ABS ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5480 of 6020

8A-542 ELECTRICAL-BODY AND CHASSIS

KEYLESS ENTRY CONTROL UNIT

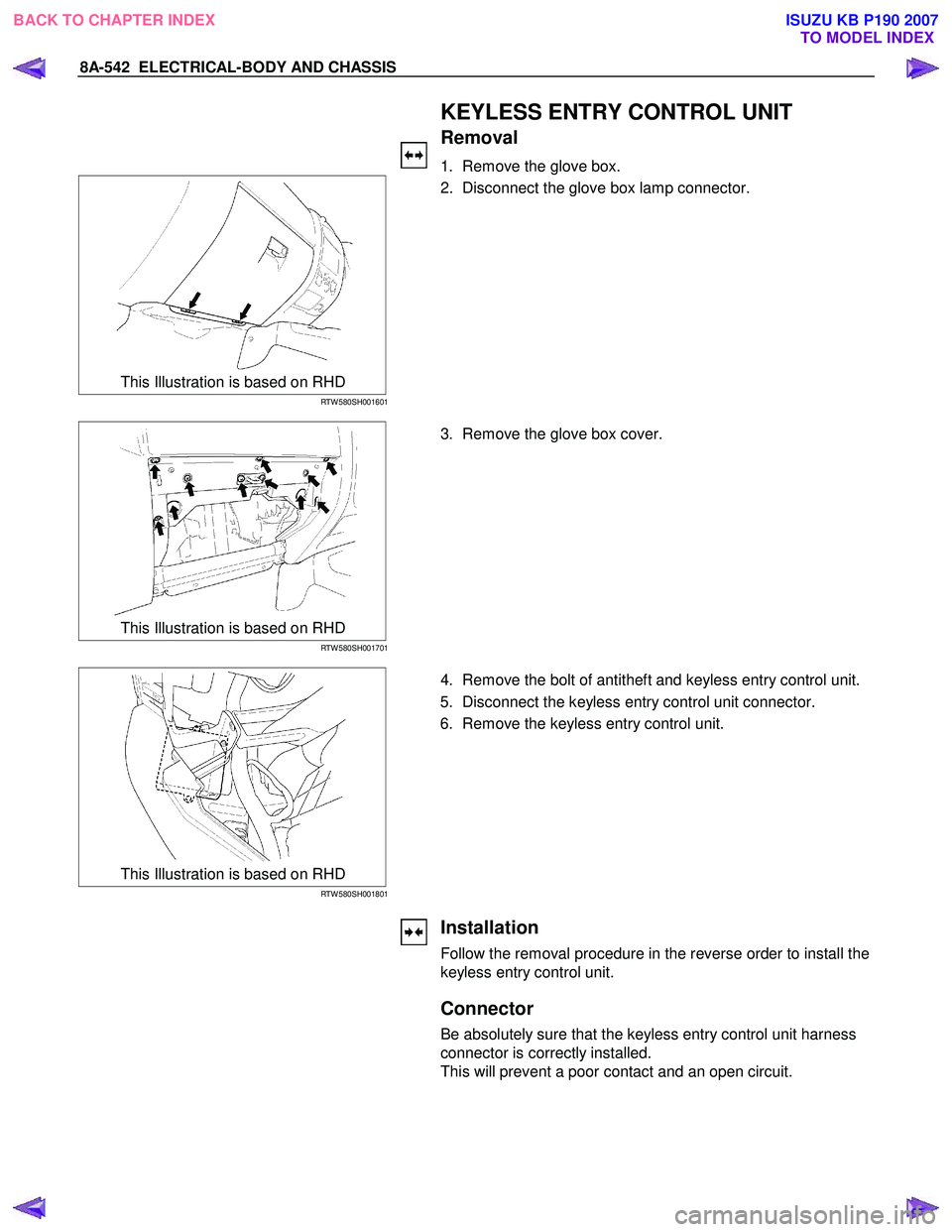

Removal

1. Remove the glove box.

This Illustration is based on RHD

RTW 580SH001601

2. Disconnect the glove box lamp connector.

This Illustration is based on RHD

RTW 580SH001701

3. Remove the glove box cover.

This Illustration is based on RHD

RTW 580SH001801

4. Remove the bolt of antitheft and keyless entry control unit.

5. Disconnect the keyless entry control unit connector.

6. Remove the keyless entry control unit.

Installation

Follow the removal procedure in the reverse order to install the

keyless entry control unit.

