warning ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 308 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-47

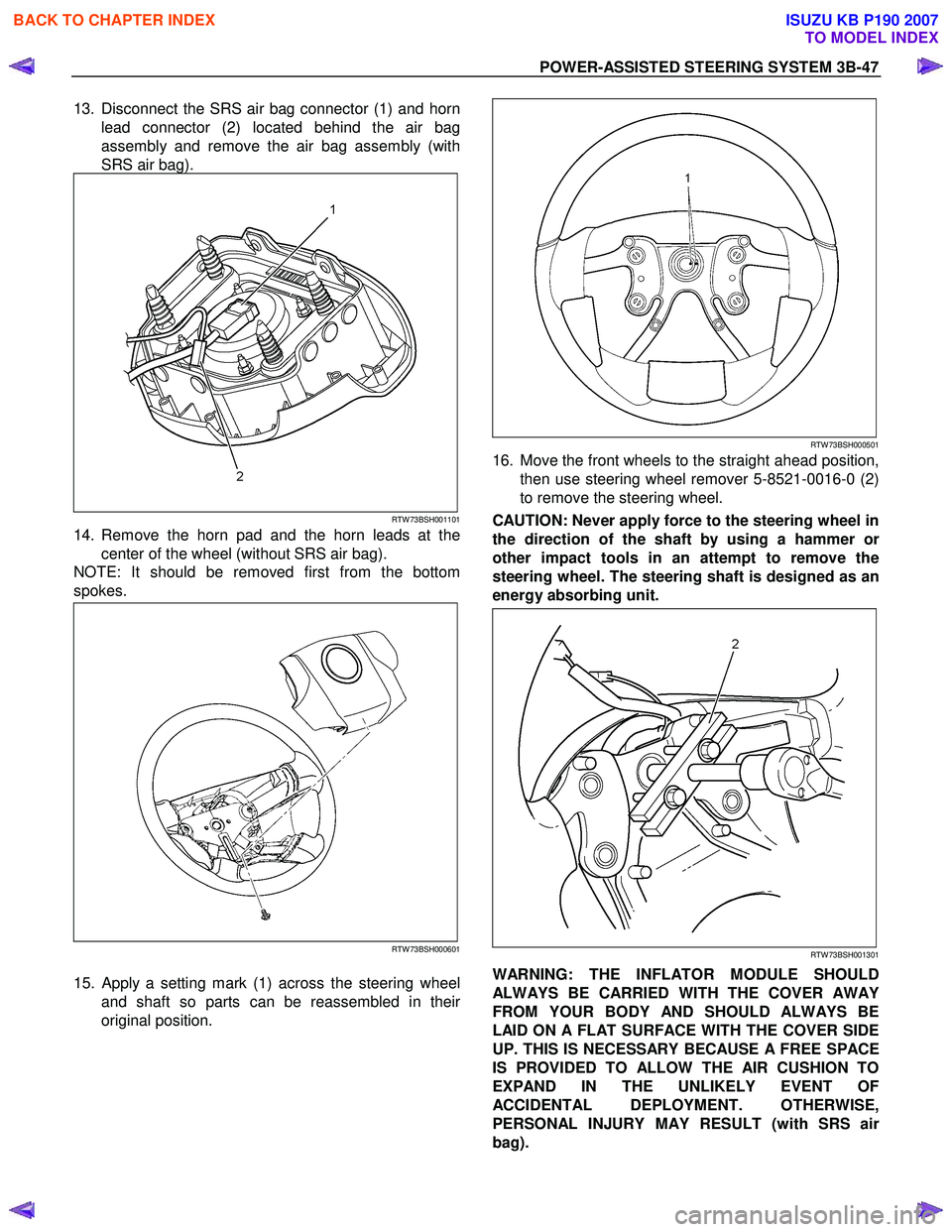

13. Disconnect the SRS air bag connector (1) and horn

lead connector (2) located behind the air bag

assembly and remove the air bag assembly (with

SRS air bag).

RTW 73BSH001101

14. Remove the horn pad and the horn leads at the center of the wheel (without SRS air bag).

NOTE: It should be removed first from the bottom

spokes.

