engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3045 of 6020

Engine Mechanical – V6 Page 6A1–268

Page 6A1–268

NOTE

The cap and rod are a matched set and must be

kept together.

16 Reattach the connecting rod cap (1) to the connecting rod (2) to prevent damage to their mating surfaces.

17 Repeat steps 4 to 16 for the remaining piston and connecting rod assemblies.

Figure 6A1 – 470

Disassemble

CAUTION

A piston ring expander must be used to

remove and install the piston rings. Only

expand the rings far enough to fit over the

piston lands. If the rings are overexpanded,

the top ring will shatter and the others will

distort.

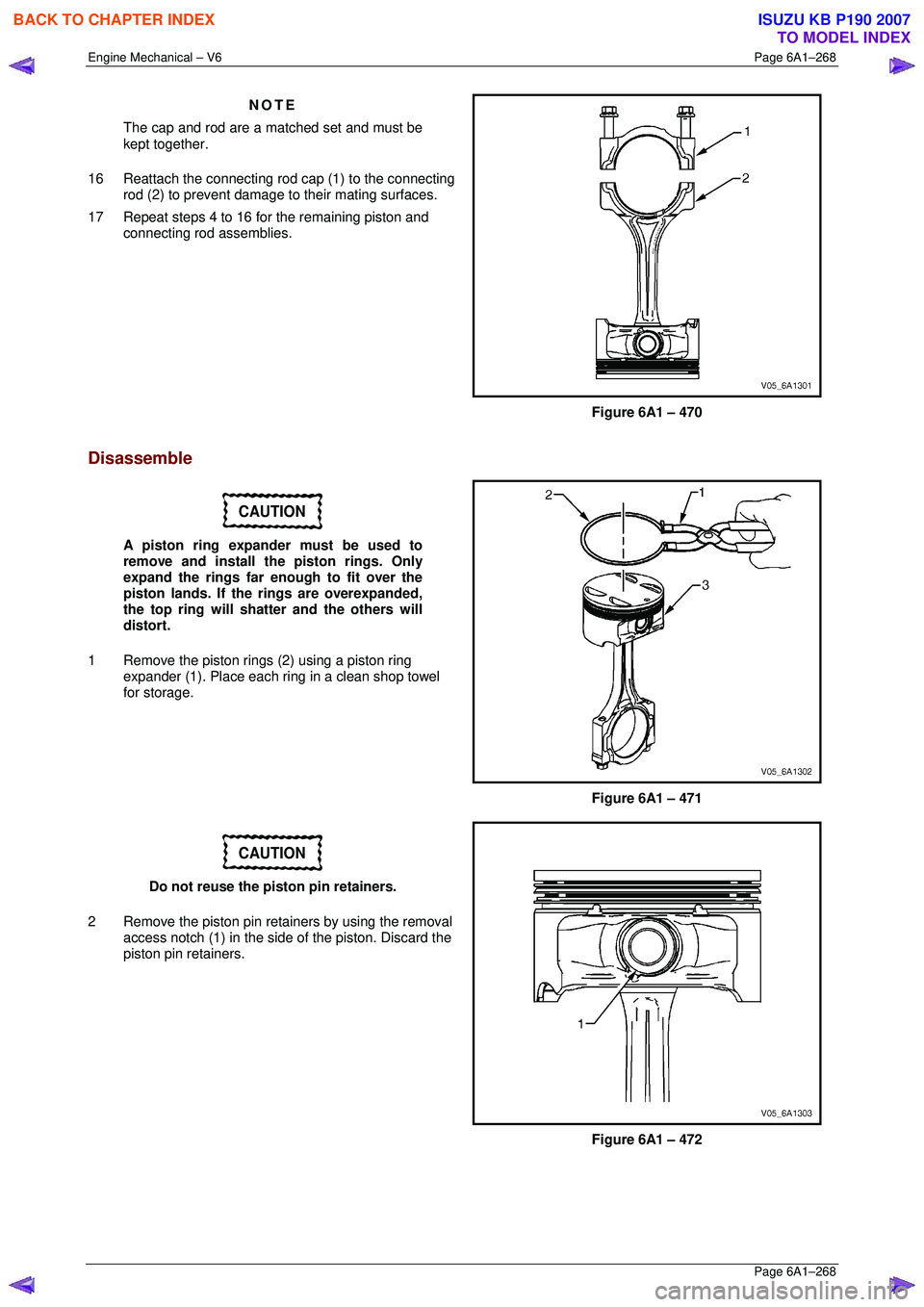

1 Remove the piston rings (2) using a piston ring expander (1). Place each ring in a clean shop towel

for storage.

Figure 6A1 – 471

CAUTION

Do not reuse the piston pin retainers.

2 Remove the piston pin retainers by using the removal access notch (1) in the side of the piston. Discard the

piston pin retainers.

Figure 6A1 – 472

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3046 of 6020

Engine Mechanical – V6 Page 6A1–269

Page 6A1–269

3 Slide the piston pin (1) out of the piston (2). The

piston will disconnect from the connecting rod.

Figure 6A1 – 473

Clean and Inspect

Piston Cleaning Procedure

CAUTION

Do not use a wire brush to clean any part of

the piston.

1 Clean the piston skirts and the pi ns with a suitable solvent.

2 Clean the piston ring grooves with a groove cleaner . Ensure the oil ring holes and slots are clean.

Safety glasses must be worn when using

compressed air.

