light ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2806 of 6020

Engine Mechanical – V6 Page 6A1–29

Page 6A1–29

Fasteners

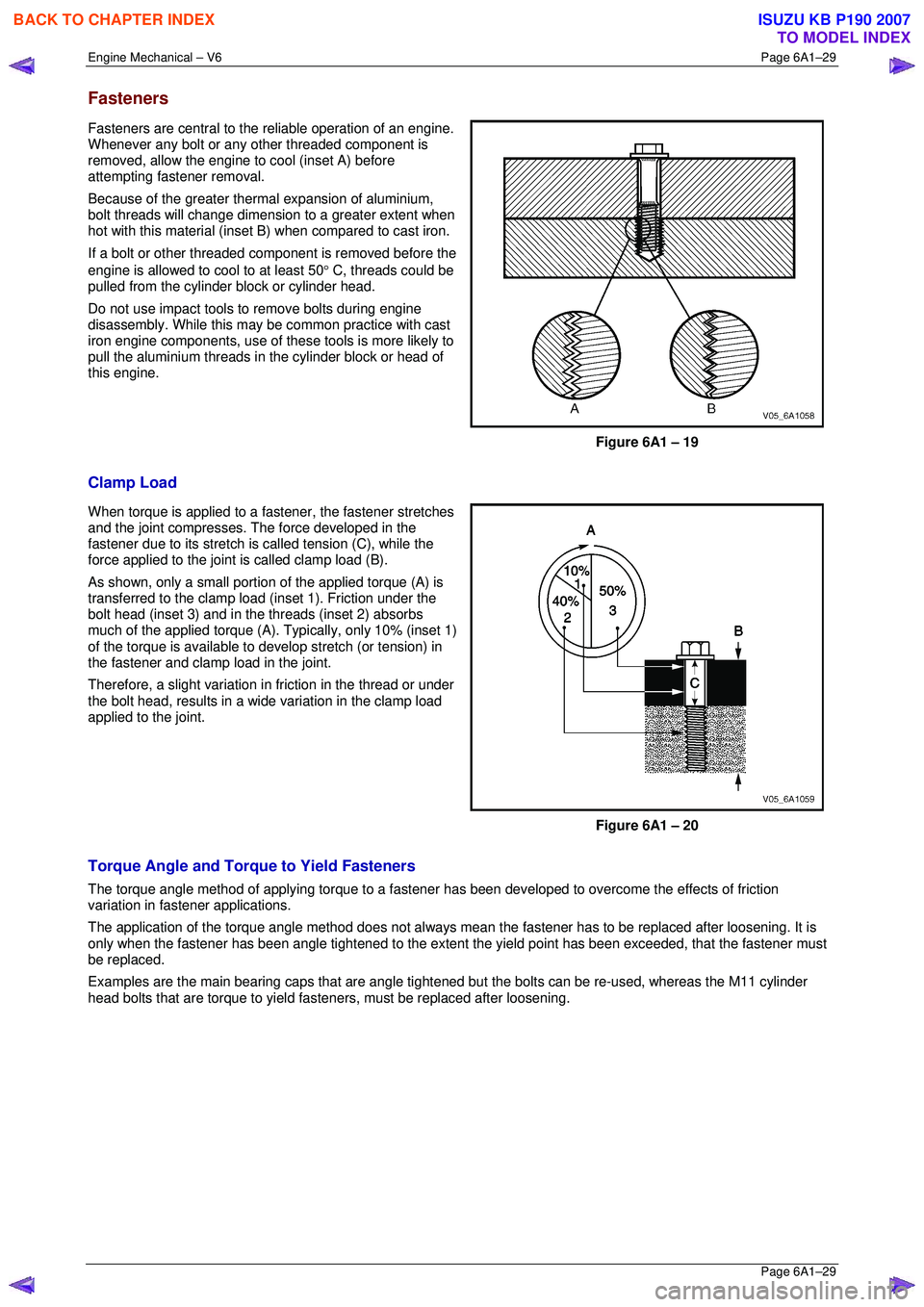

Fasteners are central to the reliable operation of an engine.

Whenever any bolt or any other threaded component is

removed, allow the engine to cool (inset A) before

attempting fastener removal.

