lights ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1798 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-181

Circuit/ System Testing DTC P0563

51. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for a poor connection and for corrosion at the harness

connector of the ECM (pin 72 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Diagnostic

Aids

6 1. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and let idle.

5. Load the electrical system by turning ON the headlights, A/C, etc. while observing the

Ignition Voltage parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 10.0 volts

Go to Step 7 Go to Step 3

7 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Was the vehicle recently jump started or a battery

charger placed on the battery? —

Go to Step 7 Go to Step 3

3 1. Install a scan tool.

2. Start the engine and let idle.

3. Observe the Ignition Voltage parameter with the scan tool.

Does the scan tool indicate less than the specified

value? 16.0 volts

Go to Diagnostic Aids Go to Step 4

4 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 5 Go to Diagnostic

Aids

5 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1808 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-191

DTC P0571 (Flash Code 26)

Circuit Description

The brake switch is installed on the brake pedal

bracket. The brake switch 1 is a normally open type

switch and the brake switch 2 is a normally closed type

switch. When the brake pedal is pressed, the brake

switch 1 signal is provided to the ECM and the

stoplights are turned ON. Then, the brake switch 2

signal to the ECM is stopped (low voltage). If the ECM

detects the brake switch signals out of correlation, this

DTC will set.

Condition for Running the DTC • The ignition switch is ON.

Condition for Setting the DTC • The ECM detects a brake switch 1 (normally open type switch) signal and brake switch 2 (normally

closed type switch) signal correlation error for

longer than 10 seconds over 33 times since

ignition switch is ON. Action Taken When the DTC Sets

• The ECM will not illuminate the MIL or SVS lamp. Refer to DTC Type Definitions for Action Taken

When the DTC Sets - Type D.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the DTC - Type D.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

• Misadjusted brake switch will cause this DTC to set.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P0571

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Observe the Brake Switch 1 parameter with a scan tool while fully depressing and releasing

the brake pedal.

Does the scan tool indicate Applied when the brake

pedal is applied and Released when the brake

pedal is released? —

Go to Step 8 Go to Step 3

3 1. Check to ensure the brake switch is adjusted

correctly. The plunger should be all the way in

when the pedal is released, yet should not

impede with the brake pedal full upward travel.

2. Adjust the brake switch as necessary.

Did you find and correct the condition? —

Go to Step 18 Go to Step 4

4 1. Turn OFF the ignition.

2. Disconnect the brake switch harness connector.

3. Connect a test lamp between the battery voltage feed circuit of the brake switch 1

harness (pin 1 of C-44) and a known good

ground.

Does the test lamp illuminate? —

Go to Step 5 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1867 of 6020

6E-250 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P156A or P156B (Flash Code 135)

Circuit Description

The ECM monitors the battery voltage on the ECM

main relay voltage feed terminal to make sure that the

voltage stays within the proper range. If the ECM

detects an excessively low or high battery voltage, DTC

P156A or P156B will set.

Condition for Running the DTC • The ignition voltage is more than 9 volts. (DTC P156B)

Condition for Setting the DTC • The ECM detects that the battery voltage feed circuit is less than 8 volts for 20 seconds. (DTC

P156A)

• The ECM detects that the battery voltage feed circuit is more than 16 volts for 5 seconds. (DTC

P156B)

Action Taken When the DTC Sets • The ECM illuminates the SVS lamp when the diagnostic runs and fails. Refer to DTC Type

Definitions for Action Taken When the DTC Sets -

Type C. (Euro 4 Specification) • The ECM illuminates the MIL when the diagnostic

runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

(Except Euro 4 Specification)

• The ECM limits fuel injection quantity. (DTC P156B)

• The ECM inhibits pilot injection. (DTC P156B)

• The ECM inhibits cruise control. (DTC P156B)

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the SVS Lamp/ DTC - Type C. (Euro 4

Specification)

• Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A. (Except Euro 4

Specification)

Diagnostic Aids • A charging system problem may set this DTC.

• The weakened battery may set DTC P156A.

• Jump starting the vehicle or a battery charger may have set DTC P156B.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P156A

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle.

4. Load the electrical system by turning ON the headlights, A/C, etc. while observing the

Battery Voltage parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 10.0 volts

Go to Diagnostic Aids Go to Step 3

3 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 4 Go to Step 5

4 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1868 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-251

Circuit/ System Testing DTC P156B

51. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for a poor connection and for corrosion at the harness

connector of the ECM (pin 73 of C-58).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Diagnostic

Aids

6 1. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and let idle.

