check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1558 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-17

Record the Fuel Injector ID Code Data from

each injector housing

1. Remove each fuel injector harness connector.

2. Record all numbers of each cylinder on the harness connector housing. The correct order fo

r

the fuel injector ID codes of the following

illustration is as follows:

5F 05 00 FB 00 F7 08 F5 19 FF 04 49

RTW 76ESH002601

Legend

1. Fuel Injector ID Code

2. Fuel Injector

Programming Fuel Injector ID Codes

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Select Diagnostics > appropriate vehicle identification > 4JK1 or 4JJ1 > Programming >

Replace Injector.

4. In order to get programming approval, the on- screen displays a message to user. Get

programming approval from the TIS 2000 using

the following procedure:

a. Connect a scan tool to the terminal that installed TIS 2000 with the latest software and

the hardware key is plugged into port.

b. Turn ON the scan tool and keep at title screen.

c. Launch the TIS application.

d. Select the Security Access at the main screen.

e. Highlight the "Tech" 2 on the Diagnostic Tool Selection screen and click "Next".

f. Click "Close" on the Security Access Enabled screen.

g. Turn OFF the scan tool.

h. Disconnect the scan tool from the terminal.

5. Reinstall a scan tool to the vehicle.

6. Turn ON the ignition, with the engine OFF.

7. Select Diagnostics > appropriate vehicle identification > 4JK1 or 4JJ1 > Programming >

Replace Injector.

8. Enter 24 figures of replaced fuel injector ID code.

9.

After complete the programming, turn OFF the

ignition for 30 seconds.

10.Start the engine and let idle.

11.Inspect for a proper engine running condition and for no DTC's. Refer to the Diagnostic System

Check - Engine Controls if needed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1578 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-37

