troubleshooting engine ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 804 of 6020

TROUBLESHOOTING 6 – 19

15. Starter Motor Problem

Visual/physical check the following items before diagnosis.

The battery terminals connection condition.

The ground connection condition.

The starter motor or the battery fastener condition.

The battery fluid level and specific gravity.

15-1 Starter motor pinion engages to ring gear but engine does not turn over

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Check the contact condition between the brush and

the commutator.

Was the brush and the commutator contact

intermittent? —

Replace the

brush or repair the

commutator. Go to Step 3

3 Were the brush and the commutator contact faces

dirty?

—

Clean contact face Go to Step 4

4 Was the pinion clutch slipped? — Replace the

pinion clutch Go to Step 5

5 Inspect the armature field coil.

Was there an open circuit or a short circuit in the

armature field coil? —

Repair or

replace the

armature field coil. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC. Solved

15-2 Incorrect pinion and ring gear engagement

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the pinion and the ring gear teeth.

Were the pinion and/or the ring gear teeth worn or

broken? —

Replace the wron parts. Go to Step 3

3 Inspect the pinion gear return movement.

Was the pinion gear return movement incorrect? —

Adjust or

replace the movement parts. Go to Step 4

4 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 837 of 6020

6A – 32 ENGINE MECHANICAL

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80 °C (158 – 176 °F).

2. Remove the following parts.

• Leak off pipe

• Injection nozzle holder bracket

• Injection nozzle holder

3. Install the following parts.

• Set the adapter and compression gauge (SST) to

the No.1 cylinder injection nozzle hole.

• Injection nozzle holder bracket

Injection nozzle holder bracket Bolt Torque

N·m (kg·m /lb·ft)

37 (3.8/27)

Compression Gauge: 5-8840-2675-0

Adapter; Compression Gauge: 5-8531-7001-0

4. Turn the engine over with the starter motor and take the compression gauge reading.

Compression Pressure MPa (kg/cm

2 /psi) at 200 rpm

Standard Limit

3.0 (31.0/441) 2.1 (21.7/309)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

If the measured value is less than the specified limit,

refer to “Troubleshooting” in this Manual.

F06XL056

901R100003

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1372 of 6020

6A-12 ENGINE MECHANICAL (4JK1/4JJ1)

Turbocharger Troubleshooting

Condition Possible Cause Correction

Air leakage from intake pipe rubber

hose Repair

Air leakage from intake cover Repair

Clogged intercooler cooling section Clean

Clogged air cleaner element Clean or replace

Intake throttle valve stuck

Repair or replace

Turbine and housing contact

(Interference) Replace

Excessive carbon deposit near

turbine exhaust port that interferes

with turbine Clean or repair

Rough turbine shaft rotation Repair or replace

Engine has less than normal power

Damaged turbine blade Repair or replace

Oil leakage from turbocharger oil

seal Repair or replace

Clogged turbocharger oil return

pipe Repair

Clogged center housing oil

passages Repair or replace

Blue exhaust smoke

Engine oil deterioration Change engine oil

Gas leakage from intake or

exhaust system Repair

Turbine and housing contact

(Interference) Repair or replace

Damaged turbine blade

Replace

Noisy turbocharger operation

Turbine shaft bearing abrasion or

scoring Repair or replace

Engine oil deterioration

Change engine oil

Clogged turbocharger oil feed pipe Repair

Excessive rotating part wear

Low engine oil pressure Repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1589 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-1

SECTION 6D

ENGINE ELECTRICAL

TABLE OF CONTENTS

Charging System ................................................ 6D-2

Servicing Cautions .......................................... 6D-2

Important Generator Components and

Function.......................................................... 6D-2

Troubleshooting .............................................. 6D-5

Diagnosis......................................................... 6D-7

Specifications .................................................. 6D-8

Unit Se rv ic ing (4 JJ 1) ....................................... .... ..6D -9

Disassembly .................................................... 6D-10

Inspection and Repair ..................................... 6D-11 Rotor Assembly ........................................... 6D-11