3 Dry the piston with compressed air.

Piston Inspection Procedure

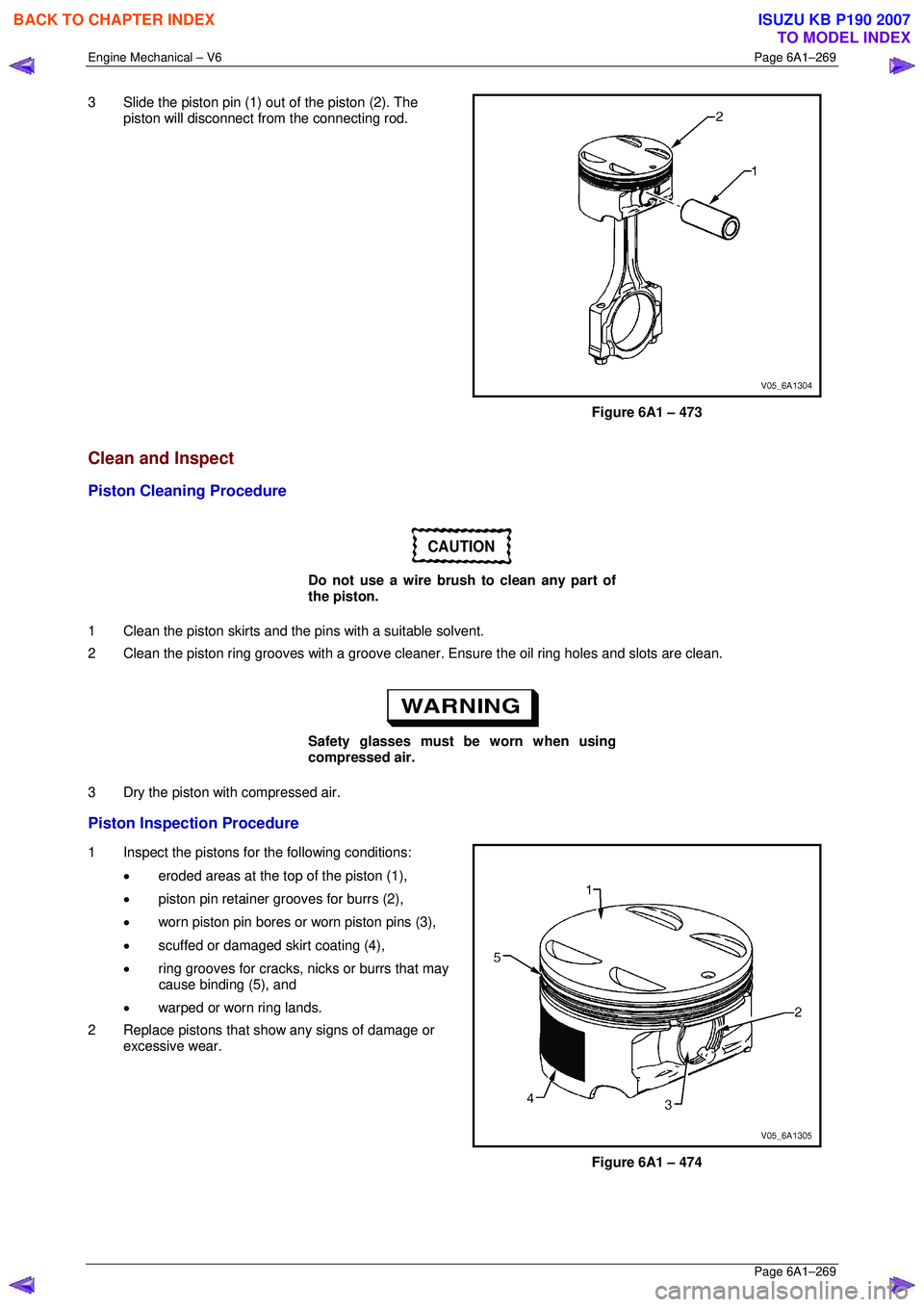

1 Inspect the pistons for the following conditions: • eroded areas at the top of the piston (1),

• piston pin retainer grooves for burrs (2),

• worn piston pin bores or worn piston pins (3),

• scuffed or damaged skirt coating (4),

• ring grooves for cracks, nicks or burrs that may

cause binding (5), and

• warped or worn ring lands.

2 Replace pistons that s how any signs of damage or

excessive wear.

Figure 6A1 – 474

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3047 of 6020

Engine Mechanical – V6 Page 6A1–270

Page 6A1–270

Piston Measurement

1 Measure piston width using the following procedure:

a Using an outside micr ometer, measure the

width of the piston at 30 mm below the crown

top (1), at the thrust surfaces of the piston,

perpendicular to the piston pin centreline.

b Compare the measurement of the piston to its

original cylinder by subtracting the piston width

from the cylinder diameter.

c Check your measurements with specifications, refer to 5 Specifications .

d If the clearance obtai ned through measurement

is greater than the prov ided specifications and

the cylinder bores are wi thin specification,

replace the piston.

Figure 6A1 – 475

2 Measure the piston pin bore to piston pin (2) clearances using the following procedure:

a Piston pin bores and pins must be free of varnish or scuffing.

b Use an outside micrometer (1) to measure the

piston pin in the piston contact areas.

Figure 6A1 – 476

3 Using an inside micrometer , measure the piston pin

bore (1). Compare the resu lt with the piston pin

diameter and piston pin to piston pin bore clearance

listed in the specifications, refer to 5 Specifications.

4 If the clearance is excessive, determine which piece is out of specification and replace as required.

5 Replace the piston if any of its dimensions are out of

specification.

