sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1365 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-5

EGR system

Based upon data, including water temperature, engine

speeds or engine loads, it is controlled via Engine

Control Module (ECM) to purify exhaust by recycling

part of it.

Its main components include an EGR valve, an EGR

cooler and various sensors.

Connecting rod cap bolt

The angular tightening method of the connecting rod

cap bolt further increases reliability and durability.

Fuel rail-type electronic control injection system

The fuel rail-type electronic control injection system is

composed of a fuel supply pump that sets the target

pressure of high-pressure fuel and supply it, a fuel rail

that measures such high-pressure fuel and a fuel

injector that turns it into a fine spray and injects it. Each

is controlled via ECM based upon various signals, while

injection timing or fuel injection quantity is controlled

under every possible driving condition.

Fuel injector

The fuel injector is a 6-hole nozzle that adjusts fuel

injection quantity or injection timing by opening o

r

closing an electromagnetic valve on the head of the fuel

injector.

ECM corrects the dispersion of fuel injection quantit

y

between fuel injector according to ID code data in

memory. At the replacement of fuel injector, ID code

data should be stored in ECM.

Fuel filter with sedimenter

It is a fuel filter with sedimenter that gets rid of water by

making use of the difference in specific gravity between

light oil and water, which comes with an indicator that

notifies you that it is filled with water.

Preheating system

The preheating system consists of the ECM, the glow

relay, glow plugs and the glow indicator lamp. The

preheating system is operated when the engine coolant

temperature is low, and makes the engine easy to start.

Lubrication system

It is an oil filter with full-flow bypass, which uses a

water-cool oil cooler and oil jet to cool the piston.

Functional inspection

Inspection/adjustment of valve clearance 1. Inspection of valve clearance

• Remove the fuel injector harness assembly.

• Remove the leak off hose.

• Remove the cylinder head cover.

• Rotate the crankshaft to make the No.1

cylinder meet the compression top dead cente

r

(TDC).

RTW 76ASH001301

Legend

1. TDC

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1368 of 6020

6A-8 ENGINE MECHANICAL (4JK1/4JJ1)

Trouble Shooting

Engine does not turn over

Condition Possible Cause Correction

Dead or weak battery Charge battery

Replace battery

Incomplete circuit Connect

Repair

Starter motor brushes stuck, worn,

or broken Replace brushes

Starter motor does not rotate

Starter motor internal damage Repair motor

Ring gear abrasion Replace ring gear Starter motor not meshed with

flywheel Magnetic switch (starter motor) not

properly adjusted Adjust

Dead or weak battery

Charge battery

Replace battery

Insufficient contact pressure

between starter motor brushes and

commutator Adjust pressure

Armature (starter motor) stuck Repair armature

Starter motor pinion meshed with

ring gear but does not rotate

Engine internal damage (Seizure) Repair engine

Engine turns over but does not start

Condition Possible Cause Correction

Air in fuel system Bleed air from fuel system

Air entering fuel pipe Replace pipe and bleed air from

fuel system

Empty fuel tank Replenish fuel

Clogged strainer (fuel suction) Clean or replace strainer

Clogged fuel pipe Clean or replace pipe

Feed pump malfunction Replace pump

Use of wrong fuel for prevailing

temperatures Drain existing fuel and replace with

appropriate fuel

Fuel is not delivered to fuel supply

pump

Clogged fuel filter Replace filter

Loose injection pipe connections Tighten connections

Loose or broken electrical

connectors Tighten and/or replace connectors

Bad rotational sensor

Replace sensor

Fuel is delivered to fuel supply

pump

Engine control system malfunction System diagnosis

Air in fuel system Bleed air from fuel system

Feed pump malfunction Repair pump

Loose or broken electrical

connectors Tighten and/or replace connectors

Clogged fuel filter

Replace filter

Insufficient or unstable fuel delivery

volume

Engine control system malfunction System diagnosis

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1369 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-9

