ABS ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4313 of 6020

![ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental r ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental r](/img/61/57177/w960_57177-4312.png)

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-29

Scan Tool Does Not Communicate with Keyword Device

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental restraint system

(SRS) control module all communicate with the scan

tool over the Keyword serial data link.

Diagnostic Aids

The following conditions will cause a loss of Keyword

serial data communication between the scan tool and

the TCM.

• A Keyword serial data circuit open • A Keyword serial data circuit shorted to ground

• A Keyword serial data circuit shorted to voltage

• An internal condition within a module or connector on the Keyword serial data circuit, that causes a

short to voltage or ground to the Keyword serial

data circuit

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Scan Tool Does Not Communicate with Keyward Device

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission Controls

2 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Attempt to establish communication with the listed control modules.

•TCM

• Electronic hydraulic control unit (EHCU) [ABS module] (If so equipped)

• Supplemental restraint system (SRS) control module (If so equipped)

Does the scan tool communicate with any of the

listed control modules? —

Go to Step 3 Go to Step 7

3 Does the scan tool communicate with the TCM?

—Go to Step 4 Go to Lost

Communication with

The Transmission Control Module (TCM)

4 Notice:

If no ABS is installed, skip to Step 5.

Does the scan tool communicate with the EHCU? —

Go to Step 5 Go to Diagnostic

System Check - Anti-lock Brake Controls

5 Notice:

If no SRS is installed, skip to Step 6.

Does the scan tool communicate with the SRS

control module? —

Go to Step 6 Go to Diagnostic

System Check -SRS Controls

6 Test the Keyword serial data circuit for an

intermittently short to ground or intermittently short

to voltage. Then, test the Keyword serial data

circuit for an intermittently open (based on which

control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition? —

Go to Step 15 System OK

7 1. Inspect for an intermittent, for a poor

connection and for corrosion at the data link

connector (DLC) (pin 7 of B-58).

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 15 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4314 of 6020