6 If the new piston does not meet clearance specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 477

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3048 of 6020

Engine Mechanical – V6 Page 6A1–271

Page 6A1–271

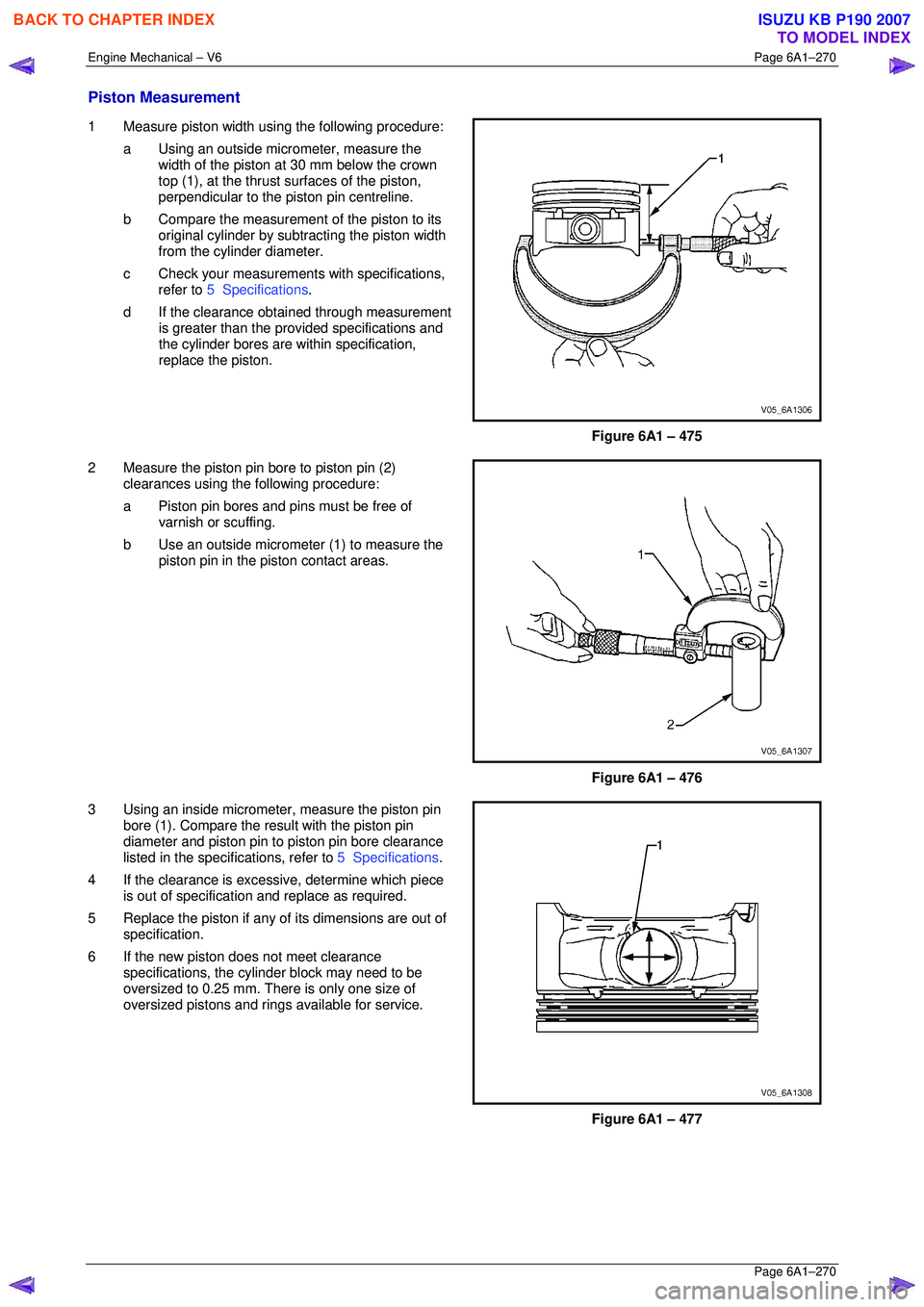

Piston Ring Measurement

1 Measure the piston ring end gap using the following

procedure:

a Place the piston ring (1) in the area of the bore where

the piston ring will travel, approximately 25 mm below

the deck surface. Ensure t he ring is square with the

cylinder bore by positioning the ring with the piston

head.

b Measure the end gap of the piston ring with feeler

gauges (2), refer to 5 Specifications.

c If the clearance exceeds t he provided specifications,

the piston rings must be replaced.

d Repeat the procedure for all piston rings.

Figure 6A1 – 478

2 Measure the piston ring side clearance using the

following procedure:

a Roll the piston ring (1) ent irely around the piston ring

groove. If any binding is c aused by the ring groove,

dress the groove with a fine file. If any binding is

caused by a distorted piston ring, replace the ring.

b With the piston ring on the piston, use feeler

gauges (2) to check clearance at multiple locations.

c Compare the measurement s with piston ring side

clearance listed in the spec ifications, refer to

5 Specifications .

d If the clearance is greater than specifications, replace

the piston rings.

