fuse ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3903 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–117

2 1 Connect Tech 2 to the DLC.

2 Turn on the ignition, with the engine off.

NOTE

Before clearing the DTC, use the Tech 2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3 On Tech 2 select: Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4 Select the relevant DTC and note the parameters at the time of the DTC setting.

5 On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6 Follow the instructions on Tech 2 and clear the DTCs.

Are any of the following DTCs also set?

• P0787

• P0973

• P0976

• P2764.

Go to Step 3 Go to Step 4

3 Inspect fuse F8 and check if it is blown, refer to 8A Electrical-Body

and Chassis.

Is the fuse blown? Replace the fuse

Go to Step 9 Go to Step 5

4 1 Turn off the ignition.

2 Disconnect connector E-95 from the transmission.

NOTE

Additional DTCs may set.

3 Install Tool No. J 44152 Jumper Harness (20 pins) on to the harness connector E-95.

4 Turn on the ignition, with the engine off.

5 Using a test lamp, probe between connector E-95 pin 10 and a known ground.

Does the test lamp illuminate? Go to Step 7 Go to Step 12

5 1 Using a test lamp, probe connector E-95 pin 10 with the ground

lead to connector E-95 pin 20.

2 On Tech 2 select: Automatic Transmission / Miscellaneous Tests / TCC

Solenoid.

3 With Tech 2 command the TCC Solenoid On and

Off three

times.

Does the test lamp turn on and off with each command? Go to Step 7 Go to Step 6

6 Is the test lamp always illuminated? Go to Step 13 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3957 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–44

b Starter motor, refer to 6D1-2 Starting System.

b Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

6 On 4WD vehicle, disconnect the harness two clips from the upper side of the transfer case.

7 From within the starter motor access hole, remove the three bolts (2) attaching the torque converter to the flexplate and discard, refer to Figure 7C4 – 62.

8 Remove the transmission support, refer to 3.7 Transmission Support and Mount.

9 Disconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

Before lowering the transmission take care of

the following:

• Do not strain the harness and connector

as the connector pins could be

permanently damaged.

• Ensure the inlet manifold does not hit the

firewall.