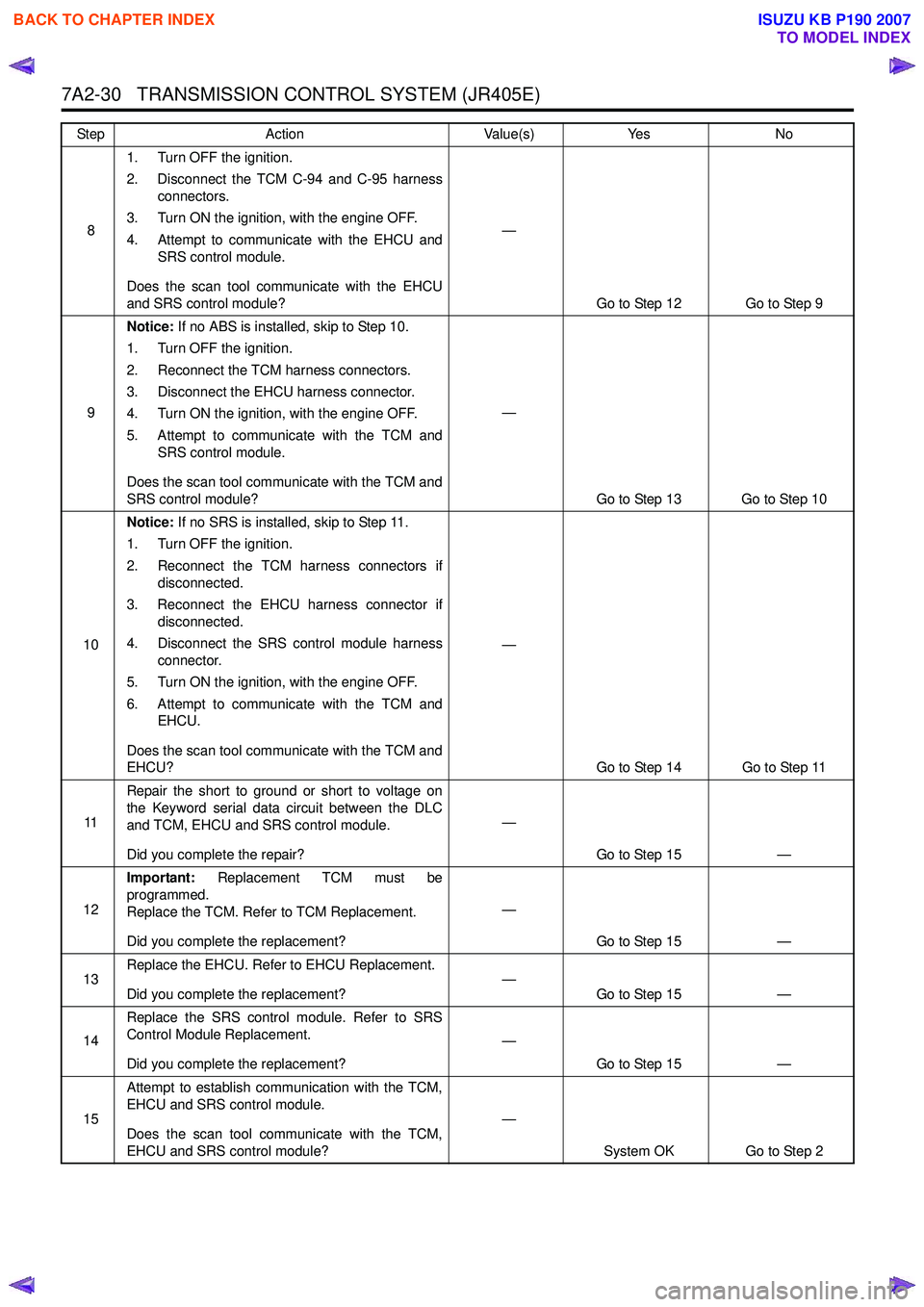

7A2-30 TRANSMISSION CONTROL SYSTEM (JR405E)

81. Turn OFF the ignition.

2. Disconnect the TCM C-94 and C-95 harness connectors.

3. Turn ON the ignition, with the engine OFF.

4. Attempt to communicate with the EHCU and SRS control module.

Does the scan tool communicate with the EHCU

and SRS control module? —

Go to Step 12 Go to Step 9

9 Notice:

If no ABS is installed, skip to Step 10.

1. Turn OFF the ignition.

2. Reconnect the TCM harness connectors.

3. Disconnect the EHCU harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the TCM and SRS control module.

Does the scan tool communicate with the TCM and

SRS control module? —

Go to Step 13 Go to Step 10

10 Notice:

If no SRS is installed, skip to Step 11.

1. Turn OFF the ignition.

2. Reconnect the TCM harness connectors if disconnected.

3. Reconnect the EHCU harness connector if disconnected.

4. Disconnect the SRS control module harness connector.

5. Turn ON the ignition, with the engine OFF.

6. Attempt to communicate with the TCM and EHCU.

Does the scan tool communicate with the TCM and

EHCU? —

Go to Step 14 Go to Step 11

11 Repair the short to ground or short to voltage on

the Keyword serial data circuit between the DLC

and TCM, EHCU and SRS control module.

Did you complete the repair? —

Go to Step 15 —

12 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 15 —

13 Replace the EHCU. Refer to EHCU Replacement.

Did you complete the replacement? —

Go to Step 15 —

14 Replace the SRS control module. Refer to SRS

Control Module Replacement.

Did you complete the replacement? —

Go to Step 15 —

15 Attempt to establish communication with the TCM,

EHCU and SRS control module.

Does the scan tool communicate with the TCM,

EHCU and SRS control module? —

System OK Go to Step 2

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4315 of 6020

![ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup](/img/61/57177/w960_57177-4314.png)

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental restraint system

(SRS) control module all communicate with the scan

tool over the Keyword serial data link. Schematic Reference:

Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Lost Communication with The Transmission Control Module (TCM)

Step Action ActionYes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission

Controls

2 Attempt to establish communication with the TCM.

Does the scan tool communicate with the TCM? —

Go to Intermittent

Conditions Go to Step 3

3 1. Inspect for an intermittent, for poor

connections and for corrosion at the TCM C-

94 and C-95 harness connectors.

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 4

4 1. Check the TCM (15A) in the cabin fuse block.

Replace and retest if open. If any fuse

continues to open, repair the short to ground

on each circuit fed by that fuse.

2. Turn OFF the ignition.

3. Disconnect the TCM C-95 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at

the TCM (pins 18 and 24 of C-95).

Does the test lamp illuminate? —

Go to Step 6 Go to Step 5

5 Repair the open in the ignition voltage circuit to the

TCM.

Did you complete the repair? —

Go to Step 9 —

6 1. Turn OFF the ignition.