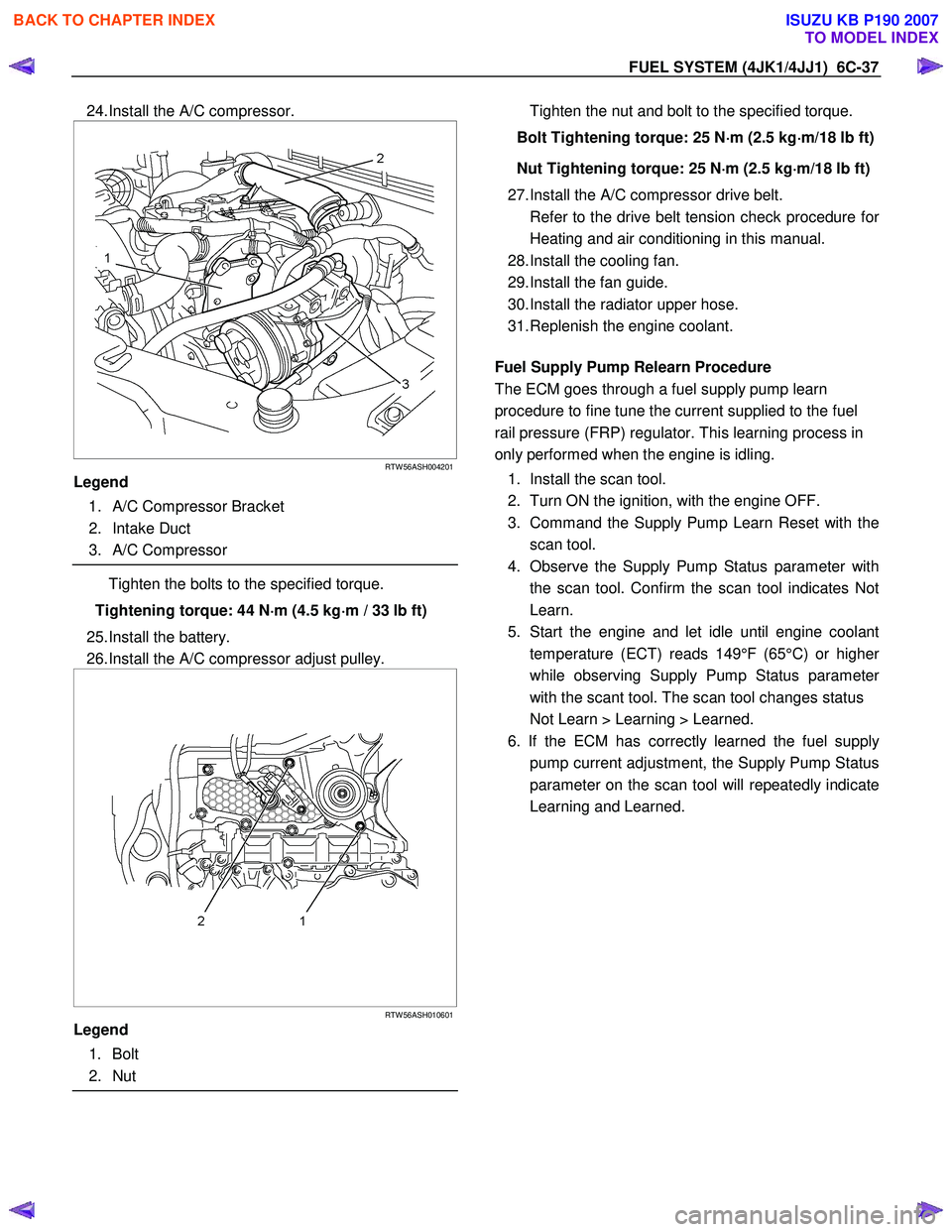

24. Install the A/C compressor.

RTW 56ASH004201

Legend

1. A/C Compressor Bracket

2. Intake Duct

3. A/C Compressor

Tighten the bolts to the specified torque.

Tightening torque: 44 N ⋅

⋅⋅

⋅

m (4.5 kg ⋅

⋅⋅

⋅

m / 33 lb ft)

