engine coolant ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2310 of 6020

6E–140 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0118

Engine Coolant Temperature Sensor High Input

Step Action Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

2 1. Connect the Tech 2. 2. Review and record the failure information.

3. Select “F0: Read DTC Infor By Priority” in “F0: Diagnostic Trouble Code”.

Is the DTC P0118 stored as “Present Failure”? — Go to Step 3Refer to

Diagnostic Aids and Go to Step

3

3 1. Using the Tech2, ignition “On” and engine “Off”. 2. Select “Clear DTC Information” with the Tech2 andclear the DTC information.

3. Operate the vehicle and monitor the “F5: Failed This Ignition” in “F2: DTC Information”.

Was the DTC P0118 stored in this ignition cycle? — Go to Step 4Refer to

Diagnostic Aids and Go to Step

4

4 Check for poor/faulty connection at the ECT sensor or ECM connector. If a poor/faulty connection is found,

repair as necessary.

Was the problem found?

— Verify repair Go to Step 5

5 Visually check the ECT sensor. Was the problem found? — Go to Step 12Go to Step 6

6 Using the DVM and check the ECT sensor. 1. Ignition “Off”, engine “Off”.

2. Disconnect ECT sensor connector.

3. Measure the resistance of ECT sensor.

Does the tester indicate standard resistance as shown

in the following table?

Standard

resistance Go to Step 7Go to Step 12

E60(J1) E69

32 27

Temperature (°C) Resistance ( Ω) (Approximately)

-20 26740

09 12 0

20 3500

40 1464

60 664

80 333

100 175

120 102

21

ECT Sensor

Ω

12

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2321 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–151

DIAGNOSTIC TROUBLE CODE (DTC) P0131 O2 SENSOR CIRCUIT LOW

VOLTAGE (BANK 1 SENSOR 1)

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal and low circuits. The oxygen

sensor varies the voltage within a range of about 1000

mV when the exhaust is rich, down through about 10

mV when exhaust is lean. The ECM constantly monitors

the HO2S signal during “Closed Loop” operation and

compensates for a rich or lean condition by decreasing

or increasing injector pulse width as necessary. If the Bank 1 HO2S 1 voltage remains excessively low for an

extended period of time, Diagnostic Trouble Code

P0131 will be set.

Diagnostic Aids

Check for the following conditions:

• Heated oxygen sensor wiring - The sensor pigtail may be routed incorrectly and/or contacting the

exhaust system. Also, check for shorts to ground,

shorts to battery positive and open circuits.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0131 A O

2 SensorCircuit Low Voltage (Bank 1

Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. O

2 sensor bank 1 output voltage is below

50mV in “Closed Loop” condition. “Open Loop” fuel control.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2325 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–155

DIAGNOSTIC TROUBLE CODE (DTC) P0132 O2 SENSOR CIRCUIT HIGH

VOLTAGE (BANK 1 SENSOR 1)

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal and low circuits. The oxygen

sensor varies the voltage within a range of about 1000

mV when the exhaust is rich, down through about 10

mV when exhaust is lean. The ECM constantly monitors

the HO2S signal during “Closed Loop” operation and

compensates for a rich or lean condition by decreasing

or increasing injector pulse width as necessary. If the Bank 1 HO2S 1 voltage remains excessively high for an

extended period of time, Diagnostic Trouble Code

P0132 will be set.

Diagnostic Aids

Check the following items:

• Fuel pressure - The system will go rich if pressure is too high. The ECM can compensate for some

increase. However, if fuel pressure is too high, a

Diagnostic Trouble Code P0132 may be set. Refer to

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0132 A O

2 Sensor Circuit High Voltage (Bank 1

Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. O

2 sensor bank 1 output voltage is more

than 952mV in “Closed Loop” condition. “Open Loop” fuel control.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2329 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–159

DIAGNOSTIC TROUBLE CODE (DTC) P0134 O2 SENSOR NO ACTIVITY

DEFECTED (BANK 1 SENSOR 1)

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) high and low circuits. The oxygen

sensor varies the voltage within a range of about 1000

mV when the exhaust is rich, down through about 10

mV when exhaust is lean. The ECM constantly monitors

the HO2S signal during “Closed Loop” operation and compensates for a rich or lean condition by decreasing

or increasing injector pulse width as necessary. If the

Bank 1 HO2S 1 voltage remains at or near the 450 mV

bias for an extended period of time, Diagnostic Trouble

Code P0134 will be set, indicating an open sensor

signal or sensor low circuit.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0134 A O

2 Sensor Circuit No Activity Detected

(Bank 1 Sensor 1) 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg.C.

