check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1662 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-45

Diagnostic System Check - Engine Controls

Description

The Diagnostic System Check - Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine

control system. The Diagnostic System Check must be

the starting point for any driveability concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the

concern. Understanding and correctly using the

diagnostic table reduces diagnostic time, and prevents

the replacement of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the serial data circuit.

7. The presence of DTCs which begin with U, indicate

that some other module is not communicating.

10. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order:

• Component level DTCs, such as sensor DTCs, solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise. Diagnostic System Check Engine Controls

Important:

• DO NOT perform this diagnostic if there is not a driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search for applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO NOT clear the DTCs.

• If there is a condition with the starting system, refer to the starting system section in the engine

mechanical.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and tight.

• Ensure the ECM grounds are clean, tight, and in the correct location.

• Ensure the ECM harness connectors are clean and correctly connected. DO NOT attempt to

crank the engine with ECM harness connectors

disconnect.

• Ensure the ECM terminals are clean and correctly mating.

• Ensure the fuel injector ID code data is correctly programmed in to the ECM.

• Ensure the immobilizer security information is correctly programmed into the ECM and

immobilizer control unit (ICU).

• If there are fuel system DTC’s (P0087, P0088, P0089, P0093, P1093 or P1094), diagnose sensor

DTCs, solenoid DTCs, actuator DTCs and relay

DTCs first.

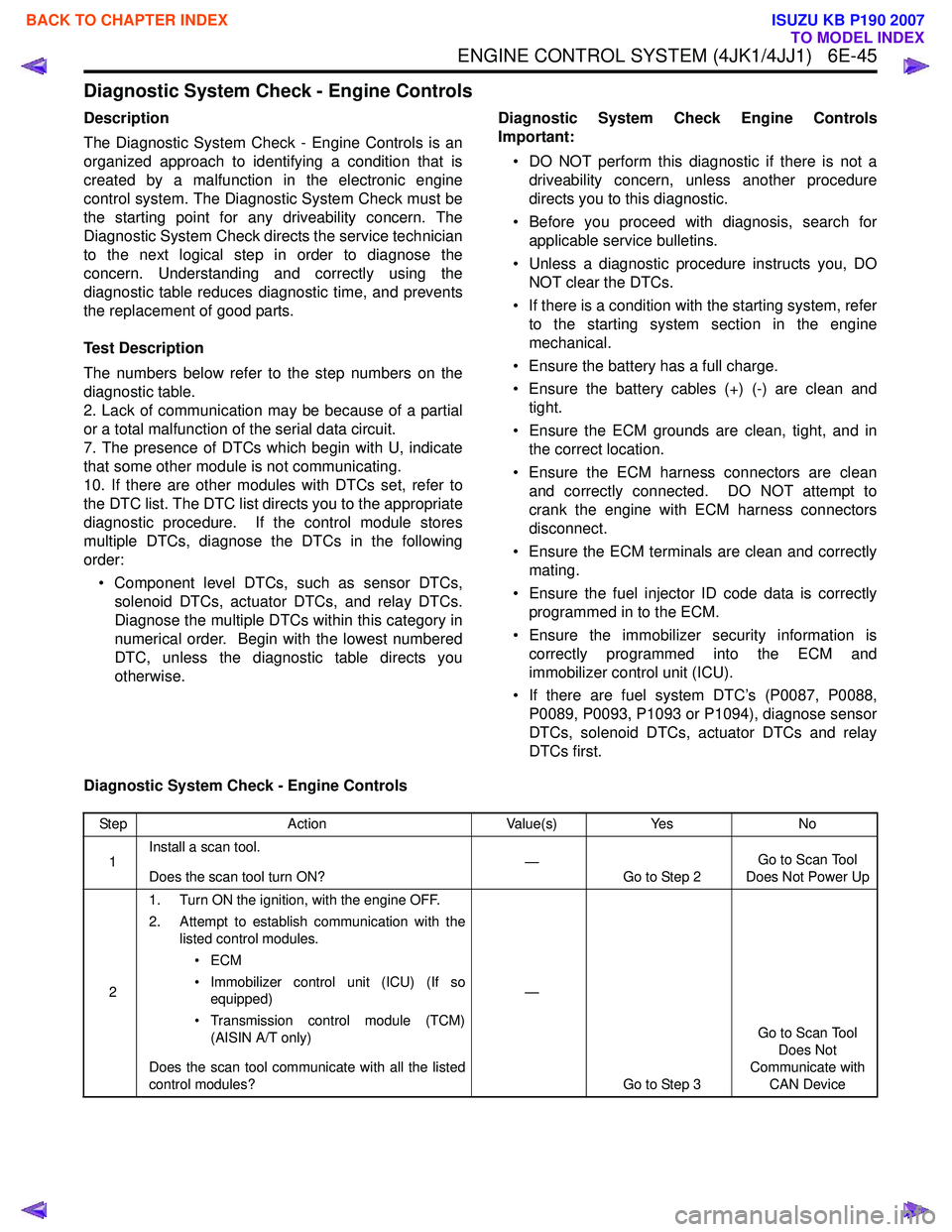

Diagnostic System Check - Engine Controls

Step Action Value(s)Yes No

1 Install a scan tool.

Does the scan tool turn ON? —

Go to Step 2 Go to Scan Tool

Does Not Power Up

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules.

