engine coolant ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2646 of 6020

Engine Mechanical – V6 Page 6A1–167

Inspect

Visual Inspection

1 Inspect the cylinder head (1) camshaft bearing

surfaces for the following conditions:

• excessive scoring or pitting,

• discoloration from overheating, and

• deformation from excessive wear.

2 If any of the above conditions exist on the camshaft bearing surfaces, replace the cylinder head. Do not

machine the camshaft bearing journals.

Figure 6A1 – 287

3 Inspect the cylinder head for the following: • Cracks, damage or pitting in the combustion chambers.

• Debris in the oil galleries. continue to clean the galleries until all debris is removed.

• Coolant leaks or damage to the deck face sealing surface. if coolant leaks are present, measure the surface

warpage as described under Cylinder Head Measurement within this Section.

• Burrs or any defects that would degrade the sealing of a new secondary camshaft chain tensioner gasket.

• Damage to any gasket surfaces.

• Damage to any threaded bolt holes.

• Burnt or eroded areas in the combustion chamber.

• Cracks in the exhaust ports and combustion chambers.

• External cracks in the water passages.

• Restrictions in the intake or exhaust passages.

• Restrictions in the cooling system passages.

• Rusted, damaged or leaking core plugs.

4 If the cylinder head is cracked or damaged, it must be replaced. No welding or patching of the cylinder head is recommended.

Cylinder Head Measurement

NOTE

For all cylinder head and associated component

specifications, refer to 5 Specifications.

Camshaft Journal Clearance

1 Install the camshaft bearing cap in the cylinder head without the camshaft.

2 Install the camshaft cap bolts and tighten to the correct torque specification

Camshaft bearing cap attaching bolt........8.0 – 12.0 Nm.

3 Measure the camshaft bearings using an inside micrometer.

4 Subtract the camshaft journal diameter from the camshaft bearing diameter. This will provide the running clearance. If the running clearance exceeds specifications and the camshaft journals are within specification, replace the

cylinder head.

Camshaft Journal Alignment

1 Ensure the camshafts are serviceable, refer to 3.19 Camshaft for measuring procedures.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2653 of 6020

Engine Mechanical – V6 Page 6A1–174

Valve Stem Height Measurement Procedure

CAUTION

To determine the valve stem height

measurement, measure from the valve

spring seat to the valve spring retainer.

1 Install the valve into the valve guide.

2 Ensure the valve is seated to the valve seat.

3 Install the valve stem oil seal.

4 Install the valve spring retainer and valve stem keys.

5 Measure the distance (1) between the cylinder head to the bottom of the valve spring retainer, refer to 5

Specifications.

6 If the maximum height specification is exceeded, a new valve should be installed and the valve stem

height re-measured.

Figure 6A1 – 297

CAUTION

Do not grind the valve stem tip. The tip of the

valve is hardened and grinding the tip will

eliminate the hardened surface causing

premature wear and possible engine damage.

CAUTION

Do not use shims to adjust valve stem height.

The use of shims will cause the valve spring

to bottom out before the camshaft lobe is at

peak lift and engine damage could result.