Because of the greater the rmal expansion of aluminium,

bolt threads will change dimensi on to a greater extent when

hot with this material (inset B) when compared to cast iron.

If a bolt or other threaded com ponent is removed before the

engine is allowed to cool to at least 50 ° C, threads could be

pulled from the cylinder block or cylinder head.

Do not use impact tools to remove bolts during engine

disassembly. While this may be common practice with cast

iron engine components, use of thes e tools is more likely to

pull the aluminium threads in the cylinder block or head of

this engine.

Figure 6A1 – 19

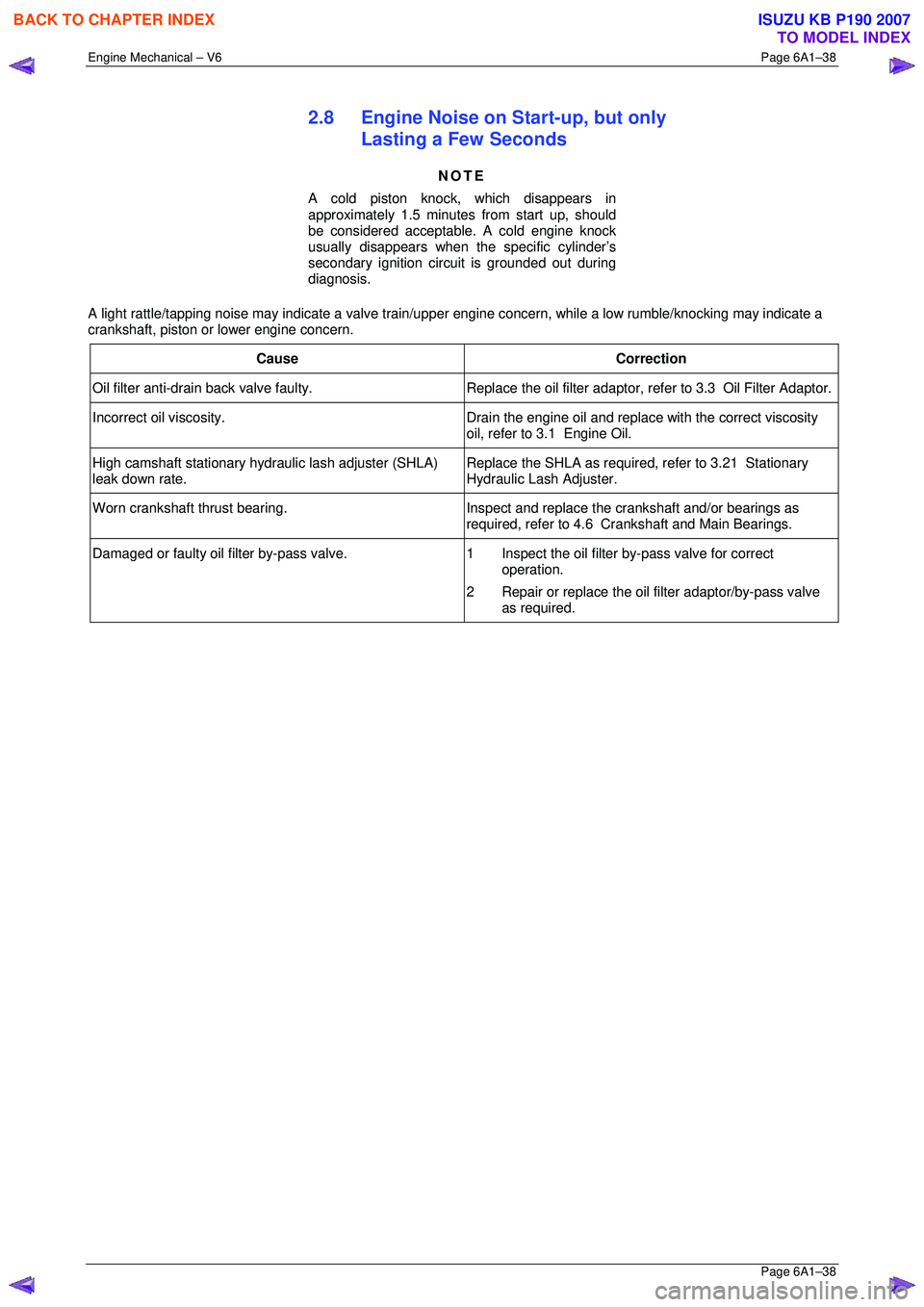

Clamp Load

When torque is applied to a fa stener, the fastener stretches

and the joint compresses. The force developed in the

fastener due to its stretch is called tension (C), while the

force applied to the joint is called clamp load (B).

