engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3085 of 6020

Engine Mechanical – V6 Page 6A1–308

Page 6A1–308

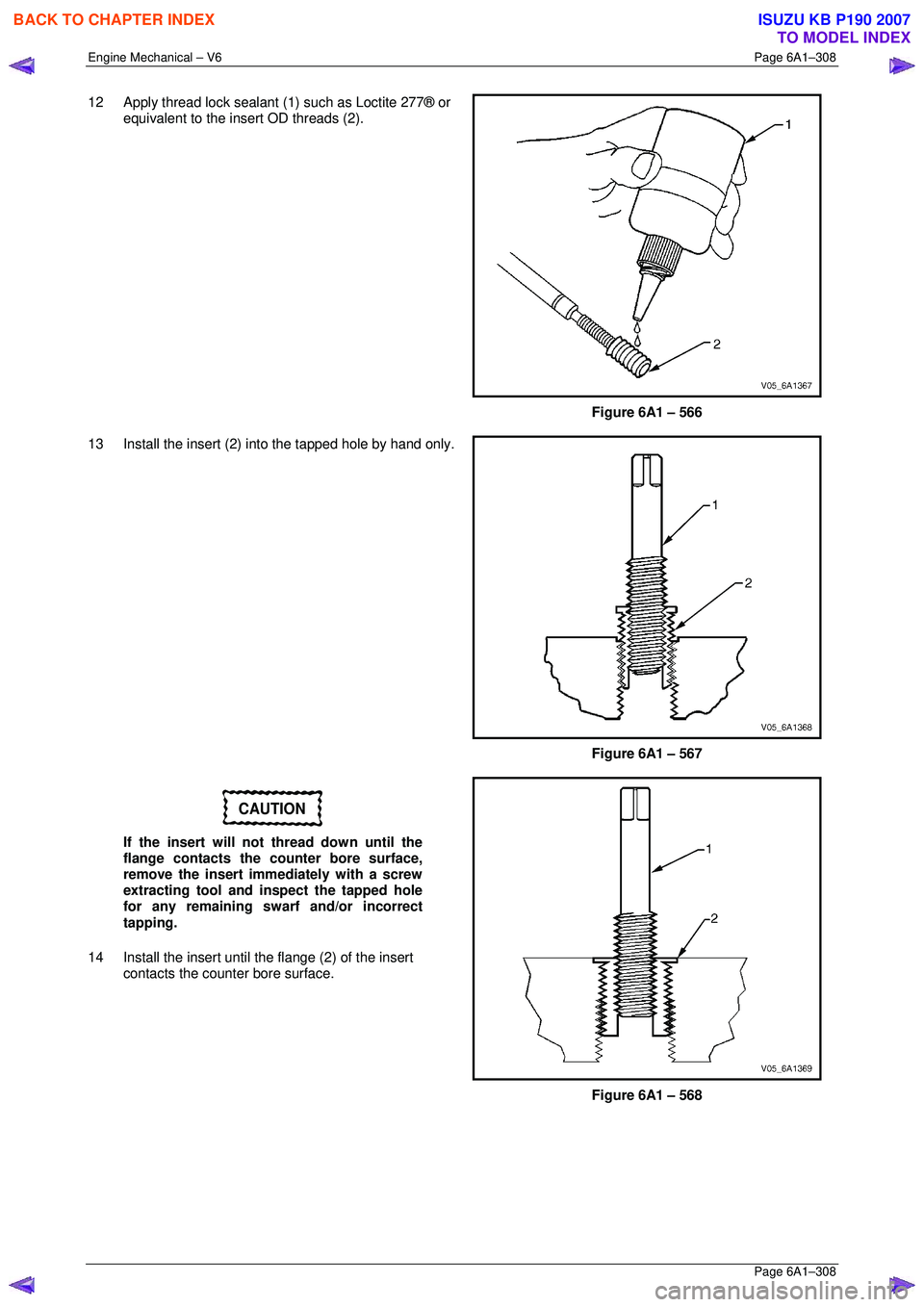

12 Apply thread lock sealant (1) such as Loctite 277® or

equivalent to the insert OD threads (2).

Figure 6A1 – 566

13 Install the insert (2) into the tapped hole by hand only.

Figure 6A1 – 567

CAUTION

If the insert will not thread down until the

flange contacts the counter bore surface,

remove the insert immediately with a screw

extracting tool and inspect the tapped hole

for any remaining swarf and/or incorrect

tapping.

14 Install the insert until t he flange (2) of the insert

contacts the count er bore surface.

Figure 6A1 – 568

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3086 of 6020

Engine Mechanical – V6 Page 6A1–309

Page 6A1–309

NOTE

The driver installation tool will tighten up before

cutting completely through the insert. This is

acceptable. The threads at the bottom of the

insert are being formed and the insert is

mechanically locking the insert into the base

material threads.

15 Continue to rotate the driver installation tool (1) through the insert (2)

16 Remove the driver installation tool.

Figure 6A1 – 569

17 Inspect the insert for co rrect installation into the

tapped hole. A correctly installed insert (1) will be

either flush or slightly below flush with the surface of

the base material (2).

Figure 6A1 – 570

18 Any installed insert that restricts or blocks an oil or

engine coolant passage (3) will need to have the oil or

engine coolant passage drilled out (4) to the original

size of the oil or engine c oolant passage. After drilling

the restriction or block age, clean out any swarf and

thread the installation driver tool through the insert

again to remove any burrs caused by the drilling of

the oil or engine coolant passage.