RTW 73BSH000601

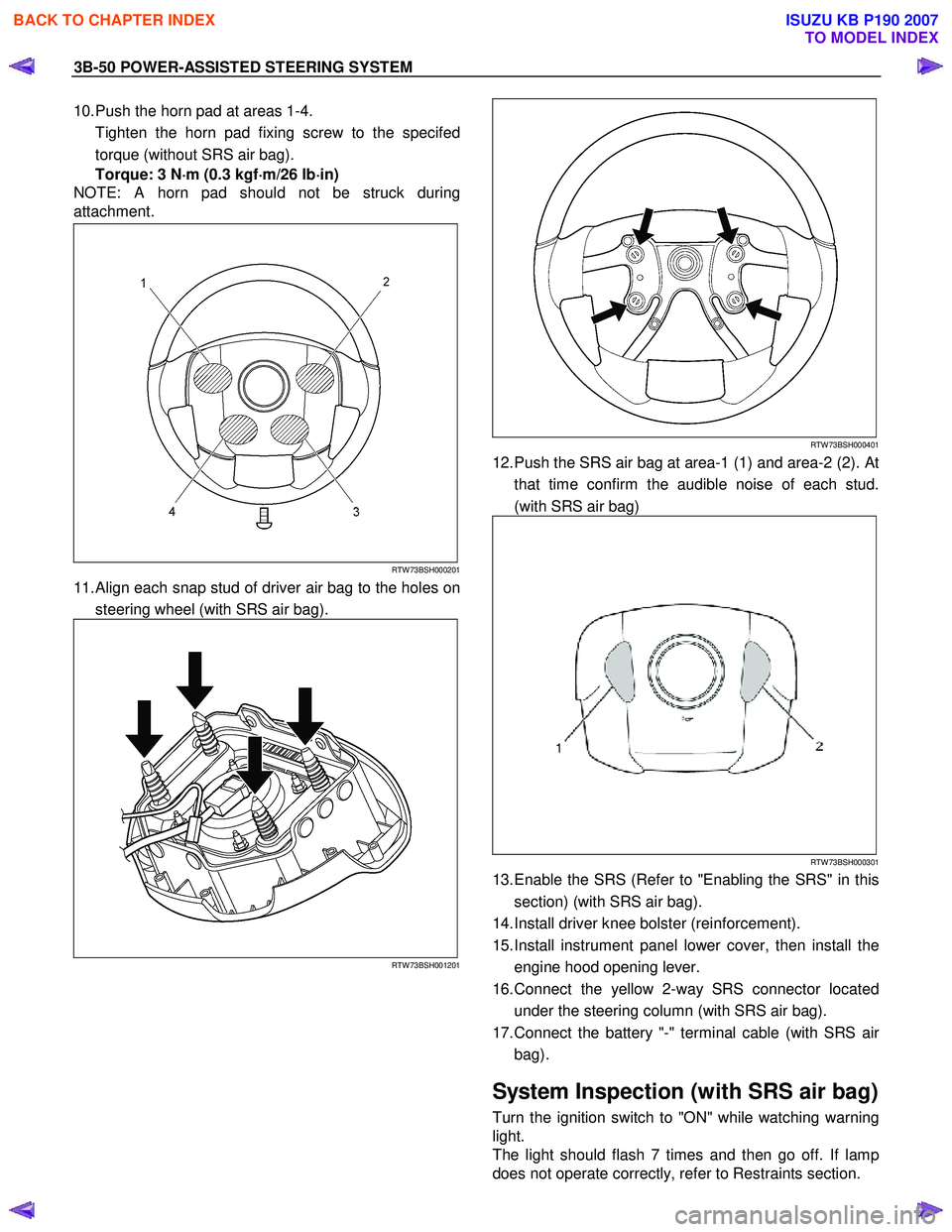

15.

Apply a setting mark (1) across the steering wheel

and shaft so parts can be reassembled in thei

r

original position.

RTW 73BSH000501

16. Move the front wheels to the straight ahead position,

then use steering wheel remover 5-8521-0016-0 (2)

to remove the steering wheel.

