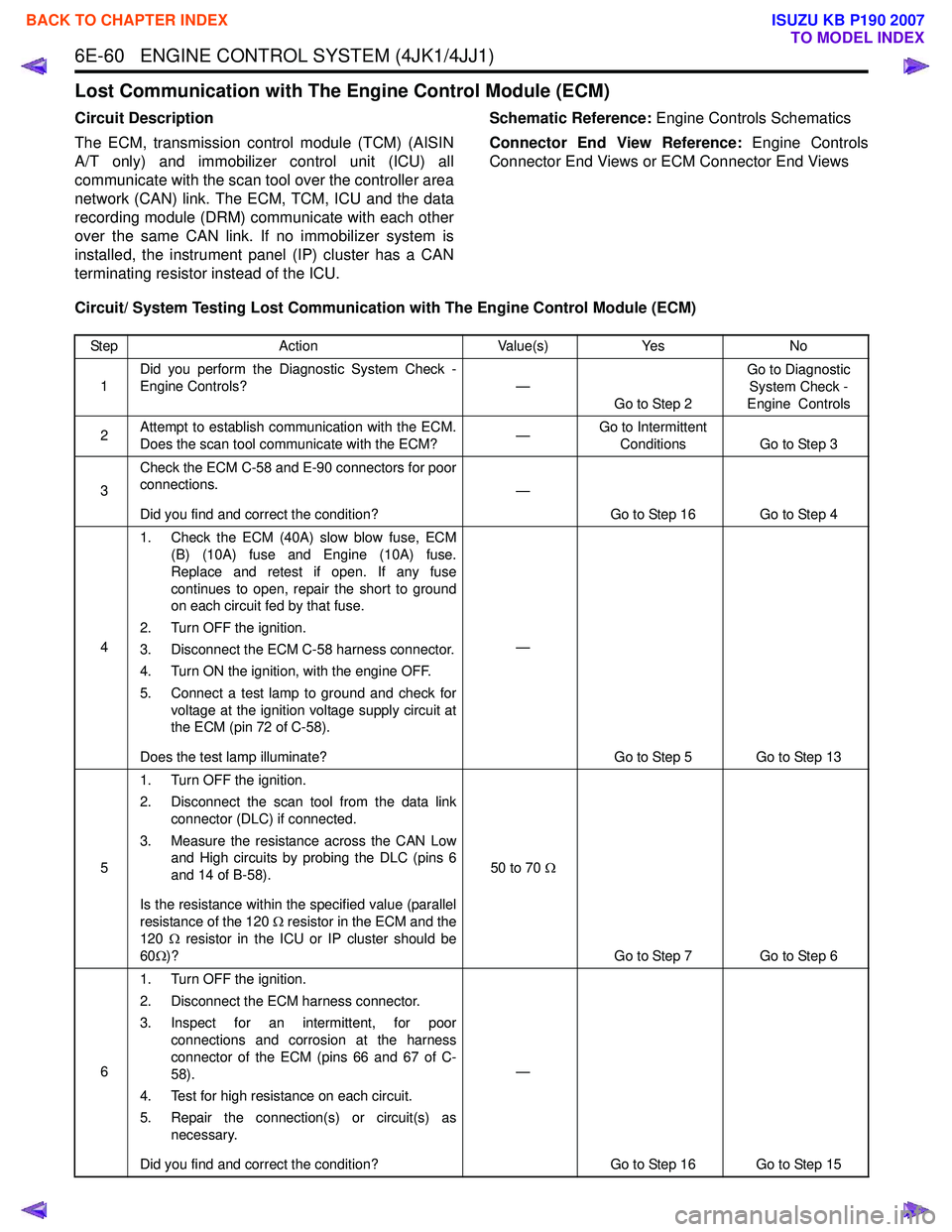

Lost Communication with The Engine Control Module (ECM)

Circuit Description

The ECM, transmission control module (TCM) (AISIN

A/T only) and immobilizer control unit (ICU) all

communicate with the scan tool over the controller area

network (CAN) link. The ECM, TCM, ICU and the data

recording module (DRM) communicate with each other

over the same CAN link. If no immobilizer system is

installed, the instrument panel (IP) cluster has a CAN

terminating resistor instead of the ICU. Schematic Reference:

Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Lost Communication with The Engine Control Module (ECM)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Attempt to establish communication with the ECM.

Does the scan tool communicate with the ECM? —Go to Intermittent

Conditions Go to Step 3

3 Check the ECM C-58 and E-90 connectors for poor

connections.

Did you find and correct the condition? —

Go to Step 16 Go to Step 4

4 1. Check the ECM (40A) slow blow fuse, ECM

(B) (10A) fuse and Engine (10A) fuse.

Replace and retest if open. If any fuse

continues to open, repair the short to ground

on each circuit fed by that fuse.

2. Turn OFF the ignition.

3. Disconnect the ECM C-58 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at

the ECM (pin 72 of C-58).

Does the test lamp illuminate? —

Go to Step 5 Go to Step 13

5 1. Turn OFF the ignition.

2. Disconnect the scan tool from the data link connector (DLC) if connected.

3. Measure the resistance across the CAN Low and High circuits by probing the DLC (pins 6

and 14 of B-58).

Is the resistance within the specified value (parallel

resistance of the 120 Ω resistor in the ECM and the

120 Ω resistor in the ICU or IP cluster should be

60 Ω)? 50 to 70

Ω

Go to Step 7 Go to Step 6

6 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 66 and 67 of C-

58).