5. Load the electrical system by turning ON the headlights, A/C, etc. while observing the

Battery Voltage parameter with a scan tool.

Does the scan tool indicate more than the specified

value? 10.0 volts

Go to Step 7 Go to Step 3

7 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Was the vehicle recently jump started or a battery

charger placed on the battery? —

Go to Step 7 Go to Step 3

3 1. Install a scan tool.

2. Start the engine and let idle.

3. Observe the Battery Voltage parameter with the scan tool.

Does the scan tool indicate less than the specified

value? 16.0 volts

Go to Diagnostic Aids Go to Step 4

4 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 5 Go to Diagnostic

Aids

5 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1940 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-323

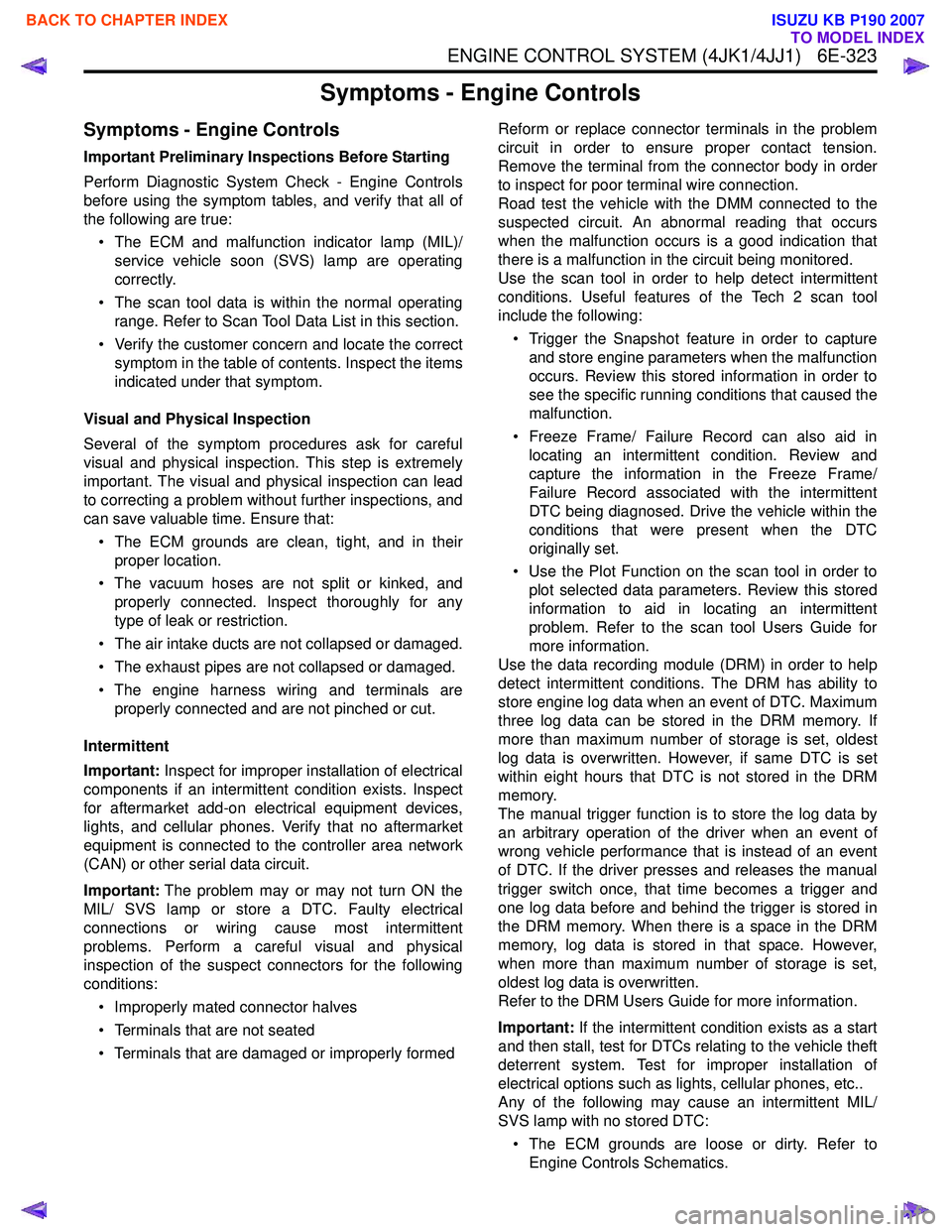

Symptoms - Engine Controls

Symptoms - Engine Controls

Important Preliminary Inspections Before Starting

Perform Diagnostic System Check - Engine Controls

before using the symptom tables, and verify that all of

the following are true:

• The ECM and malfunction indicator lamp (MIL)/ service vehicle soon (SVS) lamp are operating

correctly.