Connector

Be absolutely sure that the keyless entry control unit harness

connector is correctly installed.

This will prevent a poor contact and an open circuit.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5516 of 6020

8A-578 ELECTRICAL-BODY AND CHASSIS

KEYLESS ENTRY CONTROL UNIT

Removal

1. Remove the glove box.

RTW 580SH001601

2. Disconnect the glove box lamp connector.

RTW 580SH001701

3. Remove the glove box cover.

RTW 580SH001801

4. Remove the bolt of antitheft and keyless entry control unit.

5. Disconnect the antitheft and keyless entry control unitconnector.

6. Remove the antitheft and keyless entry control unit.

Installation

Follow the removal procedure in the reverse order to install the

antitheft and keyless entry control unit.

Connector

Be absolutely sure that the antitheft and keyless entry control

unit harness connector is correctly installed.

This will prevent a poor contact and an open circuit.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5550 of 6020

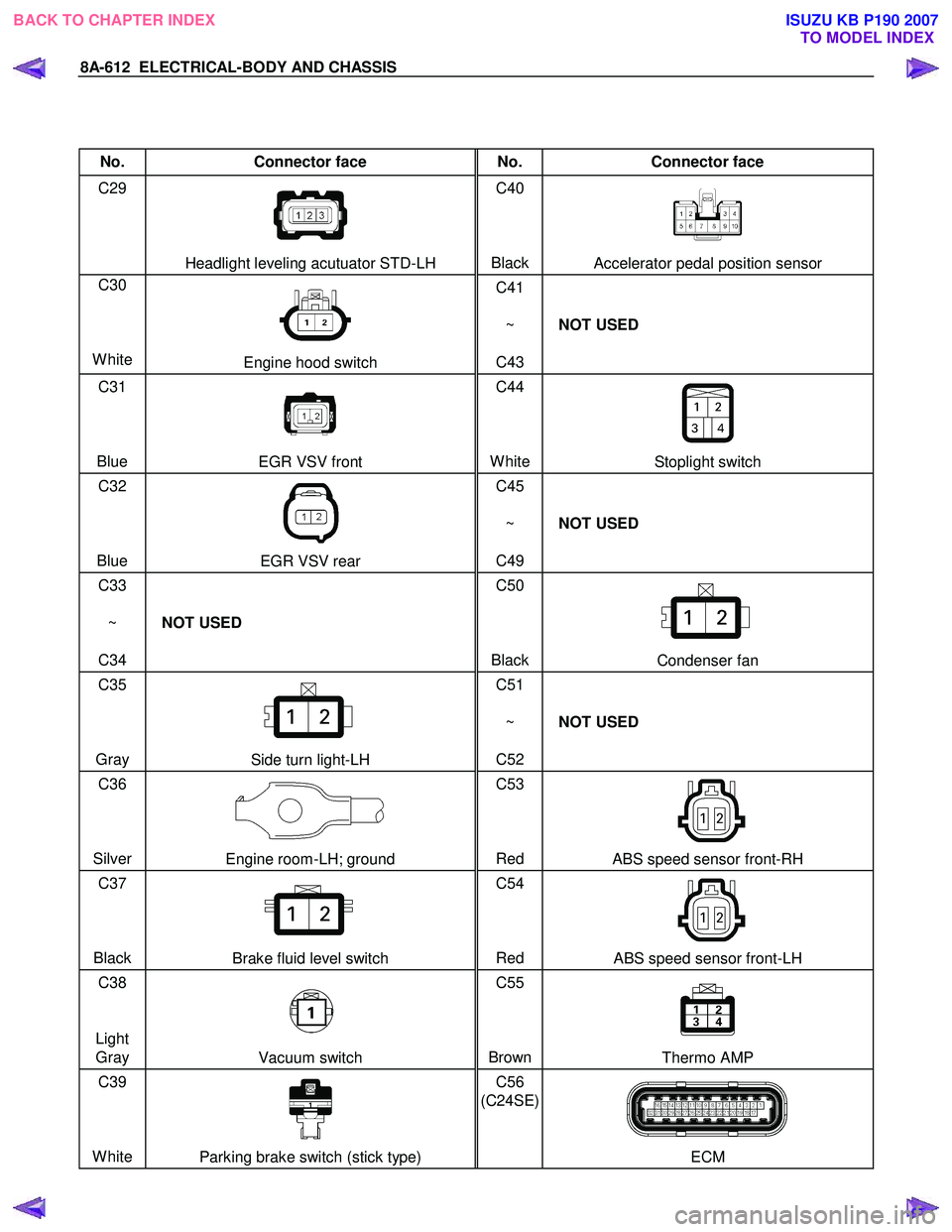

8A-612 ELECTRICAL-BODY AND CHASSIS

No. Connector face No. Connector face

C29

Headlight leveling acutuator STD-LH C40

BlackAccelerator pedal position sensor

C30

White

Engine hood switch C41

~

C43 NOT USED

C31

Blue

EGR VSV front C44

WhiteStoplight switch

C32

Blue

EGR VSV rear C45

~

C49 NOT USED

C33

~

C34 NOT USED C50

Black

Condenser fan

C35

Gray

Side turn light-LH C51

~

C52 NOT USED

C36

Silver

Engine room-LH; ground C53

Red ABS speed sensor front-RH

C37

Black

Brake fluid level switch C54

Red ABS speed sensor front-LH

C38

Light Gray

Vacuum switch C55

BrownThermo AMP

C39

White

Parking brake switch (stick type) C56

(C24SE)