Stator Coil .................................................... 6D-12

Brushes ....................................................... 6D-12

Rectifier ....................................................... 6D-13

Regulator Assembly..................................... 6D-13

Measuring Procedure .................................. 6D-13

Reassembly..................................................... 6D-14

Final Assembly ................................................ 6D-14

Starter Motor ...................................................... 6D-15 Starting Circuit Diagram .................................. 6D-15

Removal and Installation ................................. 6D-15 Important Operations – Removal................. 6D-15

Important Operations – Installation.............. 6D-15

Disassembly .................................................... 6D-16 Disassembly Steps ...................................... 6D-16

Important Operations ................................... 6D-17

Inspection and Repair ..................................... 6D-20 Armature ...................................................... 6D-20

Yoke............................................................. 6D-21

Brush and Brush Holder .............................. 6D-22

Overrunning Clutch...................................... 6D-22

Bearing ........................................................ 6D-23

Reassembly..................................................... 6D-24 Reassembly Steps ....................................... 6D-24

Important Operations ................................... 6D-25

Inspection After Assembly ........................... 6D-26

Magnetic Switch .............................................. 6D-27

Torque Specifications...................................... 6D-28

Pre-Heating System ........................................... 6D-29 Inspection and Repair ..................................... 6D-29 Visual Check................................................ 6D-29

Glow Relay .................................................. 6D-29

Glow Plug .................................................... 6D-29

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1593 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-5