2. Disconnect the TCM C-94 harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the TCM (pin 5 of C-94).

4. Test the Keyword serial data circuit between the TCM (pin 5 of C-94) and the DLC (pin 7 of

B-58) for an open circuit or high resistance.

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 7

7 1. Check TCM ground for corrosion and

tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4459 of 6020

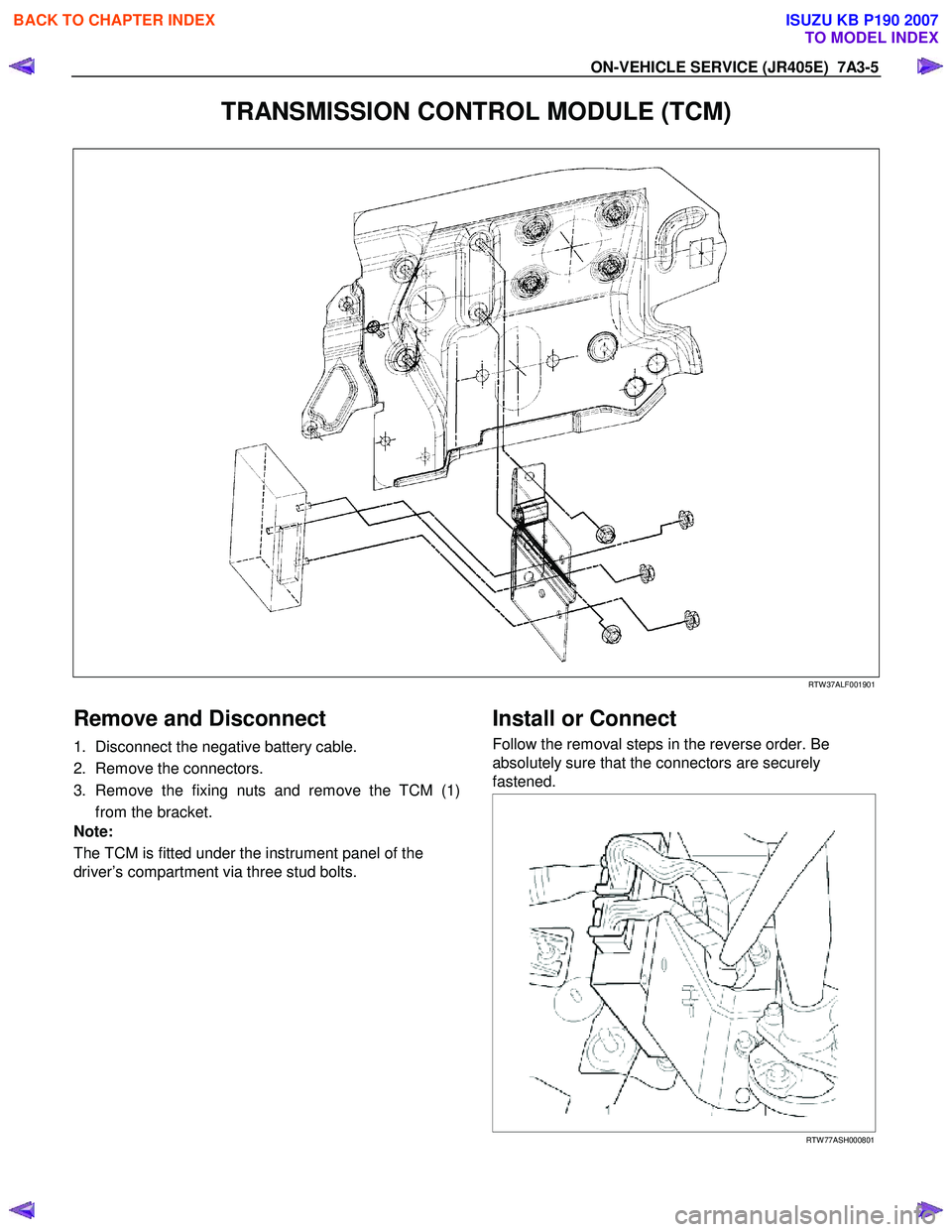

ON-VEHICLE SERVICE (JR405E) 7A3-5

TRANSMISSION CONTROL MODULE (TCM)

RTW 37ALF001901

Remove and Disconnect

1. Disconnect the negative battery cable.

2. Remove the connectors.

3. Remove the fixing nuts and remove the TCM (1) from the bracket.

Note:

The TCM is fitted under the instrument panel of the

driver’s compartment via three stud bolts.