Excessive black exhaust smoke

Condition Possible Cause Correction

Bad injection timing Engine control system malfunction System diagnosis

Carbon deposit at nozzle tip Clean fuel injector assembly

Sticking nozzle Replace fuel injector assembly

Bad fuel injector condition

Engine control system malfunction System diagnosis

Excessive valve clearance Adjust clearance

Sticking valve stem (valve open) Repair or replace valve

Damaged valve spring Replace spring

Valve seat abrasion Repair valve seat

Compression leakage due to

damaged piston ring Replace piston ring

Damaged gasket

Replace gasket

Insufficient compression pressure

Piston scoring Replace piston

W ater in fuel Drain existing fuel and replace with

new fuel Fuel condition

Poor fuel quality Drain existing fuel and replace with

new fuel

Clogged intake pipes Clean or replace pipes Poor engine aspiration

Clogged air cleaner element Clean or replace element

Defective sensor Replace sensor Malfunction detected by engine

control system Engine control system malfunction System diagnosis

Intake throttle valve sticking Repair or replace valve

EGR valve sticking Repair or replace valve

EGR valve and/or intake throttle

valve malfunction

Engine control system malfunction System diagnosis

Damaged turbocharger blade Replace turbocharger

Rough turbocharger shaft rotation Replace turbocharger

Oil leakage from oil seal Replace turbocharger

Turbocharger malfunction

Broken actuator Replace turbocharger

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1370 of 6020

6A-10 ENGINE MECHANICAL (4JK1/4JJ1)

Excessive white exhaust smoke

Condition Possible Cause Correction

Bad injection timing Engine control system malfunction System diagnosis

Defective sensor Replace sensor

Control unit malfunction Replace unit

Malfunction detected by engine

control system

Engine control system malfunction System diagnosis

Excessive valve clearance Adjust clearance

Sticking valve stem (valve open) Repair or replace valve

Damaged valve spring Replace spring

Valve seat abrasion Repair valve seat

Compression leakage due to

damaged piston ring Replace piston ring

Damaged gasket

Replace gasket

Insufficient compression pressure

Piston scoring Replace piston

Fuel condition W ater in fuel Drain existing fuel and replace with

new fuel

W orn or damaged piston ring(s) Replace ring(s)

Defective valve stem oil seal Replace oil seal

Defective turbocharger oil seal Replace turbocharger

Excessive oil consumption

Clogged turbocharger oil return

pipe Repair pipe

Engine knocking

Condition Possible Cause Correction

Bad timing Engine control system malfunction System diagnosis

Defective sensor Replace sensor

Control unit malfunction Replace unit

Malfunction detected by engine

control system

Engine control system malfunction System diagnosis

Fuel condition Poor quality fuel Drain existing fuel and replace with

new fuel

Clogged air cleaner element Clean or replace element

Clogged intake pipes Clean or replace pipes

Poor engine aspiration

Engine control system malfunction System diagnosis

Foreign material in cylinders Engine overhaul Engine break-down Scored pistons and/or bearings Replace pistons and/or bearings

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1375 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-15

Engine Assembly

Removal

1. Disconnect the negative battery cable.

2. Remove the engine hood.

3. Drain the coolant.

4. Remove the starter motor.

5. Remove the transmission assembly.

Refer to removal procedure for “TRANSMISSION” in this manual.

6. Disconnect the ECM harness connector.

7. Remove the ECM.

8. Remove the air cleaner. • Disconnect the MAF sensor harness connector.

• Remove the intake pipe with the lid of ai

r

cleaner box.

• Remove the air cleaner box.

RTW 76ASH000401

Legend

1. ECM Harness Connector

2. ECM

3. Air Cleaner Box

4. MAF Sensor Harness Connector

9. Remove the intake hose (intercooler - intake

throttle) (Standard output).

10. Remove the intake hose (turbocharger - intercooler) (Standard output).

Remove the harness connector.

RTW 56ASH004001

Legend

1. Intake Hose (intercooler - intake throttle)

2. Intake Hose (turbocharger - intercooler)

11. Remove the intercooler (High output).

• Disconnect the BARO sensor harness

connector (2).

• Remove the two intake hoses.

• Remove the intercooler (1).

RTW 76ASH000501

12. Remove the radiator upper hose.

13. Remove the engine harness clip (1).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1378 of 6020

6A-18 ENGINE MECHANICAL (4JK1/4JJ1)

21.Install the intake hose (intercooler - intake throttle)

(Standard output).

RTW 56ASH004001

22.Install the intercooler (High output).

• Install the intercooler.

• Install the two intake hoses.

• Connect the BARO sensor harness connector.