Figure 6A1 – 571

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3087 of 6020

Engine Mechanical – V6 Page 6A1–310

Page 6A1–310

Main Bearing Cap Bolt Hole Thread Repair

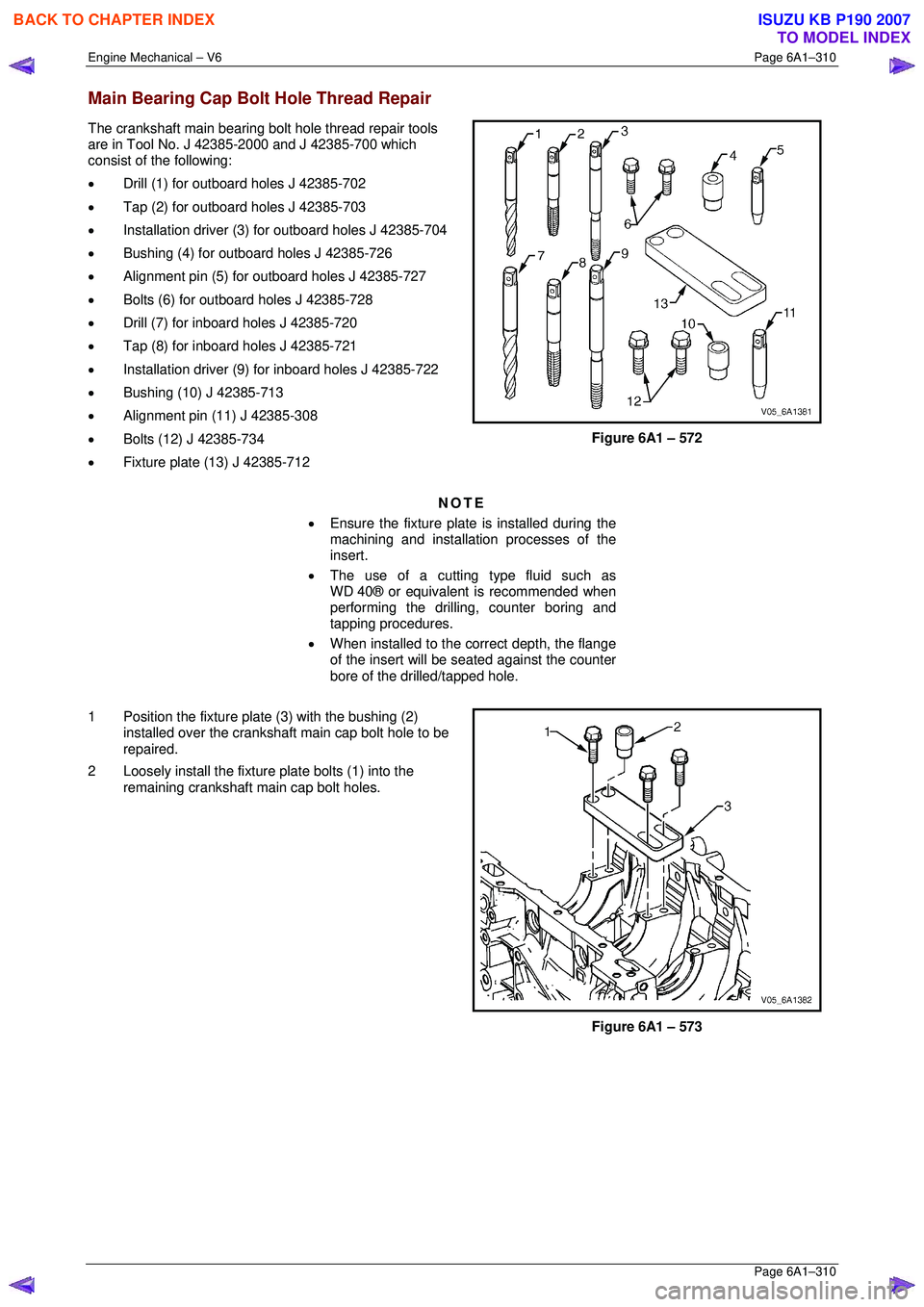

The crankshaft main bearing bolt hole thread repair tools

are in Tool No. J 42385-2000 and J 42385-700 which

consist of the following:

• Drill (1) for outboard holes J 42385-702

• Tap (2) for outboard holes J 42385-703

• Installation driver (3) for outboard holes J 42385-704

• Bushing (4) for outboard holes J 42385-726

• Alignment pin (5) for outboard holes J 42385-727

• Bolts (6) for outboard holes J 42385-728

• Drill (7) for inboard holes J 42385-720

• Tap (8) for inboard holes J 42385-721

• Installation driver (9) for inboard holes J 42385-722

• Bushing (10) J 42385-713

• Alignment pin (11) J 42385-308

• Bolts (12) J 42385-734

• Fixture plate (13) J 42385-712

Figure 6A1 – 572

NOTE

• Ensure the fixture plate is installed during the

machining and installation processes of the

insert.

• The use of a cutting type fluid such as

WD 40® or equivalent is recommended when

performing the drilling, counter boring and

tapping procedures.

• When installed to the correct depth, the flange

of the insert will be s eated against the counter

bore of the drilled/tapped hole.

1 Position the fixture plate (3) with the bushing (2) installed over the crankshaft main cap bolt hole to be

repaired.

2 Loosely install the fixture plate bolts (1) into the

remaining crankshaft main cap bolt holes.