25. Install the battery.

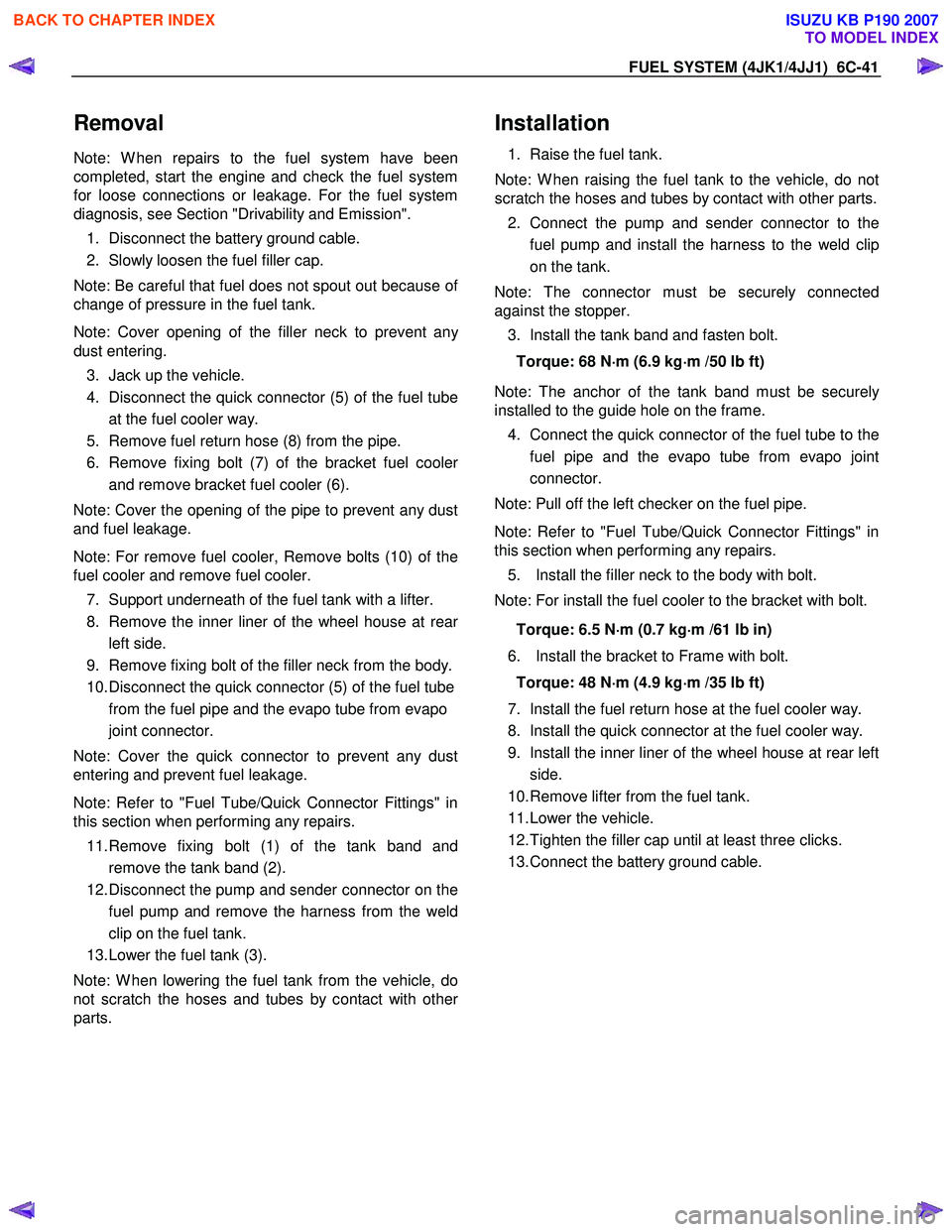

26. Install the A/C compressor adjust pulley.

RTW 56ASH010601

Legend

1. Bolt

2. Nut

Tighten the nut and bolt to the specified torque.

Bolt Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

Nut Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

27. Install the A/C compressor drive belt.

Refer to the drive belt tension check procedure fo

r

Heating and air conditioning in this manual.

28. Install the cooling fan.

29. Install the fan guide.

30. Install the radiator upper hose.

31. Replenish the engine coolant.

Fuel Supply Pump Relearn Procedure

The ECM goes through a fuel supply pump learn

procedure to fine tune the current supplied to the fuel

rail pressure (FRP) regulator. This learning process in

only performed when the engine is idling.

1. Install the scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Command the Supply Pump Learn Reset with the scan tool.

4. Observe the Supply Pump Status parameter with the scan tool. Confirm the scan tool indicates Not

Learn.

5. Start the engine and let idle until engine coolant temperature (ECT) reads 149°F (65°C) or highe

r

while observing Supply Pump Status parameter

with the scant tool. The scan tool changes status

Not Learn > Learning > Learned.

6. If the ECM has correctly learned the fuel supply pump current adjustment, the Supply Pump Status

parameter on the scan tool will repeatedly indicate

Learning and Learned.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1582 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-41

Removal

Note: W hen repairs to the fuel system have been

completed, start the engine and check the fuel system

for loose connections or leakage. For the fuel system

diagnosis, see Section "Drivability and Emission".

1. Disconnect the battery ground cable.

2. Slowly loosen the fuel filler cap.

Note: Be careful that fuel does not spout out because o

f

change of pressure in the fuel tank.

Note: Cover opening of the filler neck to prevent an

y

dust entering. 3. Jack up the vehicle.

4. Disconnect the quick connector (5) of the fuel tube at the fuel cooler way.

5. Remove fuel return hose (8) from the pipe.

6. Remove fixing bolt (7) of the bracket fuel coole

r

and remove bracket fuel cooler (6).

