engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3075 of 6020

Engine Mechanical – V6 Page 6A1–298

Page 6A1–298

Measuring Cylinder Bore Taper

1 Measure the cylinder bore along the thrust surfaces, perpendicular to the crankshaft centreline, at 10 mm below the

deck surface and record the measurement.

2 Measure the cylinder bore along the th rust surfaces, perpendicular to the crankshaft centreline, at 100 mm below

the deck surface and record the measurement.

3 Calculate the difference betw een the two measurements. The re sult will be the cylinder taper.

4 Compare the results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

Measuring Cylinder Bore Out-of-Round

1 Measure both the thrust and non-thrust cylinder diameter at 10 mm below the deck. Record your measurements.

2 Calculate the difference bet ween the two measurements. The result will indicate out-of-r ound at the upper end of

the cylinder.

3 Measure both the thrust and non-thru st cylinder diameter at 100 mm below the deck surface. Record your

measurements.

4 Calculate the difference between the tw o measurements. The result will indicate out-of-round at the lower end of

the cylinder.

5 Compare your results with the dimensions listed in the specifications, refer to 5 Specifications.

NOTE

If the cylinder diameter exceeds the

specifications, the cylinder block may be

oversized to 0.25 mm. Only one size of oversized

pistons and rings are available for service. If the

cylinder bore diameter ex ceeds specification by

more than 0.25 mm, the cylinder block must be

replaced.

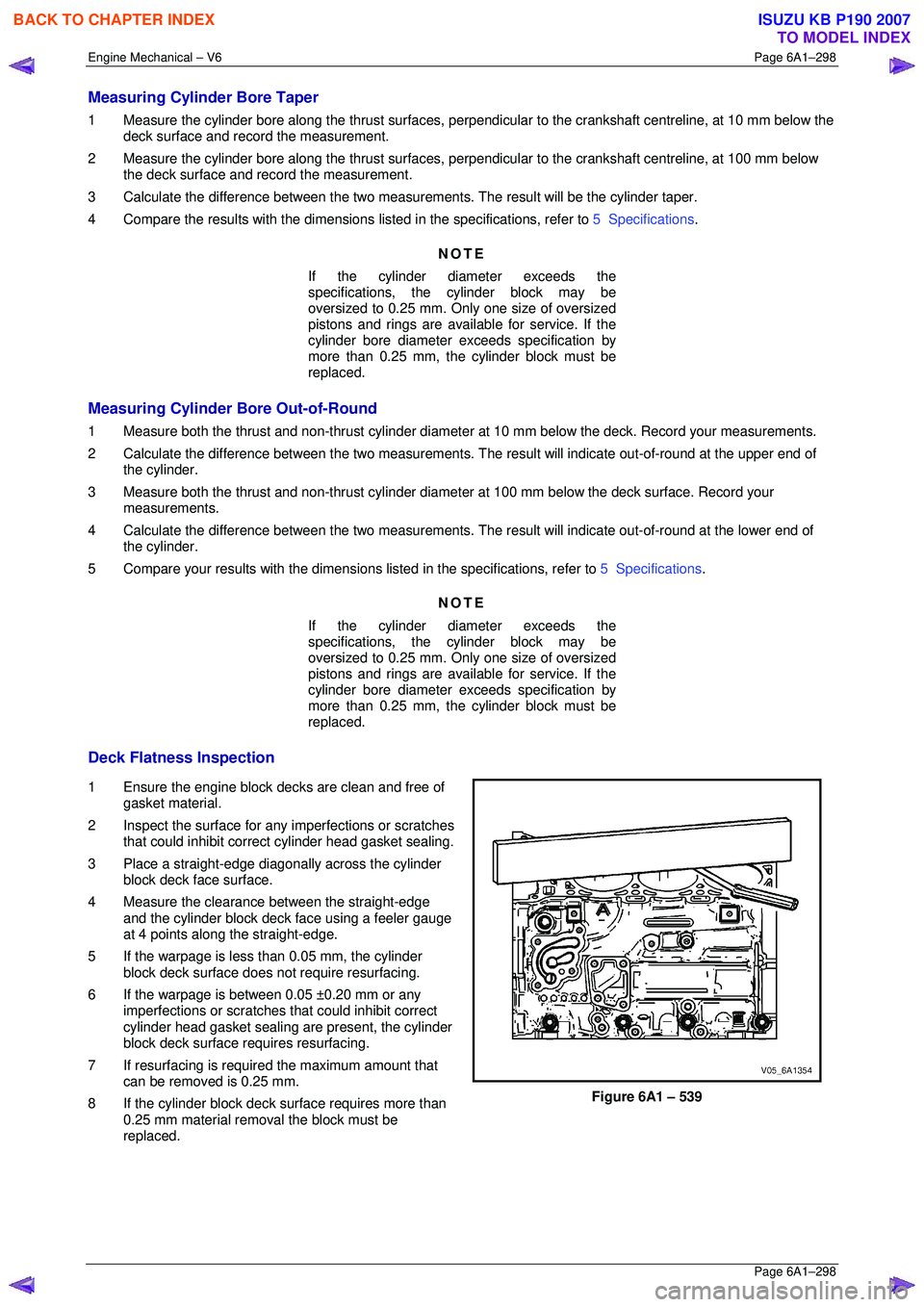

Deck Flatness Inspection

1 Ensure the engine block decks are clean and free of gasket material.

2 Inspect the surface for any imperfections or scratches

that could inhibit correct cylinder head gasket sealing.