• The scan tool data is within the normal operating range. Refer to Scan Tool Data List in this section.

• Verify the customer concern and locate the correct symptom in the table of contents. Inspect the items

indicated under that symptom.

Visual and Physical Inspection

Several of the symptom procedures ask for careful

visual and physical inspection. This step is extremely

important. The visual and physical inspection can lead

to correcting a problem without further inspections, and

can save valuable time. Ensure that:

• The ECM grounds are clean, tight, and in their proper location.

• The vacuum hoses are not split or kinked, and properly connected. Inspect thoroughly for any

type of leak or restriction.

• The air intake ducts are not collapsed or damaged.

• The exhaust pipes are not collapsed or damaged.

• The engine harness wiring and terminals are properly connected and are not pinched or cut.

Intermittent

Important: Inspect for improper installation of electrical

components if an intermittent condition exists. Inspect

for aftermarket add-on electrical equipment devices,

lights, and cellular phones. Verify that no aftermarket

equipment is connected to the controller area network

(CAN) or other serial data circuit.

Important: The problem may or may not turn ON the

MIL/ SVS lamp or store a DTC. Faulty electrical

connections or wiring cause most intermittent

problems. Perform a careful visual and physical

inspection of the suspect connectors for the following

conditions:

• Improperly mated connector halves

• Terminals that are not seated

• Terminals that are damaged or improperly formed Reform or replace connector terminals in the problem

circuit in order to ensure proper contact tension.

Remove the terminal from the connector body in order

to inspect for poor terminal wire connection.

Road test the vehicle with the DMM connected to the

suspected circuit. An abnormal reading that occurs

when the malfunction occurs is a good indication that

there is a malfunction in the circuit being monitored.

Use the scan tool in order to help detect intermittent

conditions. Useful features of the Tech 2 scan tool

include the following:

• Trigger the Snapshot feature in order to capture and store engine parameters when the malfunction

occurs. Review this stored information in order to

see the specific running conditions that caused the

malfunction.

• Freeze Frame/ Failure Record can also aid in locating an intermittent condition. Review and

capture the information in the Freeze Frame/

Failure Record associated with the intermittent

DTC being diagnosed. Drive the vehicle within the

conditions that were present when the DTC

originally set.

• Use the Plot Function on the scan tool in order to plot selected data parameters. Review this stored

information to aid in locating an intermittent

problem. Refer to the scan tool Users Guide for

more information.

Use the data recording module (DRM) in order to help

detect intermittent conditions. The DRM has ability to

store engine log data when an event of DTC. Maximum

three log data can be stored in the DRM memory. If

more than maximum number of storage is set, oldest

log data is overwritten. However, if same DTC is set

within eight hours that DTC is not stored in the DRM

memory.

The manual trigger function is to store the log data by

an arbitrary operation of the driver when an event of

wrong vehicle performance that is instead of an event

of DTC. If the driver presses and releases the manual

trigger switch once, that time becomes a trigger and

one log data before and behind the trigger is stored in

the DRM memory. When there is a space in the DRM

memory, log data is stored in that space. However,

when more than maximum number of storage is set,

oldest log data is overwritten.

Refer to the DRM Users Guide for more information.

Important: If the intermittent condition exists as a start

and then stall, test for DTCs relating to the vehicle theft

deterrent system. Test for improper installation of

electrical options such as lights, cellular phones, etc..