Figure 6A1 – 573

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3088 of 6020

Engine Mechanical – V6 Page 6A1–311

Page 6A1–311

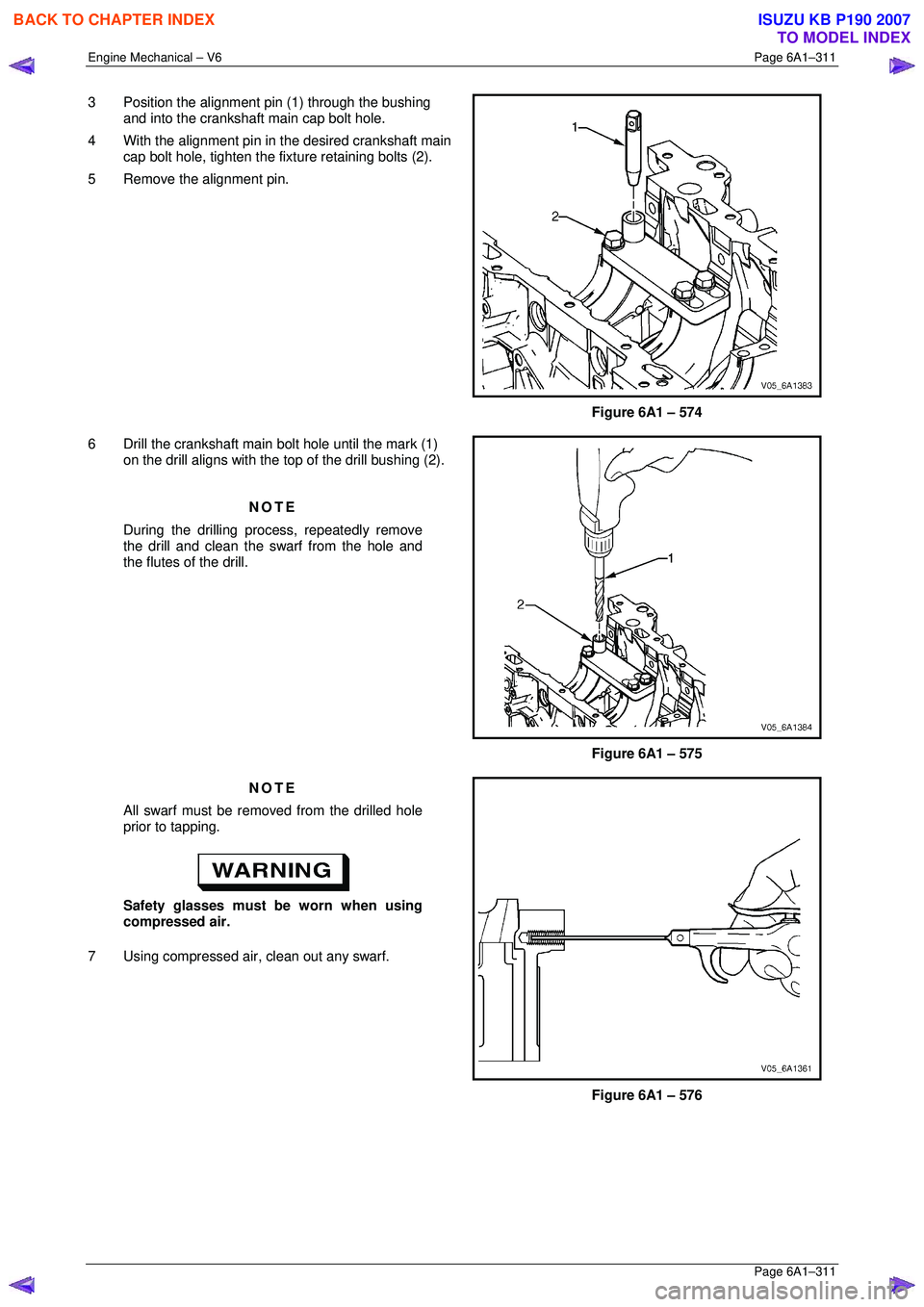

3 Position the alignment pin (1) through the bushing

and into the crankshaft main cap bolt hole.

4 With the alignment pin in the desired crankshaft main cap bolt hole, tighten the fixt ure retaining bolts (2).

5 Remove the alignment pin.

Figure 6A1 – 574

6 Drill the crankshaft main bolt hole until the mark (1) on the drill aligns with the top of the drill bushing (2).

NOTE

During the drilling process, repeatedly remove

the drill and clean the swarf from the hole and

the flutes of the drill.