3 Place a straight-edge diagonally across the cylinder block deck face surface.

4 Measure the clearance between the straight-edge

and the cylinder block deck face using a feeler gauge

at 4 points along the straight-edge.

5 If the warpage is less t han 0.05 mm, the cylinder

block deck surface does not require resurfacing.

6 If the warpage is between 0.05 ±0.20 mm or any imperfections or scratches that could inhibit correct

cylinder head gasket sealing are present, the cylinder

block deck surface requires resurfacing.

7 If resurfacing is requir ed the maximum amount that

can be removed is 0.25 mm.

8 If the cylinder block deck surface requires more than 0.25 mm material removal the block must be

replaced.

Figure 6A1 – 539

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3076 of 6020

Engine Mechanical – V6 Page 6A1–299

Page 6A1–299

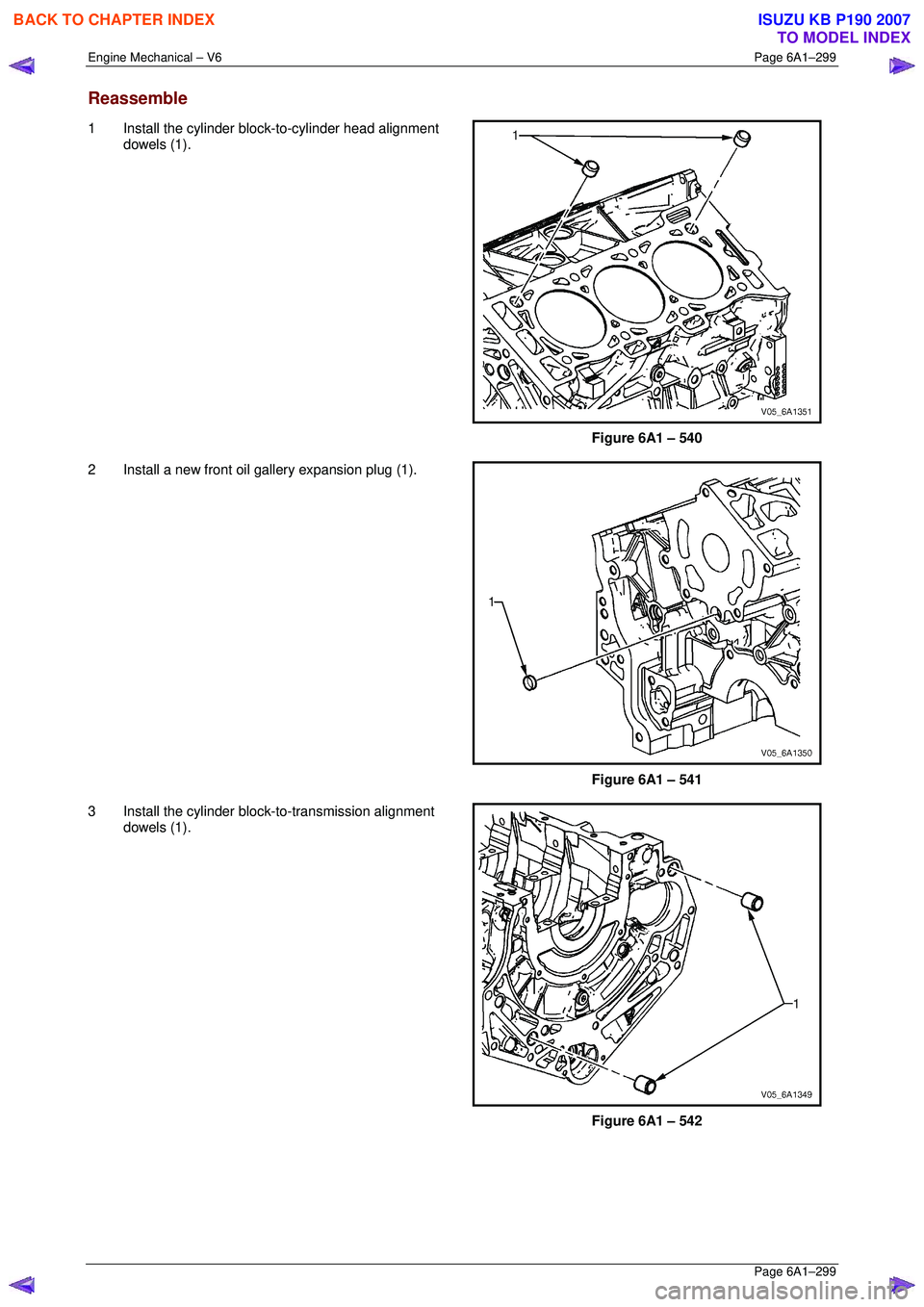

Reassemble

1 Install the cylinder block-to-cylinder head alignment

dowels (1).