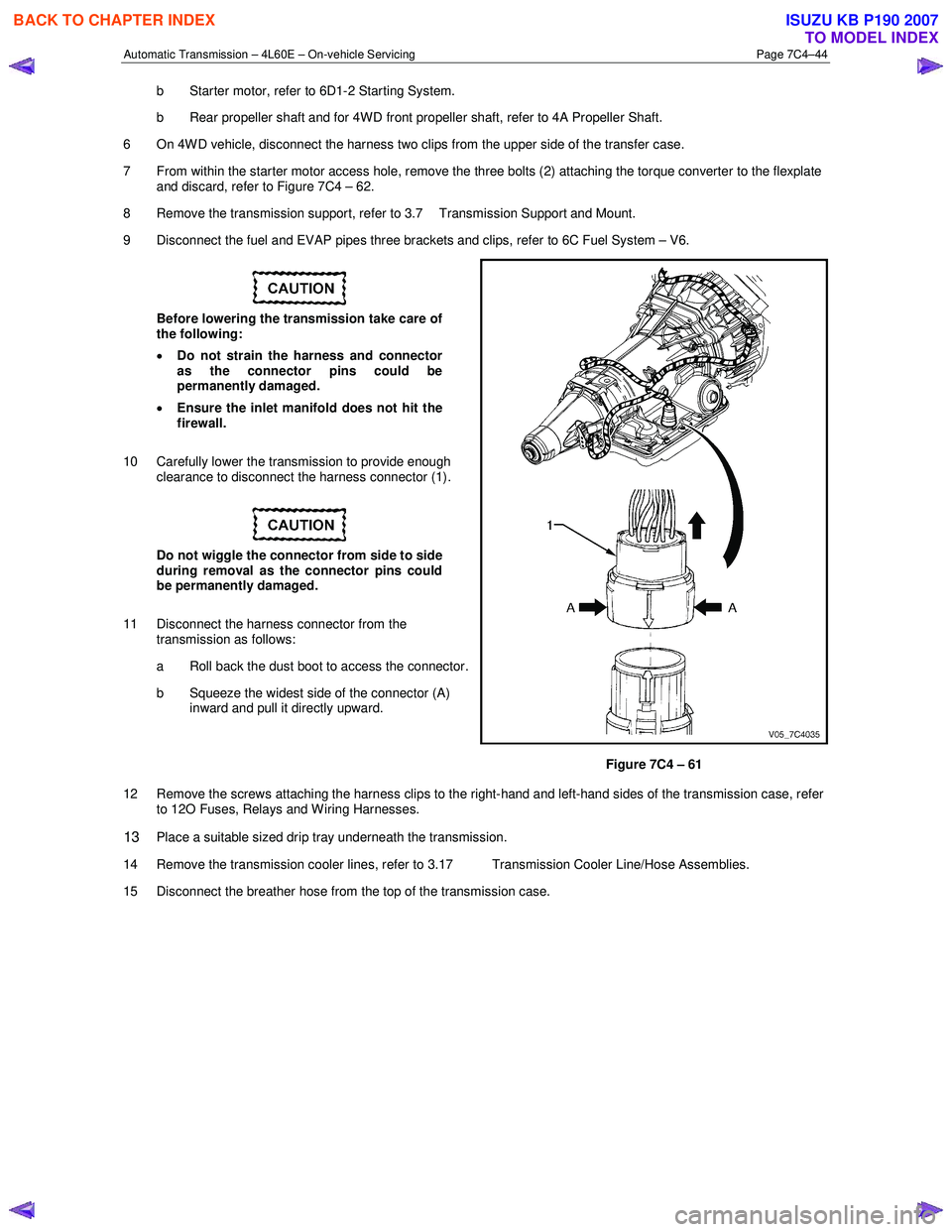

10 Carefully lower the transmission to provide enough clearance to disconnect the harness connector (1).

Do not wiggle the connector from side to side

during removal as the connector pins could

be permanently damaged.

11 Disconnect the harness connector from the transmission as follows:

a Roll back the dust boot to access the connector.

b Squeeze the widest side of the connector (A) inward and pull it directly upward.

Figure 7C4 – 61

12 Remove the screws attaching the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and W iring Harnesses.

13 Place a suitable sized drip tray underneath the transmission.

14 Remove the transmission cooler lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

15 Disconnect the breather hose from the top of the transmission case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3959 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–46

Reinstall

1 If required on 4W D vehicle, reinstall the transfer case, refer to 7D Transfer Case and Adaptor Housing.

2 Ensure the transmission and the engine mating surfaces are clean and free of burrs.

3 Lubricate the torque converter spigot (7) with a small amount of high temperature wheel bearing grease, refer to Figure 7C4 – 62.

4 Install a new filler tube seal into the transmission case.

Support the transmission while installing the

attaching bolts to avoid damage to the torque

converter and flexplate. Do not have the

transmission hanging.

5 Bring the transmission up to the engine, inserting the filler tube and ensuring the locating dowels completely enter the torque converter housing.

6 Reconnect the breather hose to the top of the transmission case.

NOTE

The bolts attaching the torque converter housing

are facing forward except for the bolt in position ℑ

which is facing rearward.

7 With the transmission supported, install the bolt (1), nine places, attaching the torque converter housing to the engine and tighten to the correct torque specification following the sequence shown in

within Figure 7C4 – 62.

Torque converter housing attaching

bolt torque specification .......................... 52.0 – 66.0 Nm

8 Remove the access hole cover plate from the lower surface of the housing and push the torque converter forward to meet the flexplate, then hand start three new bolts (2) before tightening to the correct torque specification.

Reinstall the access hole cover plate.

Torque converter to flexplate attaching

bolt torque specification .......................... 60.0 – 70.0 Nm

9 Reinstall the bolt (3) and torque converter cover (4) on the transmission right-hand side and the bolt (5) and torque converter cover (6) on the transmission left-hand side, tighten the bolts to the correct torque specification.

Torque converter cover attaching

bolt torque specification .......................... 12.0 – 16.0 Nm

10 Reinstall the transmission fluid lines, refer to 3.17 Transmission Cooler Line/Hose Assemblies.

Prior to connecting the harness connector to

the transmission, check that all pins and

seals are in sound condition and the dust

boot is not torn or damaged.

11 Reconnect the transmission harness connector to the transmission as follows: a Push straight down on the connector body until a click is heard.

b Reinstall the dust boot ensuring it is correctly located.