7 If the valve stem height still exceeds the maximum height specification, the cylinder head must be replaced.

Assemble

1 Install the cylinder head coolant threaded plugs (1) and tighten to the correct torque specification.

Cylinder head threaded plug ..............................31.0 Nm

Figure 6A1 – 298

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2664 of 6020

Engine Mechanical – V6 Page 6A1–185

Remove

1 Remove the skid plate.

2 Drain the radiator coolant, refer to 6B1 Engine Cooling – V6.

3 Disconnect the battery negative and positive terminal, refer to 8A Electrical Body & Chassis.

4 Remove the battery from the vehicle.

5 Depressurise the fuel system pressure, refer to 6C Fuel System – V6.

6 Make alignment marks on the bonnet and hinges in order to return the bonnet to the exact original position.

7 Remove the bonnet, refer to 2B Sheet Metal.

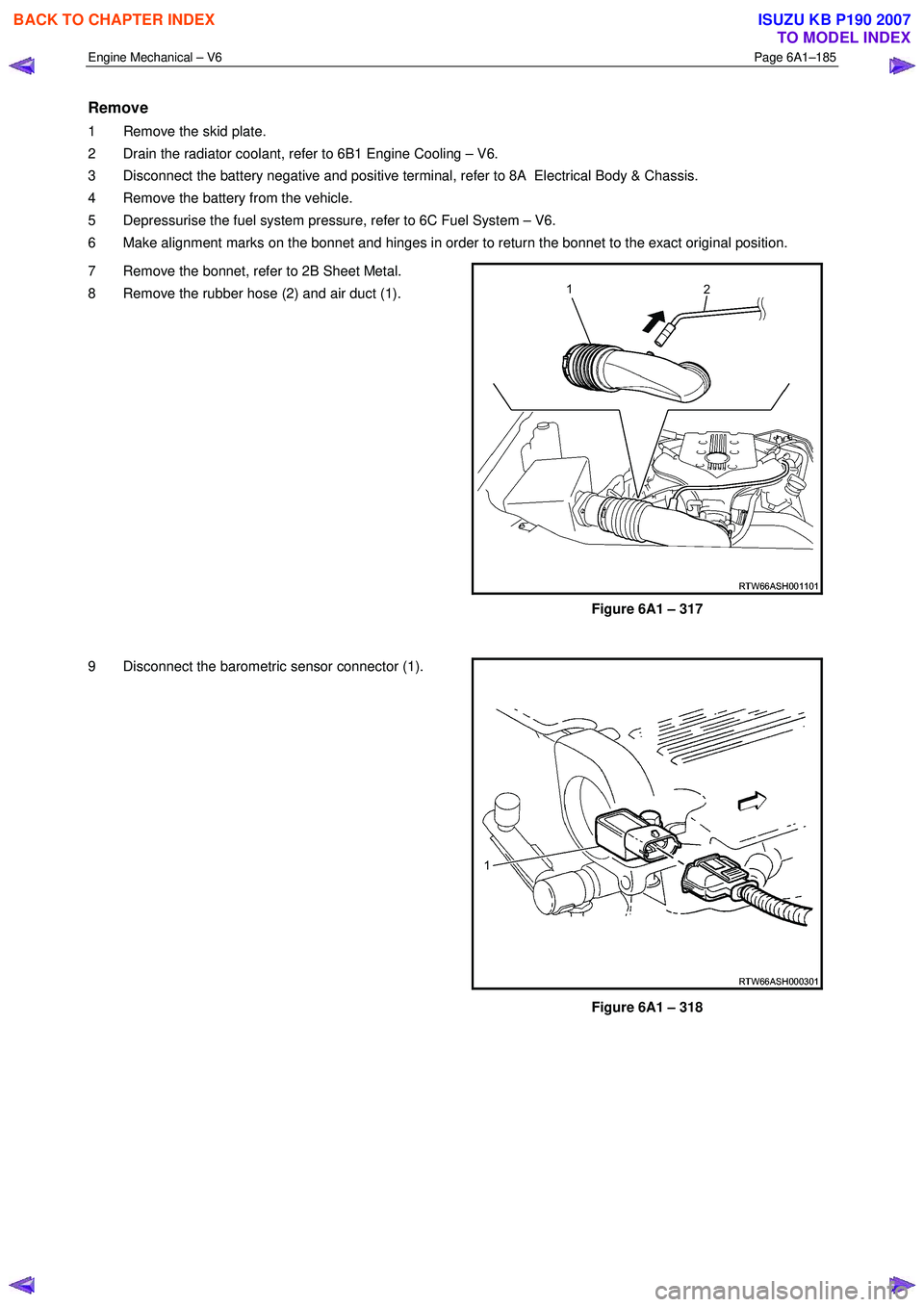

8 Remove the rubber hose (2) and air duct (1).

Figure 6A1 – 317

9 Disconnect the barometric sensor connector (1).

Figure 6A1 – 318

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2673 of 6020

Engine Mechanical – V6 Page 6A1–194

54 Remove the power steering pump bracket mounting

bolts (three places) then remove the pump bracket

(1).