Troubleshooting

Symptoms

• No charging

• Inadequate charging

• Excessive charging

• Unstable charging current

• Abnormal generator noise

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2001 of 6020

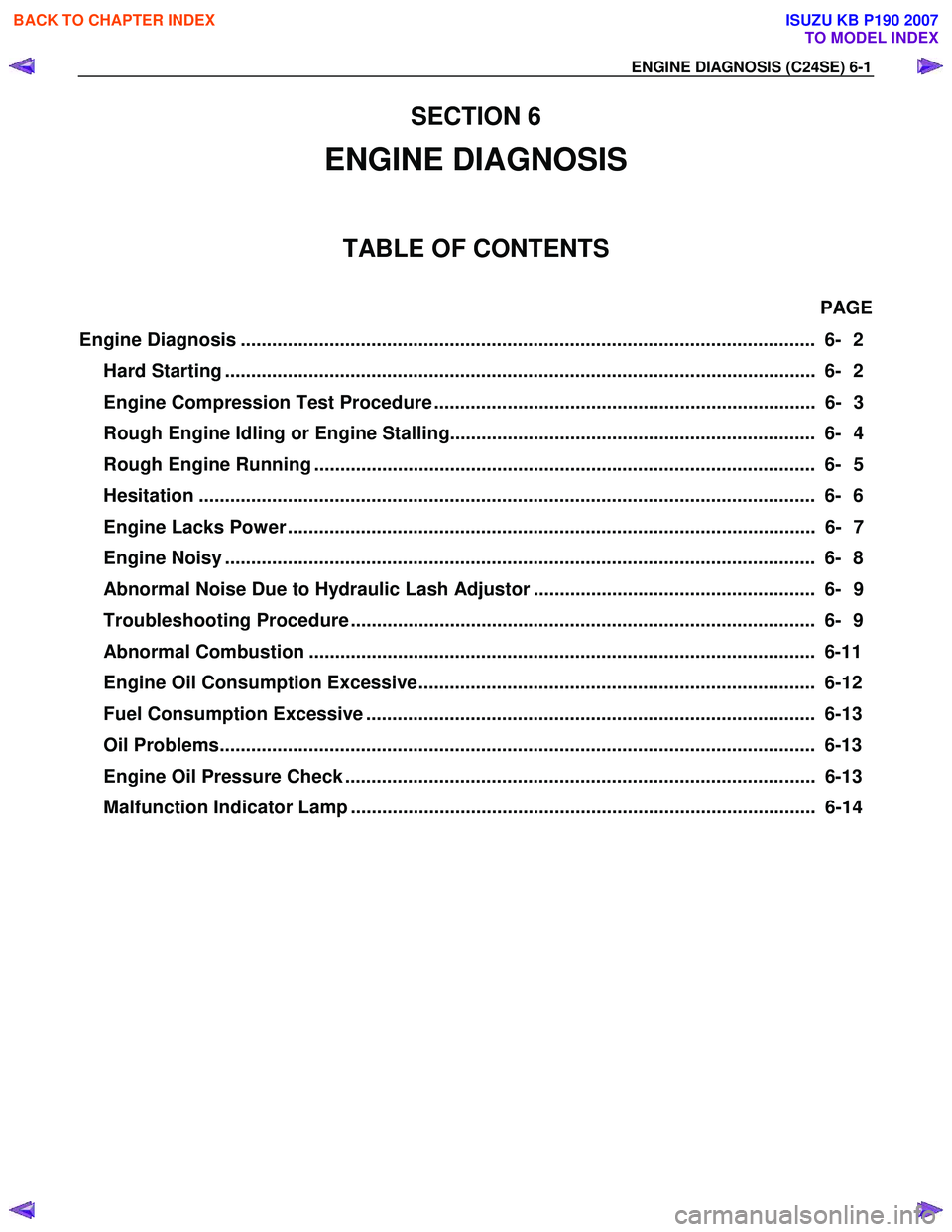

ENGINE DIAGNOSIS (C24SE) 6-1

SECTION 6

ENGINE DIAGNOSIS

TABLE OF CONTENTS

PAGE

Engine Diagnosis .............................................................................................................. 6- 2

Hard Starting ................................................................................................................. 6- 2

Engine Compression Test Procedure ......................................................................... 6- 3

Rough Engine Idling or Engine Stalling...................................................................... 6- 4

Rough Engine Running ................................................................................................ 6- 5

Hesitation ..................................................................................................................... . 6- 6

Engine Lacks Power ..................................................................................................... 6- 7

Engine Noisy ................................................................................................................. 6 - 8

Abnormal Noise Due to Hydraulic Lash Adjustor ...................................................... 6- 9

Troubleshooting Procedure ......................................................................................... 6- 9

Abnormal Combustion ................................................................................................. 6-11

Engine Oil Consumption Excessive............................................................................ 6-12

Fuel Consumption Excessive ...................................................................................... 6-13

Oil Problems.................................................................................................................. 6-13

Engine Oil Pressure Check .......................................................................................... 6-13

Malfunction Indicator Lamp ......................................................................................... 6-14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2004 of 6020