•ECM

• Immobilizer control unit (ICU) (If so equipped)

• Transmission control module (TCM) (AISIN A/T only)

Does the scan tool communicate with all the listed

control modules? —

Go to Step 3 Go to Scan Tool

Does Not

Communicate with CAN Device

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1663 of 6020

6E-46 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

3Notice:

If an immobilizer system is active the ECM

will disable the fuel injection causing the engine to

stall immediately after starting and energize the

starter cut relay to disable cranking.

Attempt to crank the engine.

Does the engine crank? —

Go to Step 4 Go to Step 5

4 Attempt to start the engine.

Does the engine start and idle? —

Go to Step 6 Go to Engine

Cranks but Does

Not Run

5 Does the scan tool display ECM DTCs P0615,

P0633, P161B or U0167?

—

Go to Applicable DTC Problem is relating

to starting system. Refer to the

applicable

diagnostic chart in starting system

6 Select the DTC display function for the following

control modules: •ECM

• ICU (If so equipped)

• TCM (AISIN A/T only)

Does the scan tool display any DTCs? —

Go to Step 7 Go to Step 11

7 Does the scan tool display DTCs which begin with

U or other control module communication fault

DTCs? —

Go to Applicable

DTC Go to Step 8

8 Does the scan tool display ECM DTCs P0601,

P0602, P0604, P0606 or P1621? —Go to Applicable

DTC Go to Step 9

9 Does the scan tool display ECM DTCs P0562 or

P0563, P156A or P156B? —

Go to Applicable

DTC Go to Step 10

10 Is there any other code in any controller that has

not been diagnosed? —Go to Applicable

DTC Go to Step 11

11 Is the customer’s concern with the automatic

transmission? —Go to Diagnostic

System Check - Transmission

Controls Go to Step 12

12 Is the customer’s concern with the immobilizer

system? —Go to Diagnostic

System Check - Immobilizer

Controls Go to Step 13

13 1. Review the following symptoms.

2. Refer to the applicable symptom diagnostic table:

• Hard Start

• Rough, Unstable, or Incorrect Idle and Stalling

• High Idle Speed

•Cuts Out

• Surges

• Lack of Power, Sluggishness, or Sponginess

• Hesitation, Sag, Stumble

• Abnormal Combustion Noise

• Poor Fuel Economy

• Excessive Smoke (Black Smoke)

• Excessive Smoke (White Smoke)

Did you find and correct the condition? —

System OK Go to Intermittent

Conditions

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1664 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-47

Scan Tool Data List

The Engine Scan Tool Data List contains all engine

related parameters that are available on the scan tool.

A given parameter may appear in any one of the data

lists, and in some cases may appear more than once,

or in more than one data list in order to group certain

related parameters together. Use the Engine Scan Tool

Data List only after the following is determined:

• The Engine Controls - Diagnostic System Check is completed. • On-board diagnostics are functioning properly.

Scan tool values from a properly running engine may

be used for comparison with the engine you are

diagnosing. The Engine Scan Tool Data List represents

values that would be seen on a normal running engine.

Only the parameters listed below are referenced in this

service manual for use in diagnosis.

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

Operating Conditions: Engine idling or 2000RPM/ Engine coolant temperature is between 75 to 85 °C (167 to 185 °F)/

Accelerator pedal is constant/ Neutral or Park/ Accessories OFF/ Vehicle located at sea level

Engine Speed RPMNearly 700 RPM Nearly 2000 RPM

Desired Engine Idle Speed RPM700 RPM 700 RPM

Calculated Engine Load %- -

Coolant Temperature °C/ °F 75 to 85 °C/ 167 to 185 °F 75 to 85 °C/ 167 to 185 °F

Engine Coolant Temperature Sensor Volts

0.4 to 0.6 volts 0.4 to 0.6 volts

Intake Air Temperature °C/ °F 20 to 40 °C/ 68 to 104 °F 20 to 40 °C/ 68 to 104 °F

Intake Air Temperature Sensor Volts 1.4 to 2.3 volts1.4 to 2.3 volts

Fuel Temperature °C/ °F 20 to 60 °C/ 68 to 140 °F 20 to 60 °C/ 68 to 140 °F

Fuel Temperature Sensor Volts0.8 to 2.3 volts 0.8 to 2.3 volts

MAF (Mass Air Flow) g/sec300 to 600 g/sec 200 to 600 g/sec

MAF Sensor (Mass Air Flow) Volts1.2 to 1.6 volts 2.0 to 2.7 volts

Barometric Pressure kPa/psi Nearly 100 kPa/ 14.5 psi at sea

levelNearly 100 kPa/ 14.5 psi at sea

level

Barometric Pressure Sensor VoltsNearly 2.3 volts at sea level Nearly 2.3 volts at sea level