12 Attach the harness clips to the right-hand and left-hand sides of the transmission case, refer to 12O Fuses, Relays and Wiring Harnesses.

13 On 4WD vehicle, connect the harness two clips from the upper side of the transfer case.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3984 of 6020

7A2-18 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Normal

C07RY005-1

2. Indicator is flashing and the flash is 0.4 seconds

“ON” and 0.4 seconds “OFF” always when ignition is

on (engine cranked or not). This means that there is

a malfunction. Go to On-Board Diagnostic (OBD)

System Check .

Abnormal

C07RY00042-1

3. Indicator is staying “ON” always when Ignition is

“ON”.

1. This means that connection between the lamp

and the indicator control unit is shorted to

ground.

2. Verify if instrument panel terminal 25 o

f

connector B–23 is shorted to ground.

3. Verify if the indicator control unit connector C–

95 terminal 3 is shorted to ground.

4. Verify that the instrument panel terminal 8 o

f

connector B–24 is connected to battery.

5. If a problem was solved: Go to Check Trans

Indicator .

NO: Replace Transmission Control Module

(TCM).

4. Indicator is staying “OFF” with the ignition “ON”

(engine “OFF”).

1. This means that connection between the lamp

and the indicator control unit is shorted to

battery or opened.

2. Verify if instrument panel terminal 25 o

f

connector B–23 is shorted to battery or open.

3. Verify if the indicator control unit connector C–

95 terminal 3 is shorted to battery or open.

4. Verify that the instrument panel terminal 25 o

f

connector B–23 is connected to battery. If not,

check the meter fuse and the connections

(terminal 2 of connector H–7) voltage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4002 of 6020

7A2-36 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Trouble Code Clear Method:

If you have Tech 2:

Follow the procedure "DIAGNOSIS WITH TECH 2" in

this manual.

If you have no Tech 2:

Remove ECM (B) fuse (10A) for at least 10 seconds

with the ignition switched off.

NOTE:

If you clear the DTC you will not be able to read an

y

codes recorded during the last occurrence.

To use the DTC again to identify a problem, you will

need to reproduce the fault or the problem. This ma

y

require a new test drive or just turning the key switch on

(this depends on the nature of the fault).

12141414323232

In case DTC 14 & 32 are stored:

TCM Precaution

The TCM can be damaged by:

1. The electrostatic discharge

2. The short circuit of some terminals to voltage or to

ground.

Electrostatic Discharge Damage Description: 1. Electronic components used to control systems are often designed to carry very low voltage, and

are very susceptible to damage caused b

y

electrostatic discharge. It is possible for less than

100 volts of static electricity to cause damage to

some electronic components. By comparison, it

takes as much as 4,000 volts for a person to even

feel the zap of a static discharge.

2. There are several ways for a person to become statically charged. The most common methods o

f

charging are by friction and induction. An example

of charging by friction is a person sliding across a

car seat, in which a charge of as much as 25,000

volts can build up. Charging by induction occurs

when a person with well insulated shoes stands

near a highly charged object and momentaril

y

touches ground. Charges for the same polarity are

drained off, leaving the person highly charged with

the opposite polarity. Static charges of either type

can cause damage, therefore, it is important to use

care when handling and testing electronic

components.

NOTE: To prevent possible electrostatic discharge

damage:

1. Do not touch the TCM connector pins or soldered

components on the TCM circuit board.

2. Be sure to follow the guidelines listed below i

f

servicing any of these electronic components:

3. Do not open the replacement part package until it is time to install the part.

4. Avoid touching electrical terminals of the part.

5. Before removing the part from its package, ground

the package to a known good ground on the

vehicle.

6.

Always touch a known good ground before handling

the part. This step should be repeated before

installing the part if the part has been handled while

sliding across the seat, while sitting down from a

standing position or while walking some distance.

Information On TCM

1. The Transmission Control Module (TCM) is located

in the place of a clutch pedal and is the control

center of the electronic transmission control system.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4019 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-53

• No L-up solenoid functional failure detection.

• Check Trans “ON”.

• DTC stored.

• MIL request “ON”. (EURO 4 only)

Conditions For Clearing The DTC

• The DTC can be cleared from the TCM history by

using a scan tool.

