transmission fluid ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4435 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-151

The transmission fluid temperature (TFT) sensor is part

of the harness assembly. The sensor is a variable

resistor and it measures the temperature of the

transmission fluid. When the TFT sensor is cold, the

sensor resistance is high. When the transmission fluid

temperature increases, the sensor resistance

decreases. With high sensor resistance, the TCM

detects a high voltage on the signal circuit. With lower

sensor resistance, the TCM detects a lower voltage on

the signal circuit.

If the fluid temperature increases to 135 °C (275 °F), the

TCM illuminates A/T Oil Temp lamp on the instrument

panel cluster. When the fluid temperature deceases

below 125 °C (257 °F), the lamp goes off.

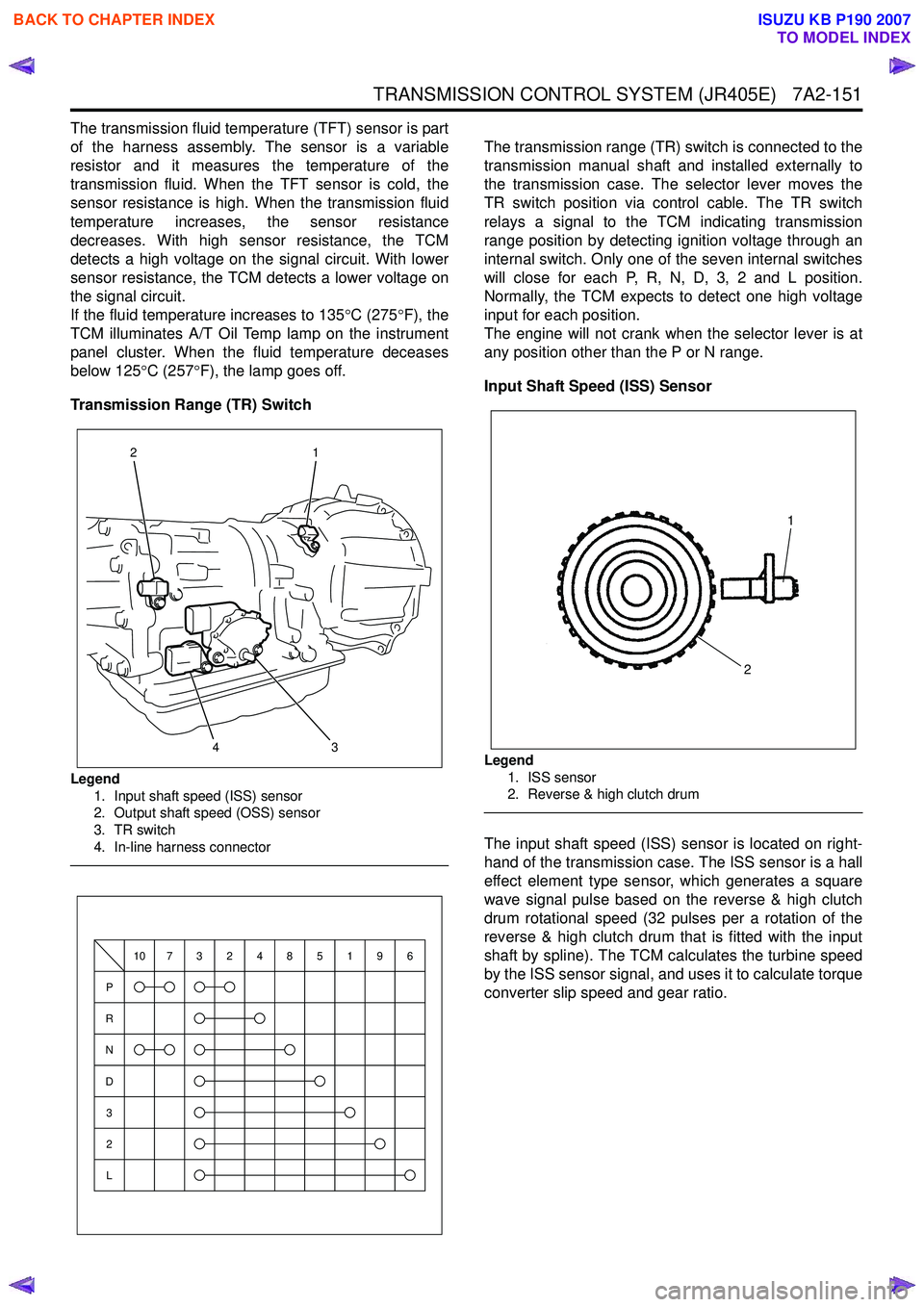

Transmission Range (TR) Switch

Legend 1. Input shaft speed (ISS) sensor

2. Output shaft speed (OSS) sensor

3. TR switch

4. In-line harness connector

The transmission range (TR) switch is connected to the

transmission manual shaft and installed externally to

the transmission case. The selector lever moves the

TR switch position via control cable. The TR switch

relays a signal to the TCM indicating transmission

range position by detecting ignition voltage through an

internal switch. Only one of the seven internal switches

will close for each P, R, N, D, 3, 2 and L position.