As shown, only a small portion of the applied torque (A) is

transferred to the clamp load (inset 1). Friction under the

bolt head (inset 3) and in the threads (inset 2) absorbs

much of the applied torque (A). Typically, only 10% (inset 1)

of the torque is available to develop stretch (or tension) in

the fastener and clamp load in the joint.

Therefore, a slight variation in friction in the thread or under

the bolt head, results in a wide variation in the clamp load

applied to the joint.

Figure 6A1 – 20

Torque Angle and Torque to Yield Fasteners

The torque angle method of applying torque to a fastener has been developed to overcome the effects of friction

variation in fastener applications.

The application of the torque angle method does not always mean the fastener has to be replaced after loosening. It is

only when the fastener has been angle tightened to the extent the yield point has been exceeded, that the fastener must

be replaced.

Examples are the main bearing caps that are angle tightened but the bolts can be re-used, whereas the M11 cylinder

head bolts that are torque to yield fasteners, must be replaced after loosening.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2810 of 6020

Engine Mechanical – V6 Page 6A1–33

Page 6A1–33

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder head and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat. 1 Inspect the spark plugs for

coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2 Inspect the cylinder heads, cylinder block and/or head gaskets, refer to 3.22 Cylinder Head Assembly

and/or 4.7 Cylinder Block.

3 Repair or replace components as required.

Worn piston rings.

Oil consumption may or ma y not cause the engine to

misfire. 1 Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2 Check the cylinders for a loss of compression, refer to 2.15 Engine Compression Test.

3 Perform compression testing to identify the cause of

low compression.

4 Repair or replace components as required.

A damaged crankshaft reluctor wheel.

A damaged crankshaft reluctor wheel can result in different

symptoms depending on the severity and location of the

damage.

Systems with severe relu ctor ring damage may exhibit

periodic loss of crankshaft posit ion, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with slight reluctor ring damage may exhibit no

loss of crankshaft position and no misfire may occur,

however, a DTC may set. Replace the crankshaft as required, refer to 4.6 Crankshaft

and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2815 of 6020

Engine Mechanical – V6 Page 6A1–38

Page 6A1–38

2.8 Engine Noise on Start-up, but only

Lasting a Few Seconds

NOTE

A cold piston knock, which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when t he specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Oil filter anti-drain back valve faulty. Replace the o il filter adaptor, refer to 3.3 Oil Filter Adaptor.

Incorrect oil viscosity.

Drain the engine oil and replace with the correct viscosity

oil, refer to 3.1 Engine Oil.

High camshaft stationary hydraulic lash adjuster (SHLA)

leak down rate. Replace the SHLA as required,

refer to 3.21 Stationary

Hydraulic Lash Adjuster.

Worn crankshaft thrust bearing. Inspect and replace the crankshaft and/or bearings as

required, refer to 4.6 Crankshaft and Main Bearings.

Damaged or faulty oil filter by-pass valve. 1 Inspect the oil filter by-pass valve for correct

operation.

2 Repair or replace the oil filter adaptor/by-pass valve

as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2816 of 6020

Engine Mechanical – V6 Page 6A1–39

Page 6A1–39

2.9 Upper Engine Noise, Regardless of

Engine Speed

NOTE

A cold piston knock, which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when t he specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure. 1 Perform an oil pressure test, refer to 2.19 Engine Oil

Pressure Diagnosis.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or valve rocker arms.

The SHLAs, rocker arm and roller bearings should be intact

and in the correct position. 1 Clean, inspect and replace the camshaft lash

adjusters as required, refer to 3.21 Stationary

Hydraulic Lash Adjuster.