Install or Connect

Follow the removal steps in the reverse order. Be

absolutely sure that the connectors are securely

fastened.

RTW 77ASH000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4869 of 6020

TRANSFER CASE 7D-39

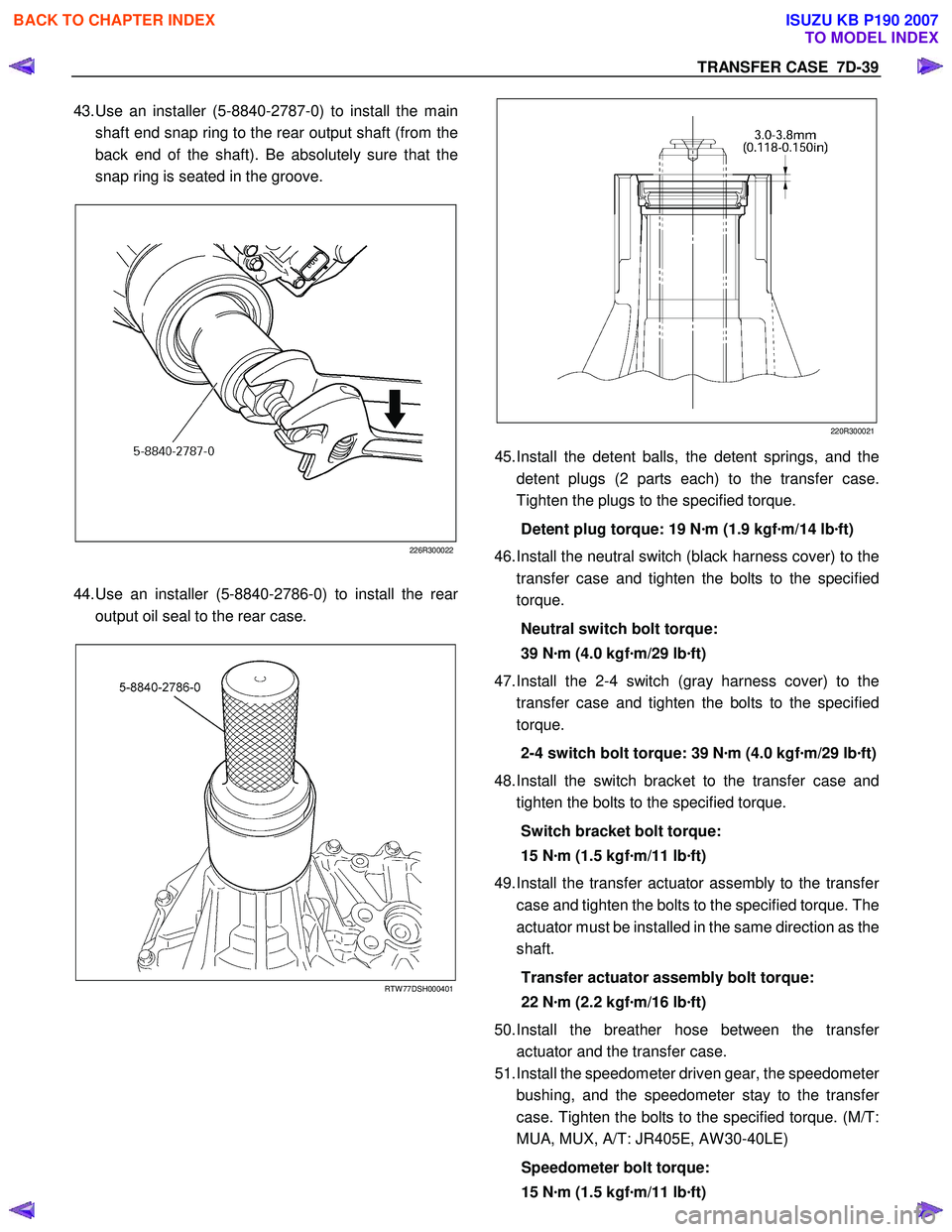

43. Use an installer (5-8840-2787-0) to install the main

shaft end snap ring to the rear output shaft (from the

back end of the shaft). Be absolutely sure that the

snap ring is seated in the groove.

226R300022

44. Use an installer (5-8840-2786-0) to install the rear

output oil seal to the rear case.

RTW 77DSH000401

220R300021

45.