ECM

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5562 of 6020

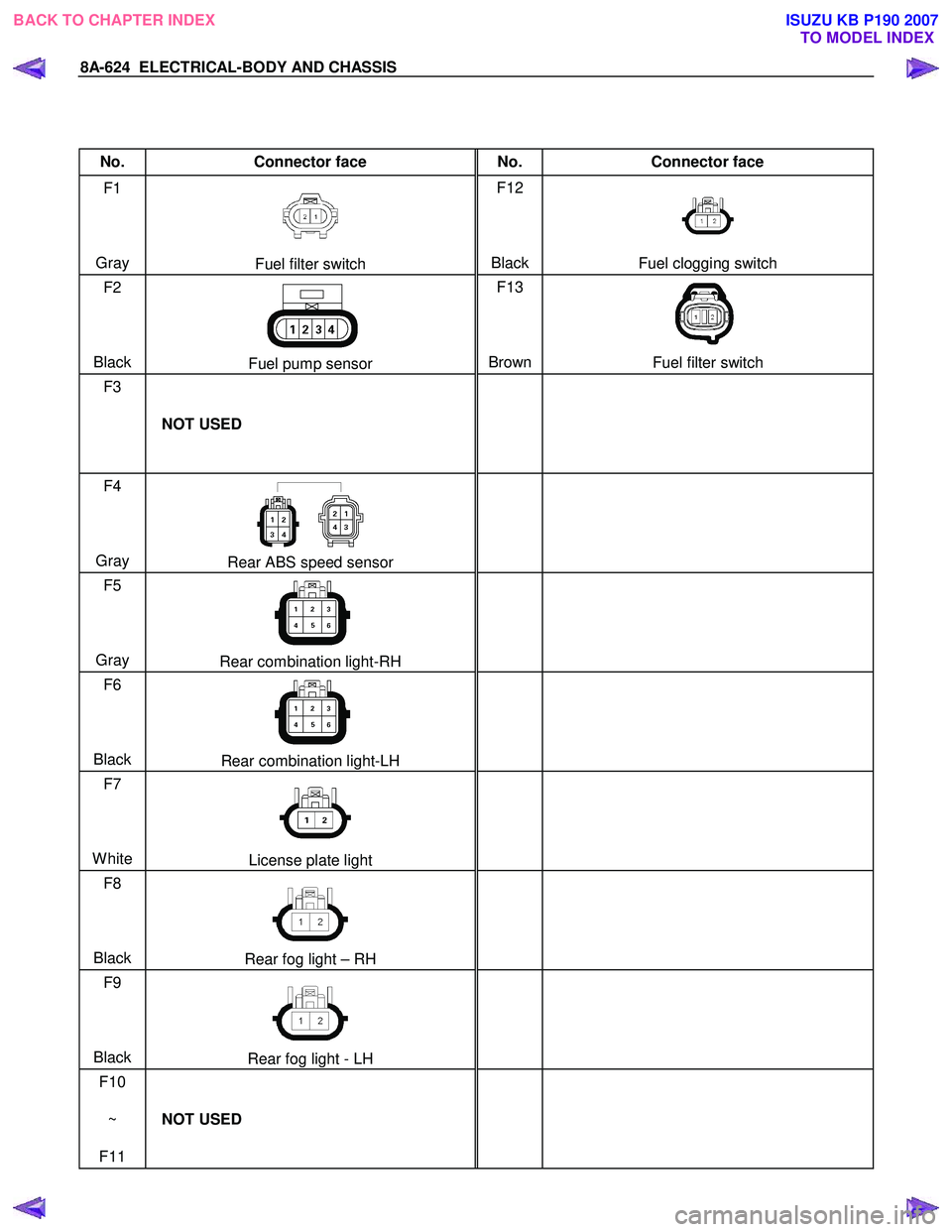

8A-624 ELECTRICAL-BODY AND CHASSIS

No. Connector face No. Connector face

F1

Gray

Fuel filter switch F12

BlackFuel clogging switch

F2

Black

Fuel pump sensor F13

BrownFuel filter switch

F3

NOT USED

F4

Gray

Rear ABS speed sensor

F5

Gray

Rear combination light-RH

F6

Black

Rear combination light-LH

F7

White

License plate light

F8

Black

Rear fog light – RH

F9

Black

Rear fog light - LH

F10

~

F11 NOT USED

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5600 of 6020

Cruise Control – HFV6 Page 8C–22

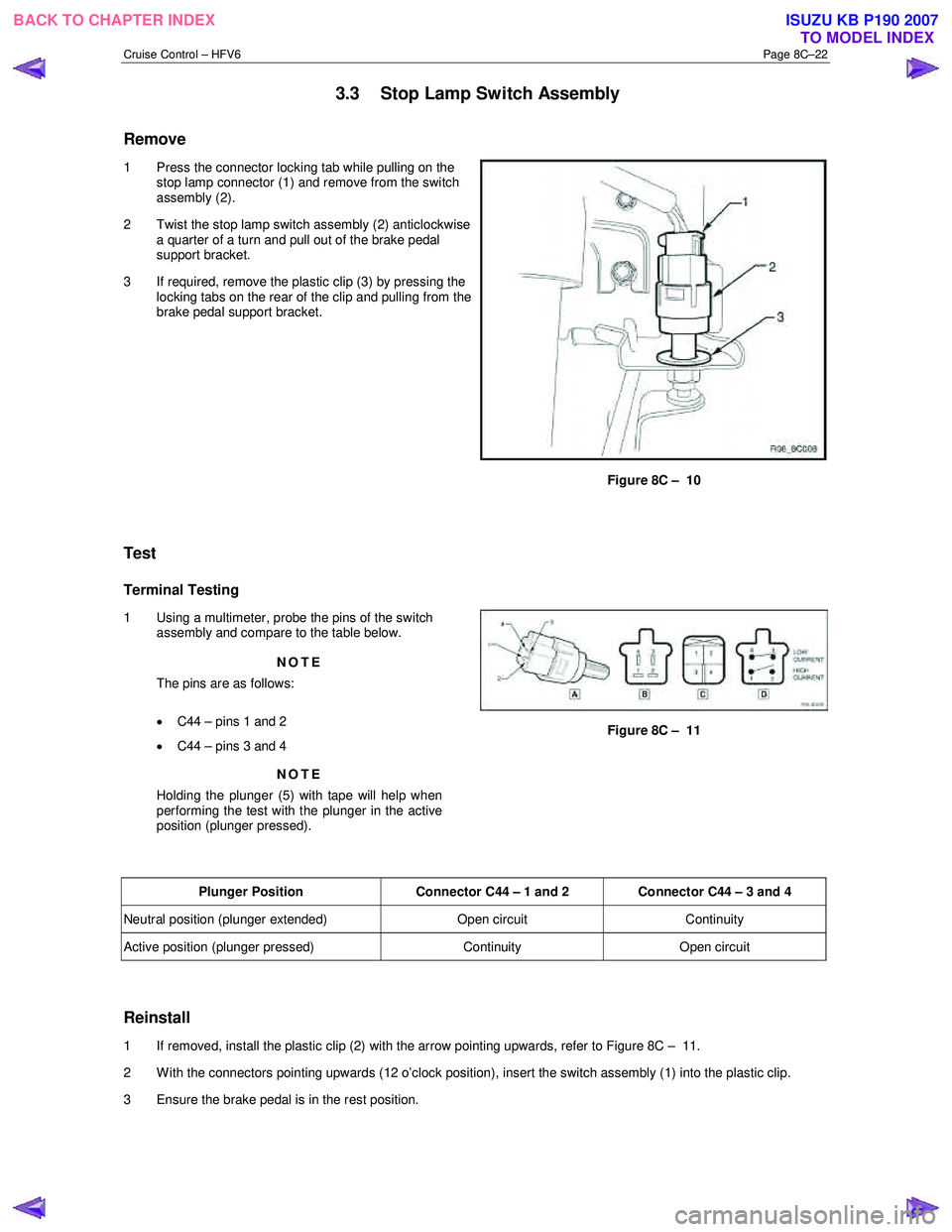

3.3 Stop Lamp Switch Assembly

Remove

1 Press the connector locking tab while pulling on the

stop lamp connector (1) and remove from the switch

assembly (2).

2 Twist the stop lamp switch assembly (2) anticlockwise a quarter of a turn and pull out of the brake pedal

support bracket.

3 If required, remove the plastic clip (3) by pressing the locking tabs on the rear of the clip and pulling from the

brake pedal support bracket.

Figure 8C – 10

Test

Terminal Testing

1 Using a multimeter, probe the pins of the switch assembly and compare to the table below.

NOTE

The pins are as follows:

• C44 – pins 1 and 2

• C44 – pins 3 and 4

NOTE

Holding the plunger (5) with tape will help when

performing the test with the plunger in the active

position (plunger pressed).

Figure 8C – 11

Plunger Position Connector C44 – 1 and 2 Connector C44 – 3 and 4

Neutral position (plunger extended) Open circuit Continuity

Active position (plunger pressed) Continuity Open circuit

Reinstall

1 If removed, install the plastic clip (2) with the arrow pointing upwards, refer to Figure 8C – 11.

2 With the connectors pointing upwards (12 o’clock position), insert the switch assembly (1) into the plastic clip.

3 Ensure the brake pedal is in the rest position.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5639 of 6020

9A-4 SUPPLEMENTAL RESTRAINT SYSTEM

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING A SERVICE ON, OR NEAR, THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING A SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastener torque

and the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

General Description

CAUTION: When fasteners are removed, always

reinstall them at the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener fo

r

that application. If the correct part numbe

r

fastener is not available, a fastener of equal size

and strength (or stronger) may be used.

Fasteners that are not reused, and those requiring

thread locking compound will be called out. The

correct torque value must be used when installing

fasteners that require it. If the above conditions

are not followed, parts or system damage could

result.