Normally, the TCM expects to detect one high voltage

input for each position.

The engine will not crank when the selector lever is at

any position other than the P or N range.

Input Shaft Speed (ISS) Sensor

Legend 1. ISS sensor

2. Reverse & high clutch drum

The input shaft speed (ISS) sensor is located on right-

hand of the transmission case. The ISS sensor is a hall

effect element type sensor, which generates a square

wave signal pulse based on the reverse & high clutch

drum rotational speed (32 pulses per a rotation of the

reverse & high clutch drum that is fitted with the input

shaft by spline). The TCM calculates the turbine speed

by the ISS sensor signal, and uses it to calculate torque

converter slip speed and gear ratio.

3

1

24

P

R

N

D

3

2

L

10732485196

1

2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4437 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-153

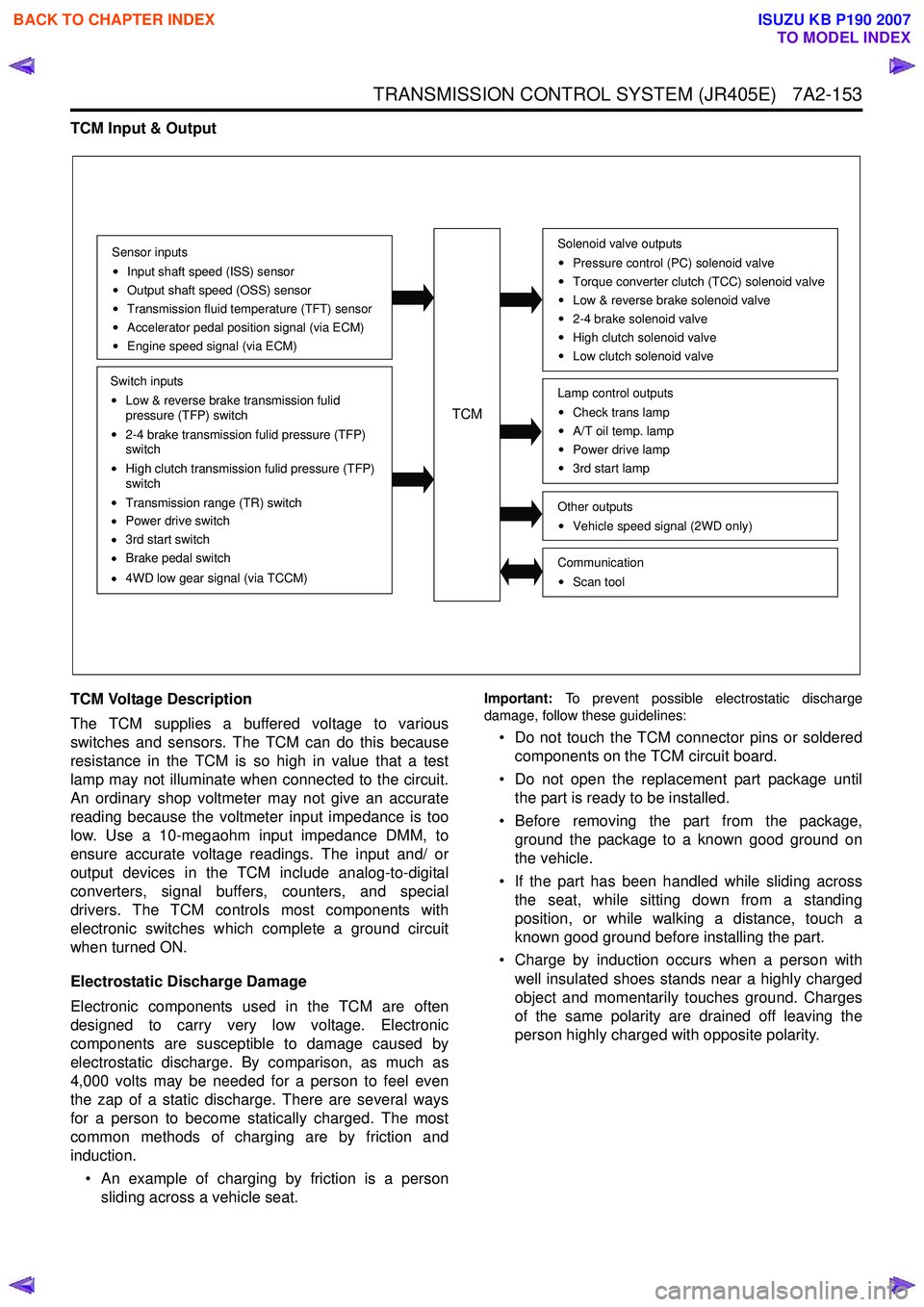

TCM Input & Output

TCM Voltage Description

The TCM supplies a buffered voltage to various

switches and sensors. The TCM can do this because

resistance in the TCM is so high in value that a test

lamp may not illuminate when connected to the circuit.