Figure 6A1 – 540

2 Install a new front oil gallery expansion plug (1).

Figure 6A1 – 541

3 Install the cylinder blo ck-to-transmission alignment

dowels (1).

Figure 6A1 – 542

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3077 of 6020

Engine Mechanical – V6 Page 6A1–300

Page 6A1–300

4 Place RTV sealant on new coolant expansion plugs

(1) and install the new coolant expansion plugs.

Figure 6A1 – 543

5 Install the left-hand side M20 oil gallery threaded plug (1) and tighten to the correct torque specification.

Left-hand side M20 cylinder block

oil gallery threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 544

6 Install the left-hand side M14 coolant drain threaded

plug (1) and tighten to the co rrect torque specification.

Left-hand side M14 cylinder block

coolant drain threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 545

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3078 of 6020

Engine Mechanical – V6 Page 6A1–301

Page 6A1–301

7 Install the M14 rear oil gallery threaded plug (1) and

tighten to the correct torque specification.

M14 cylinder block rear oil gallery

threaded plug torque specif ication .......... 27.0 – 35.0 Nm

Figure 6A1 – 546

8 Install the right-hand side M14 coolant drain threaded

plug (1) and tighten to the co rrect torque specification.

Right-hand side M14 cylinder block

coolant drain threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 547

