light ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3001 of 6020

Engine Mechanical – V6 Page 6A1–224

Page 6A1–224

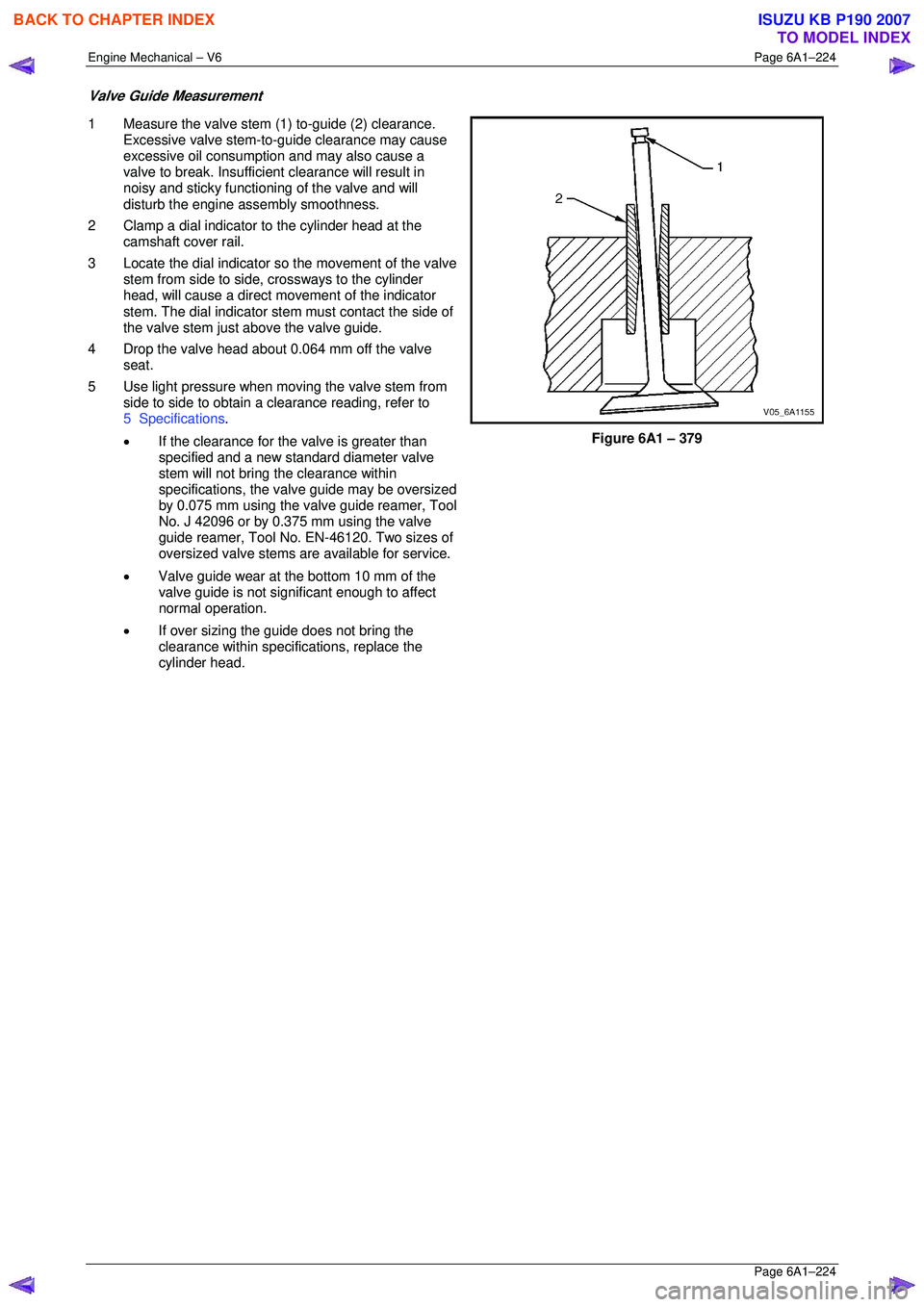

Valve Guide Measurement

1 Measure the valve stem (1) to-guide (2) clearance.

Excessive valve stem-to-guide clearance may cause

excessive oil consumption and may also cause a

valve to break. Insufficient clearance will result in

noisy and sticky functioning of the valve and will

disturb the engine assembly smoothness.

2 Clamp a dial indicator to the cylinder head at the camshaft cover rail.

3 Locate the dial indicator so the movement of the valve

stem from side to side, crossways to the cylinder

head, will cause a direct mo vement of the indicator

stem. The dial indicator stem must contact the side of

the valve stem just above the valve guide.

4 Drop the valve head about 0.064 mm off the valve seat.

5 Use light pressure when moving the valve stem from side to side to obtain a clearance reading, refer to

5 Specifications .

• If the clearance for the valve is greater than

specified and a new st andard diameter valve

stem will not bring the clearance within

specifications, the valv e guide may be oversized

by 0.075 mm using the valve guide reamer, Tool

No. J 42096 or by 0.375 mm using the valve

guide reamer, Tool No. EN-46120. Two sizes of

oversized valve stems are available for service.

• Valve guide wear at the bottom 10 mm of the

valve guide is not significant enough to affect

normal operation.

• If over sizing the guide does not bring the

clearance within specif ications, replace the

cylinder head.