An ordinary shop voltmeter may not give an accurate

reading because the voltmeter input impedance is too

low. Use a 10-megaohm input impedance DMM, to

ensure accurate voltage readings. The input and/ or

output devices in the TCM include analog-to-digital

converters, signal buffers, counters, and special

drivers. The TCM controls most components with

electronic switches which complete a ground circuit

when turned ON.

Electrostatic Discharge Damage

Electronic components used in the TCM are often

designed to carry very low voltage. Electronic

components are susceptible to damage caused by

electrostatic discharge. By comparison, as much as

4,000 volts may be needed for a person to feel even

the zap of a static discharge. There are several ways

for a person to become statically charged. The most

common methods of charging are by friction and

induction.

• An example of charging by friction is a person sliding across a vehicle seat.

Important: To prevent possible electrostatic discharge

damage, follow these guidelines:

• Do not touch the TCM connector pins or soldered components on the TCM circuit board.

• Do not open the replacement part package until the part is ready to be installed.

• Before removing the part from the package, ground the package to a known good ground on

the vehicle.

• If the part has been handled while sliding across the seat, while sitting down from a standing

position, or while walking a distance, touch a

known good ground before installing the part.

• Charge by induction occurs when a person with well insulated shoes stands near a highly charged

object and momentarily touches ground. Charges

of the same polarity are drained off leaving the

person highly charged with opposite polarity.

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fulid

pressure (TFP) switch

2-4 brake transmission fulid pressure (TFP)

switch

High clutch transmission fulid pressure (TFP)

switch

Transmission range (TR) switch

Power drive switch

3rd start switch

Brake pedal switch

4WD low gear signal (via TCCM)

TCM

Solenoid valve outputs

Pressure control (PC) solenoid valve

Torque converter clutch (TCC) solenoid valve

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

Other outputsVehicle speed signal (2WD only)

CommunicationScan tool

Lamp control outputsCheck trans lamp

A/T oil temp. lamp

Power drive lamp

3rd start lamp

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4439 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-155