Install the detent balls, the detent springs, and the

detent plugs (2 parts each) to the transfer case.

Tighten the plugs to the specified torque.

Detent plug torque: 19 N ·m (1.9 kgf ·m/14 lb ·ft)

46. Install the neutral switch (black harness cover) to the

transfer case and tighten the bolts to the specified

torque.

Neutral switch bolt torque:

39 N ·m (4.0 kgf ·m/29 lb ·ft)

47. Install the 2-4 switch (gray harness cover) to the

transfer case and tighten the bolts to the specified

torque.

2-4 switch bolt torque: 39 N ·m (4.0 kgf ·m/29 lb ·ft)

48. Install the switch bracket to the transfer case and

tighten the bolts to the specified torque.

Switch bracket bolt torque:

15 N ·m (1.5 kgf ·m/11 lb ·ft)

49. Install the transfer actuator assembly to the transfe

r

case and tighten the bolts to the specified torque. The

actuator must be installed in the same direction as the

shaft.

Transfer actuator assembly bolt torque:

22 N ·m (2.2 kgf ·m/16 lb ·ft)

50. Install the breather hose between the transfe

r

actuator and the transfer case.

51. Install the speedometer driven gear, the speedomete

r

bushing, and the speedometer stay to the transfe

r

case. Tighten the bolts to the specified torque. (M/T:

MUA, MUX, A/T: JR405E, AW 30-40LE)

Speedometer bolt torque:

15 N ·m (1.5 kgf ·m/11 lb ·ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4921 of 6020

TRANSFER CONTROL SYSTEM 7D1-47

3. Shifting from 4H to 4L

3-1 When the 4L indicator flashes at 2Hz

W hen shifting from 4H to 4L, the 4L indicator continues flashing at 2Hz until shifting in the transfer case is

completed. The phases of the engaged splines may sometimes deviate preventing completion of shifting. By

correcting the deviation of phases, shifting is completed.

Step 3-1:

(In case of AT): Set the select bar of the transmission to the D position.

(In case of MT): Set the lever of the transmission to a position allowing running and engage the clutch gently.

At this time, some rotating force acts on the engaged splines, phase is corrected and the engagement is

completed.

3-2 When the 4L indicator flashes at 2Hz for 10 seconds and then keeps ON again (AT vehicle)

This condition occurs when torsional torque has been generated between the transmission and road surface

and the transfer standby mechanism cannot absorb it completely.

Step 3-2:

Set the select lever of the transmission to the N position. (Stepping on the brake pedal is effective at

this time.)

3-3 When the 4L indicator flashes at a frequency of 4Hz

Shifting from 4H to 4L is restricted.

W hen the vehicle is running, the transmission lever is at the running range and the engine speed is high (L4:

3000rpm or more V6: 2000rpm), the transfer cannot be shifted from 4H to 4L (restriction on operation).

Restriction on operation (Except 4JA1-T)

The 4H, neutral and 4L shifting mechanism has no synchronization function. Therefore, if relative rotations in the

mechanism become excessive, shifting exerts adverse influence on the internal mechanism of the transfer. To

avoid such a trouble, vehicle condition is detected to restrict the operation (vehicle speed, engine speed and TM

position).

Requirement to restrict the speed: Vehicle should be in stop. Due to the detection logic, time to wait for start of operation may be required.

A/T: If the vehicle is in stop for a long time at the TM running range (D, 1, 2) before operating the AT, waiting

time becomes longer (from 1 second to 3 minutes at the maximum).

M/T: If the vehicle is at stop with the clutch stepped on at the T/M running position (1 – R), the time to wait

becomes longer.

W aiting time means the time commencing from when other requirements (engine speed and T/M position) are

met to permission of the speed restriction. Operation during the waiting time is not permissible.

The waiting time is 1 second at the minimum and increases up to 5 seconds if the above condition continues for

3 minutes. After that, the waiting time increases up to 3 minutes in 2 minute intervals.

W hen it is clear that the above condition has continued and reduction of waiting time is required, turn on or off

the ignition or start and stop the vehicle several meters.

Requirements for permission of restriction on engine speed: Engine speed should be decreased.

The engine speed of 3000rpm (V6: 2000rpm) or below is advisable.

Requirements for permission of restriction on T/M position restriction:

(AT) N range is recommended

(MT) should be at the neutral.