2 Replace the SHLAs and/or rocker arms as required, refer to 3.21 Stationary Hydraulic Lash Adjuster or

3.20 Rocker Arm.

Incorrect lubrication to t he stationary hydraulic lash

adjusters and valve rocker arm. Inspect the following components and repair or replace as

required:

• valve rocker arms, refer to 3.20 Rocker Arm.

• stationary hydraulic lash adjusters, refer to 3.21

Stationary Hydraulic Lash Adjuster.

• oil filter by-pass valve, refe r to 3.3 Oil Filter Adaptor.

• oil pump and suction pipe, refer to 3.17 Oil Pump

Assembly.

• cylinder head oil galleries, refer to 3.22 Cylinder

Head Assembly.

• cylinder block oil galleries, refer to 4.7 Cylinder

Block.

Broken Valve Spring. Replace the valve spring, refer to 3.22 Cylinder Head

Assembly.

Stretched or broken timing chain/s and/or damaged timing

chain sprocket teeth. Replace the timing chains or sprockets as required, refer to

3.16 Timing Chains, Tensioners, Shoes and Guides.

Worn or faulty timing chain tensioner or guide. Replace the timing chains or sprockets as required, refer to

3.16 Timing Chains, Tensioners, Shoes and Guides.

Worn camshaft lobes. Replace the camshaft/s and SHLAs as required, refer to

3.19 Camshaft or 3.21 Stati onary Hydraulic Lash Adjuster.

Worn valve guides and/or valve stems.

Inspect and repair or replace valves and valve guides as

required, refer to 3.22 Cylinder Head Assembly.

Stuck valves.

Carbon on the valve stem or valve seat may cause the

valve to stay open. Inspect and repair or replace valves and valve guides as

required, refer to 3.22 Cylinder Head Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2817 of 6020

Engine Mechanical – V6 Page 6A1–40

Page 6A1–40

2.10 Lower Engine Noise, Regardless of

Engine Speed

NOTE

A cold piston knock which disappears in

approximately 1.5 minutes from start up should

be considered acceptable. A cold engine knock

usually disappears when t he specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure. 1 Perform an oil pressure test, refer to 2.19 Engine Oil

Pressure Diagnosis.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

Worn accessory drive components.

Abnormalities such as severe cracking, bumps, stretching

or missing areas on an accessory drive belt and/or

misalignment of accessory drive system components. Inspect the accessory drive system, repair or replace

components as required, refer to 3.5 Accessory Drive Belt.

Loose or damaged crankshaft balancer and pulley

assembly. Repair or replace the crankshaft balancer and pulley

assembly as required, refer to 3.13 Crankshaft Balancer

Assembly.

Detonation or spark knock. Confirm the correct operation of the ignition system, refer to

6C1-2 Engine Management – V6 – Diagnostics.

Loose torque converter bolts. Inspect and tighten the torque converter bolts to the correct

torque specification, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

Loose or damaged flexplate. Repair or replace the flexplate as required, refer to 4.3

Flexplate Assembly.

Oil pump suction pipe loos e, damaged or restricted.

Clean, inspect and repair/replace the oil pump suction pipe

as required, refer to 4.2 O il Pan and Oil Pump Suction Pipe

Assembly.

Excessive piston-to-cylinder bore clearance. Inspect the piston and cylinder bore and repair/replace

components as required, refer to 4.5 Pistons, Pins, Rings,

Connecting Rods and Big-end Bearings and 4.7 Cylinder

Block.

Excessive connecting rod bearing clearance. Inspect the connecting rod, crankshaft and bearings and

repair/replace components as required, refer to 4.5

Pistons, Pins, Rings, Connecting Rods and Big-end

Bearings and 4.6 Crankshaft and Main Bearings.

Excessive piston pin to bore clearance. Inspect the pistons and pins and repair/replace components

as required, refer to 4.5 Pistons, Pins, Rings, Connecting

Rods and Big-end Bearings.

Excessive crankshaft main bearing clearance. Inspect the crankshaft, cylinder block journals, main

bearings and main bearing caps and repair/replace

components as required, refer to 4.6 Crankshaft and Main

Bearings and 4.7 Cylinder Block.

Incorrect piston, pin and c onnecting rod installation.