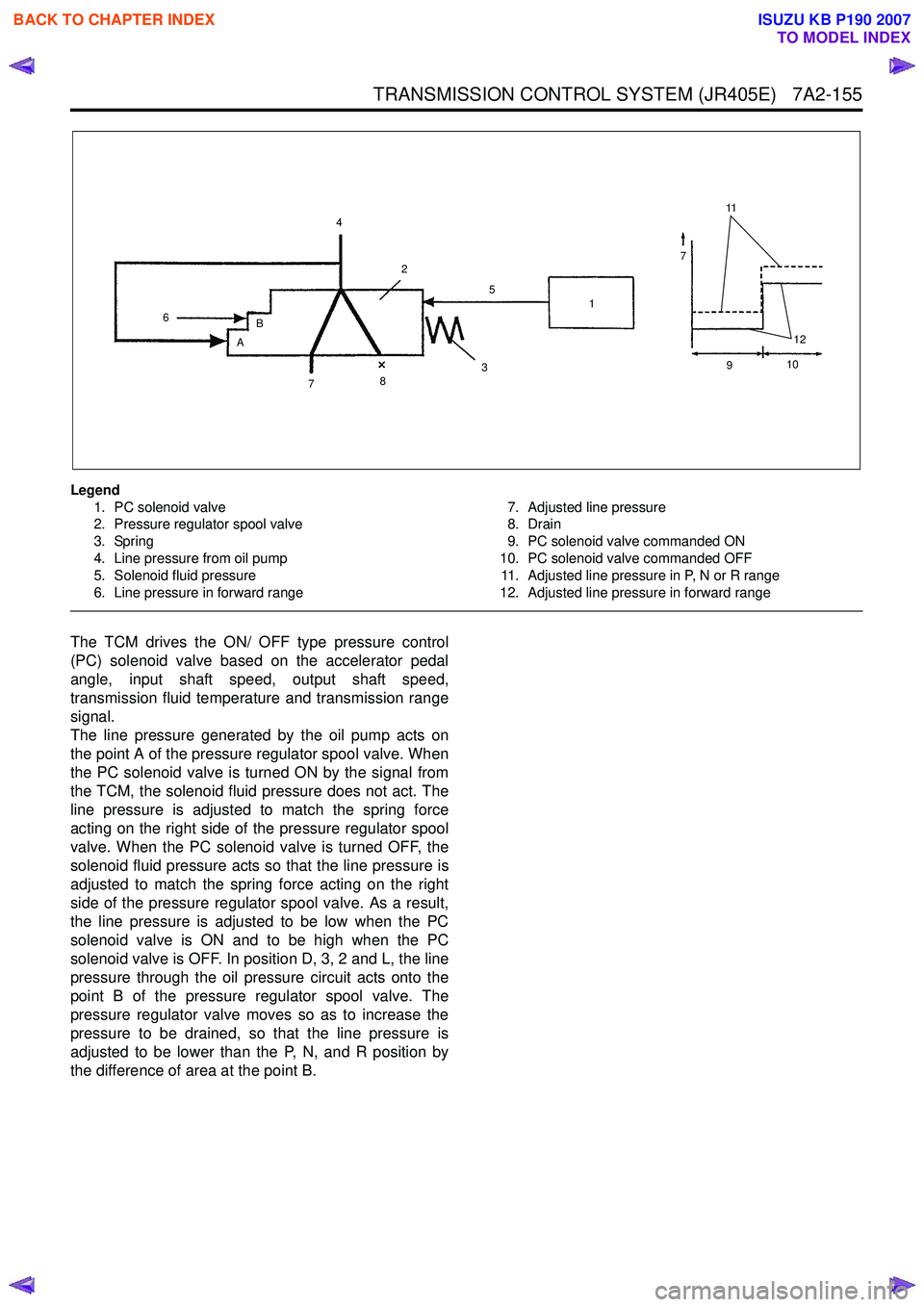

Legend1. PC solenoid valve

2. Pressure regulator spool valve

3. Spring

4. Line pressure from oil pump

5. Solenoid fluid pressure

6. Line pressure in forward range 7. Adjusted line pressure

8. Drain

9. PC solenoid valve commanded ON

10. PC solenoid valve commanded OFF 11. Adjusted line pressure in P, N or R range

12. Adjusted line pressure in forward range

The TCM drives the ON/ OFF type pressure control

(PC) solenoid valve based on the accelerator pedal

angle, input shaft speed, output shaft speed,

transmission fluid temperature and transmission range

signal.

The line pressure generated by the oil pump acts on

the point A of the pressure regulator spool valve. When

the PC solenoid valve is turned ON by the signal from

the TCM, the solenoid fluid pressure does not act. The

line pressure is adjusted to match the spring force

acting on the right side of the pressure regulator spool

valve. When the PC solenoid valve is turned OFF, the

solenoid fluid pressure acts so that the line pressure is

adjusted to match the spring force acting on the right

side of the pressure regulator spool valve. As a result,

the line pressure is adjusted to be low when the PC

solenoid valve is ON and to be high when the PC

solenoid valve is OFF. In position D, 3, 2 and L, the line

pressure through the oil pressure circuit acts onto the

point B of the pressure regulator spool valve. The

pressure regulator valve moves so as to increase the

pressure to be drained, so that the line pressure is

adjusted to be lower than the P, N, and R position by

the difference of area at the point B.

11

7

12

4

6 B

A 2

7 8 3 1

5

910

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4440 of 6020

7A2-156 TRANSMISSION CONTROL SYSTEM (JR405E)