These requirements for permission should all be met before the switch is operated. If the requirements are met

after operation, operation is not automatically effected but re-operation is required after permission is given.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4950 of 6020

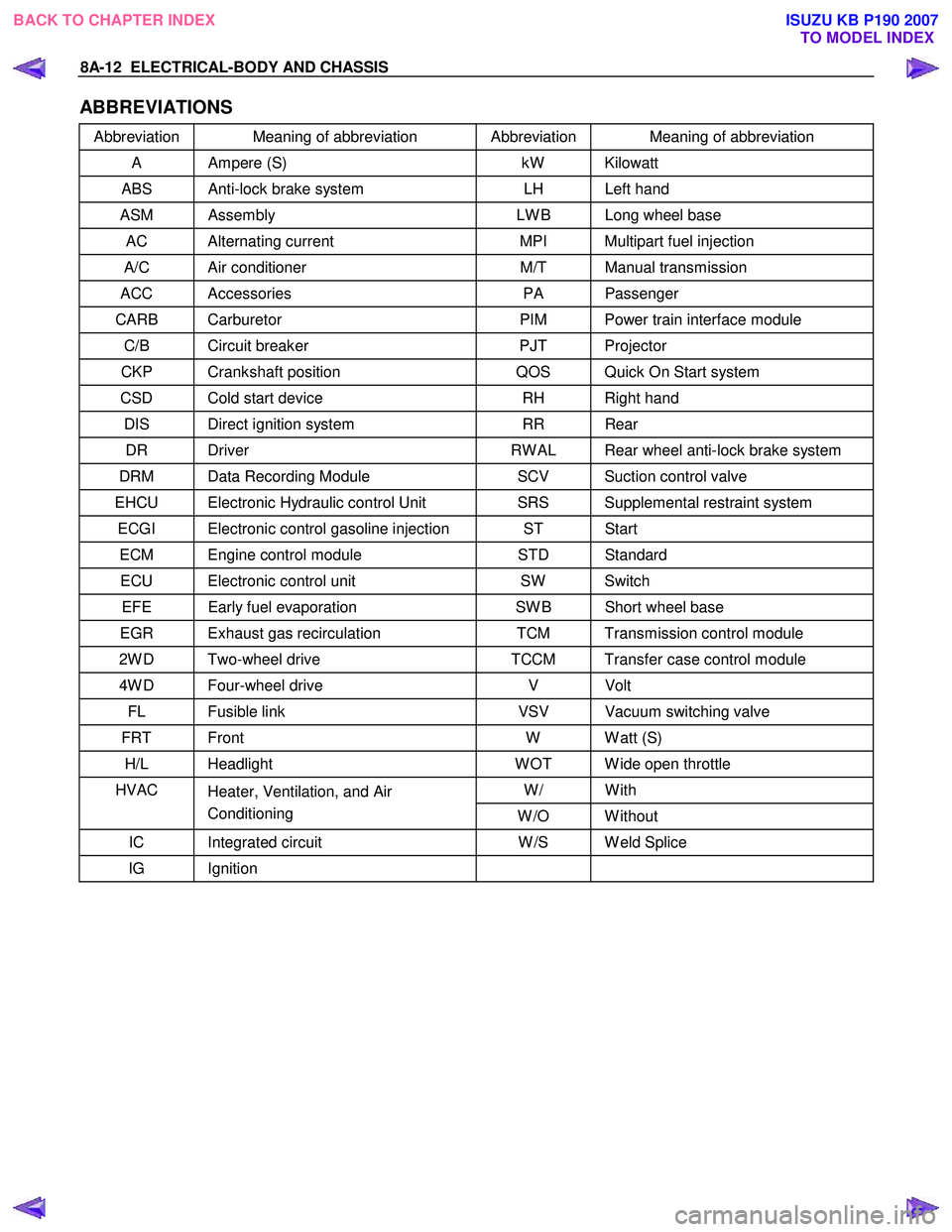

8A-12 ELECTRICAL-BODY AND CHASSIS

ABBREVIATIONS

Abbreviation Meaning of abbreviation Abbreviation Meaning of abbreviation

A Ampere (S) kW Kilowatt

ABS Anti-lock brake system LH Left hand

ASM Assembly LW B Long wheel base

AC Alternating current MPI Multipart fuel injection

A/C Air conditioner M/T Manual transmission

ACC Accessories PA Passenger

CARB Carburetor PIM Power train interface module

C/B Circuit breaker PJT Projector

CKP Crankshaft position QOS Quick On Start system

CSD Cold start device RH Right hand

DIS Direct ignition system RR Rear

DR Driver RW AL Rear wheel anti-lock brake system

DRM Data Recording Module SCV Suction control valve

EHCU Electronic Hydraulic control Unit SRS Supplemental restraint system

ECGI Electronic control gasoline injection ST Start

ECM Engine control module STD Standard

ECU Electronic control unit SW Switch

EFE Early fuel evaporation SW B Short wheel base

EGR Exhaust gas recirculation TCM Transmission control module

2W D Two-wheel drive TCCM Transfer case control module

4W D Four-wheel drive V Volt

FL Fusible link VSV Vacuum switching valve

FRT Front W W att (S)

H/L Headlight W OT W ide open throttle

W/ With HVAC

Heater, Ventilation, and Air

Conditioning W /O W ithout

IC Integrated circuit W /S W eld Splice

IG Ignition

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4959 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-21

Caution:

Do not attach the booster cable to the discharged battery

negative terminal.

11. Start the engine of the vehicle with the booster battery.

Check that all unnecessary electrical accessories are off.

12. Start the engine of the vehicle with the discharged battery.

13. Remove the jumper cables in the reverse order to which they were attached.

Caution:

Be absolutely sure to remove the negative jumper cable

from the vehicle with the discharged battery first.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 4963 of 6020