Figure 6A1 – 379

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3004 of 6020

Engine Mechanical – V6 Page 6A1–227

Page 6A1–227

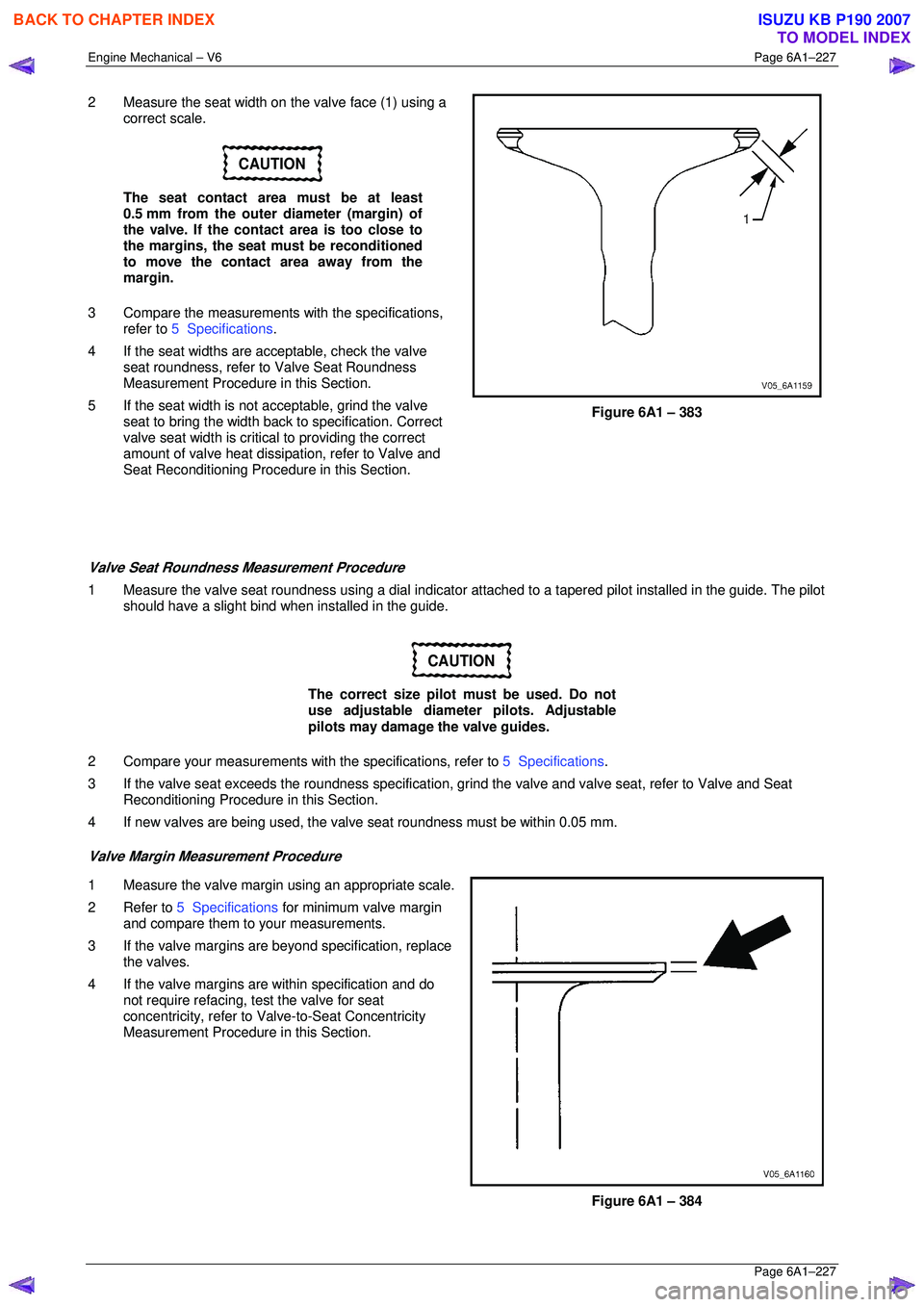

2 Measure the seat width on the valve face (1) using a

correct scale.

CAUTION

The seat contact area must be at least

0.5 mm from the outer diameter (margin) of

the valve. If the contact area is too close to

the margins, the seat must be reconditioned

to move the contact area away from the

margin.

3 Compare the measurements with the specifications,

refer to 5 Specifications .

4 If the seat widths are a cceptable, check the valve

seat roundness, refer to Valve Seat Roundness

Measurement Procedure in this Section.

5 If the seat width is not acceptable, grind the valve

seat to bring the width back to specification. Correct

valve seat width is critical to providing the correct

amount of valve heat dissipat ion, refer to Valve and

Seat Reconditioning Procedure in this Section.

Figure 6A1 – 383

Valve Seat Roundness Measurement Procedure

1 Measure the valve seat roundness using a dial indicator a ttached to a tapered pilot installed in the guide. The pilot

should have a slight bind w hen installed in the guide.

CAUTION

The correct size pilot must be used. Do not

use adjustable diameter pilots. Adjustable

pilots may damage the valve guides.

2 Compare your measurements with the specifications, refer to 5 Specifications.

3 If the valve seat exceeds the roundne ss specification, grind the valve and valve seat, refer to Valve and Seat

Reconditioning Procedure in this Section.

4 If new valves are being used, the valv e seat roundness must be within 0.05 mm.

Valve Margin Measurement Procedure

1 Measure the valve margin using an appropriate scale.

2 Refer to 5 Specifications for minimum valve margin

and compare them to your measurements.

3 If the valve margins are beyond specification, replace the valves.

4 If the valve margins are within specification and do not require refacing, test the valve for seat

concentricity, refer to Valve-to-Seat Concentricity

Measurement Procedure in this Section.