Figure 6A1 – 342

55 Release the lower radiator hose clamp (1) and remove the lower hose from the coolant pipe (2).

Figure 6A1 – 343

56 Release the upper radiator hose clamp (1) and remove the upper hose from the coolant pipe (2).

Figure 6A1 – 344

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2676 of 6020

Engine Mechanical – V6 Page 6A1–197

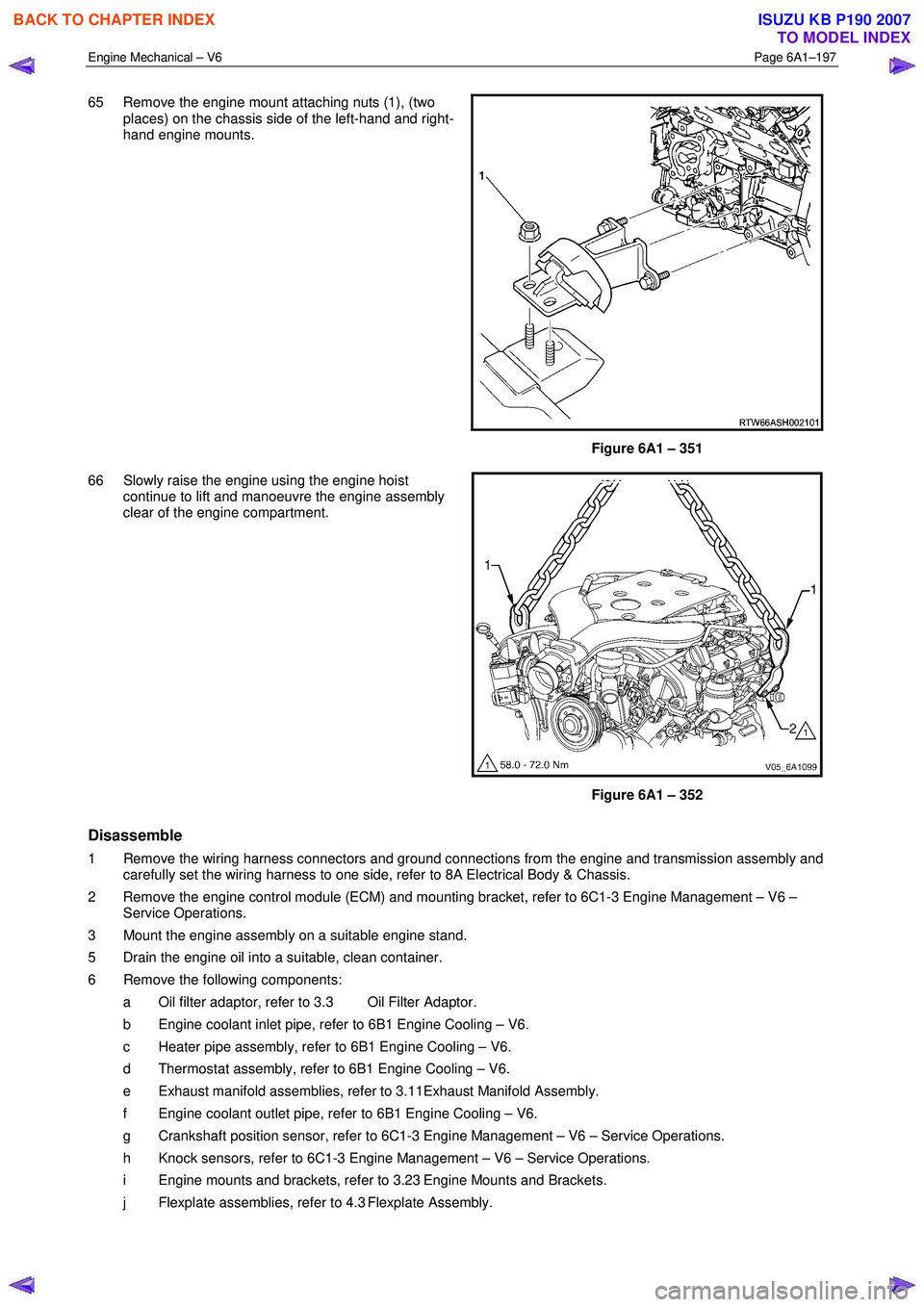

65 Remove the engine mount attaching nuts (1), (two

places) on the chassis side of the left-hand and right-

hand engine mounts.

Figure 6A1 – 351

66 Slowly raise the engine using the engine hoist continue to lift and manoeuvre the engine assembly

clear of the engine compartment.

Figure 6A1 – 352

Disassemble

1 Remove the wiring harness connectors and ground connections from the engine and transmission assembly and carefully set the wiring harness to one side, refer to 8A Electrical Body & Chassis.

2 Remove the engine control module (ECM) and mounting bracket, refer to 6C1-3 Engine Management – V6 – Service Operations.

3 Mount the engine assembly on a suitable engine stand.

5 Drain the engine oil into a suitable, clean container.

6 Remove the following components: a Oil filter adaptor, refer to 3.3 Oil Filter Adaptor.

b Engine coolant inlet pipe, refer to 6B1 Engine Cooling – V6.

c Heater pipe assembly, refer to 6B1 Engine Cooling – V6.

d Thermostat assembly, refer to 6B1 Engine Cooling – V6.

e Exhaust manifold assemblies, refer to 3.11Exhaust Manifold Assembly.

f Engine coolant outlet pipe, refer to 6B1 Engine Cooling – V6.

g Crankshaft position sensor, refer to 6C1-3 Engine Management – V6 – Service Operations.

h Knock sensors, refer to 6C1-3 Engine Management – V6 – Service Operations.

i Engine mounts and brackets, refer to 3.23 Engine Mounts and Brackets.

j Flexplate assemblies, refer to 4.3 Flexplate Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2677 of 6020

Engine Mechanical – V6 Page 6A1–198

k Timing chains, tensioners, shoes, guides & sprockets, refer to 3.16 Timing Chains, Tensioners, Shoes and

Guides.

l Cylinder head assemblies, refer to 3.22 Cylinder Head Assembly.

m Oil pan assembly, refer to 4.2 Oil Pan and Oil Pump Suction Pipe Assembly.

n Piston and connecting rod assemblies, refer to 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

o Crankshaft assembly, refer to 4.6 Crankshaft and Main Bearings.

p Piston oil nozzles, refer 4.5 Pistons, Pins, Rings, Connecting Rods and Big-end Bearings.