Any of the following may cause an intermittent MIL/

SVS lamp with no stored DTC:

• The ECM grounds are loose or dirty. Refer to Engine Controls Schematics.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1943 of 6020

6E-326 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

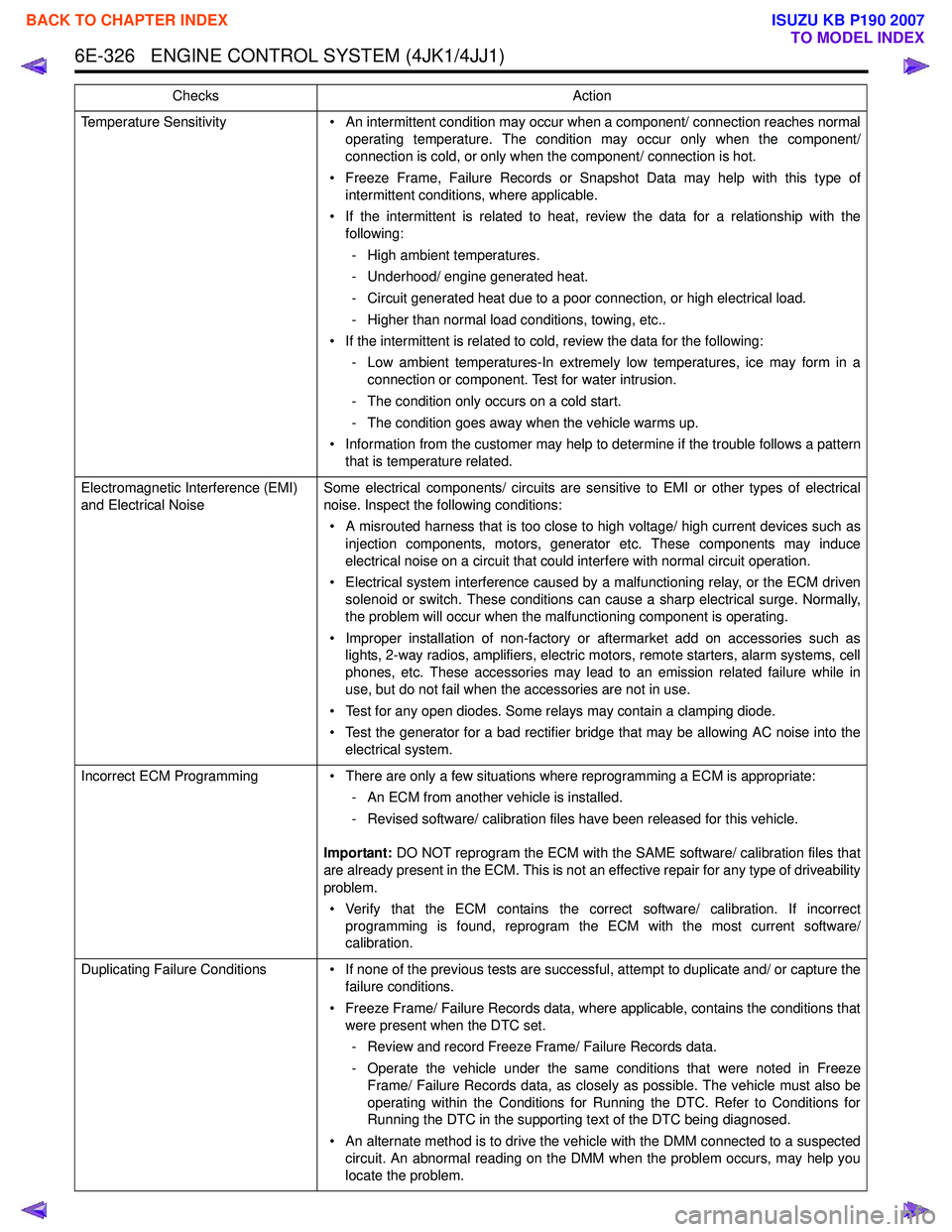

Temperature Sensitivity• An intermittent condition may occur when a component/ connection reaches normal

operating temperature. The condition may occur only when the component/

connection is cold, or only when the component/ connection is hot.

• Freeze Frame, Failure Records or Snapshot Data may help with this type of intermittent conditions, where applicable.

• If the intermittent is related to heat, review the data for a relationship with the following:

- High ambient temperatures.

- Underhood/ engine generated heat.

- Circuit generated heat due to a poor connection, or high electrical load.

- Higher than normal load conditions, towing, etc..

• If the intermittent is related to cold, review the data for the following: - Low ambient temperatures-In extremely low temperatures, ice may form in aconnection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern that is temperature related.

Electromagnetic Interference (EMI)

and Electrical Noise Some electrical components/ circuits are sensitive to EMI or other types of electrical

noise. Inspect the following conditions:

• A misrouted harness that is too close to high voltage/ high current devices such as injection components, motors, generator etc. These components may induce

electrical noise on a circuit that could interfere with normal circuit operation.