CAUTION: Never apply force to the steering wheel in

the direction of the shaft by using a hammer o

r

other impact tools in an attempt to remove the

steering wheel. The steering shaft is designed as an

energy absorbing unit.

RTW 73BSH001301

WARNING: THE INFLATOR MODULE SHOULD

ALWAYS BE CARRIED WITH THE COVER AWAY

FROM YOUR BODY AND SHOULD ALWAYS BE

LAID ON A FLAT SURFACE WITH THE COVER SIDE

UP. THIS IS NECESSARY BECAUSE A FREE SPACE

IS PROVIDED TO ALLOW THE AIR CUSHION TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. OTHERWISE,

PERSONAL INJURY MAY RESULT (with SRS ai

r

bag).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 311 of 6020

3B-50 POWER-ASSISTED STEERING SYSTEM

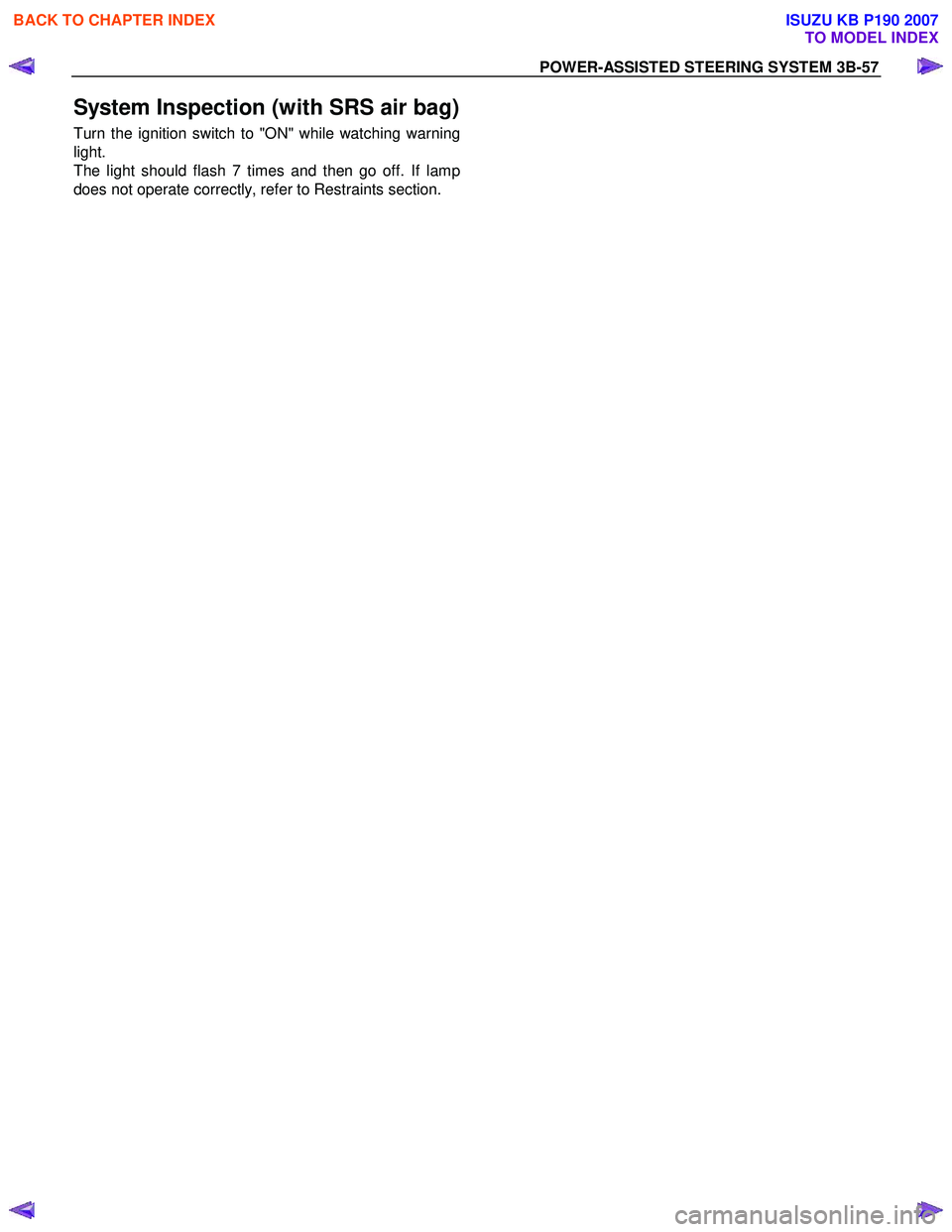

10. Push the horn pad at areas 1-4.

Tighten the horn pad fixing screw to the specifed torque (without SRS air bag).

Torque: 3 N ⋅

⋅⋅

⋅

m (0.3 kgf ⋅

⋅⋅

⋅

m/26 lb ⋅

⋅⋅

⋅

in)

NOTE: A horn pad should not be struck during

attachment.

RTW 73BSH000201

11. Align each snap stud of driver air bag to the holes on

steering wheel (with SRS air bag).

RTW 73BSH001201

RTW 73BSH000401

12. Push the SRS air bag at area-1 (1) and area-2 (2). At that time confirm the audible noise of each stud.

(with SRS air bag)

RTW 73BSH000301

13. Enable the SRS (Refer to "Enabling the SRS" in this section) (with SRS air bag).

14. Install driver knee bolster (reinforcement).

15. Install instrument panel lower cover, then install the engine hood opening lever.

16. Connect the yellow 2-way SRS connector located under the steering column (with SRS air bag).

17. Connect the battery "-" terminal cable (with SRS ai

r

bag).

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 318 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-57

System Inspection (with SRS air bag)

Turn the ignition switch to "ON" while watching warning

light.

The light should flash 7 times and then go off. If lamp

does not operate correctly, refer to Restraints section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 328 of 6020

3C-8 FRONT SUSPENSION

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will indicate those fasteners that require

replacement after removal. ISUZU/GM will also

indicate the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 351 of 6020

3C-30 FRONT SUSPENSION

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 418 of 6020

4A-2 PROPELLER SHAFT

Service Precaution

WARNING: THIS VEHICLE HAS A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS).

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS

OR THE SRS WIRING, REFER TO THE SRS

SERVICE INFORMATION. FAILURE TO FOLLOW

WARNING COULD RESULT IN POSSIBLE AIR

BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION : Always use the correct fastener in the

proper location. When you replace a fastener,

use ONLY the exact part number for that