23.Install the air cleaner.

• Install the intake pipe with the lid of air cleane

r

box.

• Install the air cleaner box.

• Connect the MAF sensor harness connector.

24.Install the ECM.

25.Connect the ECM harness connector.

26.Install the transmission assembly.

Refer to installation procedure fo

r

“TRANSMISSION”.

27.Install the starter motor.

Tightening torque: 94 N ⋅

⋅⋅

⋅

m (9.6kg ⋅

⋅⋅

⋅

m / 69 lb ft)

28.Replenish the coolant.

29.Install the engine hood.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0kg ⋅

⋅⋅

⋅

m / 87 lb in)

30.Connect the negative battery cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1384 of 6020

6A-24 ENGINE MECHANICAL (4JK1/4JJ1)

Removal

1. Remove the engine cover.

2. Remove the intake air duct (3) (Standard output).

3. Remove the harness bracket (6).

RTW 56ASH025001

Legend

1. Blow-by Hose

2. Leak-off Hose

3. Intake Air Duct

4. Fuel Injector Connector

5. Leak-off Hose

6. Harness Bracket

4. Remove the intercooler (High output).

• Disconnect the BARO sensor harness

connector (2).

• Remove the two intake hoses.

• Remove the intercooler (1).

RTW 76ASH000501

5. Disconnect the fuel injector connector (2).

6. Remove the fuel leak off hose (1).

RTW 76ASH000101

Note: Do not reuse the clips (1).

LNW 76ASH002101

7. Disconnect the blow-by hose.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1386 of 6020

6A-26 ENGINE MECHANICAL (4JK1/4JJ1)