• Electrical system interference caused by a malfunctioning relay, or the ECM driven solenoid or switch. These conditions can cause a sharp electrical surge. Normally,

the problem will occur when the malfunctioning component is operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights, 2-way radios, amplifiers, electric motors, remote starters, alarm systems, cell

phones, etc. These accessories may lead to an emission related failure while in

use, but do not fail when the accessories are not in use.

• Test for any open diodes. Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the electrical system.

Incorrect ECM Programming • There are only a few situations where reprogramming a ECM is appropriate:

- An ECM from another vehicle is installed.

- Revised software/ calibration files have been released for this vehicle.

Important: DO NOT reprogram the ECM with the SAME software/ calibration files that

are already present in the ECM. This is not an effective repair for any type of driveability

problem.

• Verify that the ECM contains the correct software/ calibration. If incorrect programming is found, reprogram the ECM with the most current software/

calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/ or capture the failure conditions.

• Freeze Frame/ Failure Records data, where applicable, contains the conditions that were present when the DTC set.

- Review and record Freeze Frame/ Failure Records data.

- Operate the vehicle under the same conditions that were noted in Freeze Frame/ Failure Records data, as closely as possible. The vehicle must also be

operating within the Conditions for Running the DTC. Refer to Conditions for

Running the DTC in the supporting text of the DTC being diagnosed.

• An alternate method is to drive the vehicle with the DMM connected to a suspected circuit. An abnormal reading on the DMM when the problem occurs, may help you

locate the problem.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1967 of 6020