Turbocharger Solenoid Command %

50 to 60 % 50 to 60 %

Desired Boost Pressure kPa/ psi Nearly 100 kPa/ 14.5 psi at sea

levelLess than 120 kPa/ 17.4 psi

Boost Pressure kPa/ psi Nearly 100 kPa/ 14.5 psi at sea

levelLess than 120 kPa/ 17.4 psi

Boost Pressure Sensor VoltsNearly 1.0 volt Less than 1.3 volts

Desired Fuel Rail Pressure MPa/ psi 30 MPa/ 4,350 psiMore than 70 MPa/ 10,200 psi

(4JJ1 Euro 4 specification)

More than 50 MPa/ 7,250 psi

(4JJ1 except Euro 4 specification)

More than 60 MPa/ 8,700 psi

(4JK1)

Fuel Rail Pressure MPa/ psi 27 to 33 MPa/ 3,900 to 4,800 psi More than 70 MPa/ 10,200 psi

(4JJ1 Euro 4 specification)

More than 50 MPa/ 7,250 psi (4JJ1 except Euro 4 specification)

More than 60 MPa/ 8,700 psi (4JK1)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1667 of 6020

6E-50 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Scan Tool Data Definitions

This information will assist in emission or driveability

problems. The displays can be viewed while the vehicle

is being driven. Always perform the Diagnostic System

Check - Engine Controls first. The Diagnostic System

Check will confirm proper system operation.

Engine Speed

This parameter displays the rotational speed of the

crankshaft as calculated by the ECM based on inputs

from the crankshaft position (CKP) sensor or camshaft

position (CMP) sensor.

Desired Idle Speed

This parameter displays the idle speed requested by

the ECM. The ECM will change desired idle speed

based on engine coolant temperature and other inputs.

Calculate Engine Load

This parameter displays the engine load in percent

based on inputs to the ECM from various engine

sensors. The scan tool will display a lower percentage

when the engine is at idle with little or no load. The

scan tool will display a higher percentage when the

engine is running at high engine speed under a heavy

load.

Coolant Temperature

This parameter displays the temperature of the engine

coolant as calculated by the ECM using the signal from

the engine coolant temperature (ECT) sensor. The

scan tool will display a low temperature when the ECT

sensor signal voltage is high, and a high temperature

when the ECT sensor signal voltage is low.

Engine Coolant Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the engine coolant temperature (ECT)

sensor. ECT sensor is a range of value indicating a low

voltage when the temperature is high, and a high

voltage when the temperature is low.

Intake Air Temperature

This parameter displays the temperature of the intake

air as calculated by the ECM using the signal from the

intake air temperature (IAT) sensor. The scan tool will

display a low temperature when the IAT sensor signal

voltage is high, and a high temperature when the IAT

sensor signal voltage is low. Intake Air Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the intake air temperature (IAT) sensor. IAT

sensor is a range of value indicating a low voltage

when the temperature is high, and a high voltage when

the temperature is low.

Fuel Temperature

This parameter displays the temperature of the fuel as

calculated by the ECM using the signal from the fuel

temperature (FT) sensor. The scan tool will display a

low temperature when the FT sensor signal voltage is

high, and a high temperature when the FT sensor

signal voltage is low.

Fuel Temperature Sensor

This parameter displays the voltage signal sent to the

ECM from the fuel temperature (FT) sensor. FT sensor

is a range of value indicating a low voltage when the

temperature is high, and a high voltage when the

temperature is low.

MAF (Mass Air Flow)

This parameter displays the air flow into the engine as

calculated by the ECM based on the mass air flow

(MAF) sensor input. The scan tool will display a high

value at higher engine speeds, and a low value at lower

engine speed.

MAF Sensor (Mass Air Flow)

This parameter displays the voltage signal sent to the

ECM from the mass air flow (MAF) sensor. MAF sensor

is a range of value indicating a low voltage at lower

engine speed, and a high voltage at a higher engine

speeds.

Barometric Pressure

This parameter displays the barometric pressure

(BARO) as calculated by the ECM using the signal from

the BARO sensor. The scan tool will display a low

barometric pressure in high altitude area.

Barometric Pressure Sensor

This parameter displays the voltage signal sent to the

ECM from the barometric pressure (BARO) sensor.

BARO sensor is a range of value indicating a low

voltage in high altitude area, and a middle voltage in

sea level.