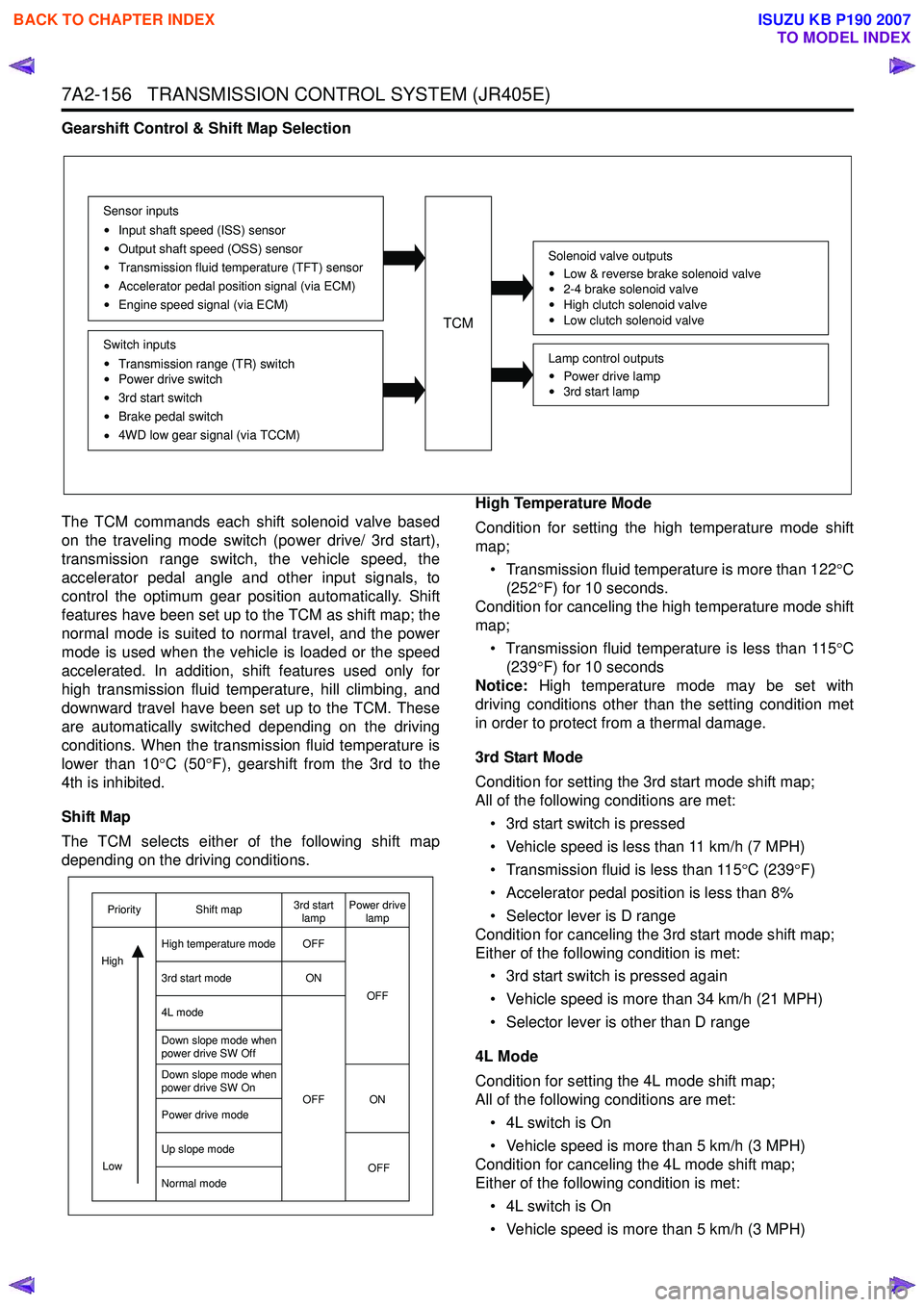

Gearshift Control & Shift Map Selection

The TCM commands each shift solenoid valve based

on the traveling mode switch (power drive/ 3rd start),

transmission range switch, the vehicle speed, the

accelerator pedal angle and other input signals, to

control the optimum gear position automatically. Shift

features have been set up to the TCM as shift map; the

normal mode is suited to normal travel, and the power

mode is used when the vehicle is loaded or the speed

accelerated. In addition, shift features used only for

high transmission fluid temperature, hill climbing, and

downward travel have been set up to the TCM. These

are automatically switched depending on the driving

conditions. When the transmission fluid temperature is

lower than 10 °C (50 °F), gearshift from the 3rd to the

4th is inhibited.

Shift Map

The TCM selects either of the following shift map

depending on the driving conditions. High Temperature Mode

Condition for setting the high temperature mode shift

map;

• Transmission fluid temperature is more than 122 °C

(252 °F) for 10 seconds.

Condition for canceling the high temperature mode shift

map;

• Transmission fluid temperature is less than 115 °C

(239 °F) for 10 seconds

Notice: High temperature mode may be set with

driving conditions other than the setting condition met

in order to protect from a thermal damage.

3rd Start Mode

Condition for setting the 3rd start mode shift map;

All of the following conditions are met:

• 3rd start switch is pressed

• Vehicle speed is less than 11 km/h (7 MPH)

• Transmission fluid is less than 115 °C (239 °F)

• Accelerator pedal position is less than 8%

• Selector lever is D range

Condition for canceling the 3rd start mode shift map;

Either of the following condition is met:

• 3rd start switch is pressed again

• Vehicle speed is more than 34 km/h (21 MPH)

• Selector lever is other than D range

4L Mode

Condition for setting the 4L mode shift map;

All of the following conditions are met:

• 4L switch is On

• Vehicle speed is more than 5 km/h (3 MPH)

Condition for canceling the 4L mode shift map;

Either of the following condition is met:

• 4L switch is On

• Vehicle speed is more than 5 km/h (3 MPH)

TCM

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Transmission range (TR) switch

Power drive switch

3rd start switch

Brake pedal switch

4WD low gear signal (via TCCM)

Solenoid valve outputs

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

Lamp control outputs

Power drive lamp

3rd start lamp

OFF

ON

OFF ON OFF

OFF

Low

Priority Shift map 3rd start

lamp Power drive

lamp

High temperature mode

3rd start mode

4L mode

Down slope mode when

power drive SW Off

Down slope mode when

power drive SW On

Power drive mode

Up slope mode

Normal mode

High

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4441 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-157

Down Slope Mode

Condition for setting the down slope mode shift map;

All of the following conditions are met:

• Brake pedal switch is depressed

• Accelerator pedal is released

• Vehicle speed is more than 60 km/h (36 MPH)

• Increment of vehicle speed is more than 1 km/h (1 MPH) per second

• Selector lever is D or 3 range

Condition for canceling the down slope mode shift map;

Either of the following condition is met:

• Accelerator pedal is depressed

• Selector lever is other than D or 3 range Power Drive Mode

When the power drive switch is ON, the TCM switches

shift map to the power drive mode map and performs

gearshift control from 1st to 4th to gain more

acceleration compared with normal mode.

Up Slope Mode

Up slope reasoning value is calculated from the

averaged accelerator pedal angle and the averaged

acceleration. Otherwise, up slope reasoning value is

calculated from the vehicle speed. The TCM selects a

up slope mode when the former is bigger than the

latter.