Figure 6A1 – 575

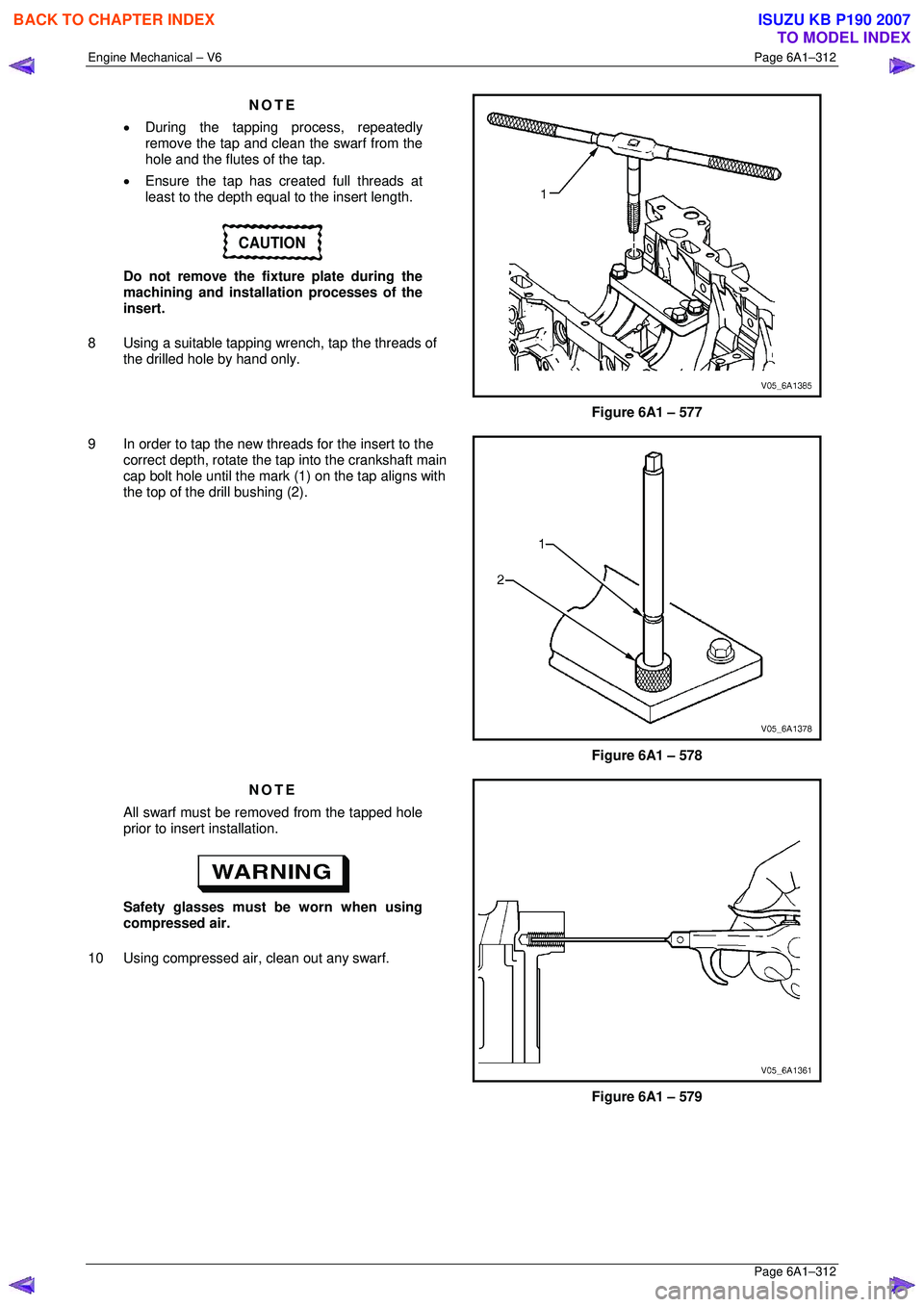

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

7 Using compressed air, clean out any swarf.

Figure 6A1 – 576

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3089 of 6020

Engine Mechanical – V6 Page 6A1–312

Page 6A1–312

NOTE

• During the tapping pr ocess, repeatedly

remove the tap and clean the swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

CAUTION

Do not remove the fixture plate during the

machining and installation processes of the

insert.

8 Using a suitable tapping wr ench, tap the threads of

the drilled hole by hand only.

Figure 6A1 – 577

9 In order to tap the new threads for the insert to the correct depth, rotate the t ap into the crankshaft main

cap bolt hole until the mark (1) on the tap aligns with

the top of the drill bushing (2).