9 Install the right-hand side M14 oil gallery threaded plug (1) and tighten to the co rrect torque specification.

Right-hand side M14 cylinder block

oil gallery threaded plug

torque specificatio n ................................. 27. 0 – 35.0 Nm

Figure 6A1 – 548

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3079 of 6020

Engine Mechanical – V6 Page 6A1–302

Page 6A1–302

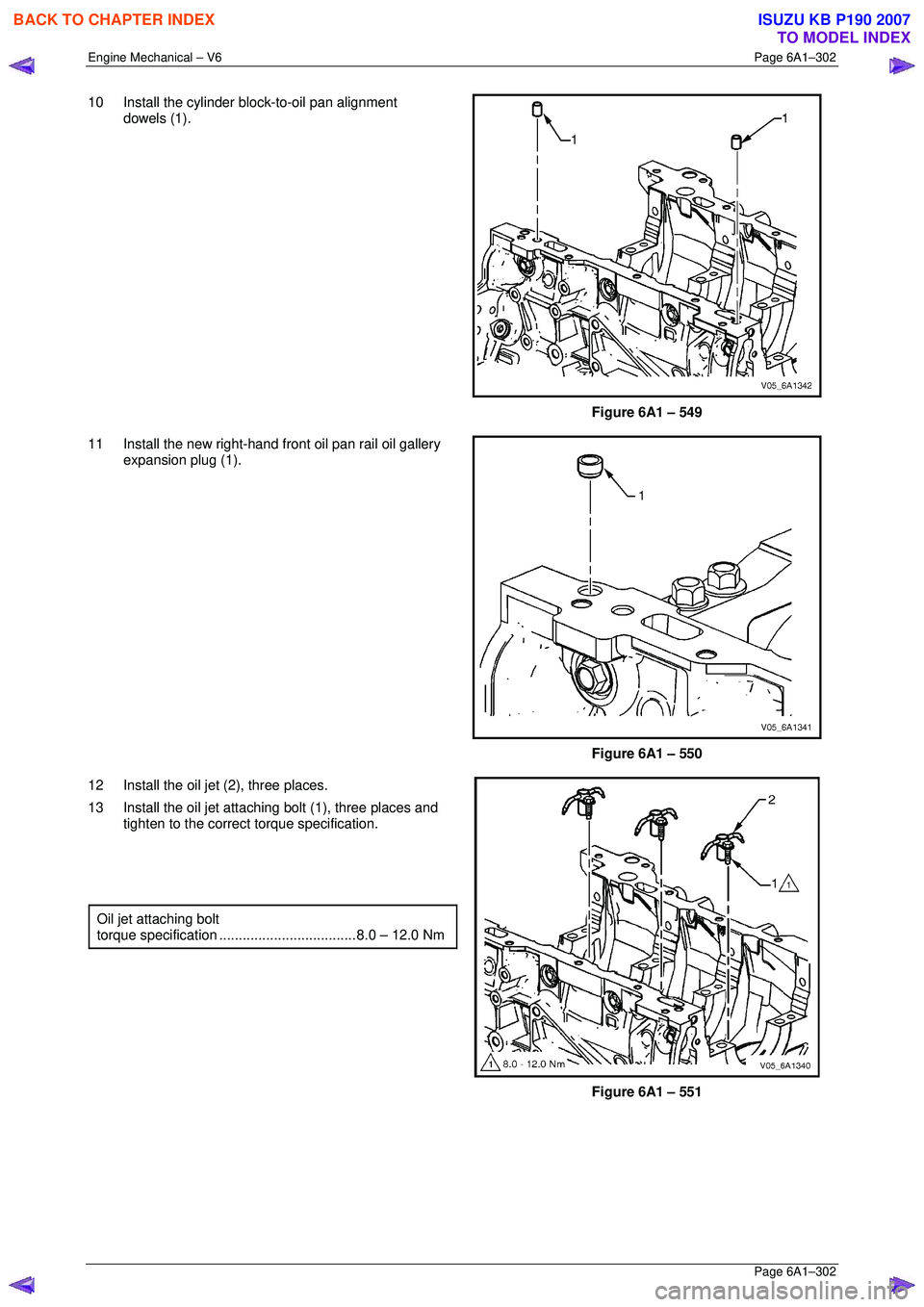

10 Install the cylinder block-to-oil pan alignment

dowels (1).

Figure 6A1 – 549

11 Install the new right-hand front oil pan rail oil gallery expansion plug (1).

Figure 6A1 – 550

12 Install the oil jet (2), three places.

13 Install the oil jet attaching bolt (1), three places and tighten to the correct torque specification.

Oil jet attaching bolt

torque specificatio n ................................... 8. 0 – 12.0 Nm

Figure 6A1 – 551

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3080 of 6020

Engine Mechanical – V6 Page 6A1–303

Page 6A1–303

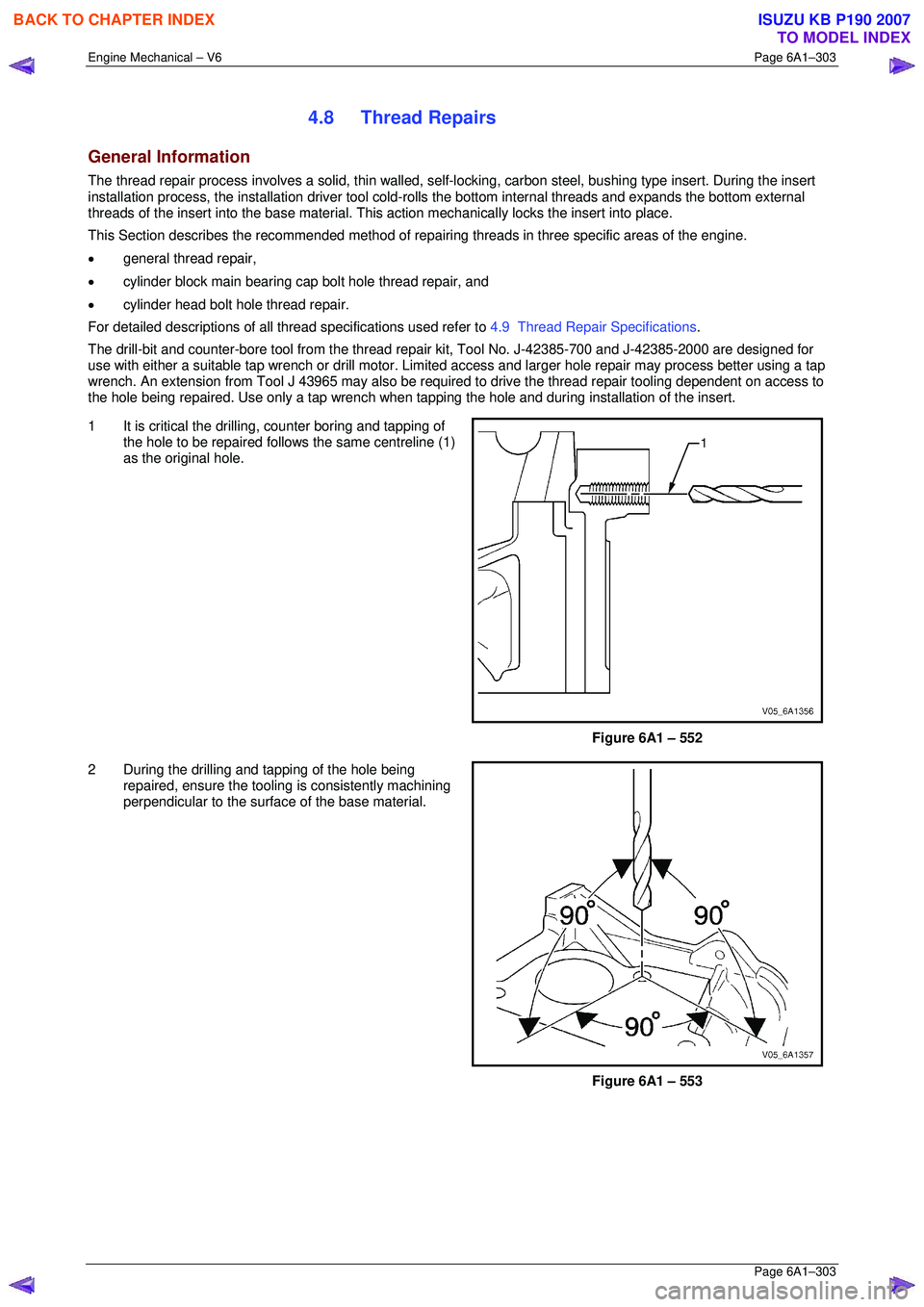

4.8 Thread Repairs

General Information

The thread repair process involves a solid, thin walled, self-locking, carbon steel, bushing type insert. During the insert

installation process, the installation dr iver tool cold-rolls the bottom internal threads and expands the bottom external

threads of the insert into the base material. This action mechanically locks the insert into place.