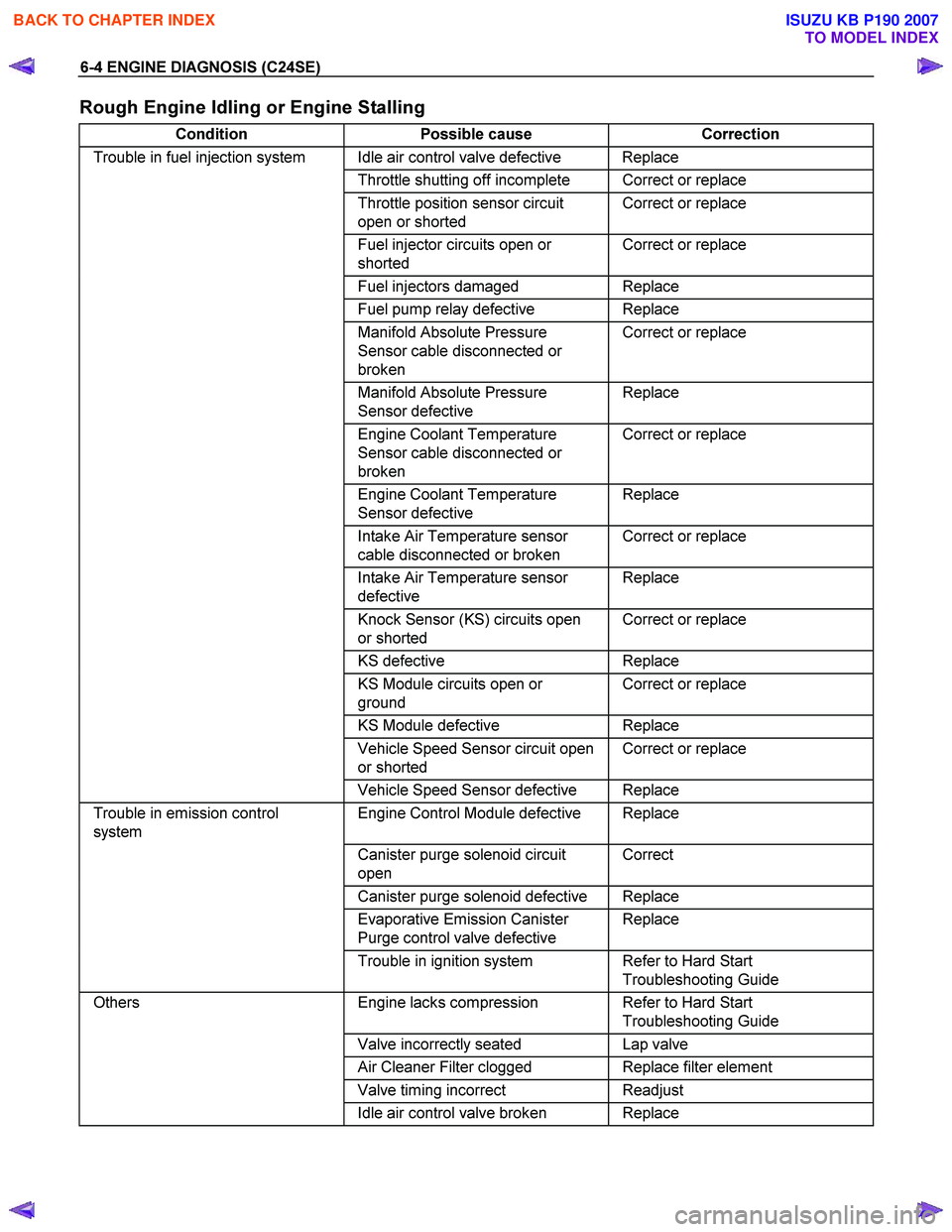

6-4 ENGINE DIAGNOSIS (C24SE)

Rough Engine Idling or Engine Stalling

Condition Possible cause Correction

Trouble in fuel injection system Idle air control valve defective Replace

Throttle shutting off incomplete Correct or replace

Throttle position sensor circuit

open or shorted Correct or replace

Fuel injector circuits open or

shorted Correct or replace

Fuel injectors damaged Replace

Fuel pump relay defective Replace

Manifold Absolute Pressure

Sensor cable disconnected or

broken Correct or replace

Manifold Absolute Pressure

Sensor defective Replace

Engine Coolant Temperature

Sensor cable disconnected or

broken Correct or replace

Engine Coolant Temperature

Sensor defective Replace

Intake Air Temperature sensor

cable disconnected or broken Correct or replace

Intake Air Temperature sensor

defective Replace

Knock Sensor (KS) circuits open

or shorted Correct or replace

KS

defective Replace

KS Module circuits open or

ground Correct or replace

KS Module defective Replace

Vehicle Speed Sensor circuit open

or shorted Correct or replace

Vehicle Speed Sensor defective Replace

Trouble in emission control

system Engine Control Module defective Replace

Canister purge solenoid circuit

open Correct

Canister purge solenoid defective Replace

Evaporative Emission Canister

Purge control valve defective Replace

Trouble in ignition system Refer to Hard Start

Troubleshooting Guide

Others Engine lacks compression Refer to Hard Start

Troubleshooting Guide

Valve incorrectly seated Lap valve

Air Cleaner Filter clogged Replace filter element

Valve timing incorrect Readjust

Idle air control valve broken Replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2007 of 6020