Figure 6A1 – 578

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

10 Using compressed air, clean out any swarf.

Figure 6A1 – 579

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3090 of 6020

Engine Mechanical – V6 Page 6A1–313

Page 6A1–313

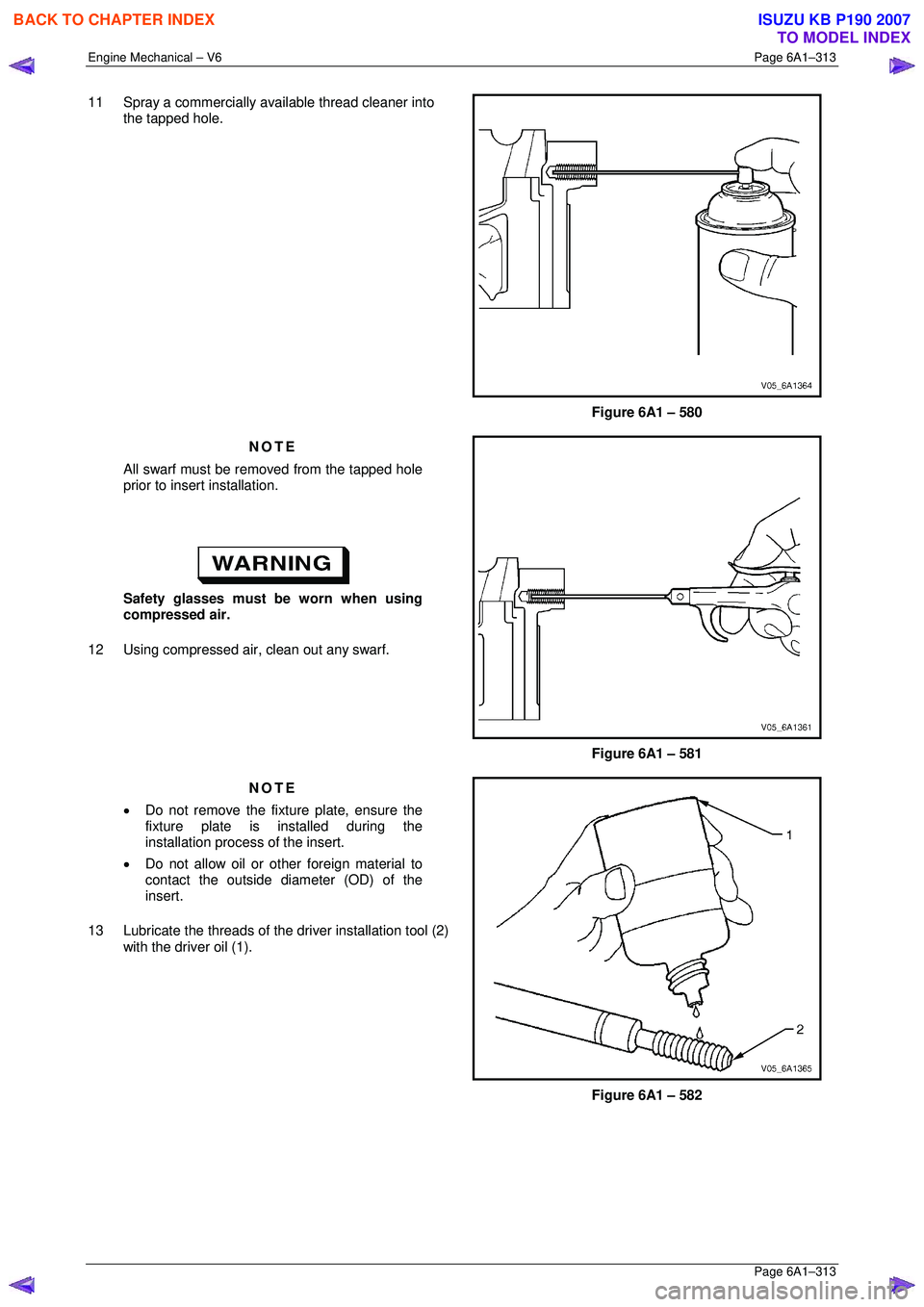

11 Spray a commercially available thread cleaner into

the tapped hole.

Figure 6A1 – 580

NOTE

All swarf must be removed from the tapped hole

prior to insert installation.

Safety glasses must be worn when using

compressed air.

12 Using compressed air, clean out any swarf.

Figure 6A1 – 581

NOTE

• Do not remove the fixt ure plate, ensure the

fixture plate is in stalled during the

installation process of the insert.

• Do not allow oil or other foreign material to

contact the outside diam eter (OD) of the

insert.

13 Lubricate the threads of the driver installation tool (2)

with the driver oil (1).