Note: Cover the opening of the pipe to prevent any dust

and fuel leakage.

Note: For remove fuel cooler, Remove bolts (10) of the

fuel cooler and remove fuel cooler.

7. Support underneath of the fuel tank with a lifter.

8. Remove the inner liner of the wheel house at rea

r

left side.

9. Remove fixing bolt of the filler neck from the body.

10. Disconnect the quick connector (5) of the fuel tube from the fuel pipe and the evapo tube from evapo

joint connector.

Note: Cover the quick connector to prevent any dust

entering and prevent fuel leakage.

Note: Refer to "Fuel Tube/Quick Connector Fittings" in

this section when performing any repairs.

11. Remove fixing bolt (1) of the tank band and remove the tank band (2).

12. Disconnect the pump and sender connector on the fuel pump and remove the harness from the weld

clip on the fuel tank.

13. Lower the fuel tank (3).

Note: W hen lowering the fuel tank from the vehicle, do

not scratch the hoses and tubes by contact with othe

r

parts.

Installation

1. Raise the fuel tank.

Note: W hen raising the fuel tank to the vehicle, do not

scratch the hoses and tubes by contact with other parts.

2. Connect the pump and sender connector to the fuel pump and install the harness to the weld clip

on the tank.

Note: The connector must be securely connected

against the stopper.

3. Install the tank band and fasten bolt.

Torque: 68 N ⋅

⋅⋅

⋅

m (6.9 kg ⋅

⋅⋅

⋅

m /50 lb ft)

Note: The anchor of the tank band must be securely

installed to the guide hole on the frame.

4. Connect the quick connector of the fuel tube to the fuel pipe and the evapo tube from evapo joint

connector.

Note: Pull off the left checker on the fuel pipe.

Note: Refer to "Fuel Tube/Quick Connector Fittings" in

this section when performing any repairs.

5. Install the filler neck to the body with bolt.

Note: For install the fuel cooler to the bracket with bolt.

Torque: 6.5 N ⋅

⋅⋅

⋅

m (0.7 kg ⋅

⋅⋅

⋅

m /61 lb in)

6. Install the bracket to Frame with bolt. Torque: 48 N ⋅

⋅⋅

⋅

m (4.9 kg ⋅

⋅⋅

⋅

m /35 lb ft)

7. Install the fuel return hose at the fuel cooler way.

8. Install the quick connector at the fuel cooler way.

9. Install the inner liner of the wheel house at rear left side.

10. Remove lifter from the fuel tank.

11. Lower the vehicle.

12. Tighten the filler cap until at least three clicks.

13. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1584 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-43

Removal

Note: W hen repairs to the fuel system have been

completed, start the engine and check the fuel system

for loose connections or leakage. For the fuel system

diagnosis, see Section "Drivability and Emission".