Figure 6A1 – 479

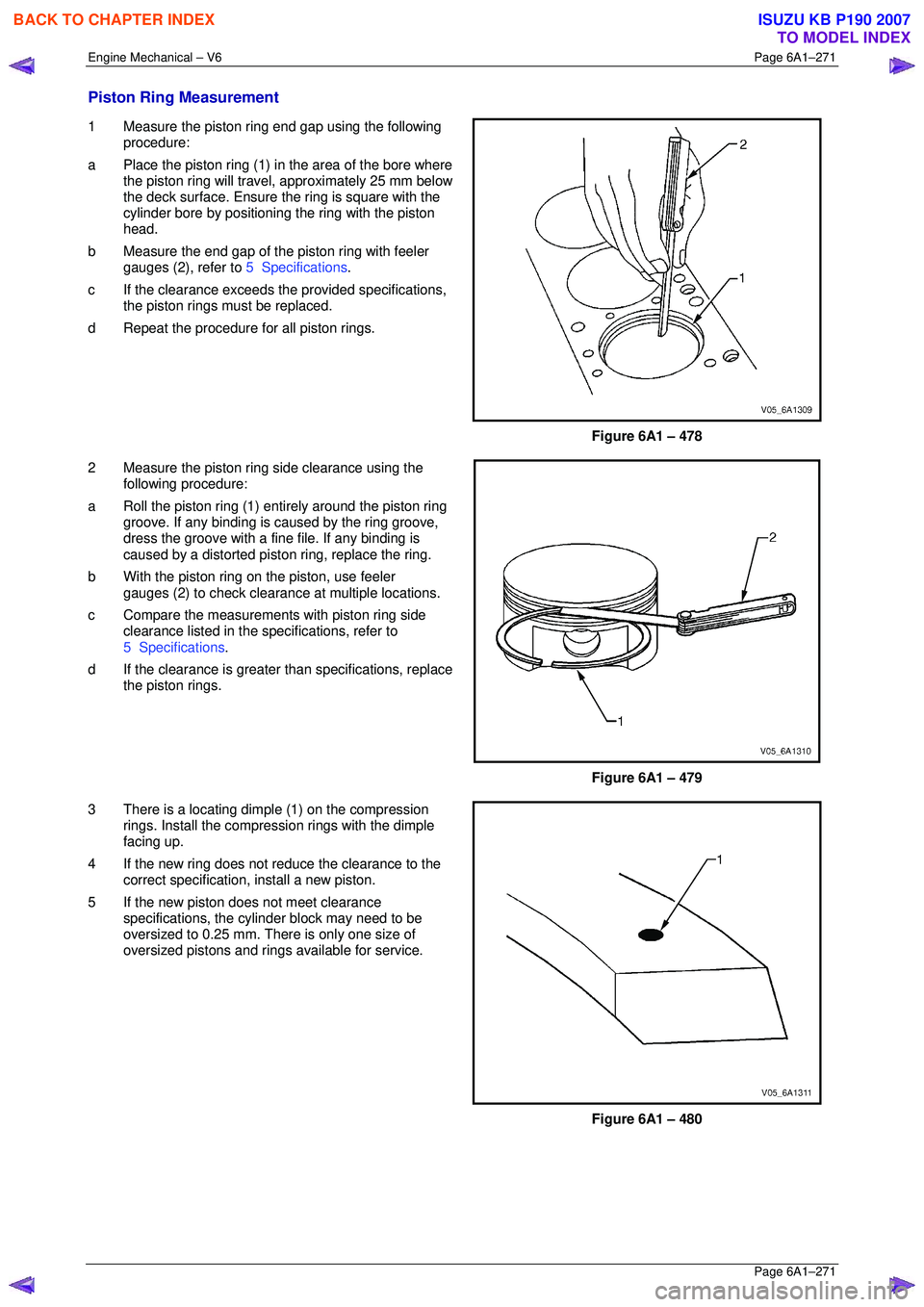

3 There is a locating dimple (1) on the compression rings. Install the compression rings with the dimple

facing up.

4 If the new ring does not r educe the clearance to the

correct specification, install a new piston.

5 If the new piston does not meet clearance specifications, the cylinder block may need to be

oversized to 0.25 mm. There is only one size of

oversized pistons and rings available for service.

Figure 6A1 – 480

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3049 of 6020

Engine Mechanical – V6 Page 6A1–272

Page 6A1–272

Connecting Rod Cleaning Procedure

1 Clean the connecting rods in solvent.

Safety glasses must be worn when using

compressed air.

2 Dry the connecting rod using compressed air.

3 Remove the connecting rod cap and clean the threads.

4 Remove the connecting rod bearing and discard. Never reuse a connecting rod bearing that has been used in a

running engine.

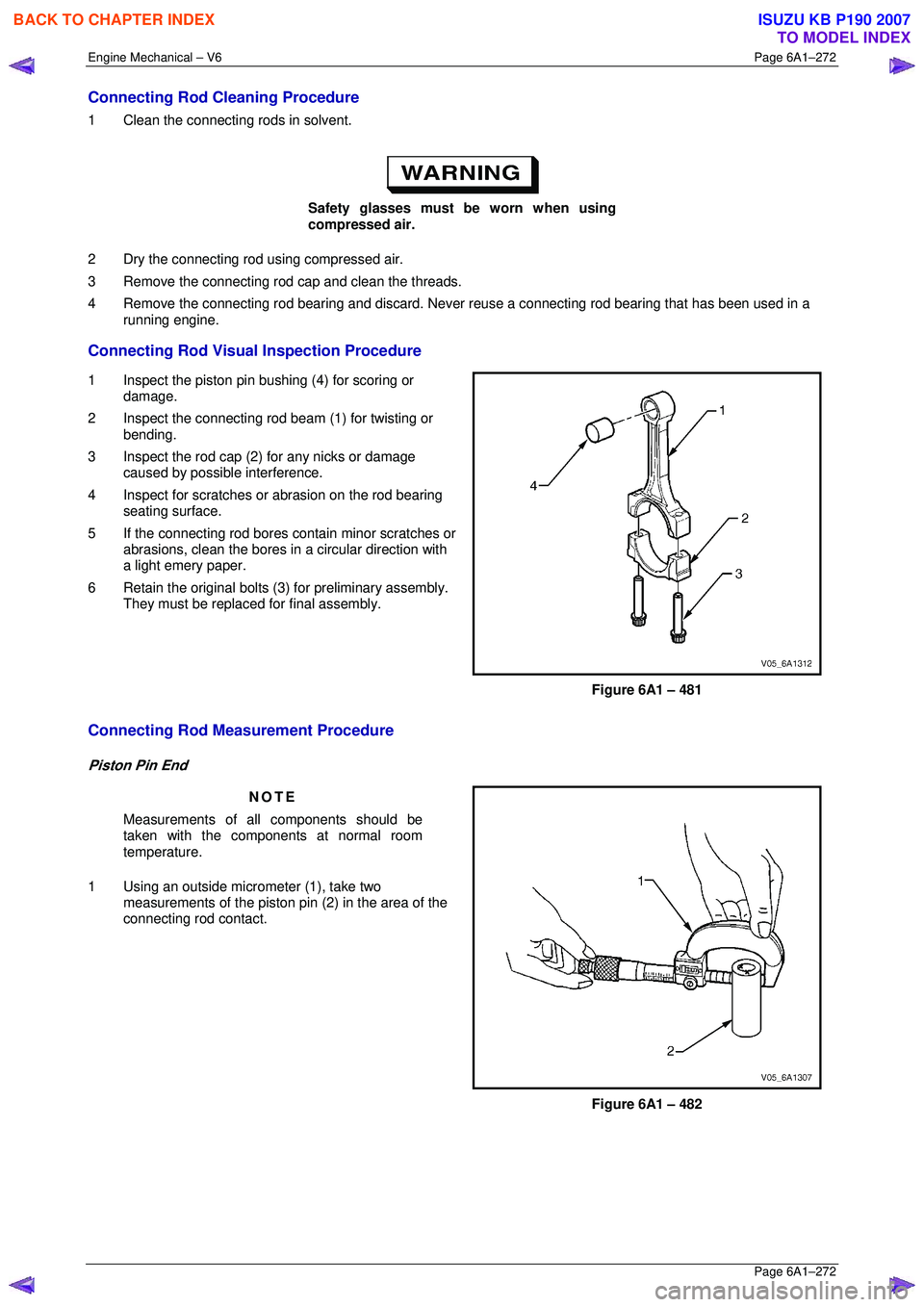

Connecting Rod Visual Inspection Procedure

1 Inspect the piston pin bushing (4) for scoring or damage.

2 Inspect the connecting rod beam (1) for twisting or bending.

3 Inspect the rod cap (2) for any nicks or damage caused by possible interference.

4 Inspect for scratches or abrasion on the rod bearing

seating surface.

5 If the connecting rod bores c ontain minor scratches or

abrasions, clean the bores in a circular direction with

a light emery paper.