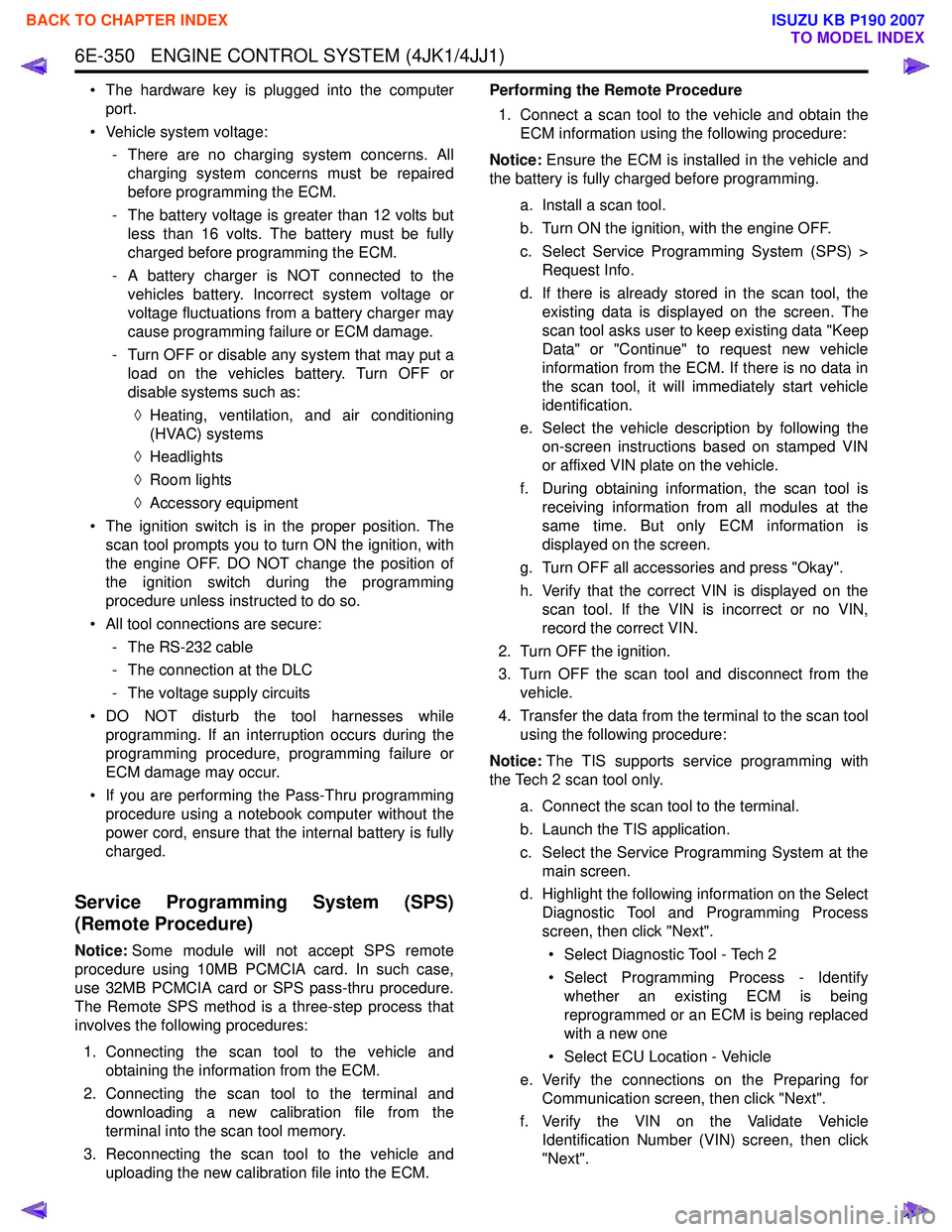

6E-350 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

• The hardware key is plugged into the computerport.

• Vehicle system voltage: - There are no charging system concerns. Allcharging system concerns must be repaired

before programming the ECM.

- The battery voltage is greater than 12 volts but less than 16 volts. The battery must be fully

charged before programming the ECM.

- A battery charger is NOT connected to the vehicles battery. Incorrect system voltage or

voltage fluctuations from a battery charger may

cause programming failure or ECM damage.

- Turn OFF or disable any system that may put a load on the vehicles battery. Turn OFF or

disable systems such as:

◊ Heating, ventilation, and air conditioning

(HVAC) systems

◊ Headlights

◊ Room lights

◊ Accessory equipment

• The ignition switch is in the proper position. The scan tool prompts you to turn ON the ignition, with

the engine OFF. DO NOT change the position of

the ignition switch during the programming

procedure unless instructed to do so.

• All tool connections are secure: - The RS-232 cable

- The connection at the DLC

- The voltage supply circuits

• DO NOT disturb the tool harnesses while programming. If an interruption occurs during the

programming procedure, programming failure or

ECM damage may occur.

• If you are performing the Pass-Thru programming procedure using a notebook computer without the

power cord, ensure that the internal battery is fully

charged.

Service Programming System (SPS)

(Remote Procedure)

Notice: Some module will not accept SPS remote

procedure using 10MB PCMCIA card. In such case,

use 32MB PCMCIA card or SPS pass-thru procedure.

The Remote SPS method is a three-step process that

involves the following procedures:

1. Connecting the scan tool to the vehicle and obtaining the information from the ECM.

2. Connecting the scan tool to the terminal and downloading a new calibration file from the

terminal into the scan tool memory.

3. Reconnecting the scan tool to the vehicle and uploading the new calibration file into the ECM. Performing the Remote Procedure

1. Connect a scan tool to the vehicle and obtain the ECM information using the following procedure:

Notice: Ensure the ECM is installed in the vehicle and

the battery is fully charged before programming.

a. Install a scan tool.

b. Turn ON the ignition, with the engine OFF.

c. Select Service Programming System (SPS) > Request Info.

d. If there is already stored in the scan tool, the existing data is displayed on the screen. The

scan tool asks user to keep existing data "Keep

Data" or "Continue" to request new vehicle

information from the ECM. If there is no data in

the scan tool, it will immediately start vehicle

identification.

e. Select the vehicle description by following the on-screen instructions based on stamped VIN

or affixed VIN plate on the vehicle.

f. During obtaining information, the scan tool is receiving information from all modules at the

same time. But only ECM information is

displayed on the screen.

g. Turn OFF all accessories and press "Okay".

h. Verify that the correct VIN is displayed on the scan tool. If the VIN is incorrect or no VIN,

record the correct VIN.

2. Turn OFF the ignition.

3. Turn OFF the scan tool and disconnect from the vehicle.

4. Transfer the data from the terminal to the scan tool using the following procedure:

Notice: The TIS supports service programming with

the Tech 2 scan tool only.

a. Connect the scan tool to the terminal.

b. Launch the TIS application.

c. Select the Service Programming System at the main screen.

d. Highlight the following information on the Select Diagnostic Tool and Programming Process

screen, then click "Next".

• Select Diagnostic Tool - Tech 2

• Select Programming Process - Identify whether an existing ECM is being

reprogrammed or an ECM is being replaced

with a new one

• Select ECU Location - Vehicle

e. Verify the connections on the Preparing for Communication screen, then click "Next".

f. Verify the VIN on the Validate Vehicle Identification Number (VIN) screen, then click

"Next".