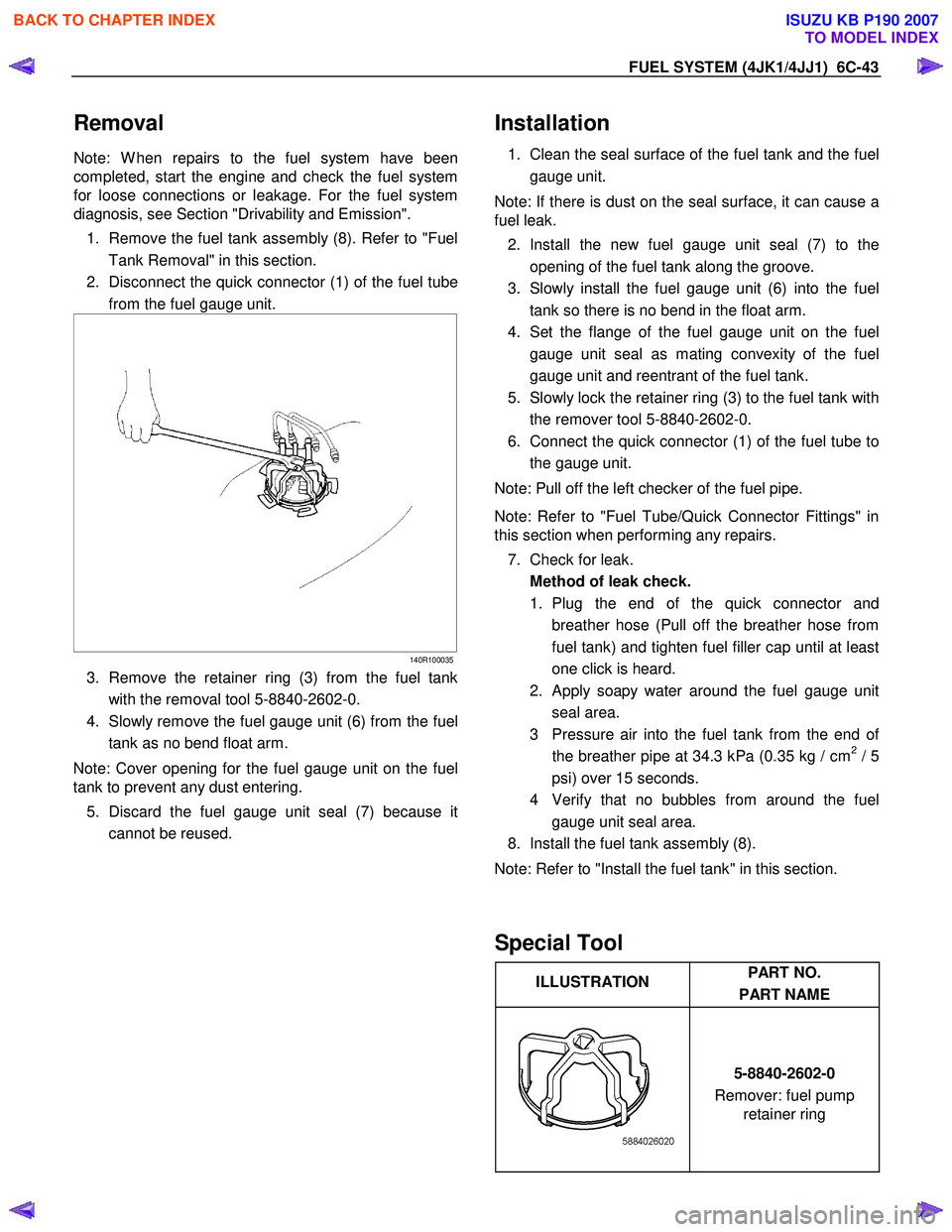

1. Remove the fuel tank assembly (8). Refer to "Fuel Tank Removal" in this section.

2. Disconnect the quick connector (1) of the fuel tube from the fuel gauge unit.

140R100035

3. Remove the retainer ring (3) from the fuel tank

with the removal tool 5-8840-2602-0.

4. Slowly remove the fuel gauge unit (6) from the fuel tank as no bend float arm.

Note: Cover opening for the fuel gauge unit on the fuel

tank to prevent any dust entering.

5. Discard the fuel gauge unit seal (7) because it cannot be reused.

Installation

1. Clean the seal surface of the fuel tank and the fuel

gauge unit.

Note: If there is dust on the seal surface, it can cause a

fuel leak.

2. Install the new fuel gauge unit seal (7) to the opening of the fuel tank along the groove.

3. Slowly install the fuel gauge unit (6) into the fuel tank so there is no bend in the float arm.

4. Set the flange of the fuel gauge unit on the fuel gauge unit seal as mating convexity of the fuel

gauge unit and reentrant of the fuel tank.

5. Slowly lock the retainer ring (3) to the fuel tank with the remover tool 5-8840-2602-0.

6. Connect the quick connector (1) of the fuel tube to the gauge unit.

Note: Pull off the left checker of the fuel pipe.