6 Retain the original bolts (3) for preliminary assembly. They must be replaced for final assembly.

Figure 6A1 – 481

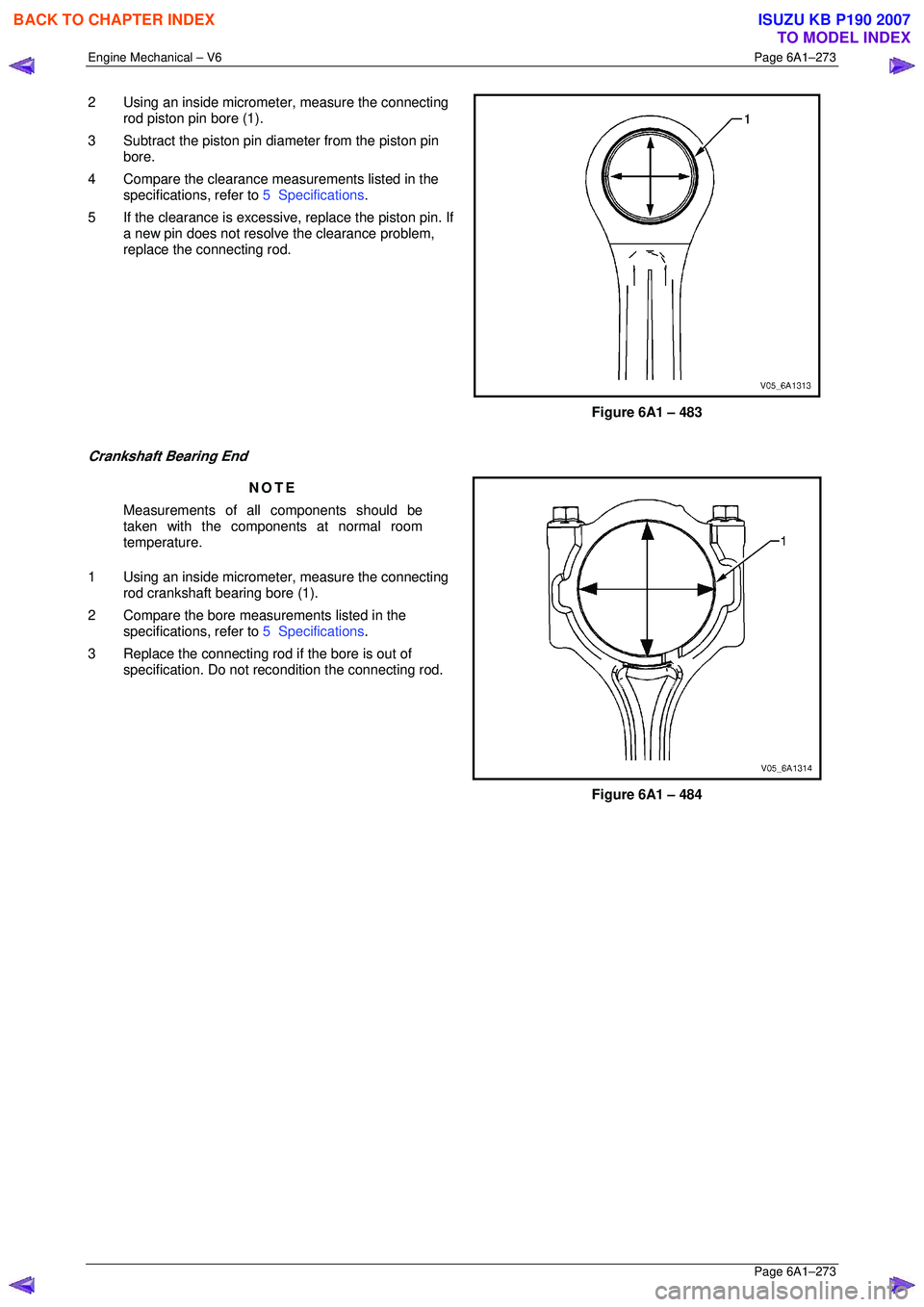

Connecting Rod Measurement Procedure

Piston Pin End

NOTE

Measurements of a ll components should be

taken with the components at normal room

temperature.

1 Using an outside micrometer (1), take two measurements of the piston pi n (2) in the area of the

connecting rod contact.

Figure 6A1 – 482

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3050 of 6020

Engine Mechanical – V6 Page 6A1–273

Page 6A1–273

2 Using an inside micrometer, measure the connecting

rod piston pin bore (1).

3 Subtract the piston pin di ameter from the piston pin

bore.

4 Compare the clearance m easurements listed in the

specifications, refer to 5 Specifications.

5 If the clearance is excessive, replace the piston pin. If a new pin does not resolve the clearance problem,

replace the connecting rod.

Figure 6A1 – 483

Crankshaft Bearing End

NOTE

Measurements of a ll components should be

taken with the components at normal room

temperature.

1 Using an inside micromet er, measure the connecting

rod crankshaft bearing bore (1).

2 Compare the bore meas urements listed in the

specifications, refer to 5 Specifications.

3 Replace the connecting rod if the bore is out of

specification. Do not re condition the connecting rod.