Immobilizer Signal Yes/ NoYes Yes

Security Wait Time Inactive/ Time

(hour: minute: second) Inactive

Inactive

Scan Tool Parameter Units Displayed Typical Data Value at Engine Idle Typical Data Value at 2000RPM

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1672 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-55

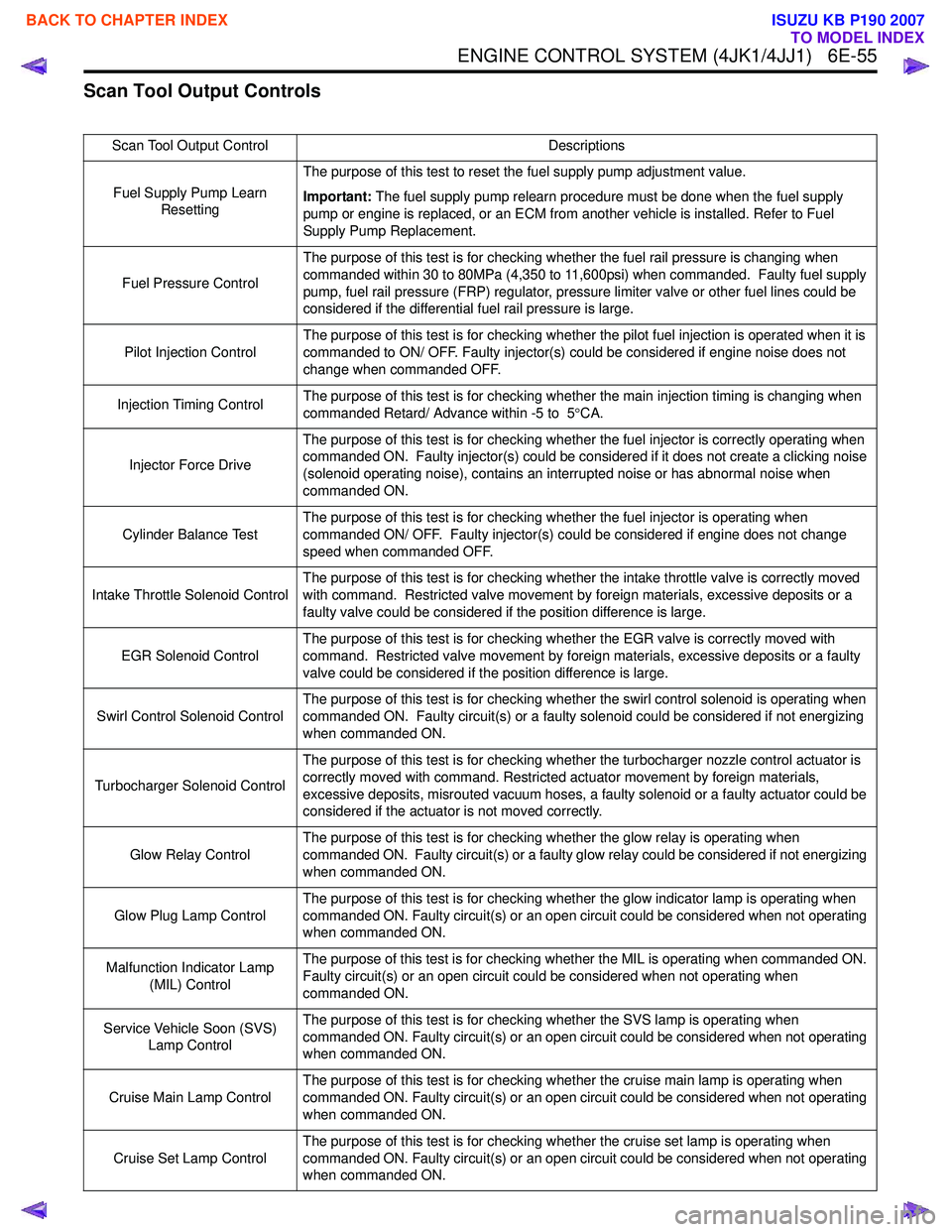

Scan Tool Output Controls

Scan Tool Output ControlDescriptions

Fuel Supply Pump Learn Resetting The purpose of this test to reset the fuel supply pump adjustment value.

Important: The fuel supply pump relearn procedure must be done when the fuel supply

pump or engine is replaced, or an ECM from another vehicle is installed. Refer to Fuel

Supply Pump Replacement.

Fuel Pressure Control The purpose of this test is for checking whether the fuel rail pressure is changing when

commanded within 30 to 80MPa (4,350 to 11,600psi) when commanded. Faulty fuel supply

pump, fuel rail pressure (FRP) regulator, pressure limiter valve or other fuel lines could be

considered if the differential fuel rail pressure is large.

Pilot Injection Control The purpose of this test is for checking whether the pilot fuel injection is operated when it is

commanded to ON/ OFF. Faulty injector(s) could be considered if engine noise does not

change when commanded OFF.

Injection Timing Control The purpose of this test is for checking whether the main injection timing is changing when

commanded Retard/ Advance within -5 to 5 °CA.

Injector Force Drive The purpose of this test is for checking whether the fuel injector is correctly operating when

commanded ON. Faulty injector(s) could be considered if it does not create a clicking noise

(solenoid operating noise), contains an interrupted noise or has abnormal noise when

commanded ON.

Cylinder Balance Test The purpose of this test is for checking whether the fuel injector is operating when

commanded ON/ OFF. Faulty injector(s) could be considered if engine does not change

speed when commanded OFF.

Intake Throttle Solenoid Control The purpose of this test is for checking whether the intake throttle valve is correctly moved

with command. Restricted valve movement by foreign materials, excessive deposits or a

faulty valve could be considered if the position difference is large.