This Section describes the recomm ended method of repairing threads in three specific areas of the engine.

• general thread repair,

• cylinder block main bearing cap bolt hole thread repair, and

• cylinder head bolt hole thread repair.

For detailed descriptions of all th read specifications used refer to 4.9 Thread Repair Specifications .

The drill-bit and counter-bore tool from the thread repair kit, Tool No. J-42385-700 and J-42385-2000 are designed for

use with either a suitable tap wrench or drill motor. Limited access and larger hol e repair may process better using a tap

wrench. An extension from Tool J 43965 may also be required to drive the thread repair tooling dependent on access to

the hole being repaired. Use only a tap wrench when tapping the hole and dur ing installation of the insert.

1 It is critical the drilling, counter boring and tapping of

the hole to be repaired follows the same centreline (1)

as the original hole.

Figure 6A1 – 552

2 During the drilling and tapping of the hole being repaired, ensure the tooling is consistently machining

perpendicular to the surface of the base material.

Figure 6A1 – 553

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3081 of 6020

Engine Mechanical – V6 Page 6A1–304

Page 6A1–304

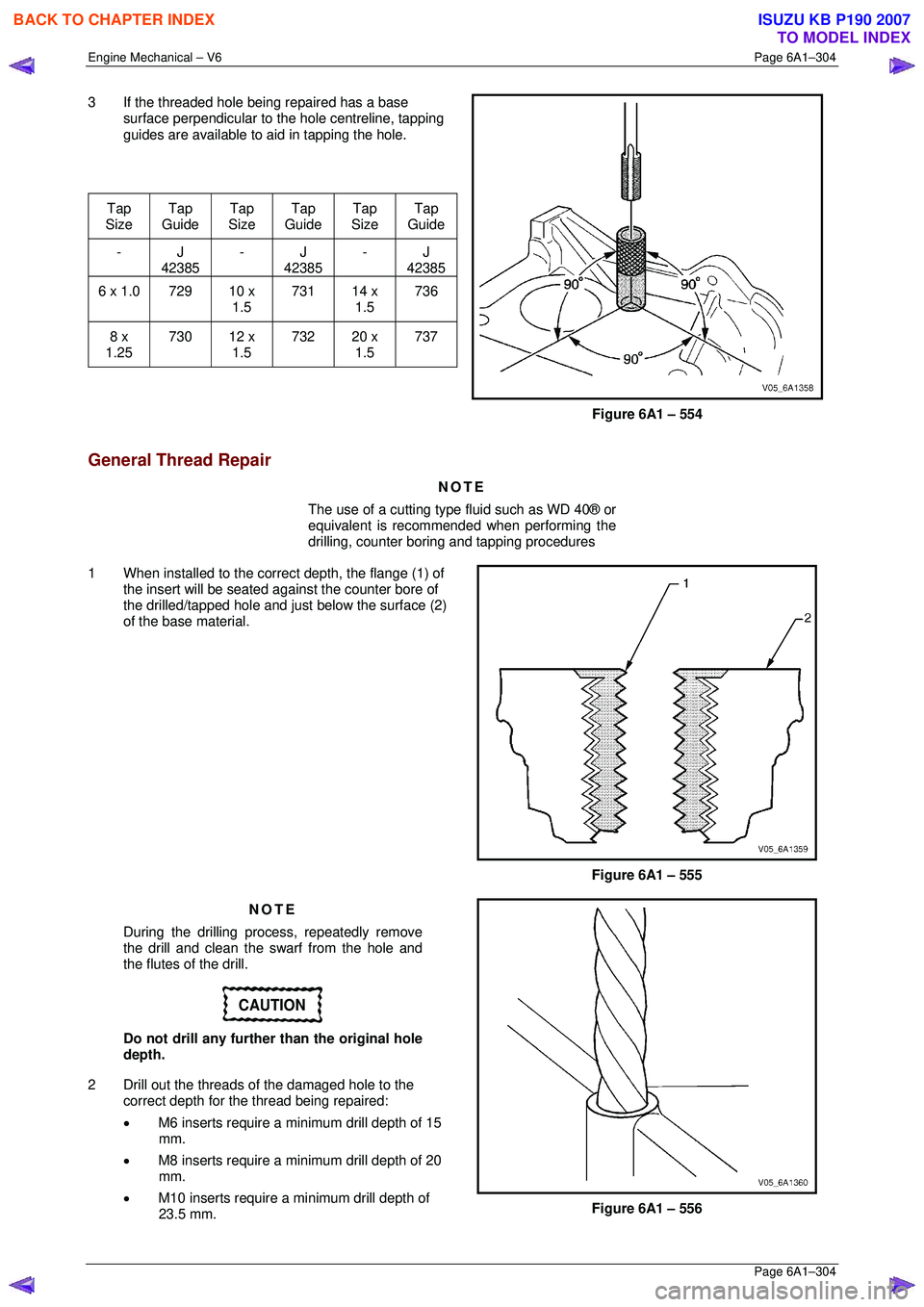

3 If the threaded hole being repaired has a base

surface perpendicular to t he hole centreline, tapping

guides are available to aid in tapping the hole.