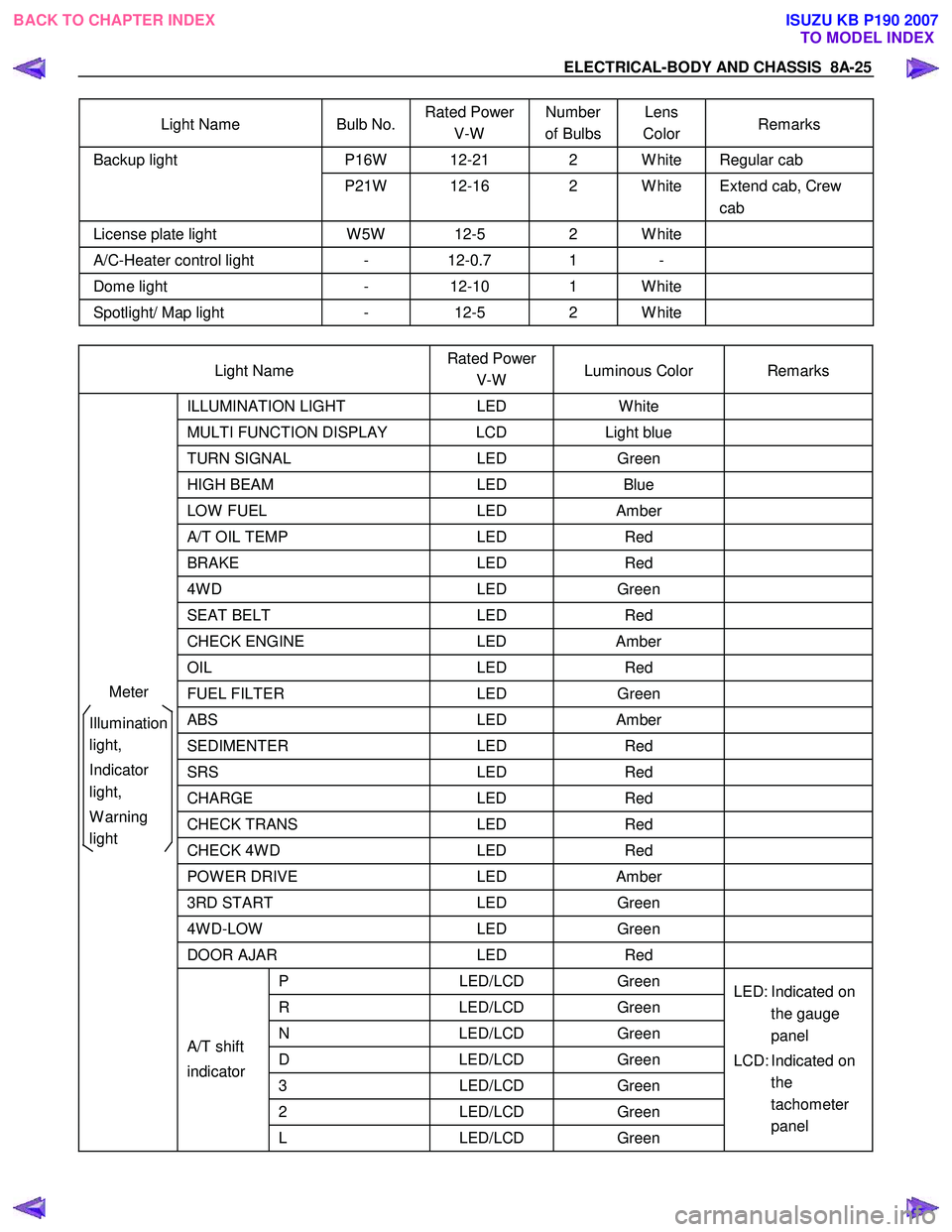

ELECTRICAL-BODY AND CHASSIS 8A-25

Light Name Bulb No. Rated Power

V-W Number

of Bulbs Lens

Color Remarks

P16W 12-21 2 W hite Regular cab Backup light

P21W 12-16 2 W hite Extend cab, Crew cab

License plate light W 5W 12-5 2 W hite

A/C-Heater control light - 12-0.7 1 -

Dome light - 12-10 1 W hite

Spotlight/ Map light - 12-5 2 W hite

Light Name Rated Power

V-W Luminous Color Remarks

ILLUMINATION

LIGHT LED W hite

MULTI FUNCTION DISPLAY LCD Light blue

TURN SIGNAL LED Green

HIGH BEAM LED Blue

LOW FUEL LED Amber

A/T OIL TEMP LED Red

BRAKE LED Red

4W D LED Green

SEAT BELT LED Red

CHECK ENGINE LED Amber

OIL LED Red

FUEL FILTER LED Green

ABS LED Amber

SEDIMENTER LED Red

SRS LED Red

CHARGE LED Red

CHECK TRANS LED Red

CHECK 4W D LED Red

POW ER DRIVE LED Amber

3RD START LED Green

4W D-LOW LED Green

DOOR AJAR LED Red

P LED/LCD Green

R LED/LCD Green

N LED/LCD Green

D LED/LCD Green

3 LED/LCD Green

2 LED/LCD Green

A/T shift

indicator

L LED/LCD Green LED: Indicated on

the gauge

panel

LCD: Indicated on the

tachometer

panel

Meter

Illumination

light,

Indicator

light,

W arning

light