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2002 of 6020

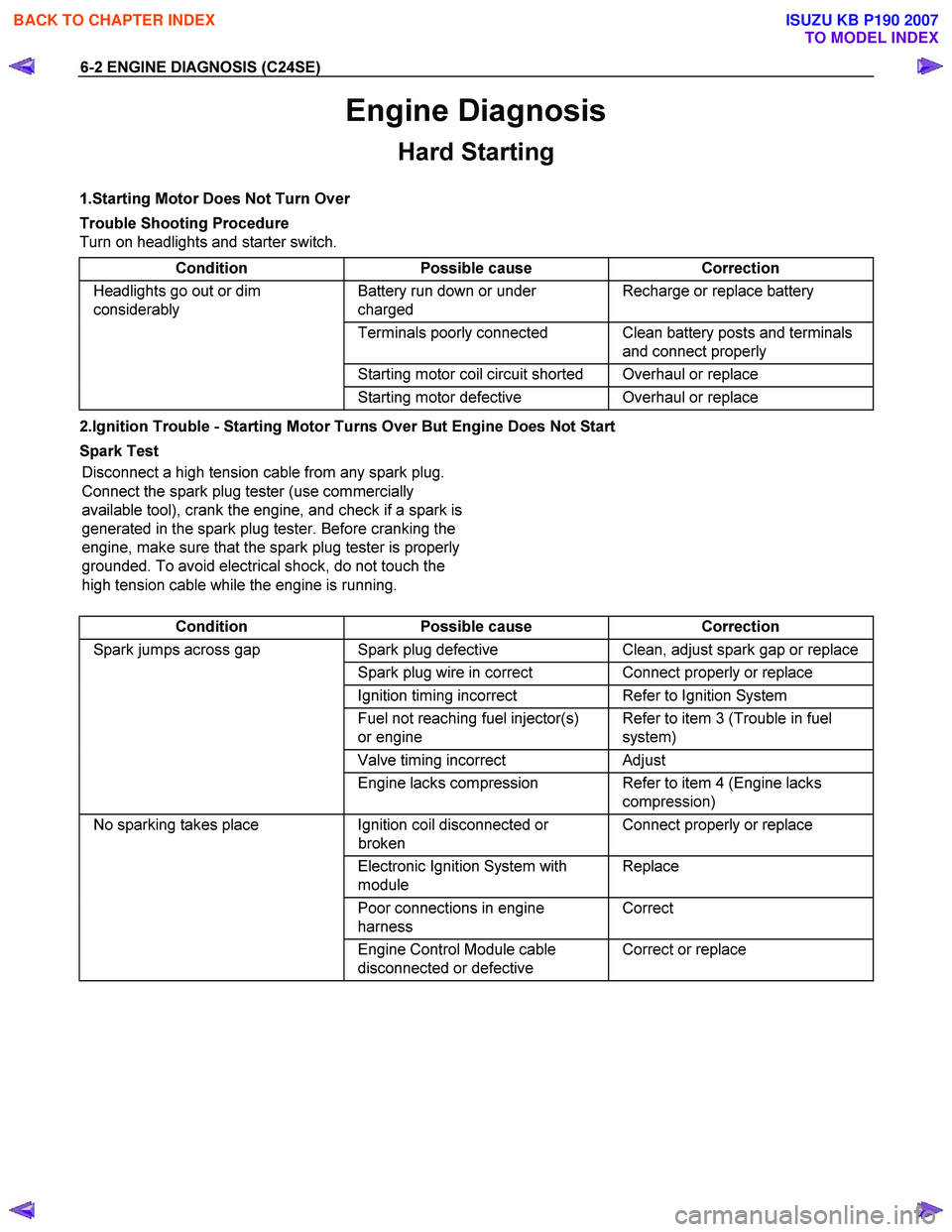

6-2 ENGINE DIAGNOSIS (C24SE)

Engine Diagnosis

Hard Starting

1.Starting Motor Does Not Turn Over

Trouble Shooting Procedure

Turn on headlights and starter switch.

Condition Possible cause Correction

Headlights go out or dim

considerably Battery run down or under

charged Recharge or replace battery

Terminals poorly connected Clean battery posts and terminals

and connect properly

Starting motor coil circuit shorted Overhaul or replace

Starting motor defective Overhaul or replace

2.Ignition Trouble - Starting Motor Turns Over But Engine Does Not Start

Spark Test Disconnect a high tension cable from any spark plug.