Figure 6A1 – 484

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3051 of 6020

Engine Mechanical – V6 Page 6A1–274

Page 6A1–274

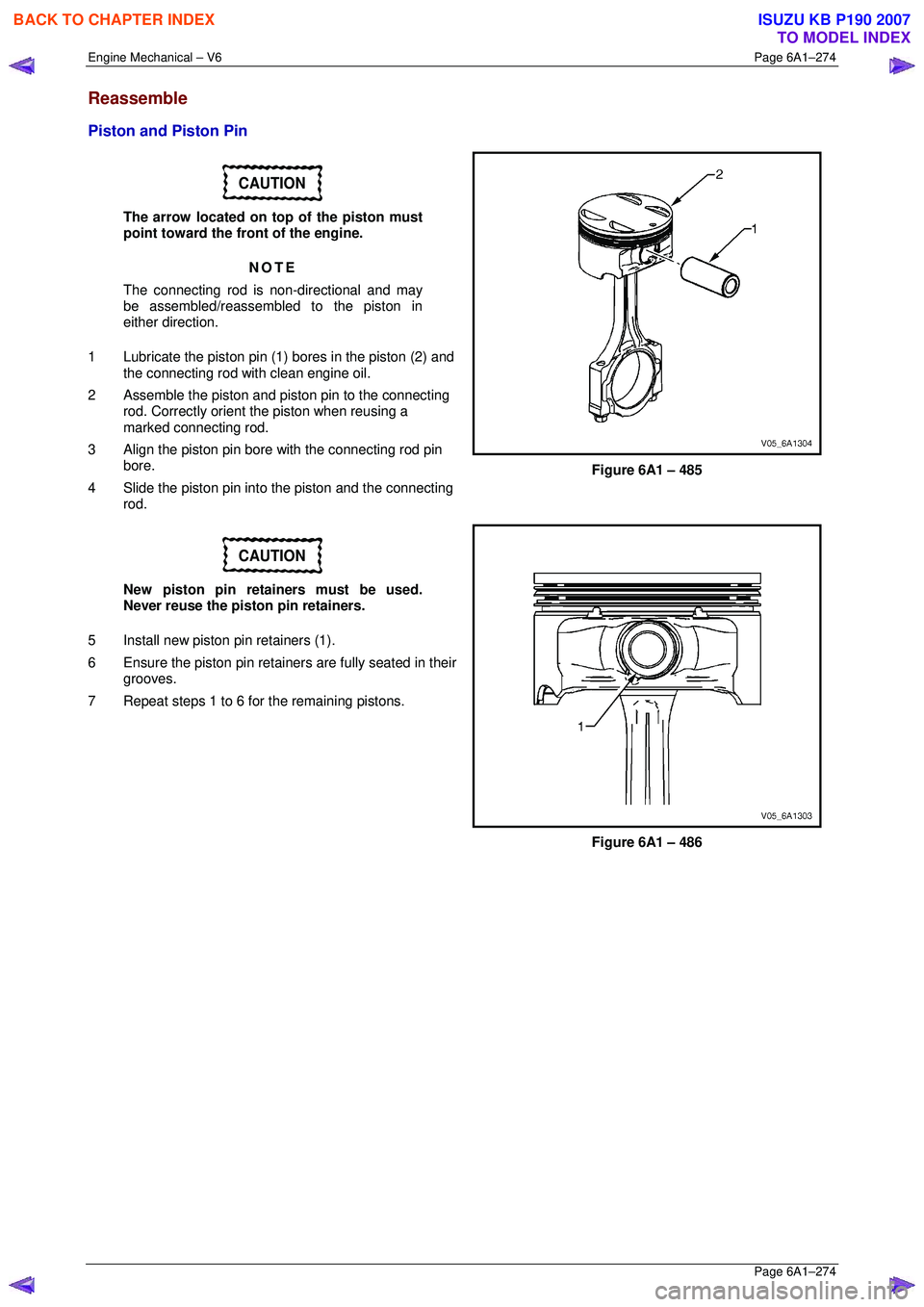

Reassemble

Piston and Piston Pin

CAUTION

The arrow located on top of the piston must

point toward the front of the engine.

NOTE

The connecting rod is non-directional and may

be assembled/reassembled to the piston in

either direction.

1 Lubricate the piston pin (1) bores in the piston (2) and

the connecting rod with clean engine oil.

2 Assemble the piston and piston pin to the connecting rod. Correctly orient the piston when reusing a

marked connecting rod.

3 Align the piston pin bore with the connecting rod pin

bore.

4 Slide the piston pin into the piston and the connecting

rod.

Figure 6A1 – 485

CAUTION

New piston pin retainers must be used.

Never reuse the piston pin retainers.