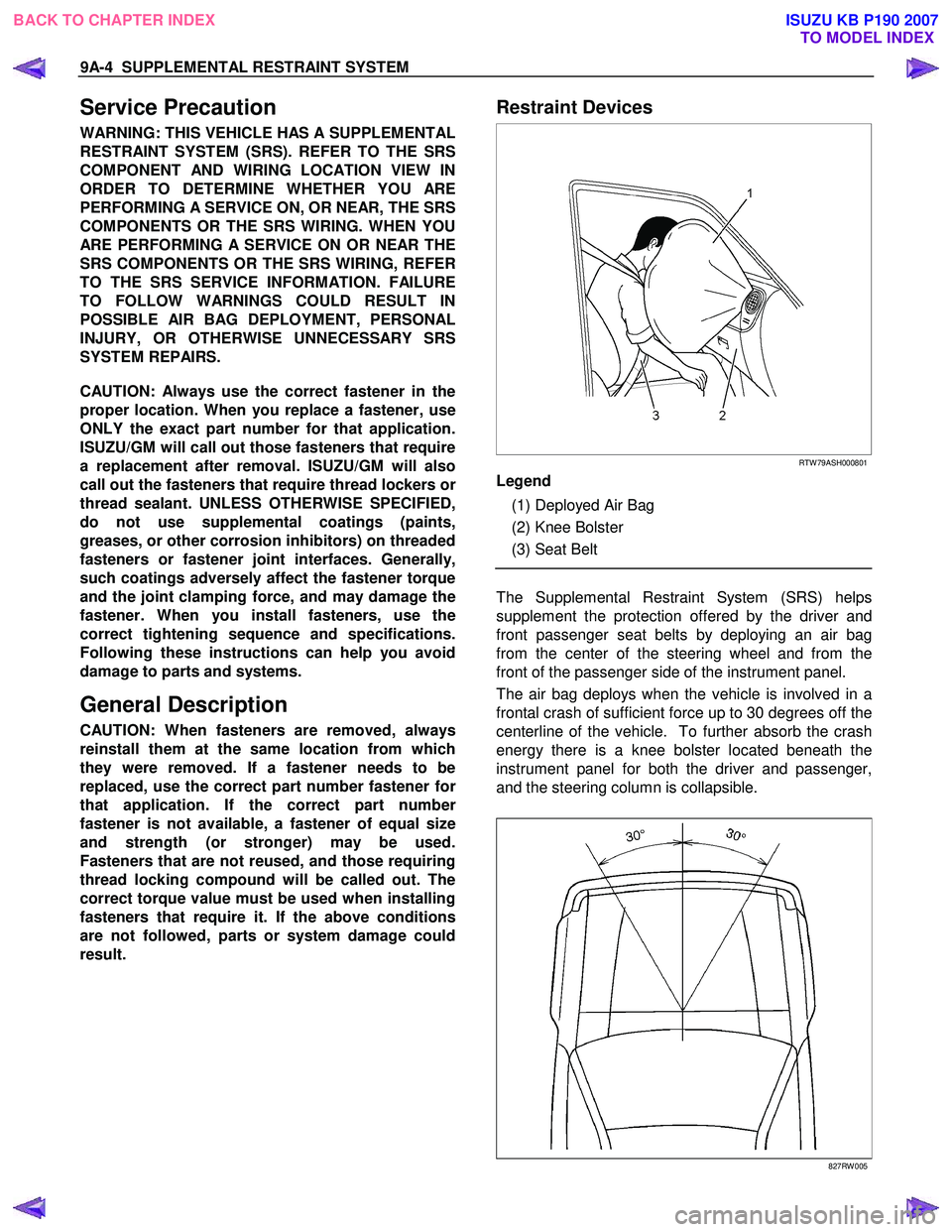

Restraint Devices

RTW 79ASH000801

Legend

(1) Deployed Air Bag

(2) Knee Bolster

(3) Seat Belt

The Supplemental Restraint System (SRS) helps

supplement the protection offered by the driver and

front passenger seat belts by deploying an air bag

from the center of the steering wheel and from the

front of the passenger side of the instrument panel.

The air bag deploys when the vehicle is involved in a

frontal crash of sufficient force up to 30 degrees off the

centerline of the vehicle. To further absorb the crash

energy there is a knee bolster located beneath the

instrument panel for both the driver and passenger,

and the steering column is collapsible.