Pistons must be installed with the mark or dimple facing the

front of the engine. Piston pi ns must be centred in the

piston pin bore. Confirm the pistons, pins and

connecting rods are installed

correctly and repair if required, refer to 4.5 Pistons, Pins,

Rings, Connecting Rods and Big-end Bearings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2818 of 6020

Engine Mechanical – V6 Page 6A1–41

Page 6A1–41

2.11 Engine Noise Under Load

NOTE

A cold piston knock which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when t he specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure. 1 Perform an oil pressure test, refer to 2.19 Engine Oil

Pressure Diagnosis.

2 Repair or replace the engine oil pump as required, refer to 3.17 Oil Pump Assembly.

Detonation or spark knock. Confirm the correct operation of the ignition system, refer to

6C1-2 Engine Management – V6 – Diagnostics.

Loose torque converter bolts. Inspect and tighten the torque converter bolts to the correct

torque specification, refer to 7C1 Automatic – 4L60E –

General Information – 4L60E – General Information.

Cracked flexplate. Replace the flywheel/flex-plate as required, refer to

4.3 Flexplate Assembly.

Excessive connecting rod bearing clearance. Inspect the connecting rod, crankshaft and bearings and

repair/replace components as required, refer to

4.5 Pistons, Pins, Rings, Connecting Rods and Big-end

Bearings and 4.6 Crankshaft and Main Bearings.

Excessive crankshaft bearing clearance Inspect the crankshaft, cylinder block journals, main

bearings and main bearing caps and repair/replace

components as required, refer to 4.6 Crankshaft and Main

Bearings and 4.7 Cylinder Block.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2825 of 6020

Engine Mechanical – V6 Page 6A1–48

Page 6A1–48

2.18 Engine Oil Leak Diagnosis

Introduction

It is important to correctly identify the source of an engine oil leak. For example, a power steering fluid leak or spillage

during servicing can travel across the va lley area of the engine and run-out the weep hole, which is located at the back of

the cylinder block. Failure to correctly identify the source of an engine oil leak can lead to unnecessary replacement of

engine components.

Most fluid leaks can be repaired by repairi ng or replacing the faulty component or resealing the gasket surface. However,

once a leak is identified it is im portant to determine and repair the c ause as well as the leak itself.

Locating and Identifying the Leak

Inspect the leaking fluid and determine whet her it is engine oil, transmission fluid, power steering fluid, brake fluid or

some other fluid. If unsure of the source of the leaking lubricant, a quick check of fluid levels should indicate where the

fluid is coming from, as one or more fluid level should be low.

Visual Inspection

Once the type of leaking fluid has been determined, a visual inspection of the affected system should be performed.

When performing the visual inspection:

1 Bring the vehicle to the normal operating temperature.

2 Park the vehicle over a large s heet of paper or other clean surface.

3 Leave the vehicle idling for 2-3 minut es, then check for dripping fluid.

4 If required, identify the type of fluid leak ing and the approximate location of the leak.

5 Visually inspect the suspected area. A small mirror may assist viewing areas that are difficult to see normally.

6 Check for leaks at all sealing surfaces and fittings.

7 Check for any cracked or damaged components.

8 If the leak cannot be located, completely clean the entire engine and surrounding components, drive the vehicle at

normal operating temperature for several k ilometres and then repeat Steps 3 to 8.

9 If the leak still cannot be located, proceed with either the Powder Method or Black Light and Dye Method as

outlined below.

Powder Method

1 Completely clean the entir e engine and surrounding components.

2 Apply an aerosol type powder (e.g. f oot powder) to the suspected area.

3 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

4 Identify the source of the leak from the discoloration of the powder around the suspect components.

5 If required, use a small mirror to assist in vi ewing areas that are difficult to see normally.

6 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

Black Light and Dye Method

A black light and die kit Tool No. J28428-E or a commercially av ailable equivalent is available to technicians to aid in

engine oil leak diagnosis. When using a black light and die kit fo r the first time, it is recommended the technician read the

manufacturers instructions prior to using the kit.

1 Add the specified amount of dye, as per manufacturers instructions, into the engine or suspected source of the oil

leak.