3. Engine run time is longer than 40 seconds.

4. Mass air flow is more than 7g/s.

5. O

2 sensor bank 1 output voltage is

between 300mV and 600mV. “Open Loop” fuel control.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2333 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–163

DIAGNOSTIC TROUBLE CODE (DTC) P0135 O2 SENSOR HEATER CIRCUIT

(BANK 1 SENSOR 1)

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

Heated oxygen sensors are used to minimize the

amount of time required for “Closed Loop” fuel control

operation and to allow accurate catalyst monitoring. The

oxygen sensor heater greatly decreases the amount of

time required for fuel control sensors Bank 1 HO2S 1 1

to become active. Oxygen sensor heaters are required

by catalyst monitor sensors Bank 1 HO2S 2 to maintain

a sufficiently high temperature which allows accurate

exhaust oxygen content readings further from the engine.

The engine control module (ECM) will run the heater

test only after a cold start (determined by engine coolant

and intake air temperature at the time of start-up) and

only once during an ignition cycle. When the engine is

started the ECM will monitor the HO2S voltage. When

the HO2S voltage indicates a sufficiently active sensor,

the ECM looks at how much time has elapsed since

start-up. If the ECM determines that too much time was

required for the Bank 1 HO2S 1 to become active, a

Diagnostic Trouble Code P0135 will set.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0135 A O

2 SensorHeater Circuit (Bank 1 Sen-

sor 1) 1. No DTC relating to MAP sensor and ECT

sensor.

2. Engine coolant temperature is more than 60 deg. C.

3. Engine run time is longer than 20 seconds.

4. MAP sensor output is more than 70kPa.

5. O

2 sensor bank 1 heater current more than

10mA. No fail-safe function.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2344 of 6020

6E–174 ENGINE DRIVEABILITY AND EMISSIONS

DIAGNOSTIC TROUBLE CODE (DTC) P0325 KNOCK SENSOR (KS) MODULE CIRCUIT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The knock sensor (KS) system is used to detect engine

detonation. The knock sensor produced an AC voltage

signal. The knock sensor sends this signal to the ECM.

The amplitude and the frequency of the AC voltage

signal depends upon the knock level being detected.

The ECM will then retard the spark timing based on the signals from the Knock Sensor.Diagnostic Aids

Correct any abnormal engine noise before using the

diagnostic table.

Check for an open circuit.

Diagnostic Trouble Code (DTC) P0325 Knock Sensor Module Circuit

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0325 B Knock Sensor Module Circuit 1. No DTC relating to MAP sensor.

2. Engine coolant temperature is more than 50 deg. C.

3. Engine speed is more than 1600rpm.

4. Knock sensor filter module integrated cir- cuit malfunction. ECM retards ignition timing 4 deg. C

.

StepAction Value(s) Yes No

1 Was the “On-Board Diagnostic (OBD) System Check” performed?

—Go to Step 2Go to

On Board

Diagnostic

(OBD) System Check

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2347 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–177

DIAGNOSTIC TROUBLE CODE (DTC) P0327 KNOCK SENSOR (KS) CIRCUIT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The ECM uses the Knock Sensor (KS) in order to detect

engine detonation. This allows the ECM to retard the

Ignition Control (IC) spark timing based on the KS signal

the ECM receives. The knock sensors produce an AC

signal that rides on the 1.3 volts DC. The signal’s

amplitude and frequency are dependent upon the

amount of the knock being experienced.

The ECM determines whether the knock is occurring by

comparing the signal level on the KS circuit with a

voltage level on the noise channel. The normal engine

noise varies depending on the engine speed and load.

Then the ECM determines that an abnormally high

noise channel voltage level is being experienced, a

Diagnostic Trouble Code P0327 sets.

Diagnostic Aids

Check for the following conditions:

A poor connection at the ECM. Inspect the knock

sensor and the ECM connectors for: , broken locks,

improperly formed or damaged terminals.

• Backed out terminals

• Broken locks

• Improperly formed or damaged terminals

Also, check the wiring harness for: shorts to ground,

shorts to battery positive, and open circuits.

• A misrouted harness. Inspect the knock sensor harness in order to ensure that it is not routed too

close to high voltage wires such as spark plug leads.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P0327 A Knock Sensor Circuit 1. No DTC relating to MAP sensor.