EGR Solenoid Control The purpose of this test is for checking whether the EGR valve is correctly moved with

command. Restricted valve movement by foreign materials, excessive deposits or a faulty

valve could be considered if the position difference is large.

Swirl Control Solenoid Control The purpose of this test is for checking whether the swirl control solenoid is operating when

commanded ON. Faulty circuit(s) or a faulty solenoid could be considered if not energizing

when commanded ON.

Turbocharger Solenoid Control The purpose of this test is for checking whether the turbocharger nozzle control actuator is

correctly moved with command. Restricted actuator movement by foreign materials,

excessive deposits, misrouted vacuum hoses, a faulty solenoid or a faulty actuator could be

considered if the actuator is not moved correctly.

Glow Relay Control The purpose of this test is for checking whether the glow relay is operating when

commanded ON. Faulty circuit(s) or a faulty glow relay could be considered if not energizing

when commanded ON.

Glow Plug Lamp Control The purpose of this test is for checking whether the glow indicator lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Malfunction Indicator Lamp (MIL) Control The purpose of this test is for checking whether the MIL is operating when commanded ON.

Faulty circuit(s) or an open circuit could be considered when not operating when

commanded ON.

Service Vehicle Soon (SVS) Lamp Control The purpose of this test is for checking whether the SVS lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Cruise Main Lamp Control The purpose of this test is for checking whether the cruise main lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Cruise Set Lamp Control The purpose of this test is for checking whether the cruise set lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1673 of 6020

6E-56 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

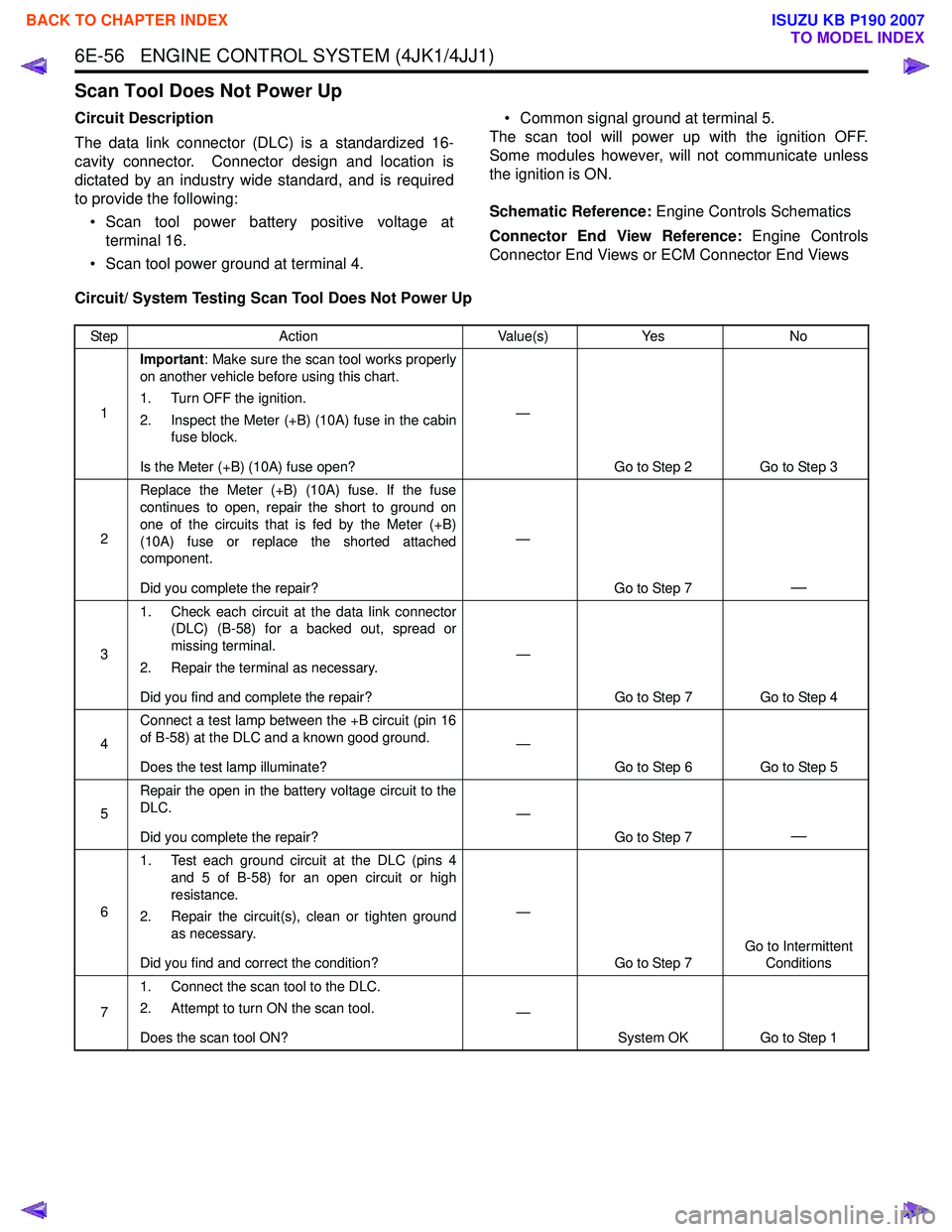

Scan Tool Does Not Power Up

Circuit Description

The data link connector (DLC) is a standardized 16-

cavity connector. Connector design and location is

dictated by an industry wide standard, and is required

to provide the following:

• Scan tool power battery positive voltage at terminal 16.