Note: Refer to "Fuel Tube/Quick Connector Fittings" in

this section when performing any repairs.

7. Check for leak. Method of leak check.

1. Plug the end of the quick connector and breather hose (Pull off the breather hose from

fuel tank) and tighten fuel filler cap until at least

one click is heard.

2. Apply soapy water around the fuel gauge unit seal area.

3 Pressure air into the fuel tank from the end o

f

the breather pipe at 34.3 kPa (0.35 kg / cm2 / 5

psi) over 15 seconds.

4 Verify that no bubbles from around the fuel gauge unit seal area.

8. Install the fuel tank assembly (8).

Note: Refer to "Install the fuel tank" in this section.

Special Tool

ILLUSTRATION PART NO.

PART NAME

5-8840-2602-0

Remover: fuel pump retainer ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1586 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-45

Note: Do not use tools of any kind. Only use bare hands

when disconnecting the connector. Use a lubricant (light

oil) and/or push and pull the connector until the pipe is

disconnected.

140R100037

Cover the connectors that were removed with a plastic

bag, to prevent dust or rain water from entering.

140R100028

Reuse of Quick-Connector

•

Replace the port and connector if a scratch, dent

or crack is found.

• Remove any dirt build up on the port when

installing the connector. Replace the connector, i

f

there is any rust, dents or scratches.

• After cleaning the port, insert it straight into the

connector until it clicks. After it clicks, try pulling it

out at 49 N (5 kg / 11 lb) to make sure that it is not

drawn and is securely locked.

140R100036

Assembling Advice

By applying engine oil or light oil to the pipe, port makes

pipe assembly easier. The pipe assembly should take

place immediately after applying oil (to prevent dust

from sticking to the pipe surface - which may decrease

sealing ability).

Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Start the engine and observe the engine idle speed. The presence of dirt in the fuel system ma

y

affect the fuel injection system.

3. Check for fuel leakage from the connector.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1589 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-1

SECTION 6D

ENGINE ELECTRICAL

TABLE OF CONTENTS

Charging System ................................................ 6D-2

Servicing Cautions .......................................... 6D-2

Important Generator Components and

Function.......................................................... 6D-2

Troubleshooting .............................................. 6D-5

Diagnosis......................................................... 6D-7

Specifications .................................................. 6D-8

Unit Se rv ic ing (4 JJ 1) ....................................... .... ..6D -9

Disassembly .................................................... 6D-10

Inspection and Repair ..................................... 6D-11 Rotor Assembly ........................................... 6D-11

Stator Coil .................................................... 6D-12

Brushes ....................................................... 6D-12

Rectifier ....................................................... 6D-13

Regulator Assembly..................................... 6D-13

Measuring Procedure .................................. 6D-13

Reassembly..................................................... 6D-14

Final Assembly ................................................ 6D-14

Starter Motor ...................................................... 6D-15 Starting Circuit Diagram .................................. 6D-15

Removal and Installation ................................. 6D-15 Important Operations – Removal................. 6D-15

Important Operations – Installation.............. 6D-15

Disassembly .................................................... 6D-16 Disassembly Steps ...................................... 6D-16

Important Operations ................................... 6D-17

Inspection and Repair ..................................... 6D-20 Armature ...................................................... 6D-20

Yoke............................................................. 6D-21

Brush and Brush Holder .............................. 6D-22

Overrunning Clutch...................................... 6D-22

Bearing ........................................................ 6D-23

Reassembly..................................................... 6D-24 Reassembly Steps ....................................... 6D-24

Important Operations ................................... 6D-25

Inspection After Assembly ........................... 6D-26

Magnetic Switch .............................................. 6D-27

Torque Specifications...................................... 6D-28

Pre-Heating System ........................................... 6D-29 Inspection and Repair ..................................... 6D-29 Visual Check................................................ 6D-29

Glow Relay .................................................. 6D-29

Glow Plug .................................................... 6D-29

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1590 of 6020

6D-2 ENGINE ELECTRICAL (4JK1/4JJ1)

Charging System

Servicing Cautions

• Battery polarity is important. If the battery cables

are reversed, the generator diodes will be

destroyed.