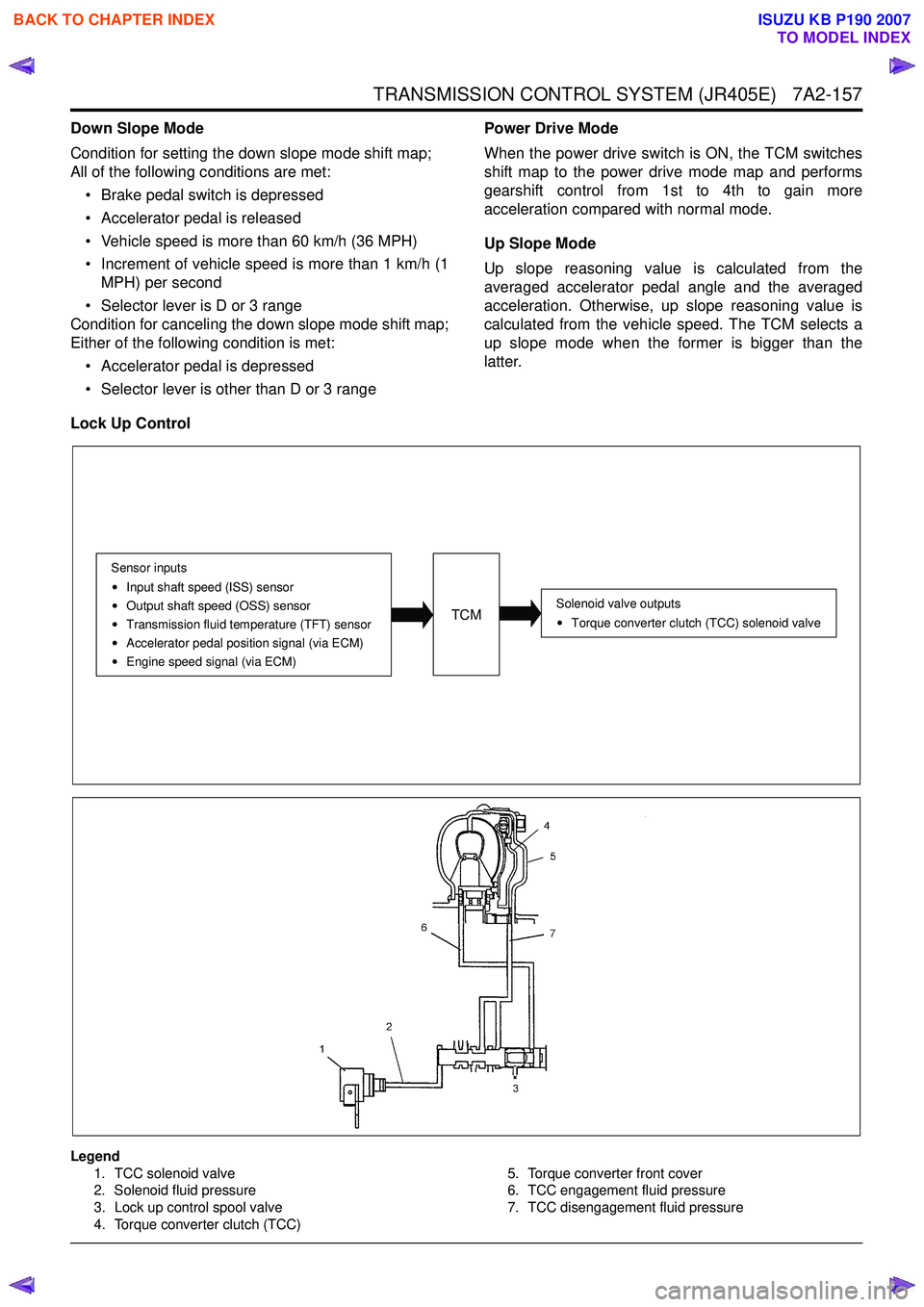

Lock Up Control

Legend 1. TCC solenoid valve

2. Solenoid fluid pressure

3. Lock up control spool valve

4. Torque converter clutch (TCC) 5. Torque converter front cover

6. TCC engagement fluid pressure

7. TCC disengagement fluid pressure

TCM

Sensor inputs

Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Solenoid valve outputsTorque converter clutch (TCC) solenoid valve

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4442 of 6020

7A2-158 TRANSMISSION CONTROL SYSTEM (JR405E)

The TCM controls the torque converter clutch (TCC)

solenoid valve based on the accelerator pedal angle,

input shaft speed, output shaft speed and transmission

fluid temperature.

Smooth lock up control is employed to engage or

disengage the TCC smoothly at the time of lock up On

or Off. When the TCM determines the TCC

engagement, the solenoid valve control duty cycle

(pulse width modulation [PWM]) signal is gradually

increased (5% to 95%) and the transmission fluid

between the TCC piston and torque converter front

cover is gradually drained. As a result, the TCC piston

is fitted slowly to the torque converter front cover under

fluid pressure securing smooth lock up engagement. The lock up control does not start when the

transmission fluid temperature is less than 20 °C (68 °F)

even though the vehicle is at the lock up control speed

area. The lock up control disengages when the

accelerator pedal angle is released.