5 Install new piston pin retainers (1).

6 Ensure the piston pin retainers are fully seated in their grooves.

7 Repeat steps 1 to 6 for the remaining pistons.

Figure 6A1 – 486

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3052 of 6020

Engine Mechanical – V6 Page 6A1–275

Page 6A1–275

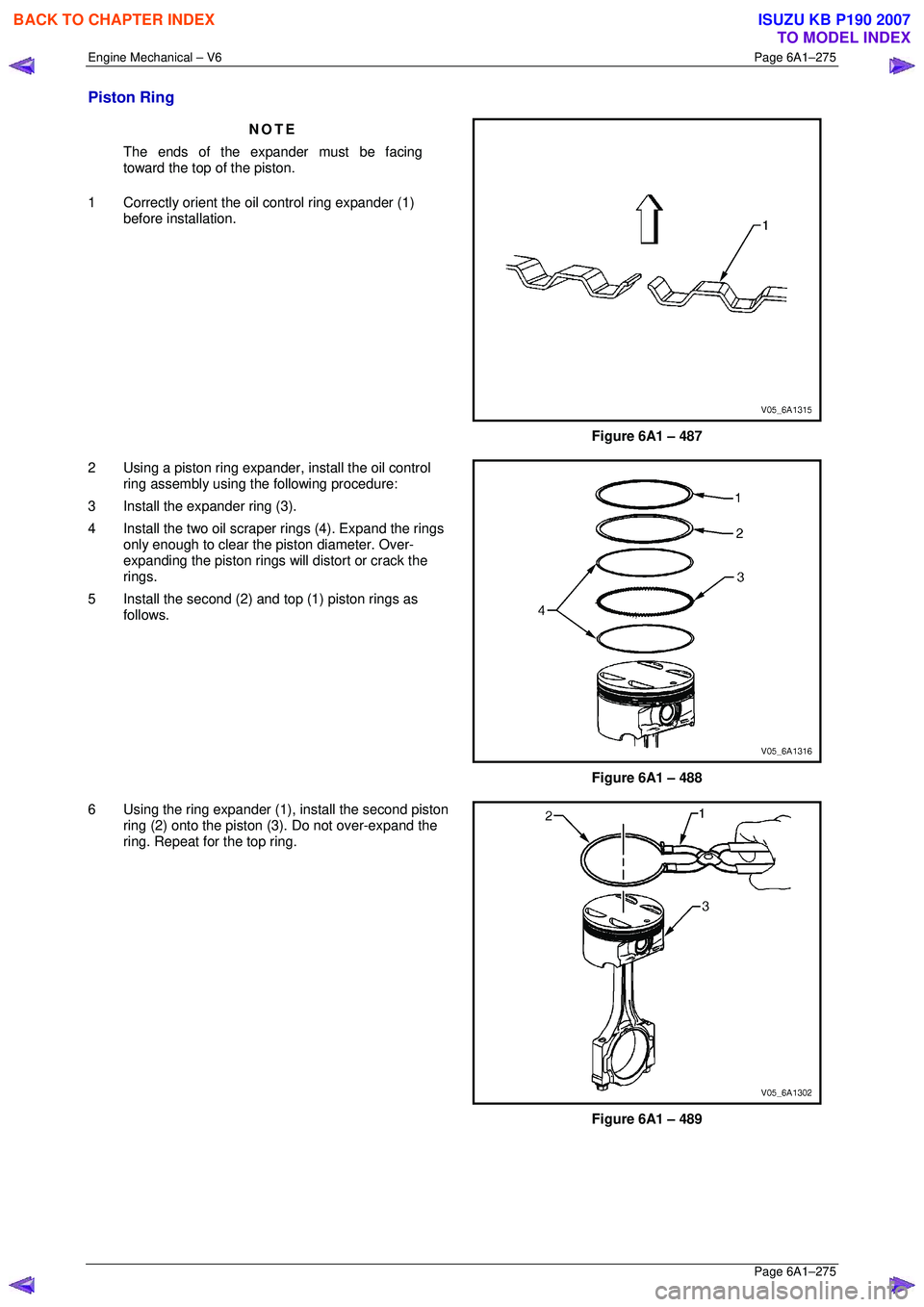

Piston Ring

NOTE

The ends of the expander must be facing

toward the top of the piston.

1 Correctly orient the oil control ring expander (1) before installation.

Figure 6A1 – 487

2 Using a piston ring expander, install the oil control

ring assembly using the following procedure:

3 Install the expander ring (3).

4 Install the two oil scraper rings (4). Expand the rings only enough to clear the piston diameter. Over-

expanding the piston rings w ill distort or crack the

rings.

5 Install the second (2) and top (1) piston rings as follows.

Figure 6A1 – 488

6 Using the ring expander (1), install the second piston

ring (2) onto the piston (3). Do not over-expand the

ring. Repeat for the top ring.

Figure 6A1 – 489

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3053 of 6020

Engine Mechanical – V6 Page 6A1–276

Page 6A1–276

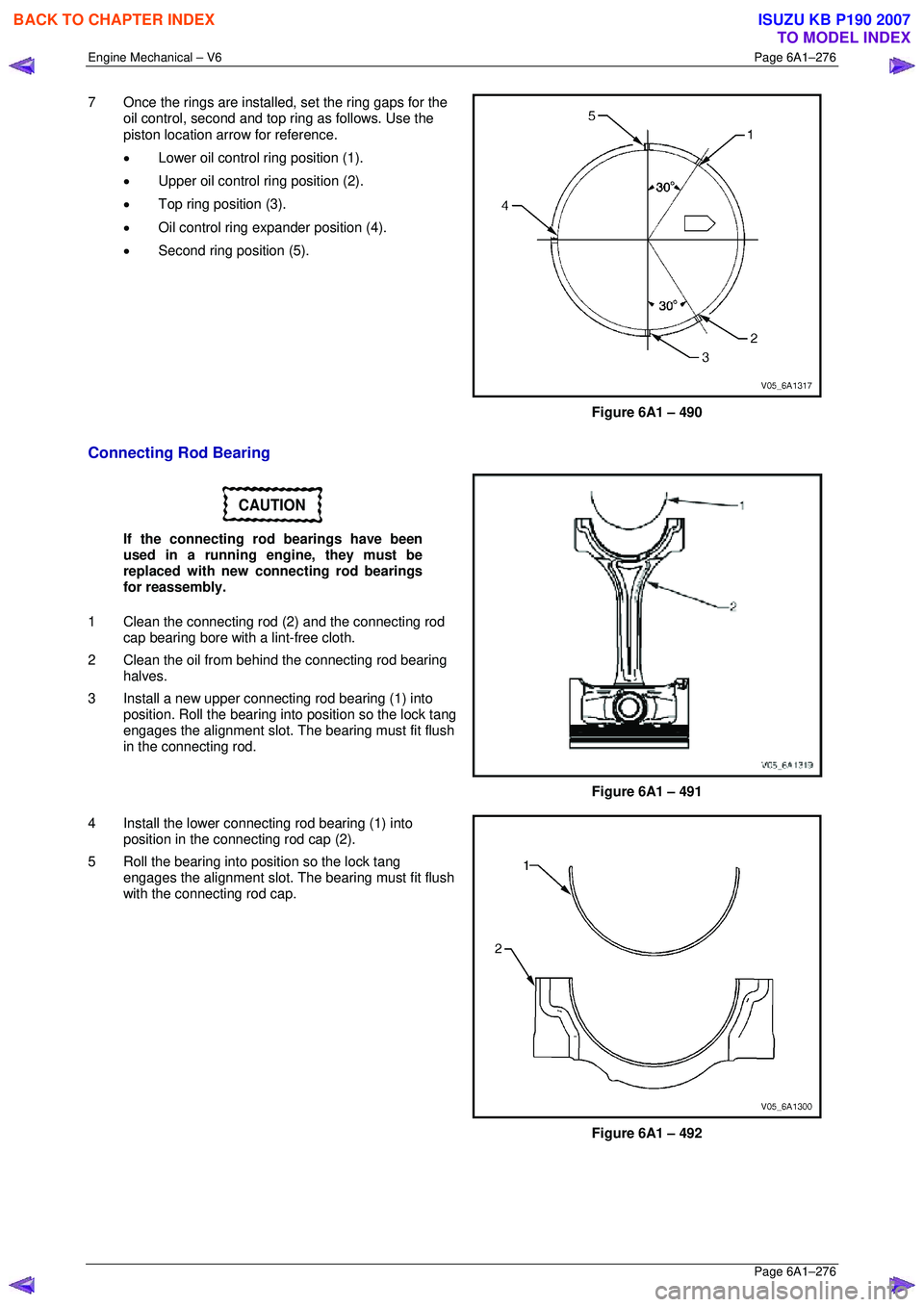

7 Once the rings are installed, set the ring gaps for the

oil control, second and top ring as follows. Use the

piston location arrow for reference.

• Lower oil control ring position (1).