Connect the spark plug tester (use commercially

available tool), crank the engine, and check if a spark is

generated in the spark plug tester. Before cranking the

engine, make sure that the spark plug tester is properly

grounded. To avoid electrical shock, do not touch the

high tension cable while the engine is running.

Condition Possible cause Correction

Spark jumps across gap Spark plug defective Clean, adjust spark gap or replace

Spark plug wire in correct Connect properly or replace

Ignition timing incorrect Refer to Ignition System

Fuel not reaching fuel injector(s)

or engine Refer to item 3 (Trouble in fuel

system)

Valve timing incorrect Adjust

Engine lacks compression Refer to item 4 (Engine lacks

compression)

No sparking takes place Ignition coil disconnected or

broken Connect properly or replace

Electronic Ignition System with

module Replace

Poor connections in engine

harness Correct

Engine Control Module cable

disconnected or defective Correct or replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2142 of 6020

ENGINE ELECTRICAL 6D1-5

Battery fluid is a highly corrosive acid.

Should battery fluid come in contact with your eyes, skin,

fabric, or a painted surface, immediately and thoroughly rinse

the affected area with clean tap water.

Never allow metal tools or jumper cables to come in contact

with the positive battery terminal, or any other metal surface of

the vahicle. This will protect against a short circuit.

Always keep batteries out of reach of young children.

Jump Starting Procedure

1. Set the vehicle parking brake and place the shift lever in the

"NEUTRAL" position.

Turn "OFF" the ignition.

Turn "OFF" all lights and any other accessory requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is completel

y

clear, do not try to jump start.

3.

Attach the end of one jumper cable to the positive terminal

of the booster battery.

Attach the other end of the same cable to the positive

terminal of the discharged battery.

Do not allow the vehicles to touch each other. This will cause a ground connection, effectively neutralizing the

charging procedure.

Be sure that the booster battery has a 12 volt rating.

4.

Attach one end of the remaining cable to the negative

terminal of the booster battery.

Attach the other end of the same cable to a solid engine ground (such as the air conditioning compressor bracket o

r

the generator mounting bracket) of the vehicle with the

discharged battery.

The ground connection must be at least 450 mm (18 in.) from the battery of the vehicle whose battery is being

charged.

WARNING: NEVER ATTACH THE END OF THE JUMPER

CABLE DIRECTLY TO THE NEGATIVE TERMINAL OF THE

DEAD BATTERY.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical accessories have been turned "OFF".

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above directions in reverse order.

Be sure to first disconnect the negative cable from the vehicle with the discharged battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2161 of 6020

STARTING AND CHARGING SYSTEM 6D3-13

5. During current output tests please make sure that the

ammeter is securely connceted into the charge circuit.

6. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Onl

y

disconnect or connect timing lights when the engine is

switched off.

7. Make sure the warning lamp circuit is functioning normall

y

before commencing tests.

8. Battery isolation switches must only be operated when the engine is stopped.

9. To protect the charging system when using 240 volt chargers it is recommeneded that the battery is

disconnected whilst charging.

10. Due to the very low resistance value of the stator winding it may not be possible to obtain accurate readings without

special equipment.

11. 12 volts must never be connected to the "L" terminal of the regulator as this will damage the lamp driver circuit.

12. No loads apart from the warning lamp can be connected to the "L" termainal. The "W " terminal is provided for this

purpose.

Disassembly

1. Mark the relative positions of the end housings in relation to the stator assembly to aid reassembly. Use a permanent

marking pen do not use centre punched as this can cause

misalignmnet of the housings.

2. Remove the EP regulator from the slipring end housing b

y

removing the two screws. Tilt the regulator slightly from the

plug connection until the regulator clears the housing, then

lift clear.

3. Remove the four through bolts.

4. Carefully remove the stator assembly along with the slipring end housing taking care not to put strain on the stator wires.

5. To disconnect the stator from the rectifier assembly, grasp the stator wires close to the wire loop with a pair of long

nosed pliers, heat the joint with a soldering iron, when the

point becomes plastic apply a slight twisting motion to the

wires, then pull upwards to release the wires. Remove the

stator.

This procedure opens the wire loop to release the stato

r

connections easily.

6. To remove the rectifier remove the three retaining scre

w

and the B+ terminal nut and washers.

Note: the B+ bolt and the positive heatsink retaining screw are

fitted with mica insulating washers.

These must be discarded and replaced with new washers and

heatsink compound.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007