Direct Electronic Shift Control (DECS)

Legend 1. Oil pump

2. Pressure regulator spool valve

3. ON/ OFF type solenoid valve (pressure control [PC]

solenoid valve 4. Duty cycle type solenoid valve (shift solenoid valve)

5. Amplifier (AMP) valve

6. Clutch

Solenoid valve outputs

Pressure control (PC) solenoid valve

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

TCM

Sensor inputsInput shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fluid

pressure (TFP) switch

2-4 brake transmission fluid pressure (TFP)

switch

High clutch transmission fluid pressure (TFP)

switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4443 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-159

Based on each transmission fluid pressure (TFP)

switch signal and each speed sensor signal and the

accelerator pedal angle, the duty cycle type shift

solenoid valve adjusts the clutch pressure to match the

engine load and vehicle running conditions. Controlling

the engagement and disengagement of the clutch and

brake pressure is directly and accurately controlled via

TCM, which is different to the conventional accumulator

type. Instead of the conventional system (On/ Off type

shift solenoid valve and shift valve), the combination of

the duty cycle type solenoid valve and the amplifier

(AMP) valve are used to adjust the clutch pressure to

match the engine load and vehicle driving conditions,

based on the signal from the TCM. Also, the TFP

switch provided in the fluid passage of the control valve

transmits to TCM, enabling the engagement and

disengagement control of the clutch and brake to be

directly and finely. When the gear is shifted from the

2nd to 3rd, 3rd to 4th, 4th to 3rd and 3rd to 2nd, the

clutch pressures on the engagement side and

disengagement side are simultaneously controlled. As

a result, engine racing or clutch drag is prevented

which enables a smooth and quick shift response.

Learning Control

Solenoid valve outputs

Low & reverse brake solenoid valve

2-4 brake solenoid valve

High clutch solenoid valve

Low clutch solenoid valve

TCM

Sensor inputs Input shaft speed (ISS) sensor

Output shaft speed (OSS) sensor

Transmission fluid temperature (TFT) sensor

Accelerator pedal position signal (via ECM)

Engine speed signal (via ECM)

Switch inputs

Low & reverse brake transmission fluid

pressure (TFP) switch

2-4 brake transmission fluid pressure (TFP)

switch

High clutch transmission fluid pressure (TFP)

switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4444 of 6020

7A2-160 TRANSMISSION CONTROL SYSTEM (JR405E)