Figure 6A1 – 582

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3091 of 6020

Engine Mechanical – V6 Page 6A1–314

Page 6A1–314

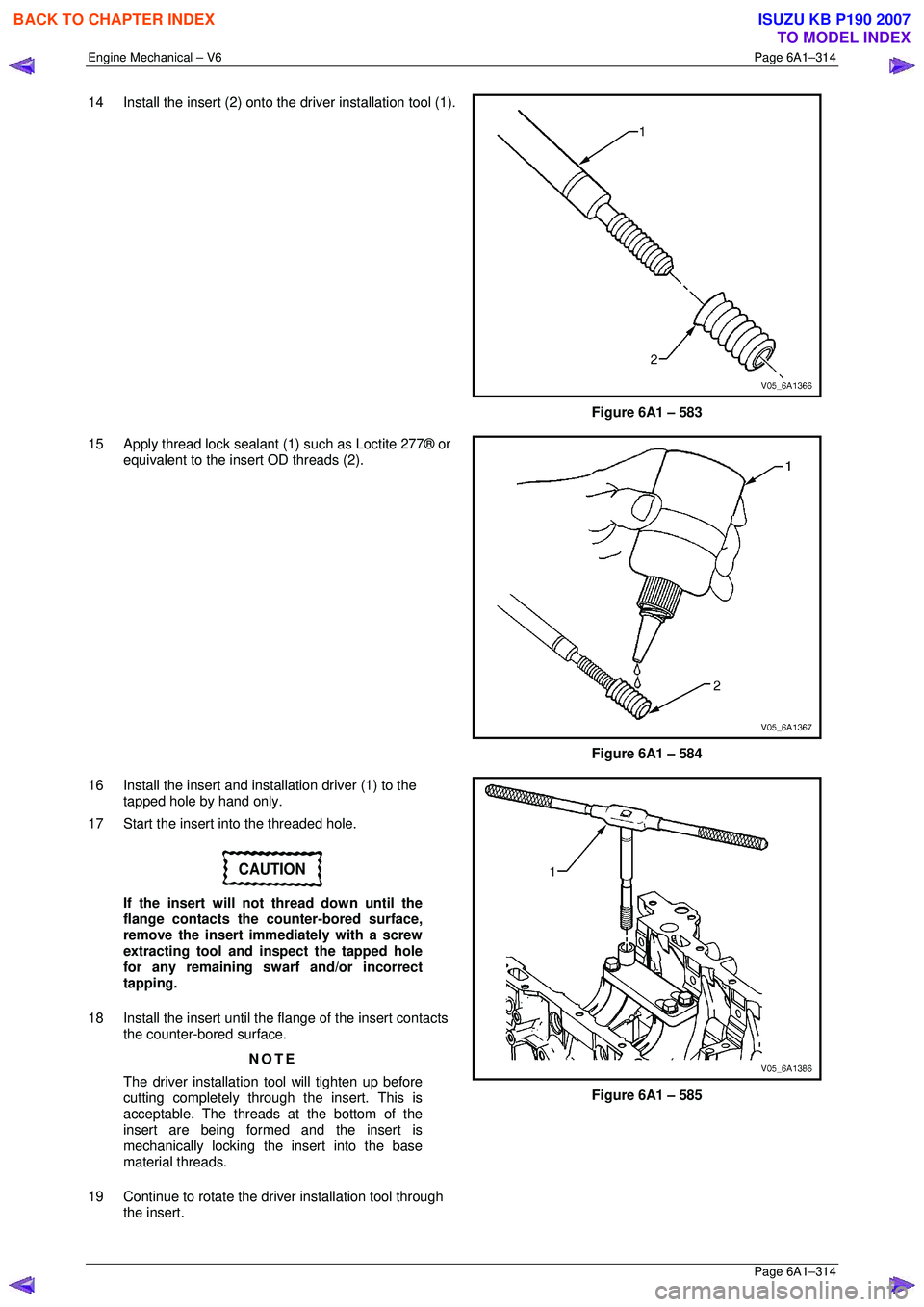

14 Install the insert (2) onto the driver installation tool (1).

Figure 6A1 – 583

15 Apply thread lock sealant (1) such as Loctite 277® or equivalent to the insert OD threads (2).

Figure 6A1 – 584

16 Install the insert and inst allation driver (1) to the

tapped hole by hand only.

17 Start the insert into the threaded hole.

CAUTION

If the insert will not thread down until the

flange contacts the counter-bored surface,

remove the insert immediately with a screw

extracting tool and inspect the tapped hole

for any remaining swarf and/or incorrect

tapping.

18 Install the insert until the flange of the insert contacts

the counter-bored surface.

NOTE

The driver installation tool will tighten up before

cutting completely through the insert. This is

acceptable. The threads at the bottom of the

insert are being formed and the insert is

mechanically locking the insert into the base

material threads.

19 Continue to rotate the driver installation tool through the insert.

Figure 6A1 – 585

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3092 of 6020

Engine Mechanical – V6 Page 6A1–315

Page 6A1–315

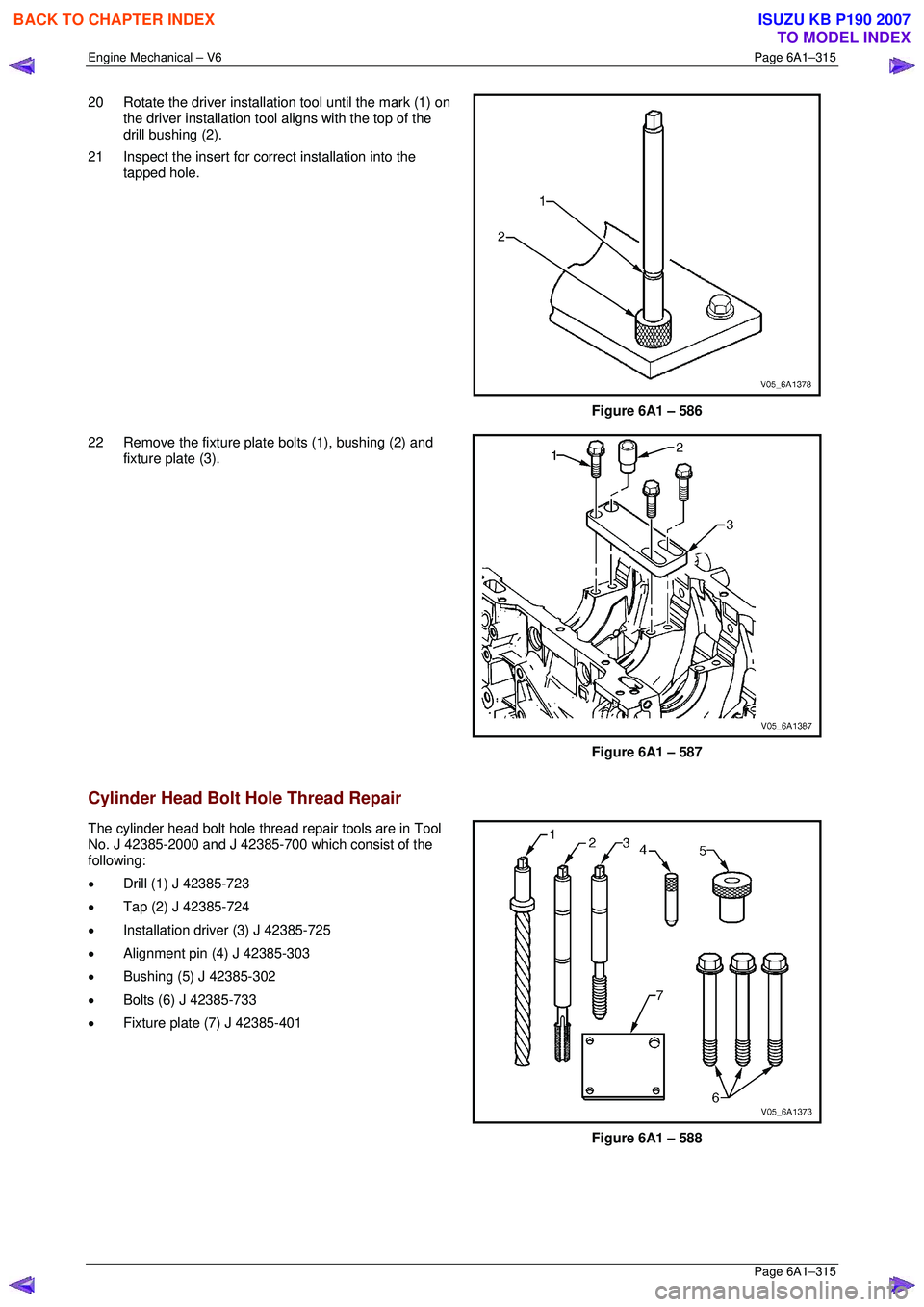

20 Rotate the driver installation tool until the mark (1) on

the driver installation tool aligns with the top of the

drill bushing (2).