• Scan tool power ground at terminal 4. • Common signal ground at terminal 5.

The scan tool will power up with the ignition OFF.

Some modules however, will not communicate unless

the ignition is ON.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Scan Tool Does Not Power Up

Step Action Value(s)Yes No

1 Important

: Make sure the scan tool works properly

on another vehicle before using this chart.

1. Turn OFF the ignition.

2. Inspect the Meter (+B) (10A) fuse in the cabin fuse block.

Is the Meter (+B) (10A) fuse open? —

Go to Step 2 Go to Step 3

2 Replace the Meter (+B) (10A) fuse. If the fuse

continues to open, repair the short to ground on

one of the circuits that is fed by the Meter (+B)

(10A) fuse or replace the shorted attached

component.

Did you complete the repair? —

Go to Step 7

—

31. Check each circuit at the data link connector

(DLC) (B-58) for a backed out, spread or

missing terminal.

2. Repair the terminal as necessary.

Did you find and complete the repair? —

Go to Step 7 Go to Step 4

4 Connect a test lamp between the +B circuit (pin 16

of B-58) at the DLC and a known good ground.

Does the test lamp illuminate? —

Go to Step 6 Go to Step 5

5 Repair the open in the battery voltage circuit to the

DLC.

Did you complete the repair? —

Go to Step 7

—

61. Test each ground circuit at the DLC (pins 4

and 5 of B-58) for an open circuit or high

resistance.

2. Repair the circuit(s), clean or tighten ground as necessary.

Did you find and correct the condition? —

Go to Step 7 Go to Intermittent

Conditions

7 1. Connect the scan tool to the DLC.

2. Attempt to turn ON the scan tool.

Does the scan tool ON? —

System OK Go to Step 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1674 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-57