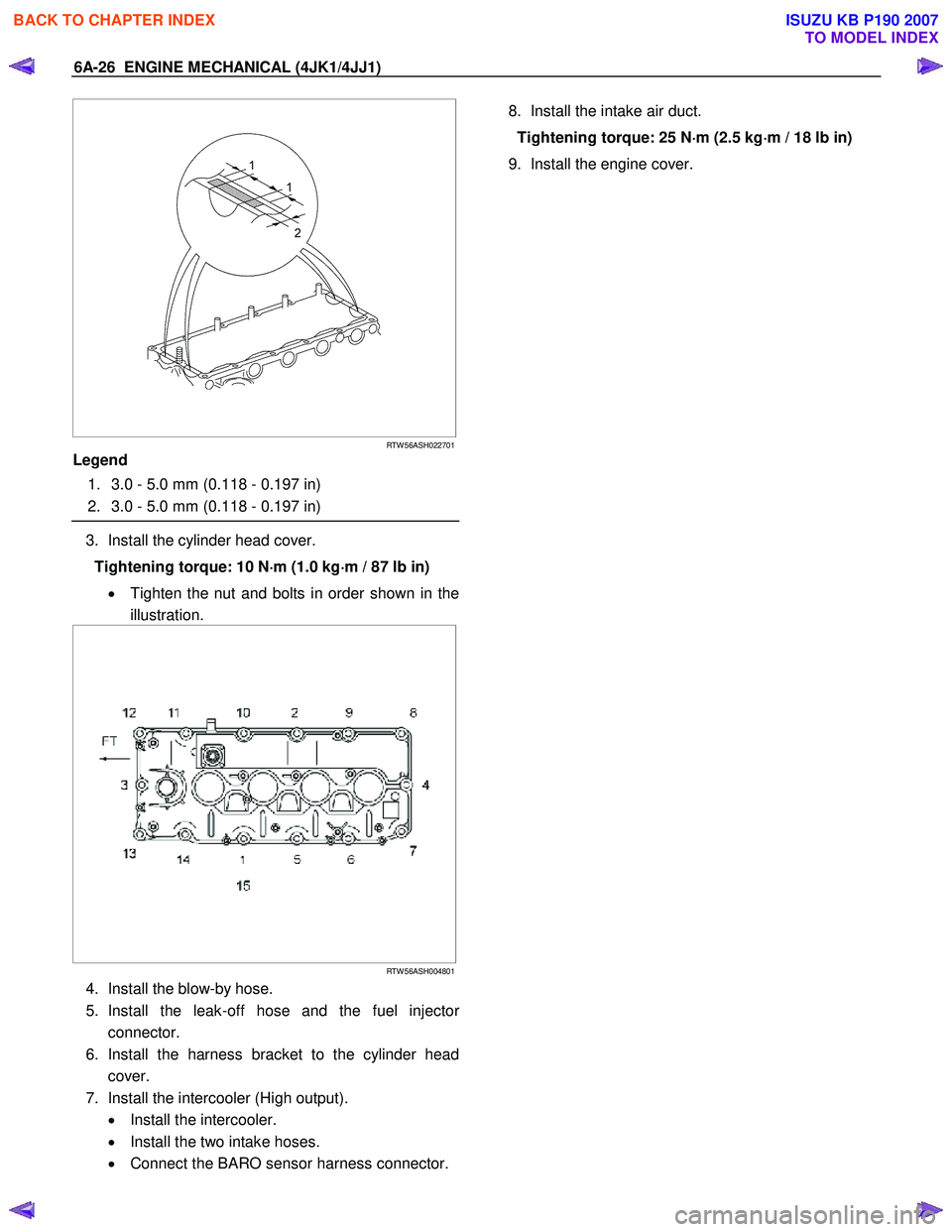

RTW 56ASH022701

Legend

1. 3.0 - 5.0 mm (0.118 - 0.197 in)

2. 3.0 - 5.0 mm (0.118 - 0.197 in)

3. Install the cylinder head cover.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kg ⋅

⋅⋅

⋅

m / 87 lb in)

• Tighten the nut and bolts in order shown in the

illustration.

RTW 56ASH004801

4. Install the blow-by hose.

5. Install the leak-off hose and the fuel injecto

r

connector.

6. Install the harness bracket to the cylinder head cover.

7. Install the intercooler (High output). • Install the intercooler.

• Install the two intake hoses.

• Connect the BARO sensor harness connector.

8. Install the intake air duct.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb in)

9. Install the engine cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1389 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-29