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 4969 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-31

FUSE AND SLOW BLOW FUSE LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

RHD

FUSE ∗1 AUSTRALIA

ENGINE MODEL

FUSE NO. C24SE

HFV6 4JA1T (L) 4JJ1-TC/ 4JK1-TC

EB1 15A ECM

← 10A ACG (S)

←

EB2

15A 02 SENS PRE

10A ECM (B)

EB3 15A FRT FOG 10A ECM (B)

10A F/PUMP

20A TRAILER ∗1

EB4 10A ACG (S)

10A TCM PIM B

10A ENGINE

EB5 10A ILLUMI

10A H/L (RH) HI

← ←

10A H/L (RH) HI ∗1

EB6 10A H/L (LH) HI

← ← ←

EB7 10A H/L (RH) LOW

← ← ←

EB8 10A H/L (LH) LOW

← ← ←

EB9 20A F/PUMP 20A TRAILER

20A TRAIKER

EB10 10A SENSOR 20A COND, FAN

EB11 10A TAIL (RH)

← ← ←

EB12 10A ILLUMI & TAIL-LH

← ← ←

EB13 10A A/C

← ← ←

EB14 10A 4W D

← ← ←

EB15 10A HORN

← ← ←

EB16 10A HAZARD

← ← ←

SLOW BLOW FUSE

ENGINE MODEL

FUSE NO. C24SE

HFV6 4JA1T (L) 4JJ1-TC / 4JK1-TC

SBF1 100A MAIN ←

80A MAIN 120A MAIN

SBF2

20A FRT FOG

40A ABS1 ←

SBF3

60A RAD. FAN

20A ABS2 ←

SBF4 20A COND, FAN 20A F/PUMP

20A COND, FAN 40A ECM

SBF5 40A IG 1

←

← ←

SBF6

30A BLOW ER ←

←

SBF7 20A FRT FOG

40A ABS1 20A FRT FOG ←

SBF8 30A BLOW ER

20A ABS2 50A GLOW 60A GLOW

SBF9

50A IG 2

60A IG 2 50A IG 2 60A IG 2

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007