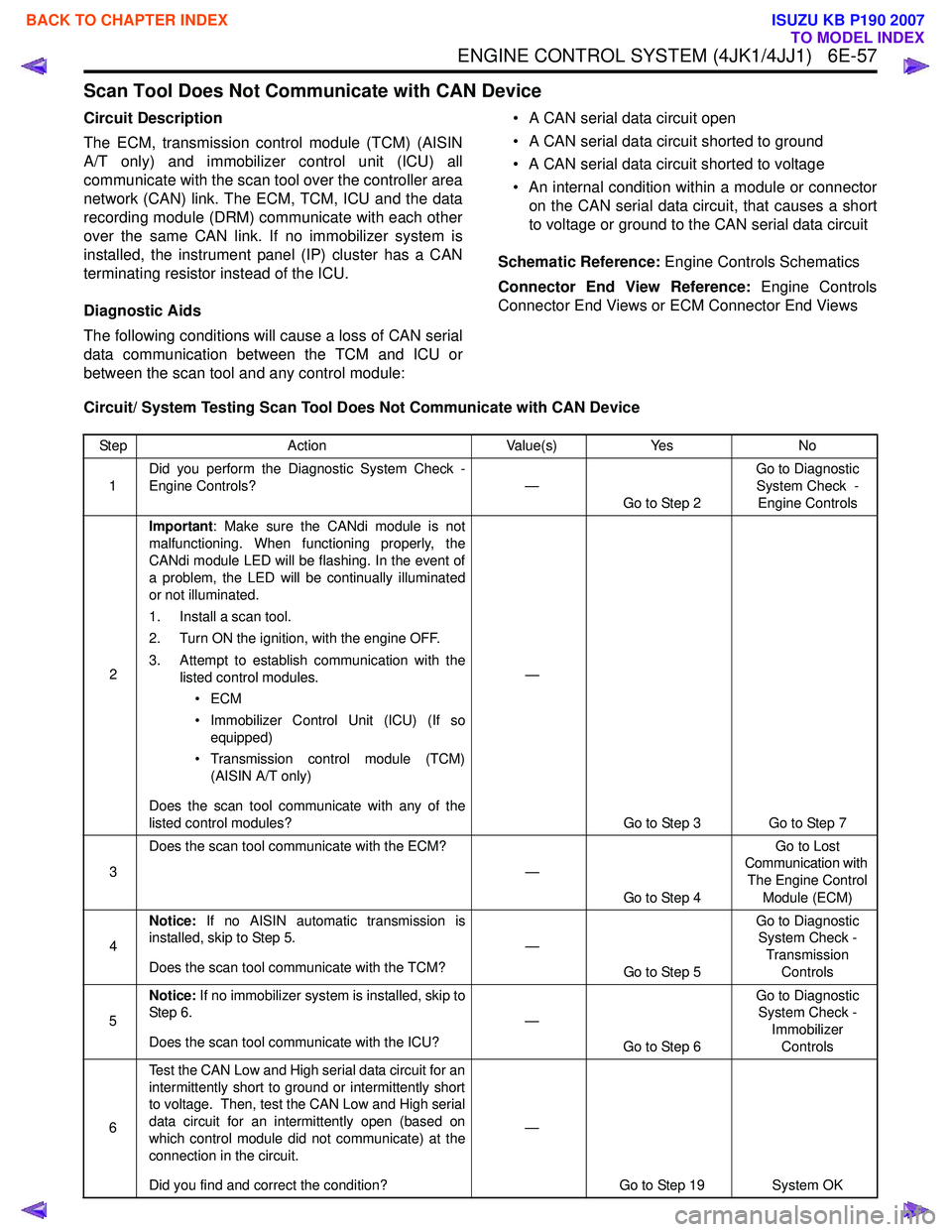

Scan Tool Does Not Communicate with CAN Device

Circuit Description

The ECM, transmission control module (TCM) (AISIN

A/T only) and immobilizer control unit (ICU) all

communicate with the scan tool over the controller area

network (CAN) link. The ECM, TCM, ICU and the data

recording module (DRM) communicate with each other

over the same CAN link. If no immobilizer system is

installed, the instrument panel (IP) cluster has a CAN

terminating resistor instead of the ICU.

Diagnostic Aids

The following conditions will cause a loss of CAN serial

data communication between the TCM and ICU or

between the scan tool and any control module: • A CAN serial data circuit open

• A CAN serial data circuit shorted to ground

• A CAN serial data circuit shorted to voltage

• An internal condition within a module or connector on the CAN serial data circuit, that causes a short

to voltage or ground to the CAN serial data circuit

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Scan Tool Does Not Communicate with CAN Device

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check - Engine Controls

2 Important

: Make sure the CANdi module is not

malfunctioning. When functioning properly, the

CANdi module LED will be flashing. In the event of

a problem, the LED will be continually illuminated

or not illuminated.

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Attempt to establish communication with the listed control modules.

•ECM

• Immobilizer Control Unit (ICU) (If so equipped)

• Transmission control module (TCM) (AISIN A/T only)

Does the scan tool communicate with any of the

listed control modules? —

Go to Step 3 Go to Step 7

3 Does the scan tool communicate with the ECM?

—

Go to Step 4 Go to Lost

Communication with

The Engine Control Module (ECM)

4 Notice:

If no AISIN automatic transmission is

installed, skip to Step 5.

Does the scan tool communicate with the TCM? —

Go to Step 5 Go to Diagnostic

System Check -

Transmission Controls

5 Notice:

If no immobilizer system is installed, skip to

Step 6.

Does the scan tool communicate with the ICU? —

Go to Step 6 Go to Diagnostic

System Check -

Immobilizer Controls

6 Test the CAN Low and High serial data circuit for an

intermittently short to ground or intermittently short

to voltage. Then, test the CAN Low and High serial

data circuit for an intermittently open (based on

which control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition? —

Go to Step 19 System OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1677 of 6020