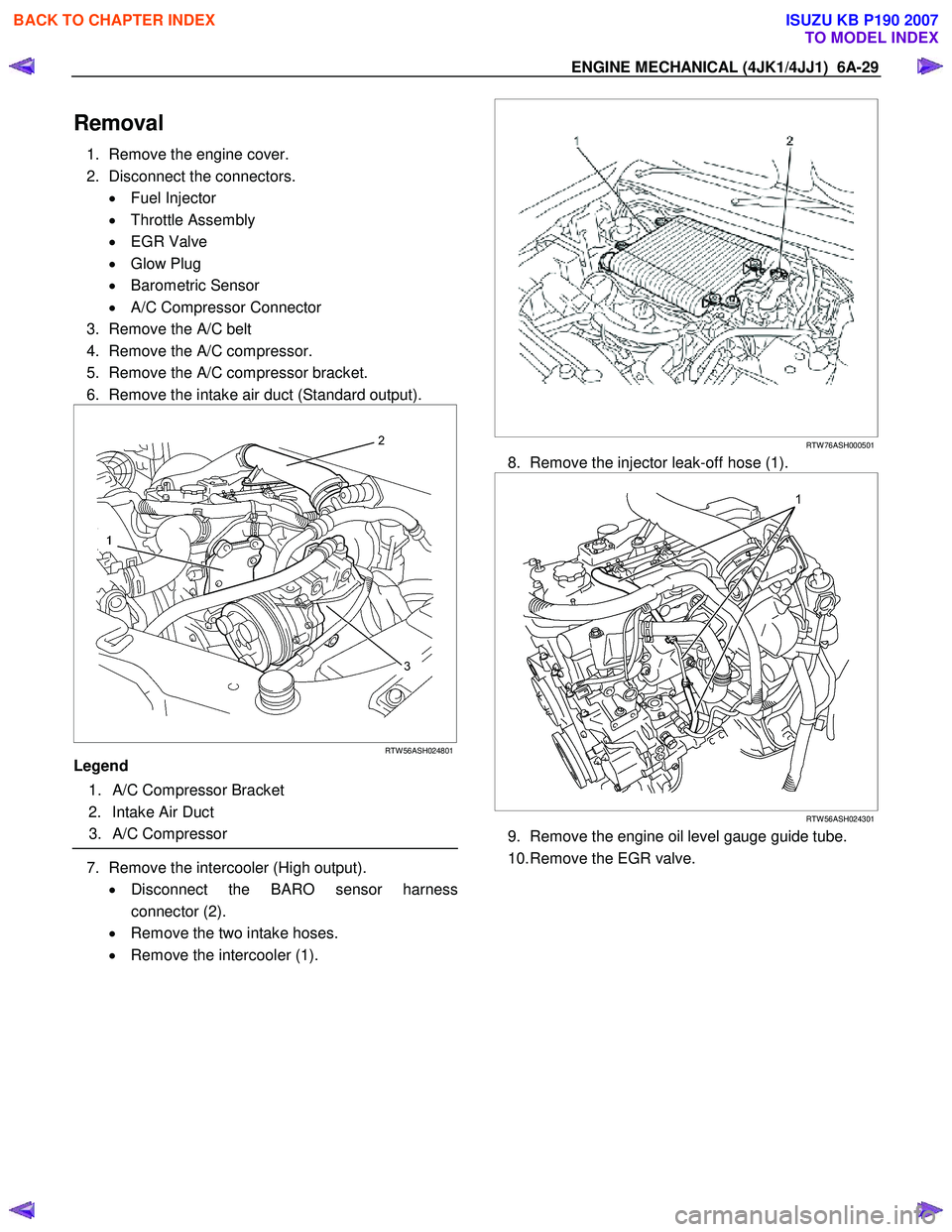

Removal

1. Remove the engine cover.

2. Disconnect the connectors. • Fuel Injector

• Throttle Assembly

• EGR Valve

• Glow Plug

• Barometric Sensor

• A/C Compressor Connector

3. Remove the A/C belt

4. Remove the A/C compressor.

5. Remove the A/C compressor bracket.

6. Remove the intake air duct (Standard output).

RTW 56ASH024801

Legend

1. A/C Compressor Bracket

2. Intake Air Duct

3. A/C Compressor

7. Remove the intercooler (High output).

• Disconnect the BARO sensor harness

connector (2).

• Remove the two intake hoses.

• Remove the intercooler (1).

RTW 76ASH000501

8. Remove the injector leak-off hose (1).

RTW 56ASH024301

9. Remove the engine oil level gauge guide tube.

10. Remove the EGR valve.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1391 of 6020

ENGINE MECHANICAL (4JK1/4JJ1) 6A-31

Installation

1. Install the intake manifold gasket.

2. Install the intake manifold. • Tighten the nuts and bolts in the orde

r

described in the drawing.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

RTW 56ASH018001

3. Install the throttle assembly and gasket.

• Tighten the bolts to the specified torque.

Tightening torque: 10 N ⋅

⋅⋅

⋅

m (1.0 kg ⋅

⋅⋅

⋅

m / 87 lb in)

4. Install the vacuum hose of swirl control valve.

5. Install the injection pipe (fuel rail - fuel injector). • It installs sequentially from No. 4 cylinder.

Tightening torque: 29 N ⋅

⋅⋅

⋅

m (3.0 kg ⋅

⋅⋅

⋅

m / 22 lb ft)

6. Install the EGR valve. • Tighten the nuts to the specified torque.

Tightening torque: 27 N ⋅

⋅⋅

⋅

m (2.8 kg ⋅

⋅⋅

⋅

m / 20 lb ft)

7. Install the engine oil level guide tube.

Tighten the nuts to the specified torque.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

8. Install the intercooler (High output).

9. Connect the connector of other parts. • Fuel Injector

• Throttle Assembly

• EGR Valve

• Glow Plug

• Barometric Sensor

• A/C Compressor Connector

10. Install the leak-off hose.

RTW 56ASH024301

Legend

1. Injector Leek-off Hose

11. Install the intake air duct.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

12.Install the A/C compressor bracket. Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m / 18 lb ft)

13.Install the A/C compressor and A/C compresso

r

connector.

Tightening torque: 44 N ⋅

⋅⋅

⋅

m (4.5 kg ⋅

⋅⋅

⋅

m / 33 lb ft)

14.Install the A/C belt.

Check the A/C belt tension.

Depress the A/C belt mid-portion with 98 N (10 kg

/

22 lb) force.

Standard deflection: 7.6 - 9.2 mm (0.29 - 0.36 in)

RTW 510SH000201

15. Install the engine cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007