• The DTC will be cleared from history when the

vehicle has achieved 40 warm-up cycles without a

failure reported.

•

After more than 1 second has elapsed after the

ignition key has been turned “ON”, short between

No.11 and No.4 (ground) of DLC (Data Link

Connector). Then, after 1 second, but within 6

seconds, discontinue shorting.

Diagnostic Aids

•

Inspect the wiring for poor electrical connection at the

TCM. Look for possible bent, backed out, deformed

or damaged terminals. Check for weak terminal

tension as well. Also check for a chafed wire that

could short to bare metal or other wiring. Inspect for a

broken wire inside the insulation.

• W hen diagnosing for a possible intermittent short o

r

open condition, move the wiring harness while

observing test equipment for a change.

• Check oil temperature sensor for proper mounting

and adjustment.

Circuit/System Testing DTC P0713

Step Action Value(s) YES NO

1

W as the On-Board Diagnostic (OBD) System Check

performed ? — Go to

Step 2 Go to OBD

System check

2 Perform the transmission fluid checking procedure. Refer to Checking Transmission Fluid Level and

condition Automatic Transmission 7A section.

W as the fluid checking procedure performed? — Go to

Step 3 Refer to

checking

Transmission

Fluid Level and Condition

Automatic

Transmission

(AW 30-40LE) section

3 1. Lift the driving wheels.

2. Start the engine and place the select lever in D

position.

3. W ait for 15 minutes.

Does a scan tool indicate DTC P0713? — Go to

Step 4 Refer to

Diagnostic Aids

4 Observe the voltage of the oil temperature sensor on the Tech 2 data.

1. Turn “OFF” the ignition.

2. Disconnect the oil temperature sensor connector

E-83

3. Install a fused jumper wire from terminal E83-2 to E83-1 on the transmission harness.

4. Turn “ON” the ignition.

Does a scan tool indicate specified value? About 0V Go to

Step 5 Go to Step 6

5 Replace the transmission fluid temperature sensor.

If the action complete? — Go to

Step 9 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4020 of 6020

7A2-54 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Step Action Value(s) YES NO

6 Measure the resistance of wire by the 5-8840-0285-0

DMM.

1. Turn “OFF” the ignition.

2. Disconnect the TCM connector.

3. Install a fused jumper wire between terminals E83-

1 and E83-2 on the transmission harness.

Does DMM indicate specified value? Less than

1

Ω

Go to Step 8 Go to Step 7

7 An open circuit between TCM from oil temperature

sensor.

Repair the harness.

Is the action complete ? — Go to

Step 9 —

8 Replace the TCM

Important: The replacement TCM must be

programmed. (Refer to SPS for procedure.)

Is the action complete? — Go to

Step 9 —

9 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with a scan tool.

3. Turn “OFF” the ignition.

4. Start the engine.

5. Operate the vehicle within the Conditions For Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame/ Failure Records.

Did the DTC fail this ignition? — Go to

Step 2 Go to Step 10

10 Observe the stored information, Capture Info with a

scan tool.

Are there any DTCs that you have not diagnosed? — Go

to

Diagnostic

Trouble Code (DTC) List Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4305 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-21

Diagnostic Information and Procedures

Diagnostic Starting Point - Transmission Controls

Begin the system diagnosis with Diagnostic System

Check - Transmission Controls. The Diagnostic System

Check - Transmission Controls will provide the

following information:

• The identification of the control modules which command the system.

• The ability of the control modules to communicate through the serial data circuit.

• The identification of any stored diagnostic trouble codes (DTCs) and the their statuses.