Figure 6A1 – 384

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3005 of 6020

Engine Mechanical – V6 Page 6A1–228

Page 6A1–228

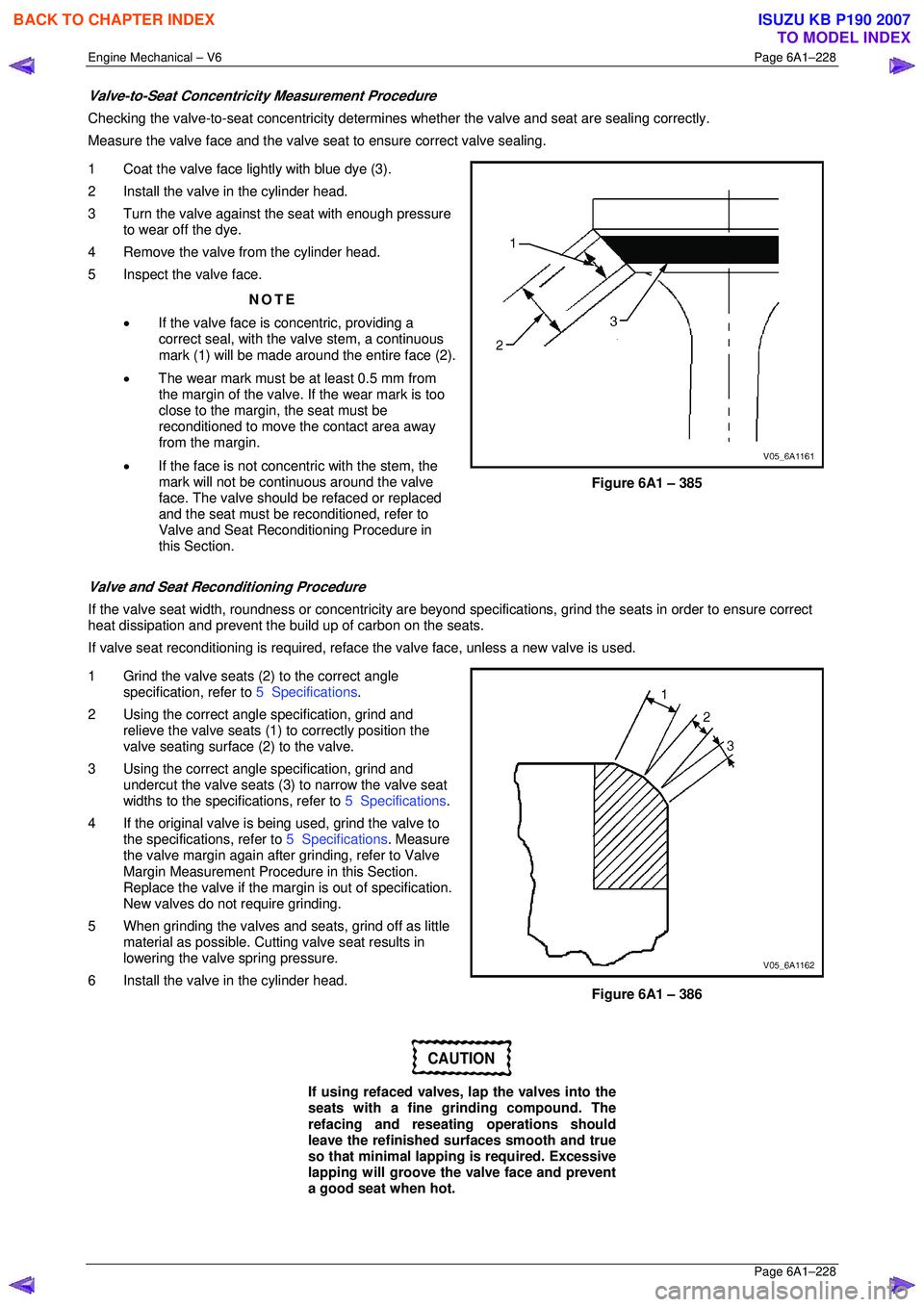

Valve-to-Seat Concentricity Measurement Procedure

Checking the valve-to-seat concentricity determines whether the valve and seat are sealing correctly.

Measure the valve face and the valve s eat to ensure correct valve sealing.

1 Coat the valve face lightly with blue dye (3).

2 Install the valve in the cylinder head.

3 Turn the valve against the seat with enough pressure to wear off the dye.

4 Remove the valve from the cylinder head.

5 Inspect the valve face.

NOTE

• If the valve face is concentric, providing a

correct seal, with the valve stem, a continuous

mark (1) will be made around the entire face (2).

• The wear mark must be at least 0.5 mm from

the margin of the valve. If the wear mark is too

close to the margin, the seat must be

reconditioned to move the contact area away

from the margin.

• If the face is not concentric with the stem, the

mark will not be continuous around the valve

face. The valve should be refaced or replaced

and the seat must be reconditioned, refer to

Valve and Seat Reconditioning Procedure in

this Section.

Figure 6A1 – 385

Valve and Seat Reconditioning Procedure

If the valve seat width, roundness or conc entricity are beyond specifications, grind the seats in order to ensure correct

heat dissipation and prevent the bu ild up of carbon on the seats.

If valve seat reconditioning is required, reface the valve face, unless a new valve is used.

1 Grind the valve seats (2) to the correct angle specification, refer to 5 Specifications.

2 Using the correct angle specification, grind and

relieve the valve seats (1) to correctly position the

valve seating surface (2) to the valve.

3 Using the correct angle specification, grind and

undercut the valve seats (3) to narrow the valve seat

widths to the specifications, refer to 5 Specifications.