• Upper oil control ring position (2).

• Top ring position (3).

• Oil control ring ex pander position (4).

• Second ring position (5).

Figure 6A1 – 490

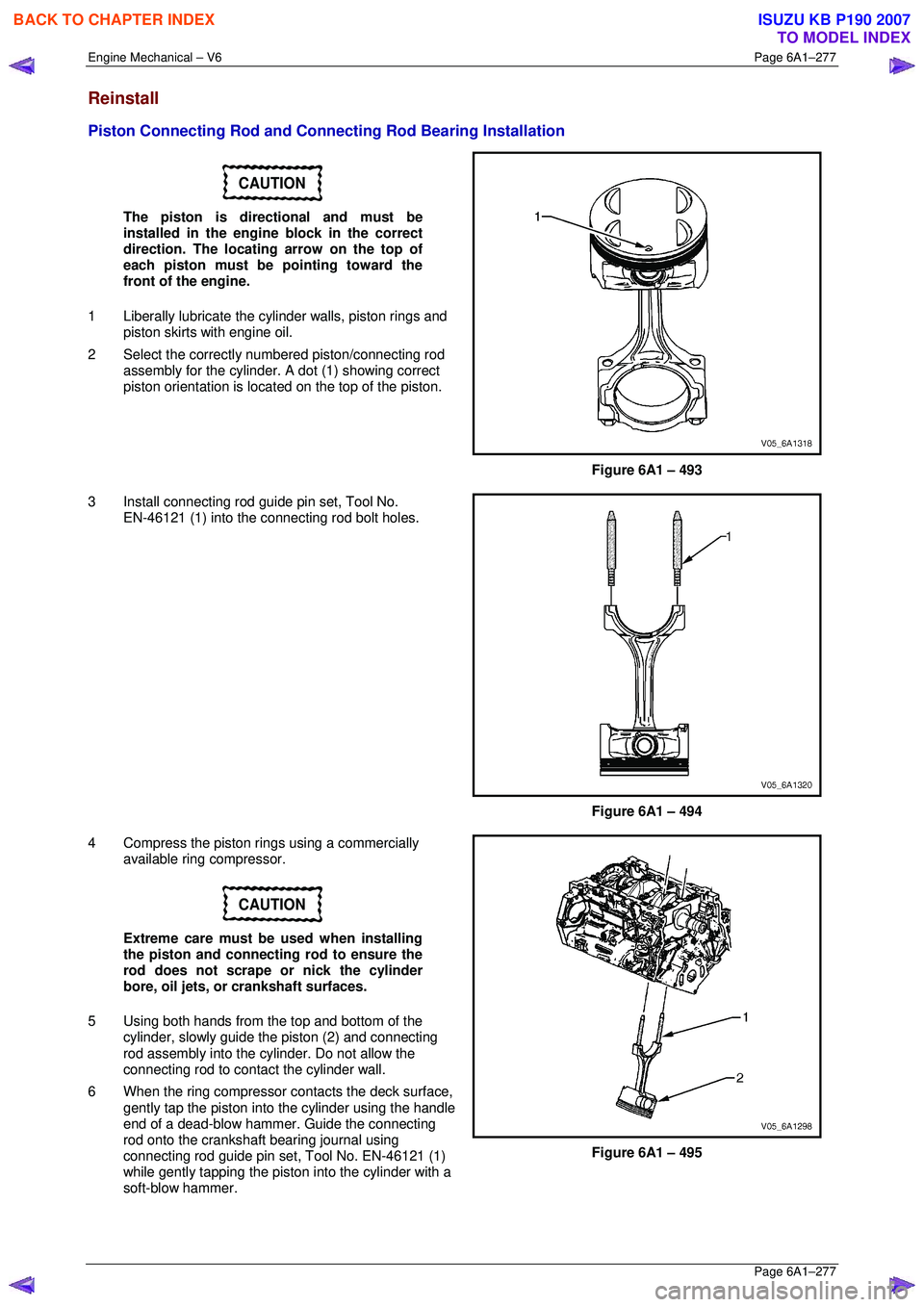

Connecting Rod Bearing

CAUTION

If the connecting rod bearings have been

used in a running engine, they must be

replaced with new connecting rod bearings

for reassembly.

1 Clean the connecting rod (2) and the connecting rod

cap bearing bore with a lint-free cloth.

2 Clean the oil from behind the connecting rod bearing halves.

3 Install a new upper connecting rod bearing (1) into position. Roll the bearing into position so the lock tang

engages the alignment slot. The bearing must fit flush

in the connecting rod.

Figure 6A1 – 491

4 Install the lower connecting rod bearing (1) into position in the connecting rod cap (2).

5 Roll the bearing into position so the lock tang engages the alignment slot. The bearing must fit flush

with the connecting rod cap.

Figure 6A1 – 492

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3054 of 6020

Engine Mechanical – V6 Page 6A1–277

Page 6A1–277

Reinstall

Piston Connecting Rod and Connecting Rod Bearing Installation

CAUTION

The piston is directional and must be

installed in the engine block in the correct

direction. The locating arrow on the top of

each piston must be pointing toward the

front of the engine.

1 Liberally lubricate the cy linder walls, piston rings and

piston skirts with engine oil.

2 Select the correctly numbered piston/connecting rod

assembly for the cylinder. A dot (1) showing correct

piston orientation is locat ed on the top of the piston.

Figure 6A1 – 493

3 Install connecting rod guide pin set, Tool No. EN-46121 (1) into the connecting rod bolt holes.

Figure 6A1 – 494

4 Compress the piston rings using a commercially available ring compressor.

CAUTION

Extreme care must be used when installing

the piston and connecting rod to ensure the

rod does not scrape or nick the cylinder

bore, oil jets, or crankshaft surfaces.

5 Using both hands from the top and bottom of the cylinder, slowly guide the piston (2) and connecting

rod assembly into the cylinder. Do not allow the

connecting rod to contact the cylinder wall.

6 When the ring compressor c ontacts the deck surface,

gently tap the piston into the cylinder using the handle

end of a dead-blow hammer. Guide the connecting

rod onto the crankshaft bearing journal using

connecting rod guide pin set, Tool No. EN-46121 (1)

while gently tapping the piston into the cylinder with a

soft-blow hammer.

Figure 6A1 – 495

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007