Tap

Size Tap

Guide Tap

Size Tap

Guide Tap

Size Tap

Guide

- J 42385 - J

42385 - J

42385

6 x 1.0 729 10 x

1.5 731

14 x

1.5 736

8 x

1.25 730

12 x

1.5 732

20 x

1.5 737

Figure 6A1 – 554

General Thread Repair

NOTE

The use of a cutting type fluid such as WD 40® or

equivalent is recommended when performing the

drilling, counter bori ng and tapping procedures

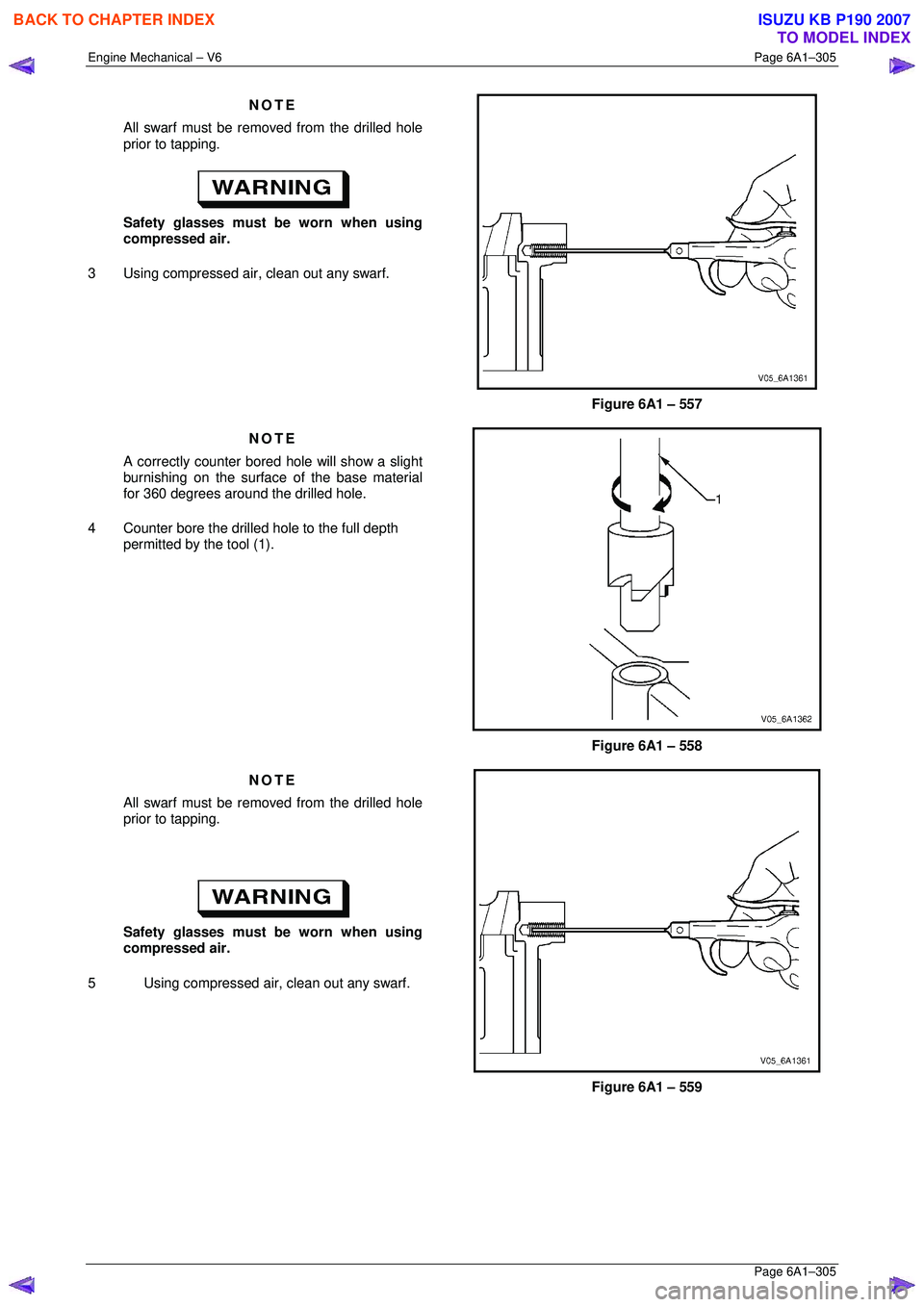

1 When installed to the corre ct depth, the flange (1) of

the insert will be seated agai nst the counter bore of

the drilled/tapped hole and just below the surface (2)

of the base material.