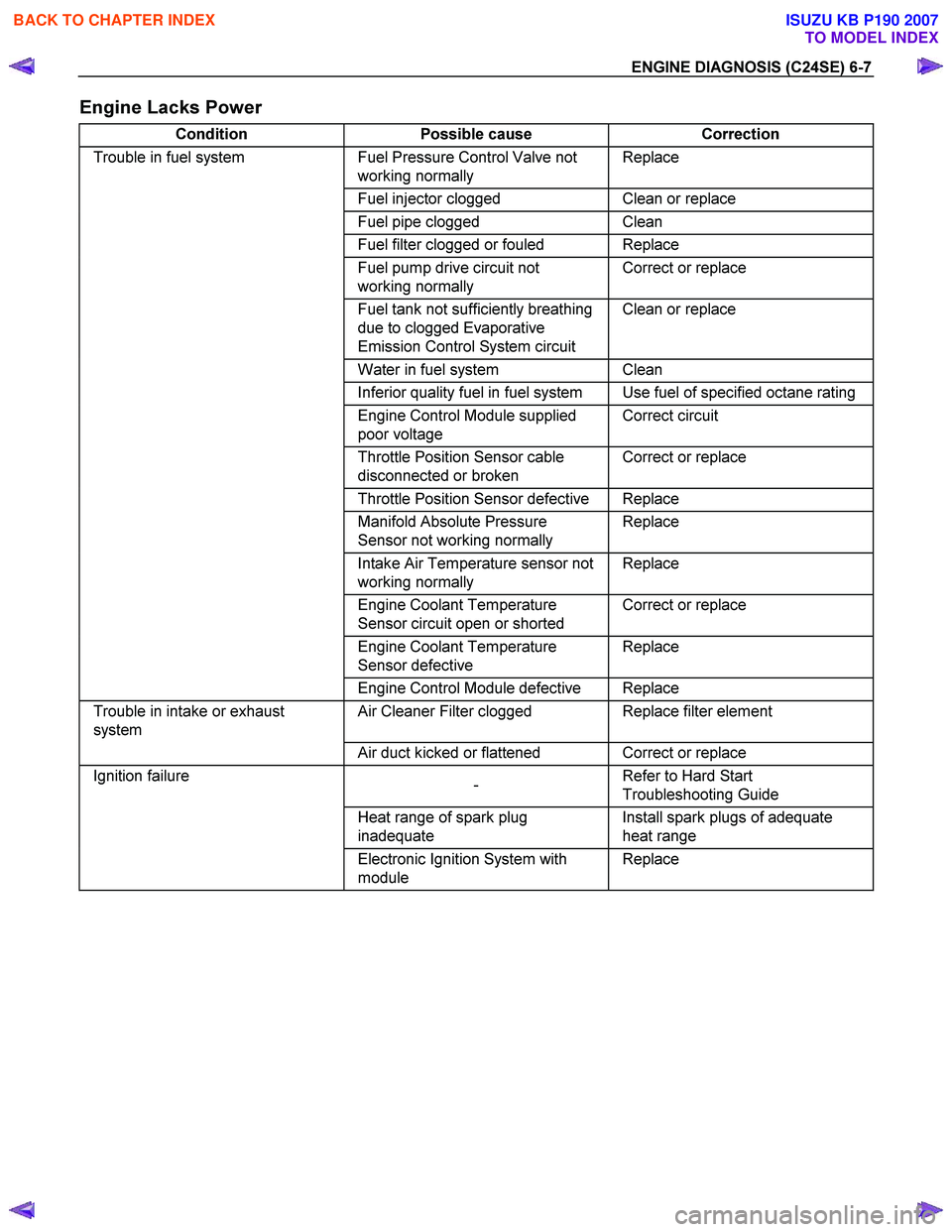

ENGINE DIAGNOSIS (C24SE) 6-7

Engine Lacks Power

Condition Possible cause Correction

Trouble in fuel system Fuel Pressure Control Valve not

working normally Replace

Fuel injector clogged Clean or replace

Fuel pipe clogged Clean

Fuel filter clogged or fouled Replace

Fuel pump drive circuit not

working normally Correct or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuit Clean or replace