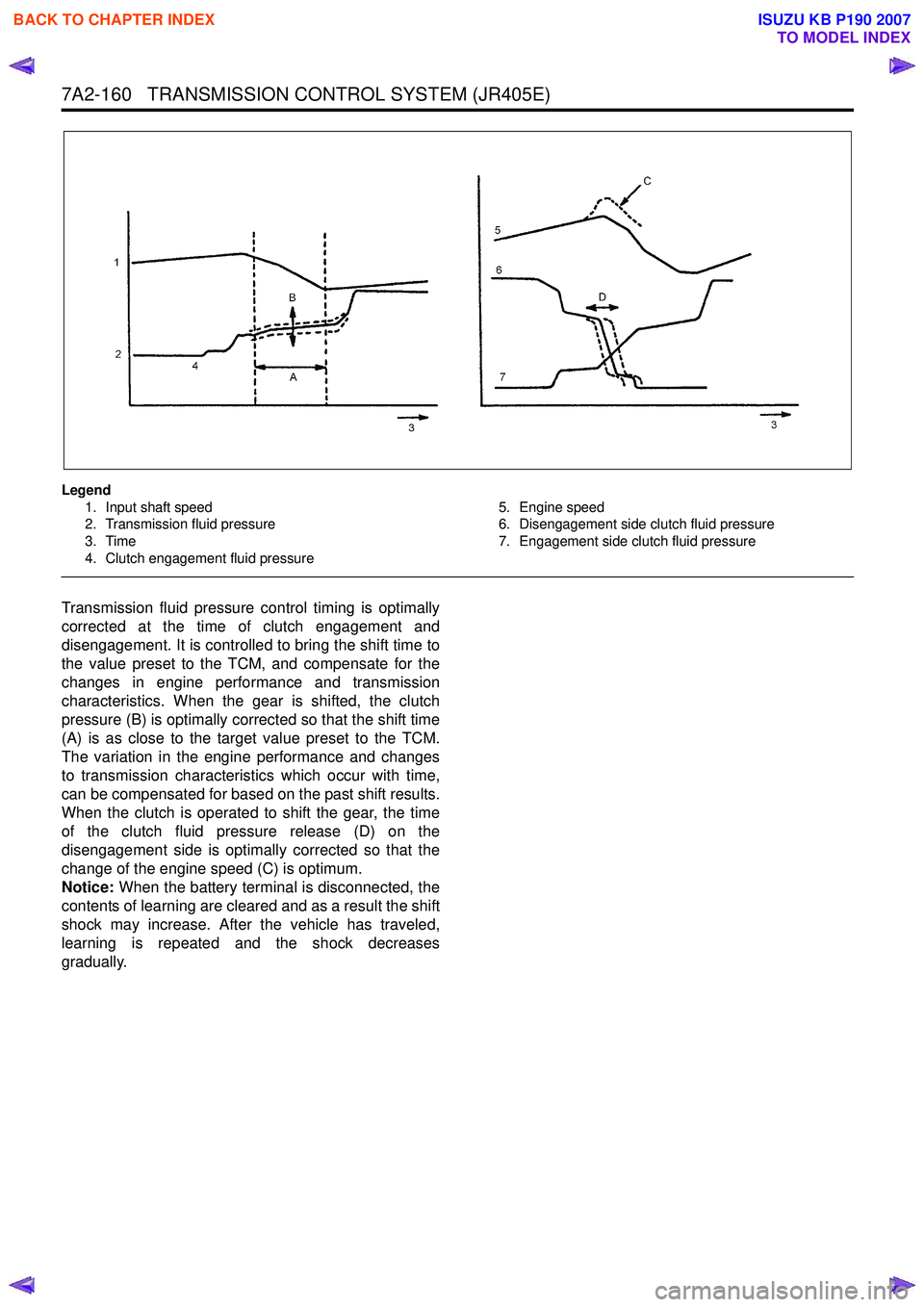

Legend1. Input shaft speed

2. Transmission fluid pressure

3. Time

4. Clutch engagement fluid pressure 5. Engine speed

6. Disengagement side clutch fluid pressure

7. Engagement side clutch fluid pressure

Transmission fluid pressure control timing is optimally

corrected at the time of clutch engagement and

disengagement. It is controlled to bring the shift time to

the value preset to the TCM, and compensate for the

changes in engine performance and transmission

characteristics. When the gear is shifted, the clutch

pressure (B) is optimally corrected so that the shift time

(A) is as close to the target value preset to the TCM.

The variation in the engine performance and changes

to transmission characteristics which occur with time,

can be compensated for based on the past shift results.

When the clutch is operated to shift the gear, the time

of the clutch fluid pressure release (D) on the

disengagement side is optimally corrected so that the

change of the engine speed (C) is optimum.

Notice: When the battery terminal is disconnected, the

contents of learning are cleared and as a result the shift

shock may increase. After the vehicle has traveled,

learning is repeated and the shock decreases

gradually.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4455 of 6020

ON-VEHICLE SERVICE (JR405E) 7A3-1

SECTION 7A3

ON-VEHICLE SERVICE (JR405E)

TABLE OF CONTENTS

PAGE

Description ................................................................................................................... ... 7A3 – 2

Automatic Transmission Fluid (ATF) ............................................................................ 7A3 – 2

ATF Level ..................................................................................................................... .... 7A3 – 2

ATF Change .................................................................................................................... . 7A3 – 3

Transmission Control Module (TCM) ............................................................................ 7A3 – 5

Inhibitor Switch .............................................................................................................. . 7A3 – 6

Speed Sensor .................................................................................................................. 7A3 – 8

Turbine Sensor ............................................................................................................... 7A3 – 9

Power and 3rd Start Switch ........................................................................................... 7A3 – 9

Select Lever .................................................................................................................. ... 7A3 –10

Shift Cable ................................................................................................................... .... 7A3 –13

Solenoids, Oil Pressure Switch and Oil Temperature Sensor .................................... 7A3 –16

Control Valve Assembly ................................................................................................. 7A3 –1 8

Flushing the Transmission Fluid Cooler and Line ...................................................... 7A3 –19

Transmission Assembly ................................................................................................. 7A3 –20

Special Service Tool ....................................................................................................... 7A 3 –23

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4456 of 6020

7A3-2 ON-VEHICLE SERVICE (JR405E)

DESCRIPTION

Before performing on-vehicle service on the automatic

transmission, check that the engine idling speed and

general engine condition are normal.

For shift interlock function, if the ignition key is out of

“LOCK” position, the shift lever select button can not be

pushed. (shift lever can not be operated.)

RTW 77ASH000901

AUTOMATIC TRANSMISSION FLUID (ATF)

Inspect

Remove the transmission dipstick to check the condition

of the ATF.

Check the color and smell of the ATF.

If the ATF is abnormal color or smells burnt, replace it

and investigate the cause of trouble.

Coloor of ATF Condition Clear red Normality

Blackish discoloration Defects of power train

parts (clutches)

W hite turbidity Include water

Discoloration of red brown Deterioration of ATF

ATF LEVEL

Inspect

Hot Level

1. W arm up the engine and the transmission by driving

the vehicle on the road so that the temperature

reaches around 80 °C (176 °F).

Do not turn the engine off.

2. Park the vehicle on a level surface.

3. Apply the parking brake firmly.

4. Let the engine run at idle.

Move the select lever slowly through all the gea

r

positions.

Stop in each gear position just long enough for the transmission to engage.

5. Return the select lever to either “P” or “N”.

6. Remove the ATF level dipstick.

7. W ipe the dipstick clean with a paper towel.

8. Reinsert the dipstick and wait several seconds.

9. Remove the dipstick.

The ATF level should be inside the “H” range on the dipstick.

242R300001

If the ATF level is below the “H” range, ATF must be added.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007