4 If the original valve is being used, grind the valve to the specifications, refer to 5 Specifications. Measure

the valve margin again after grinding, refer to Valve

Margin Measurement Procedure in this Section.

Replace the valve if the margin is out of specification.

New valves do not require grinding.

5 When grinding the valves and seats, grind off as little material as possible. Cutti ng valve seat results in

lowering the valve spring pressure.

6 Install the valve in the cylinder head.

Figure 6A1 – 386

CAUTION

If using refaced valves, lap the valves into the

seats with a fine grinding compound. The

refacing and reseati ng operations should

leave the refinished surfaces smooth and true

so that minimal lapping is required. Excessive

lapping will groove the valve face and prevent

a good seat when hot.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3013 of 6020

Engine Mechanical – V6 Page 6A1–236

Page 6A1–236

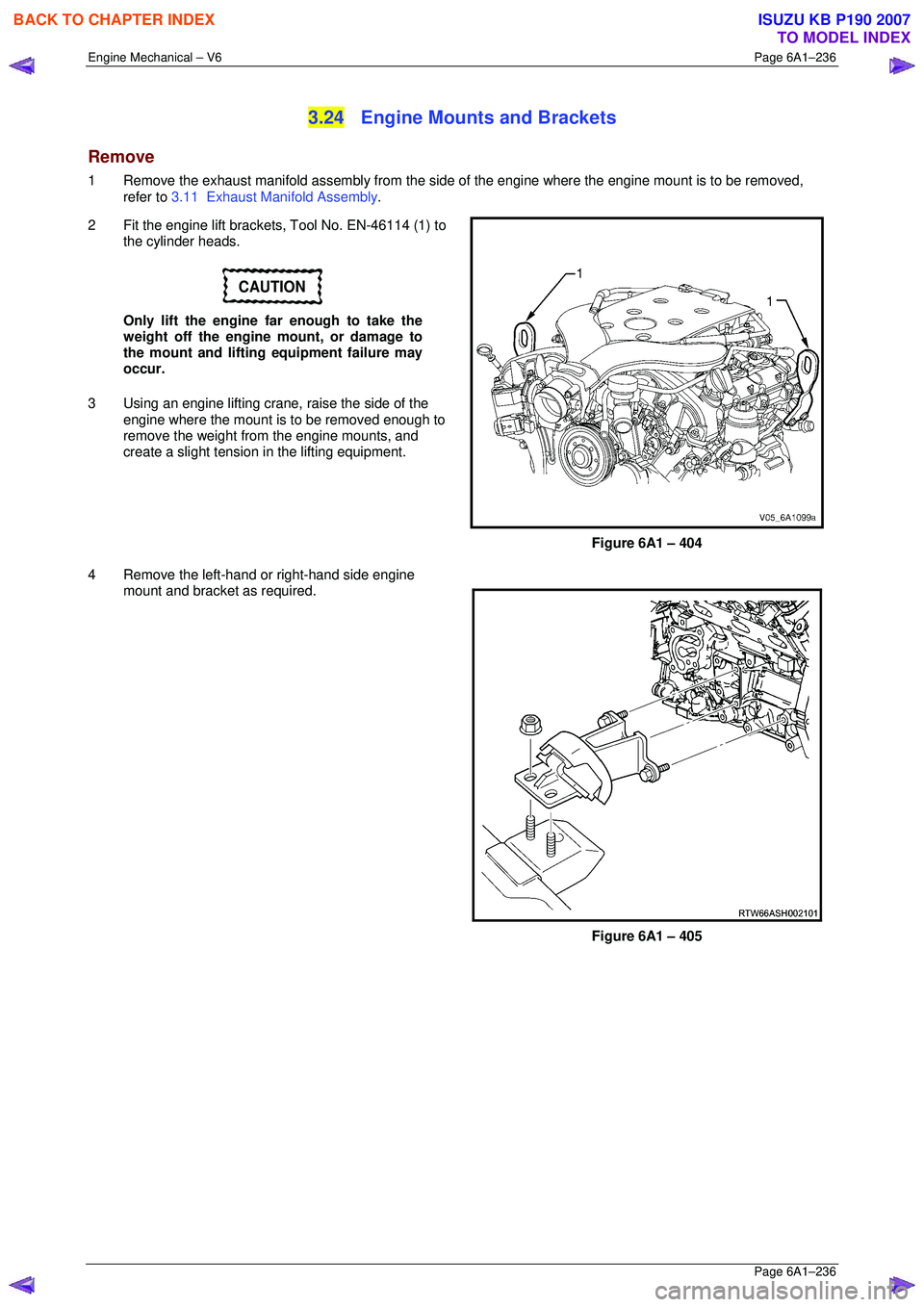

3.24 Engine Mounts and Brackets

Remove

1 Remove the exhaust manifold assembly from the side of the engine where the engine mount is to be removed,

refer to 3.11 Exhaust Manifold Assembly .

2 Fit the engine lift brackets, Tool No. EN-46114 (1) to the cylinder heads.

CAUTION

Only lift the engine far enough to take the

weight off the engine mount, or damage to

the mount and lifting equipment failure may

occur.

3 Using an engine lifting crane, raise the side of the

engine where the mount is to be removed enough to

remove the weight fr om the engine mounts, and

create a slight tension in the lifting equipment.