Figure 6A1 – 555

NOTE

During the drilling process, repeatedly remove

the drill and clean the swarf from the hole and

the flutes of the drill.

CAUTION

Do not drill any further than the original hole

depth.

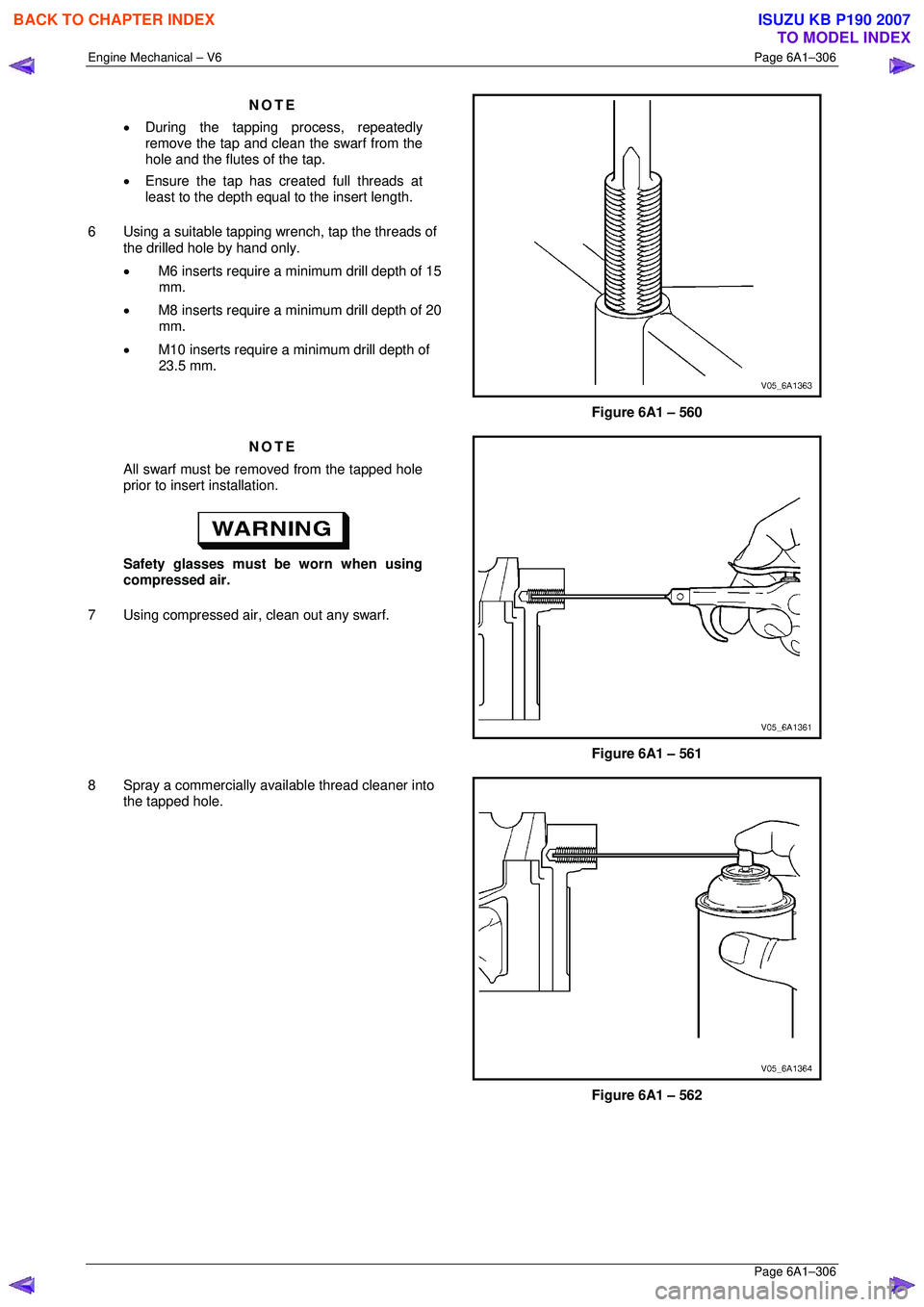

2 Drill out the threads of the damaged hole to the

correct depth for the thread being repaired:

• M6 inserts require a minimum drill depth of 15

mm.

• M8 inserts require a minimum drill depth of 20

mm.

• M10 inserts require a minimum drill depth of

23.5 mm.

Figure 6A1 – 556

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3082 of 6020

Engine Mechanical – V6 Page 6A1–305

Page 6A1–305

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

3 Using compressed air, clean out any swarf.

Figure 6A1 – 557

NOTE

A correctly counter bored hole will show a slight

burnishing on the surface of the base material

for 360 degrees around the drilled hole.