2 Operate the vehicle at normal operating temperature and at varying speeds for several kilometres.

3 With the vehicle parked on a flat leve l surface, aim the black light at the suspected component/s. The dyed fluid will

appear as a yellow path leading to the oil leak source

4 Refer to Possible Causes for Engine Oil Leaks in this Section, and repair or replace components as required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2843 of 6020

Engine Mechanical – V6 Page 6A1–66

Page 6A1–66

3 Minor Service Operations

ATTENTION

The V6 engine is a combination of numerous components, containing machined, honed, polished and lapped

surfaces manufactured on the latest, high technology production equipment. Many of the components

contain tolerances measured in thousa ndths of a millimetre. Consequently, when any e ngine component is to

be serviced, care and cleanliness are extremely important.

Prior to re-assembly of the engine, all components mu st be cleaned and inspected in accordance with the

relevant clean and inspect procedur es throughout this Section, and repl aced or repaired where required.

In addition to cleaning and inspecting components, a liberal coating of engine oil should be applied to friction

surfaces during assembly to protect and lubr icate the surfaces on initial operation.

When performing any service operation, it should be understood that correct cleaning and protection of

machined surfaces and friction areas is part of the repair procedure. This is considered standard workshop

practice, even if not specifically stated. Torque va lues must be used as specified during reassembly to

ensure correct retention of all components.

Through out this section, fastener torque wrench sp ecifications may be accompanied with the following

identification marks:

■ Fasteners must be replaced after loosening.

Fasteners either have micro encapsulated sealant a pplied or incorporate a mechanical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongs ide a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