Figure 6A1 – 404

4 Remove the left-hand or right-hand side engine mount and bracket as required.

Figure 6A1 – 405

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3014 of 6020

Engine Mechanical – V6 Page 6A1–237

Page 6A1–237

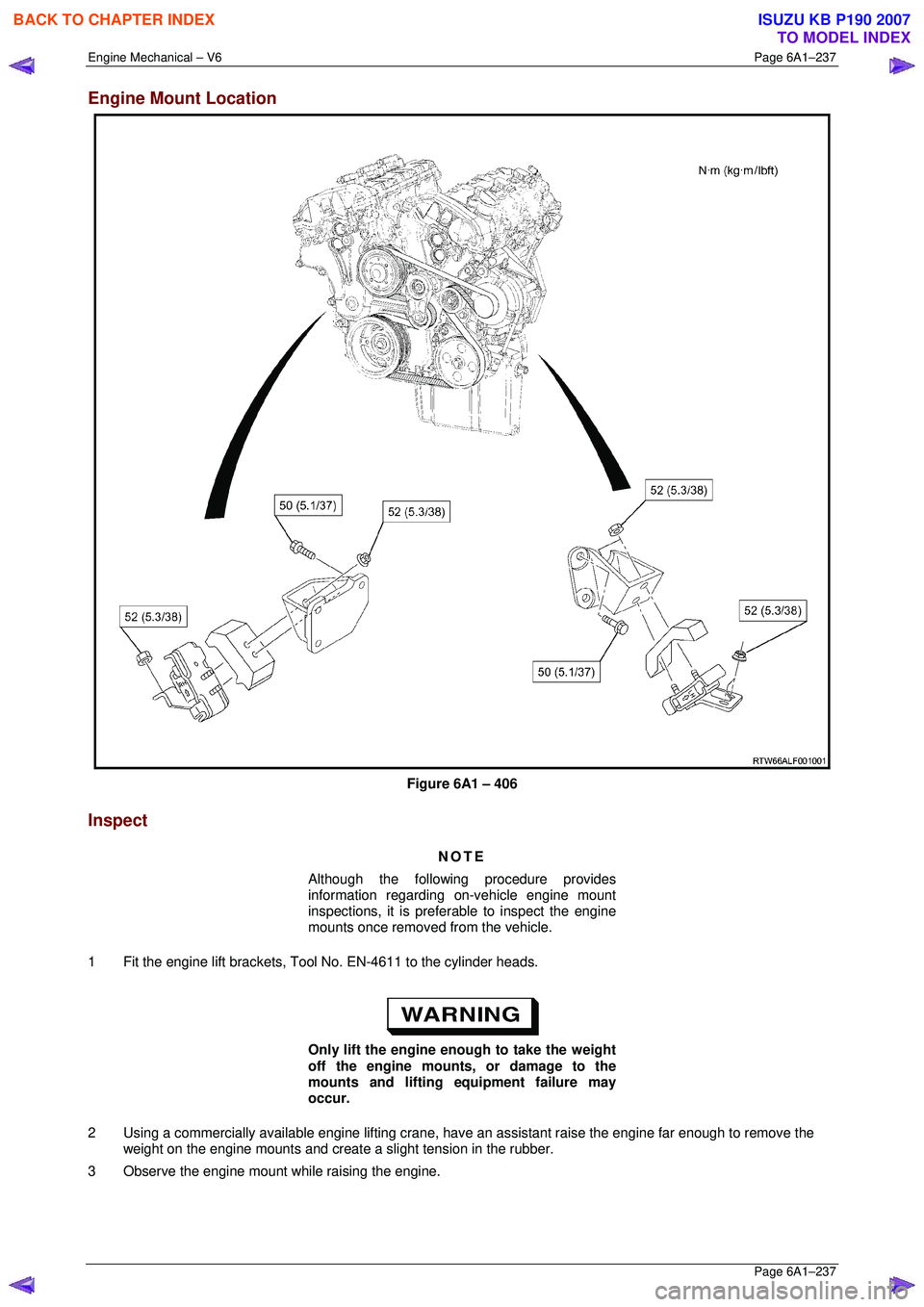

Engine Mount Location

Figure 6A1 – 406

Inspect

NOTE

Although the following procedure provides

information regarding on-vehicle engine mount

inspections, it is prefer able to inspect the engine

mounts once removed from the vehicle.

1 Fit the engine lift brackets, Tool No. EN-4611 to the cylinder heads.

Only lift the engine enough to take the weight

off the engine mounts, or damage to the

mounts and lifting equipment failure may

occur.

2 Using a commercially available engine lifting crane, hav e an assistant raise the engine far enough to remove the

weight on the engine mounts and create a slight tension in the rubber.

3 Observe the engine mount while raising the engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3049 of 6020

Engine Mechanical – V6 Page 6A1–272

Page 6A1–272

Connecting Rod Cleaning Procedure

1 Clean the connecting rods in solvent.

Safety glasses must be worn when using

compressed air.

2 Dry the connecting rod using compressed air.

3 Remove the connecting rod cap and clean the threads.

4 Remove the connecting rod bearing and discard. Never reuse a connecting rod bearing that has been used in a

running engine.