application. ISUZU/GM will call out those

fasteners that require a replacement afte

r

removal. ISUZU/GM will also call out the

fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastene

r

torque and the joint clamping force, and may

damage the fastener. When you install fasteners,

use the correct tightening sequence and

specifications. Following these instructions can

help you avoid damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 446 of 6020

4B-2 REAR AXLE

Service Precaution

WARNING:

THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE REFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.

CAUTION:

Always use the correct fastener in the prope

r

location. When you replace a fastener, use ONLY

the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastener torque

and the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 579 of 6020

SHIFT ON THE FLY SYSTEM 4C2-1

SERVICE PRECAUTION

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 593 of 6020

BRAKE CON TROL SY STE M 5 A

EHCU, Brake Pipe Diagram .......................................................................................... 5A-5

Hydraulic Unit (H/U) ...................................................................................................... 5A-6

Normal Braking ............................................................................................................. 5A- 7

Pressure Isolation (Pressure Maintain)....................................................................... 5A-8

Pressure Reduction ...................................................................................................... 5A-9

Brake Release ............................................................................................................... 5A -10

Circuit Diagram ............................................................................................................. 5A -11

Connector List ............................................................................................................... 5 A-14

Parts Location ............................................................................................................... 5 A-16

EHCU Pin-Assignment .................................................................................................. 5A-20

System Components .................................................................................................... 5A-22

Electronic Hydraulic Control Unit (EHCU).............................................................. 5A-22

ABS Warning Lamp .................................................................................................. 5A-22

Wheel Speed Sensor (WSS) .................................................................................... 5A-22

G Sensor ................................................................................................................... 5A- 22