Reassemble

Reassembly of the engine assembly is the reverse of the disassembly procedure.

Reinstall

Reinstallation of the engine assembly is the reverse to the removal procedure, noting the following:

NOTE

Refer to 6 Torque Wrench Specifications

for the correct torque specifications.

1 Tighten the fasteners to the correct torque specification.

Engine ground connector bolt

torque specification ............................................10.0 Nm

Power steering high pressure line

attaching bolt torque specification .............8.0 – 12.0 Nm

Power steering high pressure line

flare nut torque specification ...................25.0 – 35.0 Nm

Engine mount to frame attaching bolt

torque specification .................................44.0 – 60.0 Nm

Knock Sensor Attaching Nut

torque specification ............................................23.0 Nm

2 Use only the specified engine lubricant type and quantity. It is recommended that a fluorescent oil dye, such as that contained in J 28481-B, be added to assist in any future oil leak diagnosis.

3 Fill the cooling system with the correct quantity and grade of coolant, refer to 6B1 Engine Cooling – V6.

4 Check transmission fluid level, replenishing as required, using the specified lubricant for the transmission fitted, refer to 7C1 Automatic – 4L60E – General Information.

5 Disable the ignition system, refer to 6C1-3 Engine Management – V6 – Service Operations.

6 Crank the engine several times. Listen for any unusual noises or evidence that parts are binding.

7 Enable the ignition system. Start the engine and listen for any unusual noises.

8 Check the vehicle oil pressure gauge or warning indicator and confirm the engine has acceptable oil pressure. If required, install an oil pressure gauge and measure the engine oil pressure, refer to 2.19 Engine Oil Pressure

Diagnosis.

9 Run the engine at about 1,000 r.p.m. until the engine has reached normal operating temperature.

10 Listen for any unusual noises.

11 Check for oil, fuel, coolant and exhaust leaks while the engine is running, correcting as required.

12 Perform a final inspection for correct engine oil and coolant levels.

4.2 Oil Pan and Oil Pump Suction Pipe Assembly

Remove

1 Remove the engine assembly from the vehicle, refer to 4.1 Engine .

2 Separate the engine and transmission assemblies, refer to 7C1 Automatic – 4L60E – General Information.

3 Mount the engine assembly on a suitable engine stand.

4 Remove the engine front cover, refer to 3.15 Front Cover Assembly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2715 of 6020

Engine Mechanical – V6 Page 6A1–236

5 Remove the right-hand side M14 coolant drain

threaded plug (1).

Figure 6A1 – 440

6 Remove the rear M14 oil gallery threaded plug (1).

Figure 6A1 – 441

7 Remove the left-hand side M14 coolant drain threaded plug (1).

Figure 6A1 – 442

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2716 of 6020

Engine Mechanical – V6 Page 6A1–237

8 Remove the left-hand side M20 oil gallery threaded

plug (1).

Figure 6A1 – 443

CAUTION

Do not force coolant expansion plugs

downwards during removal procedure as the

cylinder block will be damaged.

9 Remove the coolant expansion plugs (1).

Figure 6A1 – 444

10 Remove the cylinder block-to-transmission alignment dowels (1).

Figure 6A1 – 445

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2720 of 6020

Engine Mechanical – V6 Page 6A1–241

2 Install a new front oil gallery expansion plug (1).

Figure 6A1 – 451

3 Install the cylinder block-to-transmission alignment dowels (1).

Figure 6A1 – 452

4 Place RTV sealant on new coolant expansion plugs (1) and install the new coolant expansion plugs.

Figure 6A1 – 453

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2721 of 6020

Engine Mechanical – V6 Page 6A1–242

5 Install the left-hand side M20 oil gallery threaded plug

(1) and tighten to the correct torque specification.

Left-hand side M20 cylinder block

oil gallery threaded plug

torque specification .................................27.0 – 35.0 Nm

Figure 6A1 – 454

6 Install the left-hand side M14 coolant drain threaded plug (1) and tighten to the correct torque specification.

Left-hand side M14 cylinder block

coolant drain threaded plug

torque specification .................................27.0 – 35.0 Nm

Figure 6A1 – 455

7 Install the M14 rear oil gallery threaded plug (1) and tighten to the correct torque specification.

M14 cylinder block rear oil gallery

threaded plug torque specification ..........27.0 – 35.0 Nm

Figure 6A1 – 456

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007