827RW 005

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5651 of 6020

9A-16 SUPPLEMENTAL RESTRAINT SYSTEM

RTW 79ASH000201

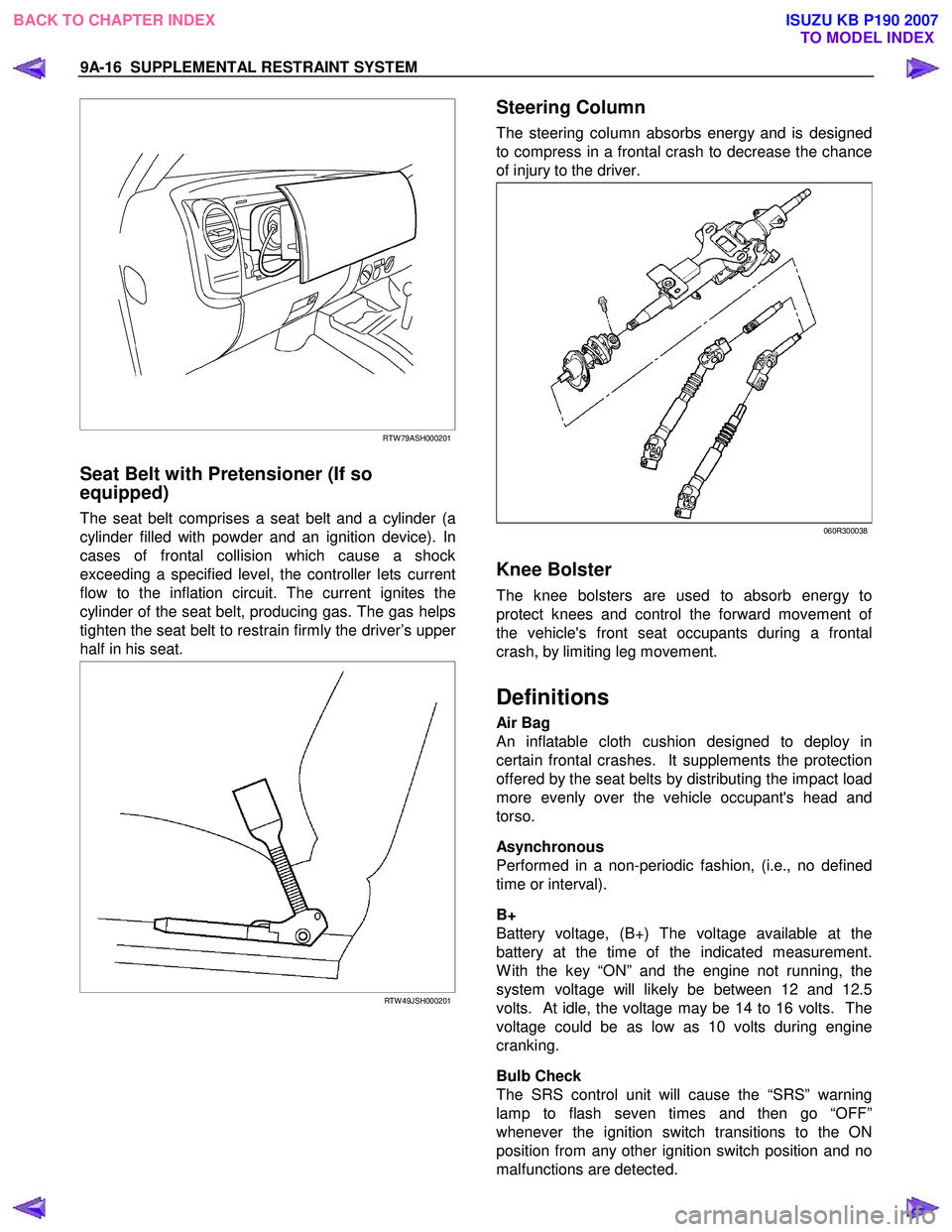

Seat Belt with Pretensioner (If so

equipped)

The seat belt comprises a seat belt and a cylinder (a

cylinder filled with powder and an ignition device). In

cases of frontal collision which cause a shock

exceeding a specified level, the controller lets current

flow to the inflation circuit. The current ignites the

cylinder of the seat belt, producing gas. The gas helps

tighten the seat belt to restrain firmly the driver’s uppe

r

half in his seat.

RTW 49JSH000201

Steering Column

The steering column absorbs energy and is designed

to compress in a frontal crash to decrease the chance

of injury to the driver.

060R300038

Knee Bolster

The knee bolsters are used to absorb energy to

protect knees and control the forward movement o

f

the vehicle's front seat occupants during a frontal

crash, by limiting leg movement.

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in

certain frontal crashes. It supplements the protection

offered by the seat belts by distributing the impact load

more evenly over the vehicle occupant's head and

torso.

Asynchronous

Performed in a non-periodic fashion, (i.e., no defined

time or interval).

B+

Battery voltage, (B+) The voltage available at the

battery at the time of the indicated measurement.

W ith the key “ON” and the engine not running, the

system voltage will likely be between 12 and 12.5

volts. At idle, the voltage may be 14 to 16 volts. The

voltage could be as low as 10 volts during engine

cranking.

Bulb Check

The SRS control unit will cause the “SRS” warning

lamp to flash seven times and then go “OFF”

whenever the ignition switch transitions to the ON

position from any other ignition switch position and no

malfunctions are detected.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5903 of 6020

IMMOBILIZER SYSTEM (C24SE, 4JA1-T) 11A-5

What happens without proper transponder

operation?

One of the function of transponder is to deactivate or

activate starter function. lf the proper transponder is not

used, starter cannot be operated. Because starter rela

y

stays off, cranking engine is not possible.

After the starter relay is activated, transponder signal

triggers to let lCU calculate by transponder address

signal and immobilizer algorithm.