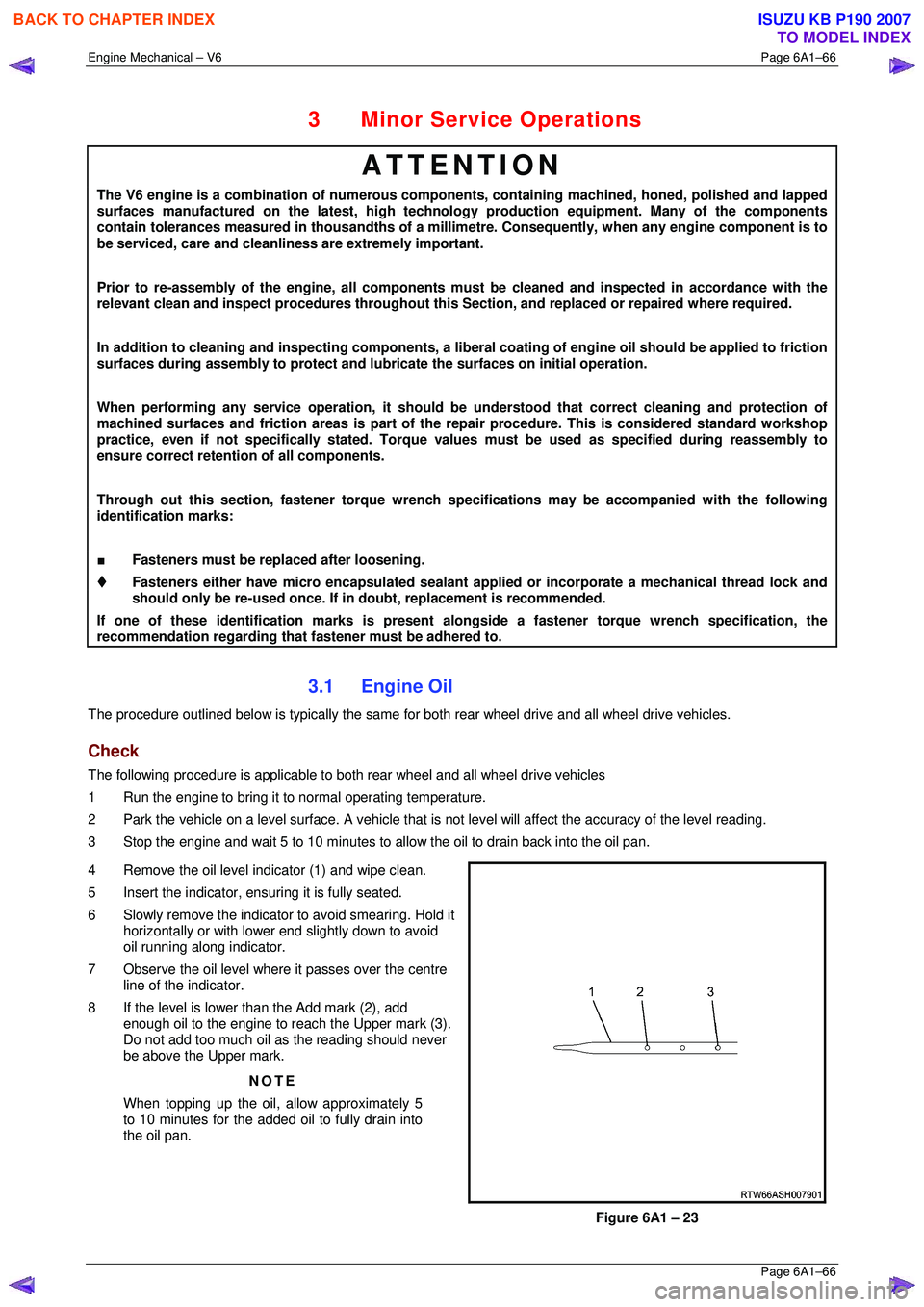

3.1 Engine Oil

The procedure outlined below is typically the same for both rear wheel drive and all wheel drive vehicles.

Check

The following procedure is applicable to both rear wheel and all wheel drive vehicles

1 Run the engine to bring it to normal operating temperature.

2 Park the vehicle on a level surface. A vehicle that is not level will affect the accuracy of the level reading.

3 Stop the engine and wait 5 to 10 minutes to a llow the oil to drain back into the oil pan.

4 Remove the oil level indicator (1) and wipe clean.

5 Insert the indicator, ens uring it is fully seated.

6 Slowly remove the indicator to avoid smearing. Hold it horizontally or with lower end slightly down to avoid

oil running along indicator.

7 Observe the oil level where it passes over the centre

line of the indicator.

8 If the level is lower than the Add mark (2), add enough oil to the engine to reach the Upper mark (3).

Do not add too much oil as the reading should never

be above the Upper mark.

NOTE

When topping up the oil, allow approximately 5

to 10 minutes for the added oil to fully drain into

the oil pan.

Figure 6A1 – 23

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2869 of 6020

Engine Mechanical – V6 Page 6A1–92

Page 6A1–92

9 Progressively loosen the seven exhaust manifold

attaching bolts (2), working from the outside to the

centre and then remove the bolts.

10 Manoeuvre the exhaust manifold (3), away from the cylinder head.

11 Remove and discard the exhaust manifold to cylinder head gasket.

Figure 6A1 – 58

12 Remove the three bolts (1), attaching the exhaust manifold inner heat shield to the exhaust manifold.

13 Using a suitable commercially available non-corrosive cleaning solvent and a soft bristled parts cleaning

brush, thoroughly clean the exhaust manifold.

14 Dry the exhaust manifold using compressed air.

Safety glasses must be worn when using

compressed air.

Figure 6A1 – 59

NOTE

• The same procedure applies to the Right-

hand exhaust manifold.

• To gain access to the lower rear exhaust

manifold attaching bolts (2), apply a slight

downward movement to the coolant inlet

pipe (1).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2996 of 6020

Engine Mechanical – V6 Page 6A1–219

Page 6A1–219

Disassemble

1 Using an appropriately sized deep socket (1) and a

plastic hammer (2), lightly tap on the valve spring

retainer to loosen the valve collets.

CAUTION

Ensure valve heads will not contact anything

during this step in order to avoid bending or

damage.

Figure 6A1 – 369

CAUTION

Do not compress the valve springs less than

24.0 mm. Contact between the valve spring

retainer and the valve stem oil seal can

cause potential valve stem oil seal damage.

Compressed valve springs (1) have high

tension against the valve spring

compressor (2). Valve springs that are not

correctly compressed by, or are released

from the valve spring compressor can be

ejected from the valve spring compressor

with intense force. Use care when

compressing or releasing the valve spring

with the valve spring compressor and when

removing or installing the valve stem keys.

Failing to use care may cause personal

injury.

2 Compress the valve spring (1) using valve spring compressor Tool No. J-8062 (2) and adaptor Tool No.

EN-46119.

Figure 6A1 – 370

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007