21 Inspect the insert for co rrect installation into the

tapped hole.

Figure 6A1 – 586

22 Remove the fixture plate bolts (1), bushing (2) and fixture plate (3).

Figure 6A1 – 587

Cylinder Head Bolt Hole Thread Repair

The cylinder head bolt hole thread repair tools are in Tool

No. J 42385-2000 and J 42385-700 which consist of the

following:

• Drill (1) J 42385-723

• Tap (2) J 42385-724

• Installation driver (3) J 42385-725

• Alignment pin (4) J 42385-303

• Bushing (5) J 42385-302

• Bolts (6) J 42385-733

• Fixture plate (7) J 42385-401

Figure 6A1 – 588

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3093 of 6020

Engine Mechanical – V6 Page 6A1–316

Page 6A1–316

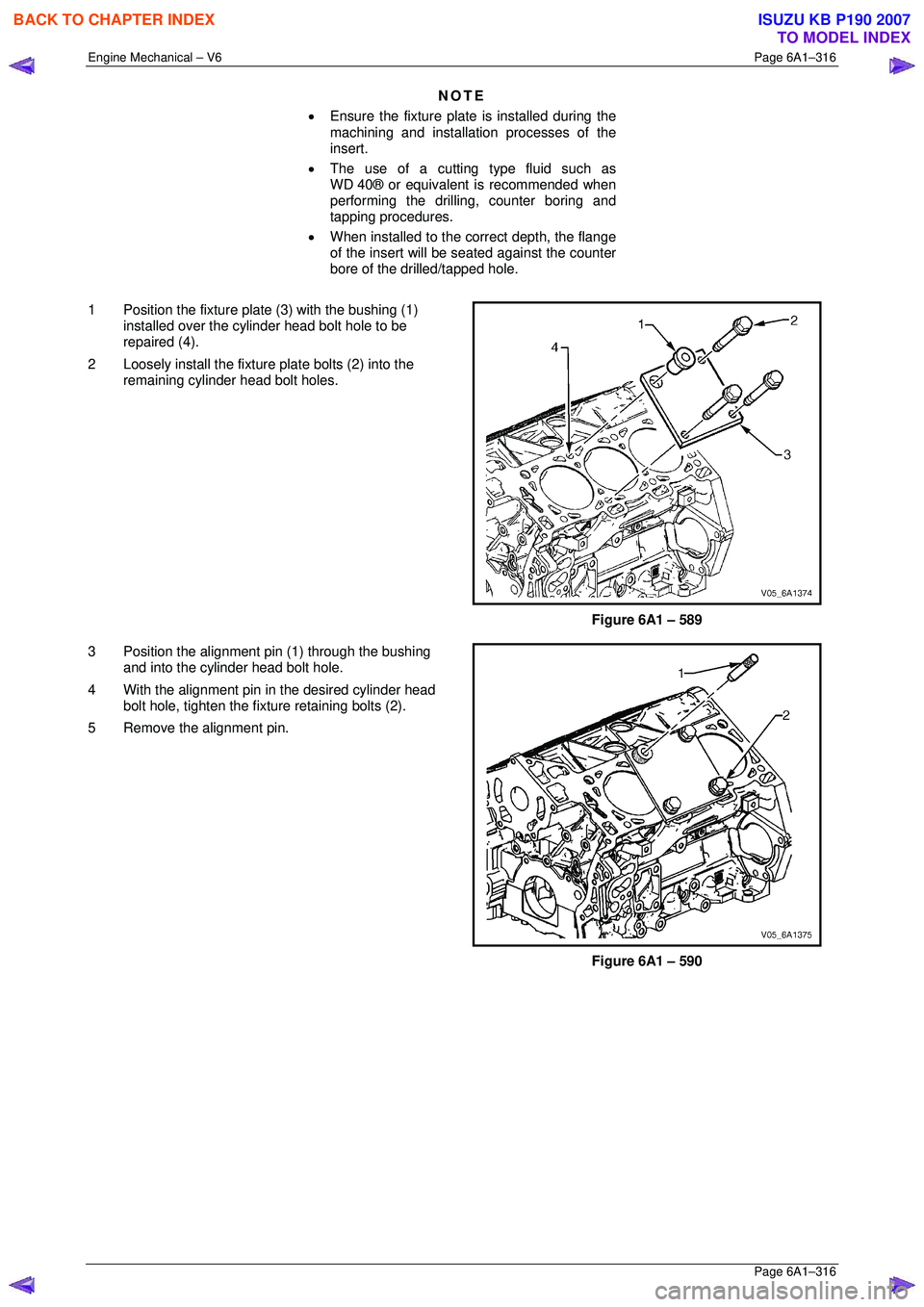

NOTE

• Ensure the fixture plate is installed during the

machining and installation processes of the

insert.