W hen the result matches with necessary condition, it

makes injector power source be activated.

If transponder does not send correct signal, lCU and

ECM do not activate injector system on.

Therefore the vehicle cannot be operated.

No proper transponder is available, what

should be done for the system?

W hen any proper transponder is not available, a new

transponder should be programmed. Up to 5

transponders can be provided with a scan tool (Tech-2)

and by proper procedure.

In addition to the absence of proper transponder, it ma

y

happen particular secret code to the particular vehicle is

missing. ln this case, the secret code must be provided

by your organization.

Otherwise transponder cannot be programmed in an

y

way.

lf the essential for a scan tool (Tech-2) for programming

and proper software for Tech-2 are not available, there

is no permanent way to fix system. Temporary replace

with new ECM, new ICU and new transponder without

any secret code can make the system be deactivated,

but it does not last long. Such a replacement does not

solve any condition. Even after replacement, the system

is activated automatically in short time and then no

operation of the vehicle can be made in any way.

Tech-2 should be provided in your organization.

Caution to the operation

lf an attempt is made to start the engine while the

immobilizer system is activated, the check engine lamp

flashes and the engine will not start.

Summary of operation

Switch on: Set the ignition and starter switch to OFF.

(Activate)

Switch off: Set the ignition and starter switch to ON b

y

using the transponder key. (Deactivate)

What your organization should provide for

your customer

•

••

•

Car Pass

For a new owner, your dealership must hand Car Pass

card, which has identification numbers of new owner's

vehicle immobilizer system. This information is ver

y

important in case of repair or lost of transponder.

The followings are necessary items provided by you

r

responsibility.

1) Car pass with identification for a new owner

2) Blank car pass card when it is for reissue

3) Instruction to dealers how to use car pass card

•

••

•

Security code management

Your organization must keep security codes for all

vehicles as confidential data. Once the security codes

are lost, anybody who have the security code can

access immobilizer system. Your organization has

responsibility of any missing vehicles caused by stolen

security code.

•

••

•

Essential tool (Scan tool : Tech-2)

Your dealership must have Tech-2, and Tech-2 updated

software for immobilizer system.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5958 of 6020

11B-4 ANTITHEFT SYSTEM

Transmitter (into remote key) power

The transmitted power is less than 10 m W .

Battery life time for transmitter power

The minimum life time of battery is 2 years with 15

lock/unlock cycles per day.

W hile the battery is changed, the data retention will be

at least 3 minutes without pressing a button.

Super lock

(Mechanical anti-theft locking system)

To Lock:

All doors must be closed; press the lock button on the

remote control unit again within 10 seconds after

locking or turn key in driver's door lock towards rear of

vehicle again within 10 seconds after locking, then turn

it back to the vertical position and remove.

Lock buttons on all doors are positioned such that doors

cannot be opened.

To unlock:

Press unlock button on remote key or turn key in

driver's door lock towards front of vehicle, then turn it

back to the vertical position and remove. If the key is

used, antitheft alarm sound operate which continues

until ignition switch turn ON. If a problem is found, open

the driver door as necessary.

No proper transmitter is available, what

should be done for the system?

W hen any proper transmitter is not available, a new

transmitter should be programmed. Up to 5 transmitters

can be provided with a scan tool (Tech-2) and by proper

procedure.

In addition to the absence of proper transmitter, it may

happen particular secret code to the particular vehicle is

missing. ln this case, the secret code must be provided

by your organization.

Otherwise transmitter cannot be programmed in any

way.

lf the essential for a scan tool (Tech-2) for programming

and proper software for Tech-2 are not available, there

is no permanent way to fix system. Temporary replace

with new ACU, new ICU and new transmitter without

any secret code can make the system be deactivated,

but it does not last long. Such a replacement does not

solve any condition. Even after replacement, the system

is activated automatically in short time and then no

operation of the vehicle can be made in any way.

Tech-2 should be provided in your organization.

• Security code management

Your organization must keep security codes for all

vehicles as confidential data. Once the security codes

are lost, anybody who have the security code can

access antitheft system. Your organization has

responsibility of any missing vehicles caused by stolen

security code.

• Essential tool (Scan tool: Tech-2)

Your dealership must have Tech-2, and Tech-2 updated

software for immobilizer system.

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007