2. Engine coolant temperature is more than 50 deg. C.

3. Engine speed is more than 1600rpm.

4. Knock sensor harness short to ground or short to voltage circuit. ECM retards ignition timing 4 deg. C

.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2384 of 6020

6E–214 ENGINE DRIVEABILITY AND EMISSIONS

DIAGNOSTIC TROUBLE CODE (DTC) P1171 FUEL SUPPLY SYSTEM LEAN DURING POWER ENRICHMENT

Condition for setting the DTC and action taken when the DTC sets

Circuit Description

The engine control module (ECM) internal circuitry can

identify if the vehicle fuel system is capable of supplying

adequate amounts of fuel during heavy acceleration

(power enrichment). The ECM monitors the voltage of

the oxygen sensor during power enrichment. When a

power enrichment mode of operation is requested

during “Closed Loop” operation (by heavy acceleration), the ECM will provide more fuel to the engine. Under

these conditions the ECM should detect a “rich”

condition (high oxygen sensor voltage). If this “rich”

exhaust is not detected at this time, a Diagnostic

Trouble Code P1171 will set. A plugged fuel filter or

restricted fuel line can prevent adequate amounts of fuel

from being supplied during power enrichment mode.

Code Type DTC Name DTC Setting Condition Fail-Safe (Back Up)

P1171 D Fuel Supply System Lean During Power Enrichment 1. No DTC relating to MAP sensor, TPS,

EVAP purge, ECT sensor, CKP sensor,

VSS, injector control circuit and ignition

control circuit.

2. Engine coolant temperature is more than 60 deg. C.

3. Mass air flow is below 13.5m/s.

4. O

2 sensor bank 1 output voltage is below

350mV in power enrichment mode. No fail-safe function.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2406 of 6020