• The use of a cutting type fluid such as

WD 40® or equivalent is recommended when

performing the drilling, counter boring and

tapping procedures.

• When installed to the correct depth, the flange

of the insert will be s eated against the counter

bore of the drilled/tapped hole.

1 Position the fixture plate (3) with the bushing (1) installed over the cylinder head bolt hole to be

repaired (4).

2 Loosely install the fixture plate bolts (2) into the

remaining cylinder head bolt holes.

Figure 6A1 – 589

3 Position the alignment pin (1) through the bushing and into the cylinder head bolt hole.

4 With the alignment pin in the desired cylinder head bolt hole, tighten the fixture retaining bolts (2).

5 Remove the alignment pin.

Figure 6A1 – 590

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3094 of 6020

Engine Mechanical – V6 Page 6A1–317

Page 6A1–317

NOTE

During the drilling process, repeatedly remove

the drill and clean swarf from the hole and the

flutes of the drill.

6 Drill the hole until the stop co llar contacts the top of

the drill bushing.

Figure 6A1 – 591

NOTE

All swarf must be removed from the drilled hole

prior to tapping.

Safety glasses must be worn when using

compressed air.

7 Using compressed air, clean out any swarf.

Figure 6A1 – 592

CAUTION

Do not remove the fixture plate during the

machining and installation processes of the

insert.

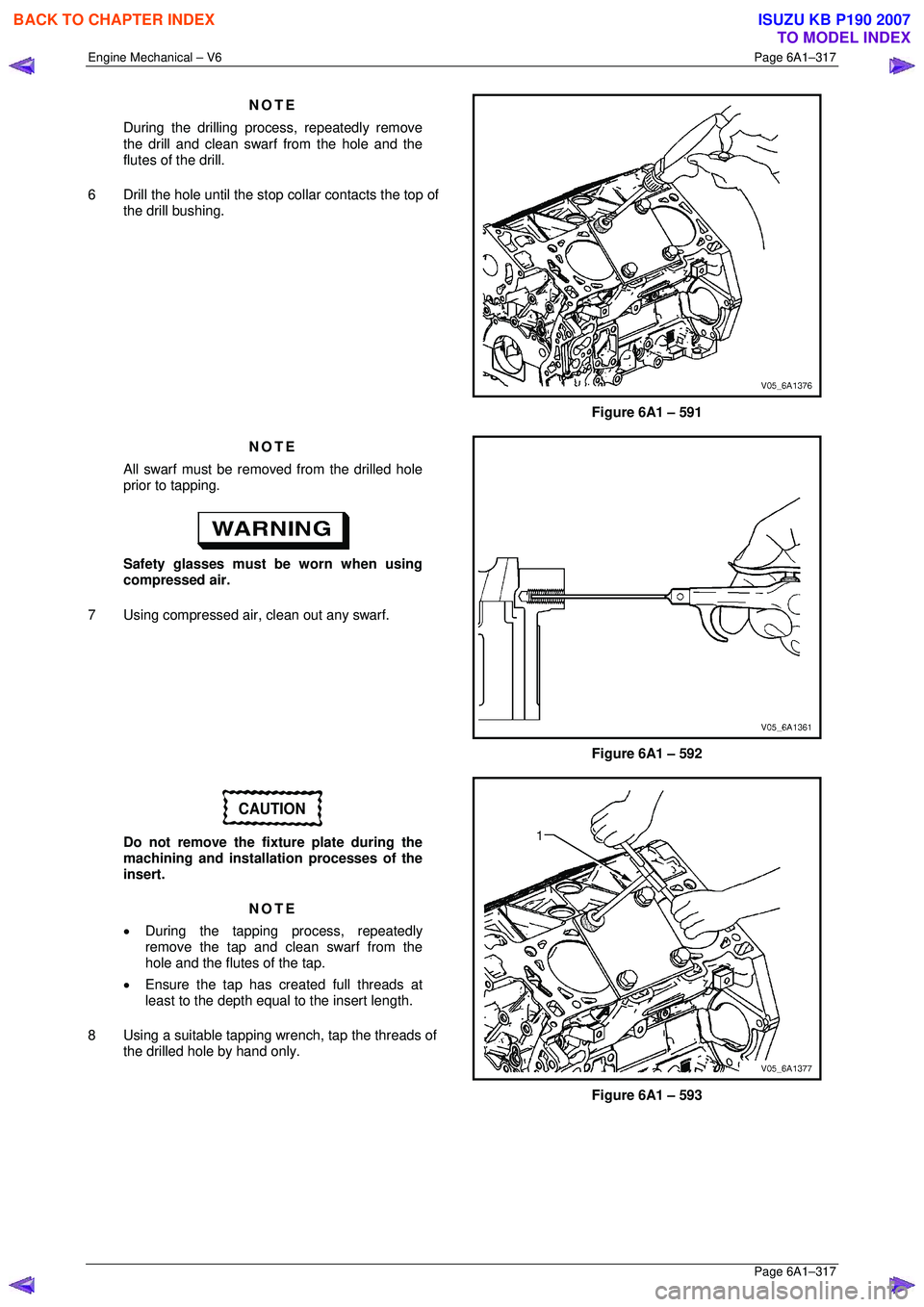

NOTE

• During the tapping pr ocess, repeatedly

remove the tap and clean swarf from the

hole and the flutes of the tap.

• Ensure the tap has created full threads at

least to the depth equal to the insert length.

8 Using a suitable tapping wr ench, tap the threads of

the drilled hole by hand only.

Figure 6A1 – 593

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007