4 Counter bore the drilled hole to the full depth permitted by the tool (1).

Figure 6A1 – 558

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

5 Using compressed air, clean out any swarf.

Figure 6A1 – 559

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3083 of 6020

Engine Mechanical – V6 Page 6A1–306

Page 6A1–306

NOTE

• During the tapping pr ocess, repeatedly

remove the tap and clean the swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

6 Using a suitable tapping wr ench, tap the threads of

the drilled hole by hand only.

• M6 inserts require a minimum drill depth of 15

mm.

• M8 inserts require a minimum drill depth of 20

mm.

• M10 inserts require a minimum drill depth of

23.5 mm.

Figure 6A1 – 560

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

7 Using compressed air, clean out any swarf.

Figure 6A1 – 561

8 Spray a commercially available thread cleaner into the tapped hole.

Figure 6A1 – 562

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3084 of 6020

Engine Mechanical – V6 Page 6A1–307

Page 6A1–307

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

9 Using compressed air, clean out any swarf.

Figure 6A1 – 563

NOTE

Do not allow oil or other foreign material to

contact the outside diameter (OD) of the insert.

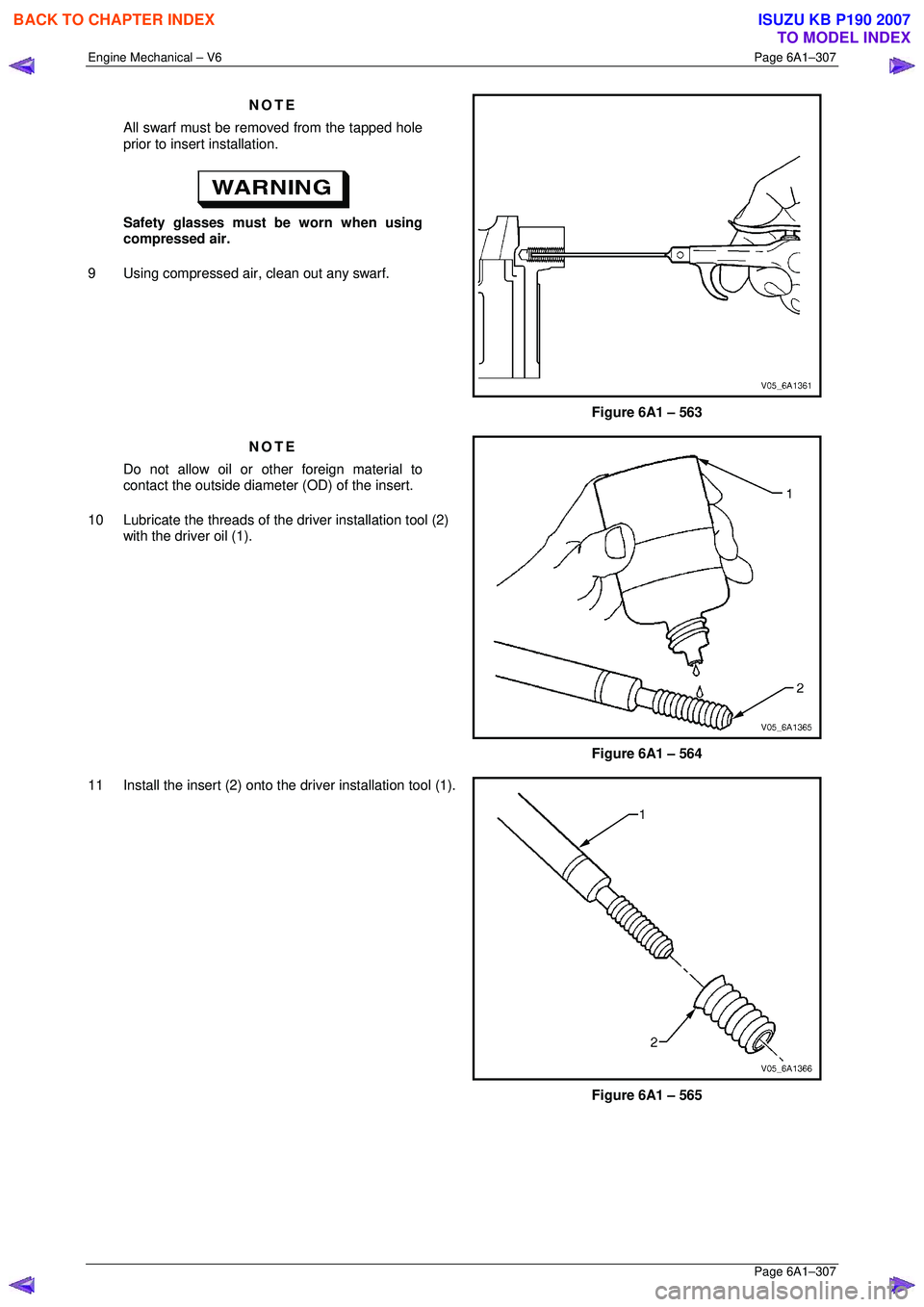

10 Lubricate the threads of the driver installation tool (2)

with the driver oil (1).

Figure 6A1 – 564

11 Install the insert (2) onto t he driver installation tool (1).

Figure 6A1 – 565

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007