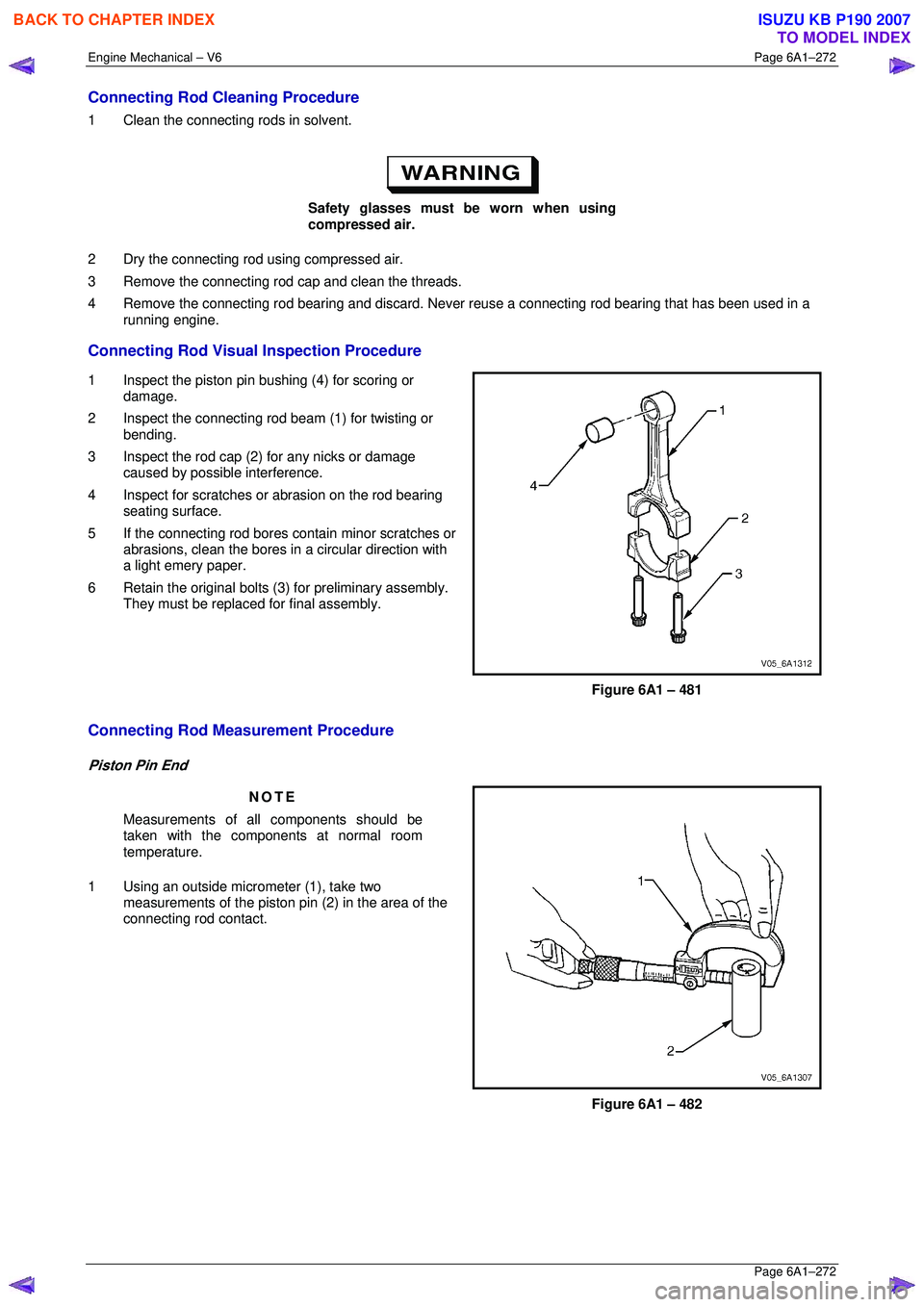

Connecting Rod Visual Inspection Procedure

1 Inspect the piston pin bushing (4) for scoring or damage.

2 Inspect the connecting rod beam (1) for twisting or bending.

3 Inspect the rod cap (2) for any nicks or damage caused by possible interference.

4 Inspect for scratches or abrasion on the rod bearing

seating surface.

5 If the connecting rod bores c ontain minor scratches or

abrasions, clean the bores in a circular direction with

a light emery paper.

6 Retain the original bolts (3) for preliminary assembly. They must be replaced for final assembly.

Figure 6A1 – 481

Connecting Rod Measurement Procedure

Piston Pin End

NOTE

Measurements of a ll components should be

taken with the components at normal room

temperature.

1 Using an outside micrometer (1), take two measurements of the piston pi n (2) in the area of the

connecting rod contact.