The use of the Diagnostic System Check -

Transmission Controls will identify the correct

procedure for diagnosing the system and where the

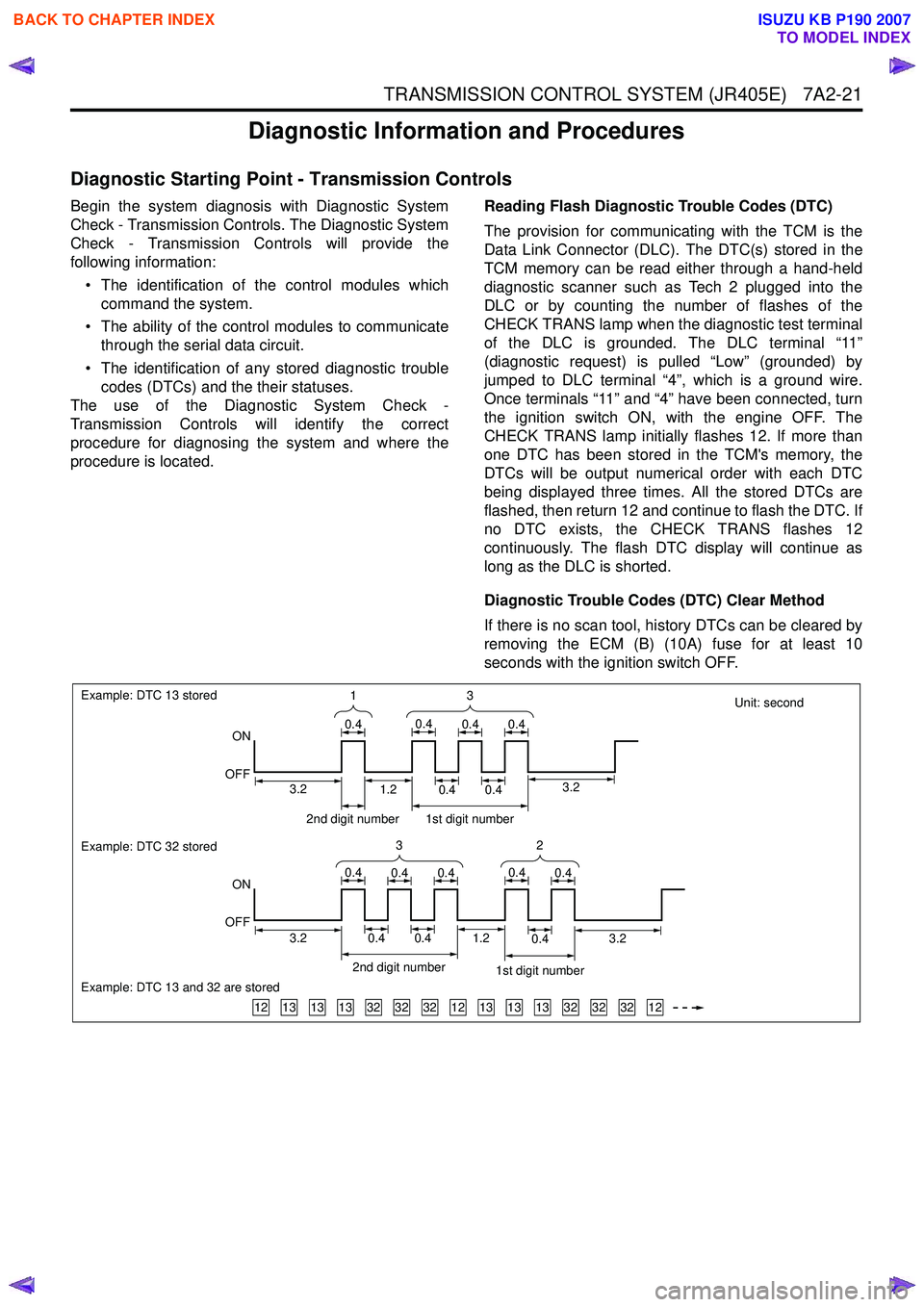

procedure is located. Reading Flash Diagnostic Trouble Codes (DTC)

The provision for communicating with the TCM is the

Data Link Connector (DLC). The DTC(s) stored in the

TCM memory can be read either through a hand-held

diagnostic scanner such as Tech 2 plugged into the

DLC or by counting the number of flashes of the

CHECK TRANS lamp when the diagnostic test terminal

of the DLC is grounded. The DLC terminal “11”

(diagnostic request) is pulled “Low” (grounded) by

jumped to DLC terminal “4”, which is a ground wire.

Once terminals “11” and “4” have been connected, turn

the ignition switch ON, with the engine OFF. The

CHECK TRANS lamp initially flashes 12. If more than

one DTC has been stored in the TCM's memory, the

DTCs will be output numerical order with each DTC

being displayed three times. All the stored DTCs are

flashed, then return 12 and continue to flash the DTC. If

no DTC exists, the CHECK TRANS flashes 12

continuously. The flash DTC display will continue as

long as the DLC is shorted.