• Do not remove the battery cables or the charging

circuit wiring when the engine is running.

• Confirm that the terminal wires are connected to

the proper terminals by checking the terminal

numbers (the number on the terminal wire and the

terminal must be the same).

• Disconnect the battery negative cable (-) before

inspecting the generator.

• Do not open or close the battery relay switch when

the engine is running.

• Disconnect the battery negative cable (-) when

using external equipment (Quick-Charge) to

charge the battery.

• W hen steam cleaning or washing the engine, do

not allow steam or water to come in direct contact

with the battery and other electrical system

components.

• Be sure to read the item on belt tension

adjustment before beginning the procedure.

Important Generator Components

and Function

• The generator used on 4JK1 engine cannot be

disassembled.

• The generator uses a built-in solid-state IC voltage

regulator. The regulator and other important

components together with their connections are

shown in the illustration.

• The voltage regulator is installed to the rear cove

r

assembly of the generator together with the brush

holder and the rectifier. The generator requires no

additional voltage regulation.

• 9 diodes are connected to the stator coil to convert

AC to DC. The DC voltage is delivered to the

generator output terminal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1595 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-7

Diagnosis

On-vehicle Inspection

The charging system warning light tells the vehicle

operator of possible problems with the system.

W hen the ignition switch is moved to the ON position,

the light turns on. The light turns off immediately afte

r

the engine is started. If the light turns on during engine

operation, there is a problem with the charging system.

Perform the checks described below.

1. Check the belt (broken or loose).

2. Check the harness connectors (loose o

r

disconnected).

3. W ith the engine off, turn the ignition switch to the ON position. If the warning lamp does not light,

remove the harness connector from the generator.

Ground the connector IG terminal. The lamp

should light. If it does not, the bulb is burned out.

Replace the bulb.

4. Start the engine. If the warning lamp remains on, the generator must be repaired or replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1599 of 6020

ENGINE ELECTRICAL (4JK1/4JJ1) 6D-11

13.Remove the stator.

066RS030

14.Remove the bolts securing the regulator, the

rectifier, and the brush holder. Separate the parts.

066RW 025

Inspection and Repair

Repair or replace any parts found to be excessively

worn or damaged during the inspection procedure.

Rotor Assembly

1. Check for dirty or rough slip ring surfaces. Remove

dirt from the surfaces with a clean rag. Use No.

500 or No. 600 sandpaper to smooth the surfaces.

2. Measure the slip ring diameters. Replace the slip ring if the diameter is less than the specified limit.

Slip ring diameter mm (in)

Standard 27 (1.063)

Limit 26 (1.024)

066RS032

3. Measure the electrical resistance between the slip

rings. If the resistance is greater than the specified

limit (open circuit), repair is required.

Slip ring resistance Ω

Less than 3.75

066RS033

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1600 of 6020

6D-12 ENGINE ELECTRICAL (4JK1/4JJ1)

4. Check for conductivity between the slip rings and

the rotor core. If there is continuity, the roto

r

assembly must be replaced.

066RS017

Stator Coil

1. Measure the stator coil resistance. If the

resistance is less than the specified value, the

stator coil must be replaced.

Stator coil resistance

0.07Ω at 20 °C (68 °F)

066RS034

2. Measure the resistance between the stator coil

and the stator core. If the resistance is less than

the specified value, the stator coil must be

replaced.

Stator coil/core resistance MΩ

1

066RS035

Brushes

Measure the brush height. If the height is less than the

specified limit, the brushes must be replaced.

Brush height mm (in)

Standard 18 (0.709)

Limit 5.5 (0.217)

066RW 024

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007