Figure 6A1 – 482

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3056 of 6020

Engine Mechanical – V6 Page 6A1–279

Page 6A1–279

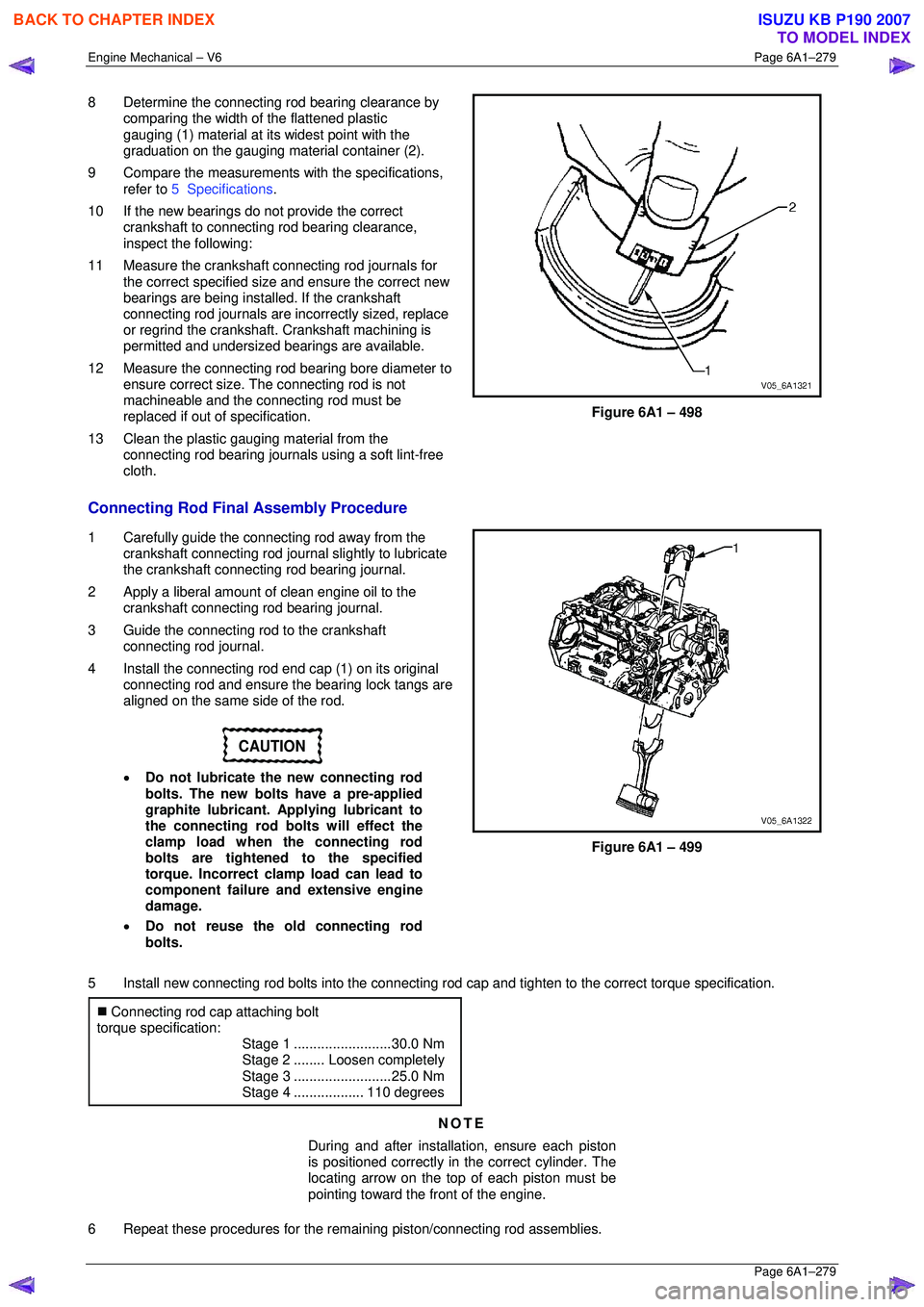

8 Determine the connecting rod bearing clearance by

comparing the width of the flattened plastic

gauging (1) material at its widest point with the

graduation on the gauging mate rial container (2).

9 Compare the measurements with the specifications,

refer to 5 Specifications .

10 If the new bearings do not provide the correct crankshaft to connecting rod bearing clearance,

inspect the following:

11 Measure the crankshaft connecting rod journals for the correct specified size and ensure the correct new

bearings are being installed. If the crankshaft

connecting rod journals are in correctly sized, replace

or regrind the crankshaft. Crankshaft machining is

permitted and undersized bearings are available.

12 Measure the connecting rod bearing bore diameter to

ensure correct size. The connecting rod is not

machineable and the connecting rod must be

replaced if out of specification.

13 Clean the plastic gauging material from the connecting rod bearing journals using a soft lint-free

cloth.

Figure 6A1 – 498

Connecting Rod Final Assembly Procedure

1 Carefully guide the connecting rod away from the crankshaft connecting rod journal slightly to lubricate

the crankshaft connecting rod bearing journal.

2 Apply a liberal amount of clean engine oil to the crankshaft connecting rod bearing journal.

3 Guide the connecting rod to the crankshaft connecting rod journal.

4 Install the connecting rod end cap (1) on its original

connecting rod and ensure t he bearing lock tangs are

aligned on the same side of the rod.

CAUTION

• Do not lubricate the new connecting rod

bolts. The new bolts have a pre-applied

graphite lubricant. Applying lubricant to

the connecting rod bolts will effect the

clamp load when the connecting rod

bolts are tightened to the specified

torque. Incorrect clamp load can lead to

component failure and extensive engine

damage.

• Do not reuse the old connecting rod

bolts.

Figure 6A1 – 499

5 Install new connecting rod bolts into the connecting r od cap and tighten to the correct torque specification.

�„ Connecting rod cap attaching bolt

torque specification:

Stage 1 .........................30.0 Nm

Stage 2 ........Loosen completely

Stage 3 .........................25.0 Nm

Stage 4 ..................110 degrees

NOTE

During and after installation, ensure each piston

is positioned correctly in the correct cylinder. The

locating arrow on the top of each piston must be

pointing toward the front of the engine.

6 Repeat these procedures for the rema ining piston/connecting rod assemblies.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3068 of 6020

Engine Mechanical – V6 Page 6A1–291

Page 6A1–291

Crankshaft Final Installation Procedure

1 If removed, install the crankshaft sprocket drive

pin (1). Lightly tap the pin in place with a small soft

face, bronze/plastic, hammer until it bottoms in the

hole.

Figure 6A1 – 522

CAUTION

Ensure the crankshaft position sensor has

been removed from the cylinder block prior

to loading the crankshaft, as damage to the

sensor may occur.

2 Apply a liberal amount of clean engine oil to the upper and lower bearing surfaces.

3 Gently lower the crankshaft (1) into position in the cylinder block (2).

Figure 6A1 – 523

4 Install the crankshaft main bearing caps.

5 Loosely install the original inner main cap bolts (1).

CAUTION

The outer crankshaft bearing cap bolts (2)

are yield tightened during assembly and

must be replaced prior to reassembly. Outer

crankshaft bearing cap bolts that are not

replaced will not torque to the correct clamp

load and can lead to serious engine damage.