4. Test for high resistance on each circuit.

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1815 of 6020

6E-198 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P0615 (Flash Code 19)

Circuit Description

The ECM controls the starter cut relay, which de-

energizes the starter relay based on engine speed

inputs or immobilizer command signal. The starter cut

relay uses normally close type relay. During engine

stopping, the starter cut relay is closed to allow

grounding the starter relay. Once engine run, the ECM

energizes the starter cut relay to open the starter relay

circuit and starter motor is disengaged even the ignition

is positioned at START. If the ECM detects an improper

voltage on the starter cut relay control circuit, this DTC

will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC

Either of following condition is met: • The ECM detects a short to ground circuit condition on the starter cut relay control circuit for

longer than 3 seconds when the relay is

commanded OFF. • The ECM detects a short to voltage circuit

condition on the starter cut relay control circuit for

longer than 3 seconds when the relay is

commanded ON.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Typ e C.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Notice: • If the starter cut relay control circuit is short to ground, engine does not crank.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0615

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 4 Go to Step 3

3 1. Start the engine.

2. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 6 Go to Diagnostic

Aids

4 1. Turn OFF the ignition.

2. Replace the starter cut relay with the head light dimmer relay or replace with a known

good relay.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1817 of 6020

6E-200 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

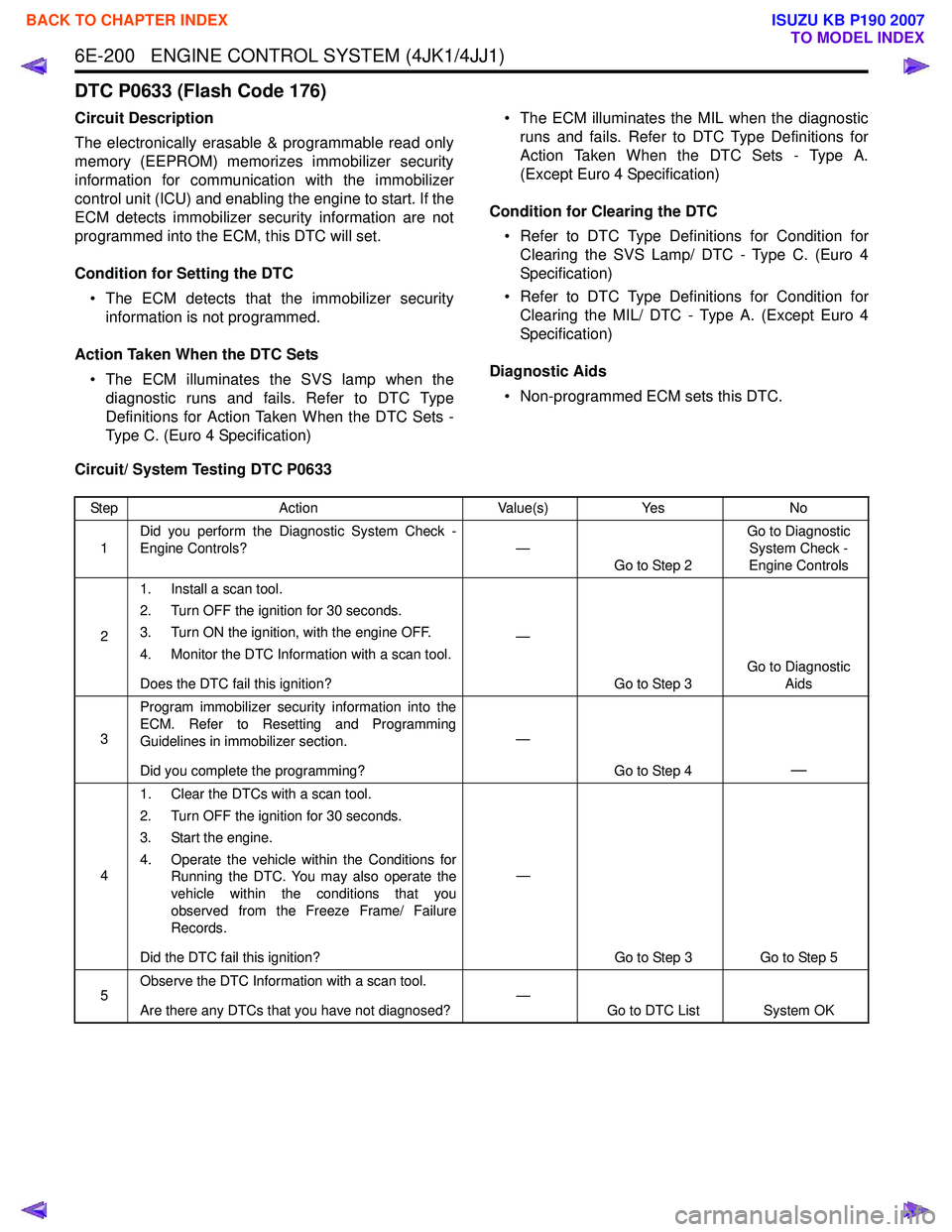

DTC P0633 (Flash Code 176)

Circuit Description

The electronically erasable & programmable read only

memory (EEPROM) memorizes immobilizer security

information for communication with the immobilizer

control unit (ICU) and enabling the engine to start. If the

ECM detects immobilizer security information are not

programmed into the ECM, this DTC will set.

Condition for Setting the DTC • The ECM detects that the immobilizer security information is not programmed.

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • Non-programmed ECM sets this DTC.

Circuit/ System Testing DTC P0633

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Program immobilizer security information into the

ECM. Refer to Resetting and Programming

Guidelines in immobilizer section.

Did you complete the programming? —

Go to Step 4

—

41. Clear the DTCs with a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Operate the vehicle within the Conditions for Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 5

5 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007