Diagnostic Trouble Codes (DTC) Clear Method

If there is no scan tool, history DTCs can be cleared by

removing the ECM (B) (10A) fuse for at least 10

seconds with the ignition switch OFF.

Unit: second

131313323232121313133232321212

Example: DTC 13 stored

ON

OFF

Example: DTC 32 stored

Example: DTC 13 and 32 are stored

ON

OFF 3

1

0.40.40.40.4

32

0.40.40.40.40.4

2nd digit number1st digit number

3.23.20.40.40.41.2

2nd digit number 1st digit number

0.40.41.23.23.2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4312 of 6020

7A2-28 TRANSMISSION CONTROL SYSTEM (JR405E)

Scan Tool Does Not Power Up

Circuit Description

The data link connector (DLC) is a standardized 16-

cavity connector. Connector design and location is

dictated by an industry wide standard, and is required

to provide the following:

• Scan tool power battery positive voltage at terminal 16

• Scan tool power ground at terminal 4 • Common signal ground at terminal 5

The scan tool will power up with the ignition OFF. Some

modules however, will not communicate unless the

ignition is ON.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Scan Tool Does Not Power Up

Step Action Value(s)Yes No

1 Important:

Make sure the scan tool works properly

on another vehicle before using this chart.

1. Turn OFF the ignition.

2. Inspect the Meter (+B) (10A) fuse in the cabin fuse block.

Is the Meter (+B) (10A) fuse open? —

Go to Step 2 Go to Step 3

2 Replace the Meter (+B) (10A) fuse. If the fuse

continues to open, repair the short to ground on

one of the circuits that is fed by the Meter (+B)

(10A) fuse or replace the shorted attached

component.

Did you complete the repair? —

Go to Step 7 —

3 1. Check each circuit at the data link connector

(DLC) (B-58) for a backed out, spread or

missing terminal.

2. Repair the terminal as necessary.

Did you find and complete the repair? —

Go to Step 7 Go to Step 4

4 Connect a test lamp between the +B circuit (pin 16

of B-58) at the DLC and a known good ground.

Does the test lamp illuminate? —

Go to Step 6 Go to Step 5

5 Repair the open in the battery voltage circuit to the

DLC.

Did you complete the repair? —

Go to Step 7 —

6 1. Test each ground circuit at the DLC (pins 4

and 5 of B-58) for an open circuit or high

resistance.

2. Repair the circuit(s), clean or tighten ground as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Intermittent

Conditions

7 1. Connect the scan tool to the DLC.

2. Attempt to turn ON the scan tool.

Does the scan tool ON? —

System OK Go to Step 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4315 of 6020

![ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup ISUZU KB P190 2007 Workshop Repair Manual TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and sup](/img/61/57177/w960_57177-4314.png)

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-31

Lost Communication with The Transmission Control Module (TCM)

Circuit Description

The TCM, electronic hydraulic control unit (EHCU)

[ABS module] and supplemental restraint system

(SRS) control module all communicate with the scan

tool over the Keyword serial data link. Schematic Reference:

Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Lost Communication with The Transmission Control Module (TCM)

Step Action ActionYes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Transmission

Controls

2 Attempt to establish communication with the TCM.

Does the scan tool communicate with the TCM? —

Go to Intermittent

Conditions Go to Step 3

3 1. Inspect for an intermittent, for poor

connections and for corrosion at the TCM C-

94 and C-95 harness connectors.

2. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 4

4 1. Check the TCM (15A) in the cabin fuse block.

Replace and retest if open. If any fuse

continues to open, repair the short to ground

on each circuit fed by that fuse.

2. Turn OFF the ignition.

3. Disconnect the TCM C-95 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at

the TCM (pins 18 and 24 of C-95).

Does the test lamp illuminate? —

Go to Step 6 Go to Step 5

5 Repair the open in the ignition voltage circuit to the

TCM.

Did you complete the repair? —

Go to Step 9 —

6 1. Turn OFF the ignition.

2. Disconnect the TCM C-94 harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the TCM (pin 5 of C-94).

4. Test the Keyword serial data circuit between the TCM (pin 5 of C-94) and the DLC (pin 7 of

B-58) for an open circuit or high resistance.

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 7

7 1. Check TCM ground for corrosion and

tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition? —

Go to Step 9 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007