6 Loosely install the new outer main bearing cap bolts (2).

7 Gently tap the crankshaft main bearing caps with a soft-faced hammer to help seat the caps.

Figure 6A1 – 524

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3082 of 6020

Engine Mechanical – V6 Page 6A1–305

Page 6A1–305

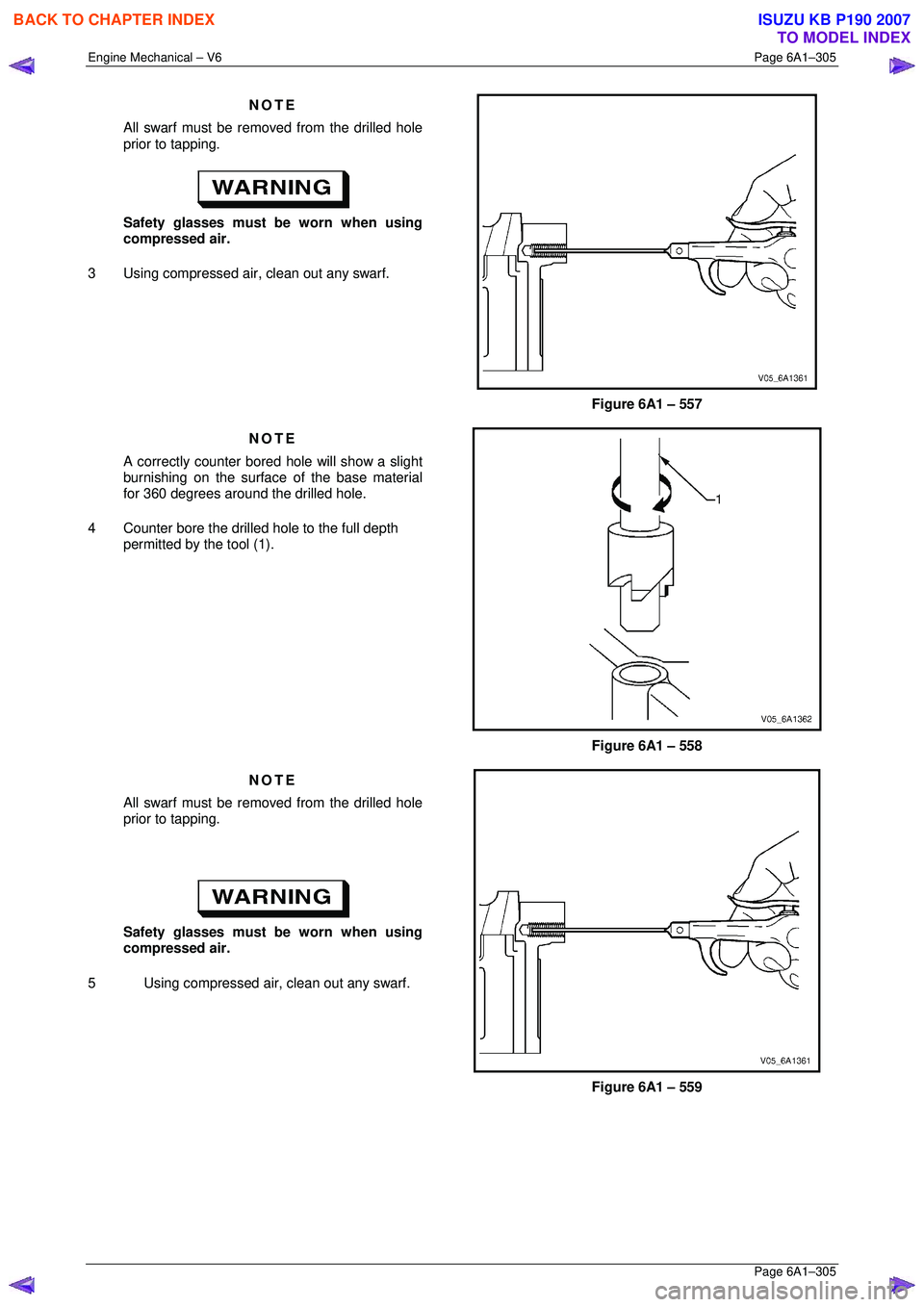

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

3 Using compressed air, clean out any swarf.

Figure 6A1 – 557

NOTE

A correctly counter bored hole will show a slight

burnishing on the surface of the base material

for 360 degrees around the drilled hole.

4 Counter bore the drilled hole to the full depth permitted by the tool (1).

Figure 6A1 – 558

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

5 Using compressed air, clean out any swarf.

Figure 6A1 – 559

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3086 of 6020

Engine Mechanical – V6 Page 6A1–309

Page 6A1–309

NOTE

The driver installation tool will tighten up before

cutting completely through the insert. This is

acceptable. The threads at the bottom of the

insert are being formed and the insert is

mechanically locking the insert into the base

material threads.

15 Continue to rotate the driver installation tool (1) through the insert (2)

16 Remove the driver installation tool.

Figure 6A1 – 569

17 Inspect the insert for co rrect installation into the

tapped hole. A correctly installed insert (1) will be

either flush or slightly below flush with the surface of

the base material (2).

Figure 6A1 – 570

18 Any installed insert that restricts or blocks an oil or

engine coolant passage (3) will need to have the oil or

engine coolant passage drilled out (4) to the original

size of the oil or engine c oolant passage. After drilling

the restriction or block age, clean out any swarf and

thread the installation driver tool through the insert

again to remove any burrs caused by the drilling of

the oil or engine coolant passage.

Figure 6A1 – 571

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007