Water in fuel system Clean

Inferior quality fuel in fuel system Use fuel of specified octane rating

Engine Control Module supplied

poor voltage Correct circuit

Throttle Position Sensor cable

disconnected or broken Correct or replace

Throttle Position Sensor defective Replace

Manifold Absolute Pressure

Sensor not working normally Replace

Intake Air Temperature sensor not

working normally Replace

Engine Coolant Temperature

Sensor circuit open or shorted Correct or replace

Engine Coolant Temperature

Sensor defective Replace

Engine Control Module defective Replace

Trouble in intake or exhaust

system Air Cleaner Filter clogged Replace filter element

Air duct kicked or flattened Correct or replace

Ignition failure

- Refer to Hard Start

Troubleshooting Guide

Heat range of spark plug

inadequate Install spark plugs of adequate

heat range

Electronic Ignition System with

module Replace

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2009 of 6020

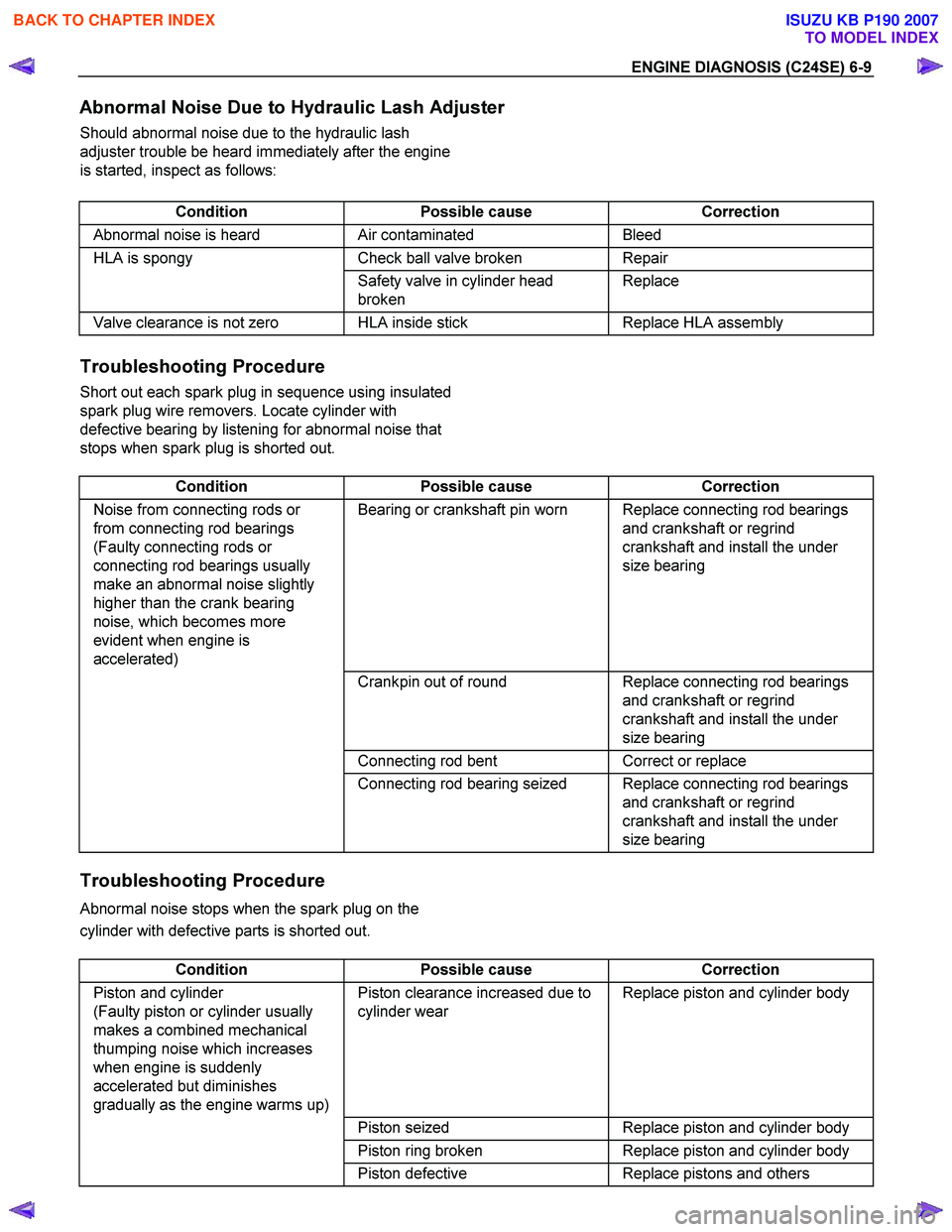

ENGINE DIAGNOSIS (C24SE) 6-9

Abnormal Noise Due to Hydraulic Lash Adjuster

Should abnormal noise due to the hydraulic lash

adjuster trouble be heard immediately after the engine

is started, inspect as follows:

Condition Possible cause Correction

Abnormal noise is heard Air contaminated Bleed

HLA is spongy Check ball valve broken Repair

Safety valve in cylinder head

broken Replace

Valve clearance is not zero HLA inside stick

Replace HLA assembly

Troubleshooting Procedure

Short out each spark plug in sequence using insulated

spark plug wire removers. Locate cylinder with

defective bearing by listening for abnormal noise that

stops when spark plug is shorted out.

Condition Possible cause Correction

Noise from connecting rods or

from connecting rod bearings

(Faulty connecting rods or

connecting rod bearings usually

make an abnormal noise slightly

higher than the crank bearing

noise, which becomes more

evident when engine is

accelerated) Bearing or crankshaft pin worn Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Crankpin out of round Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Connecting rod bent Correct or replace

Connecting rod bearing seized Replace connecting rod bearings

and crankshaft or regrind

crankshaft and install the under

size bearing

Troubleshooting Procedure

Abnormal noise stops when the spark plug on the

cylinder with defective parts is shorted out.

Condition Possible cause Correction

Piston and cylinder

(Faulty piston or cylinder usually

makes a combined mechanical

thumping noise which increases

when engine is suddenly

accelerated but diminishes

gradually as the engine warms up) Piston clearance increased due to

cylinder wear Replace piston and cylinder body

Piston seized Replace piston and cylinder body

Piston ring broken Replace piston and cylinder body

Piston defective Replace pistons and others

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2010 of 6020

6-10 ENGINE DIAGNOSIS (C24SE)