6E–236 ENGINE DRIVEABILITY AND EMISSIONS

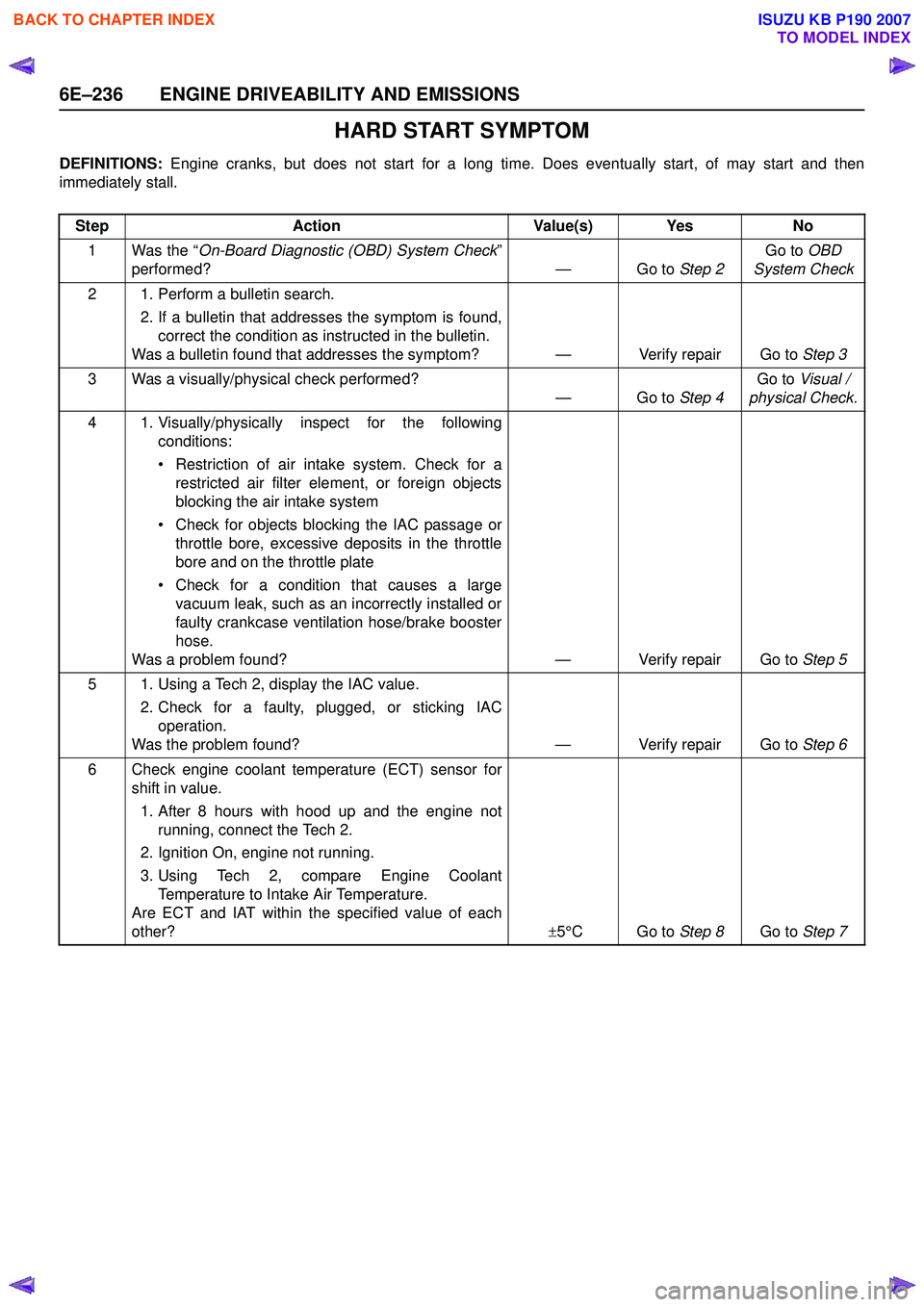

HARD START SYMPTOM

DEFINITIONS: Engine cranks, but does not start for a long time. Does eventually start, of may start and then

immediately stall.

Step Action Value(s) Yes No

1 Was the “ On-Board Diagnostic (OBD) System Check ”

performed? — Go to Step 2Go to

OBD

System Check

2 1. Perform a bulletin search. 2. If a bulletin that addresses the symptom is found,correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom? — Verify repair Go to Step 3

3 Was a visually/physical check performed? —Go to Step 4Go to

Visual /

physical Check.

4 1. Visually/physically inspect for the following conditions:

• Restriction of air intake system. Check for a restricted air filter element, or foreign objects

blocking the air intake system

• Check for objects blocking the IAC passage or throttle bore, excessive deposits in the throttle

bore and on the throttle plate

• Check for a condition that causes a large vacuum leak, such as an incorrectly installed or

faulty crankcase ventilation hose/brake booster

hose.

Was a problem found? — Verify repair Go to Step 5

5 1. Using a Tech 2, display the IAC value. 2. Check for a faulty, plugged, or sticking IACoperation.

Was the problem found? — Verify repair Go to Step 6

6 Check engine coolant temperature (ECT) sensor for shift in value.

1. After 8 hours with hood up and the engine not running, connect the Tech 2.

2. Ignition On, engine not running.

3. Using Tech 2, compare Engine Coolant Temperature to Intake Air Temperature.

Are ECT and IAT within the specified value of each

other? ± 5°C Go to Step 8Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2407 of 6020

ENGINE DRIVEABILITY AND EMISSIONS 6E–237

7 1. Using a Tech 2, display the engine coolanttemperature and note the value.

2. Check the resistance of the engine coolant temperature sensor.

Is the actual resistance near the resistance value in

the chart for the temperature that was noted?

—Go to Step 8Replace the

ECT sensor. Verify repair

8 1. Using a Tech 2, display the MAP sensor value in comparison with atmosphere temperature.

2. Check for a faulty, plugged, or incorrectly installed MAP sensor.

Was the problem found? — Verify repair Go to Step 9

9 Visually/physically inspect all spark plug high-tension cables. Check for the following conditions:

• Verify that the resistance of all spark plug high- tension cables are less than the specified value.

• Verify that the all spark plug high-tension cables are correctly fitted to eliminate cross-fitting.

• Verify that the all spark plug high-tension cables are not arcing to ground.

Spraying the spark plug high-tension cables with a

light mist of water may help locate an intermittent

problem.

Was a problem found? #1 cyl. 4.4k

Ω

#2 cyl. 3.6k Ω

#3 cyl. 3.1k Ω

#4 cyl. 2.8k ΩVerify repair Go to Step 10

10 Check for proper ignition voltage output with a spark tester.

Was the problem found? — Verify repair Go to Step 11

11 1. Remove the spark plugs and check for gas or oil fouling cracks, wear, improper gap, burned

electrodes, heavy deposits, or improper heat

range.

2. If spark plugs are fouled, the cause of fouling must be determined before replacing the spark plugs.

Was a problem found? — Verify repair Go to Step 12

12 Check for a loose ignition control module ground. Was a problem found? — Verify repair Go to Step 13

13 1. Check the ignition coil secondary resistance. 2. Replace the coil if it is greater than the specifiedresistance.

Did the coil require replacement? 2.5kΩ Verify repair Go to Step 14

Step

Action Value(s) Yes No

Temperature (°C) Resistance (Ω) (Approximately)

-20 26740

0 9120

20 3500

40 1464

60 664

80 333

100 175

120 102

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007