Normal and Anti-lock Braking ................................................................................. 5A-22

Electronic Brake-force Distribution (EBD) System................................................ 5A-23

Brake Pedal Travel ................................................................................................... 5A-23

Acronyms and Abbreviations....................................................................................... 5A-23

General Diagnosis ............................................................................................................. 5A-23

General Information ...................................................................................................... 5A-23

ABS Service Precautions ............................................................................................. 5A-23

Computer System Service Precautions ...................................................................... 5A-24

General Service Precautions ....................................................................................... 5A-24

Note on Intermittents .................................................................................................... 5A-24

Test Driving ABS Complaint Vehicles ......................................................................... 5A-24

"ABS" Warning Lamp ................................................................................................... 5A-25

Normal Operation .......................................................................................................... 5A-2 5

SECTION 5A

BRAKE CONTROL SYSTEM

TABLE OF CONTENTS

Ser vice Precau tion ............................................................................................................ 5A -3

General Descrip tio n........................................................................................................... 5A -4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 594 of 6020

5A -1 BR AKE CON TROL SY STE M

Brake (E BD) Warning Lamp ......................................................................................... 5 A -25

Tech 2 Scan Tool .......................................................................................................... 5 A -2 6

Da ta List ( T ech 2 ).......................................................................................................... 5 A -32

Diagnostic Trouble Codes ................................................................................................ 5 A -33

Diagnosis By " A BS" Warning Lamp Illumination Patter n.............................................. 5 A -35

Basic Diagnostic Flow Chart ............................................................................................ 5 A -38

Basic Inspec tion Procedure ............................................................................................. 5 A -40

1. Basic Inspec tion of Ser vice Brake .......................................................................... 5 A -40

2. Ground Inspection .................................................................................................... 5 A -40

W heel Speed Sensor Inspec tion Procedure.................................................................... 5 A -41

Symptom Diagnosis .......................................................................................................... 5A- 42

ABS Works Frequently But Vehicle Does Not Decelerate ......................................... 5A-42

Uneven Braking Occurs While ABS Works ................................................................ 5A-43

The Wheels Are Locked................................................................................................ 5A-43

Brake Pedal Feed Is Abnormal .................................................................................... 5A-44

Braking Sound (From EHCU) Is Heard While Not Braking ........................................ 5A-45

No ABS Warning Lamp ................................................................................................. 5A-46

ABS Warning Lamp ON Steady.................................................................................... 5A-47

DTC C0221 (Flash Code 21) Front Right Wheel Speed Sensor

Short Circuit or Circuit Open ......................................................................................... 5A-48

DTC C0222 (Flash Code 22) Front Right Wheel Speed Sensor Signal Malfunction..... 5A-50

DTC C0225 (Flash Code 25) Front Left Wheel Speed Sensor Short Circuit or

Circuit Open ................................................................................................................ .... 5A-52

DTC C0226 (Flash Code 26) Front Left Wheel Speed Sensor Signal Malfunction ....... 5A-54

DTC C0231 (Flash Code 31) Rear Right Wheel Speed Sensor Short Circuit or

Circuit Open ................................................................................................................ .... 5A-56

DTC C0232 (Flash Code 32) Rear Right Wheel Speed Sensor Signal Malfunction ...... 5A-58

DTC C0235 (Flash Code 35) Rear Left Wheel Speed Sensor Short Circuit or

Circuit Open ................................................................................................................ .... 5A-60

DTC C0236 (Flash Code 36) Rear Left Wheel Speed Sensor Signal Malfunction ........ 5A-62

DTC C0238 (Flash Code 38) Front Speed Sensor Correlation ....................................... 5A-64

DTC C0241 (Flash Code 41) Front Right Hold Solenoid Valve Circuit .......................... 5A-66

DTC C0242 (Flash Code 42) Front Right Release Solenoid Valve Circuit..................... 5A-66

DTC C0245 (Flash Code 45) Front Left Hold Solenoid Valve Circuit ............................. 5A-68

DTC C0246 (Flash Code 46) Front Left Release Solenoid Valve Circuit ....................... 5A-68

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007