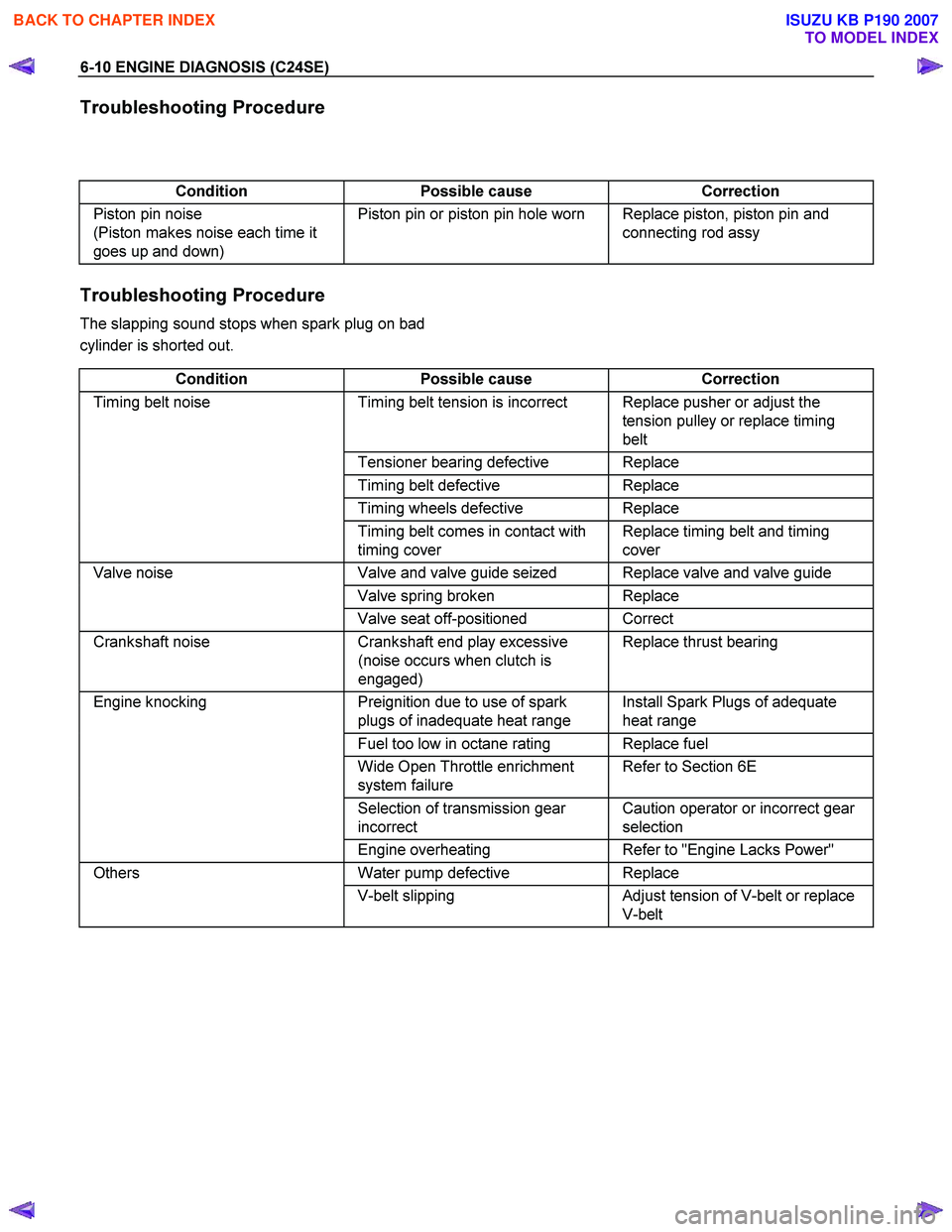

Troubleshooting Procedure

Condition Possible cause Correction

Piston pin noise

(Piston makes noise each time it

goes up and down) Piston pin or piston pin hole worn Replace piston, piston pin and

connecting rod assy

Troubleshooting Procedure

The slapping sound stops when spark plug on bad

cylinder is shorted out.

Condition Possible cause Correction

Timing belt noise Timing belt tension is incorrect Replace pusher or adjust the

tension pulley or replace timing

belt

Tensioner bearing defective Replace

Timing belt defective Replace

Timing wheels defective Replace

Timing belt comes in contact with

timing cover Replace timing belt and timing

cover

Valve noise Valve and valve guide seized Replace valve and valve guide

Valve spring broken Replace

Valve seat off-positioned Correct

Crankshaft noise Crankshaft end play excessive

(noise occurs when clutch is

engaged) Replace thrust bearing

Engine knocking

Preignition due to use of spark

plugs of inadequate heat range Install Spark Plugs of adequate

heat range

Fuel too low in octane rating Replace fuel

Wide Open Throttle enrichment

system failure Refer to Section 6E

Selection of transmission gear

incorrect Caution operator or incorrect gear

selection

Engine overheating Refer to "Engine Lacks Power"

Others Water pump defective Replace

V-belt slipping Adjust tension of V-belt or replace

V-belt

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007