6E-60 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

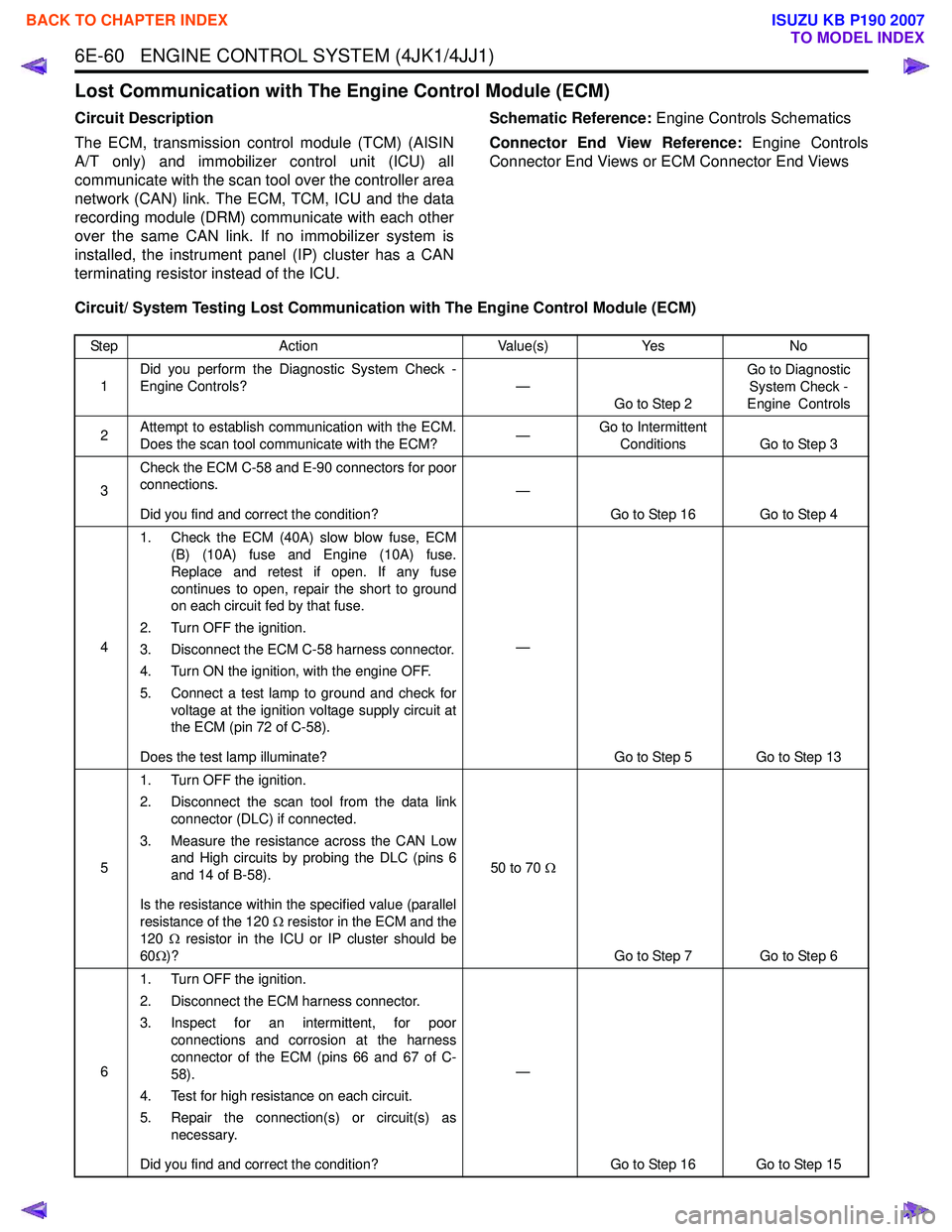

Lost Communication with The Engine Control Module (ECM)

Circuit Description

The ECM, transmission control module (TCM) (AISIN

A/T only) and immobilizer control unit (ICU) all

communicate with the scan tool over the controller area

network (CAN) link. The ECM, TCM, ICU and the data

recording module (DRM) communicate with each other

over the same CAN link. If no immobilizer system is

installed, the instrument panel (IP) cluster has a CAN

terminating resistor instead of the ICU. Schematic Reference:

Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Lost Communication with The Engine Control Module (ECM)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 Attempt to establish communication with the ECM.

Does the scan tool communicate with the ECM? —Go to Intermittent

Conditions Go to Step 3

3 Check the ECM C-58 and E-90 connectors for poor

connections.

Did you find and correct the condition? —

Go to Step 16 Go to Step 4

4 1. Check the ECM (40A) slow blow fuse, ECM

(B) (10A) fuse and Engine (10A) fuse.

Replace and retest if open. If any fuse

continues to open, repair the short to ground

on each circuit fed by that fuse.

2. Turn OFF the ignition.

3. Disconnect the ECM C-58 harness connector.

4. Turn ON the ignition, with the engine OFF.

5. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at

the ECM (pin 72 of C-58).

Does the test lamp illuminate? —

Go to Step 5 Go to Step 13

5 1. Turn OFF the ignition.

2. Disconnect the scan tool from the data link connector (DLC) if connected.

3. Measure the resistance across the CAN Low and High circuits by probing the DLC (pins 6

and 14 of B-58).

Is the resistance within the specified value (parallel

resistance of the 120 Ω resistor in the ECM and the

120 Ω resistor in the ICU or IP cluster should be

60 Ω)? 50 to 70

Ω

Go to Step 7 Go to Step 6

6 1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent, for poor connections and corrosion at the harness

connector of the ECM (pins 66 and 67 of C-

58).

4. Test for high resistance on each circuit.

5. Repair the connection(s) or circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 15

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1678 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-61

71. Check ECM ground for corrosion and

tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 8

8 1. Turn OFF the ignition.

2. Reconnect the ECM harness connector if disconnected.

3. Replace the ECM main relay with the heater relay or replace with a known good relay.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to establish communication with the ECM.

Does the scan tool communicate with the ECM? —

Go to Step 14 Go to Step 9

9 1. Turn OFF the ignition.

2. Remove the ECM main relay.

3. Turn ON the ignition, with the engine OFF.

4. Using a test lamp, check for both voltage supply circuits to the ECM main relay (pins 4

and 5 of X-12).

5. Repair the open circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 10

10 1. Reinstall the ECM main relay.

2. Turn the ignition ON and OFF while listening of feeling for the ECM main relay click. Wait 7

seconds between transitions.

Does the ECM main relay click when the ignition

switch is turned ON or OFF? —

Go to Step 12 Go to Step 11

11 Repair the ECM main relay ground circuit between

the ECM main relay (pin 2 of X-12) and engine

room ground terminal (C-36) for the following

conditions: •An open circuit

• High resistance or a poor connection at the

ECM main relay or ground terminal

Did you complete the repair? —

Go to Step 16

—

121. Test the battery voltage circuit between the

ECM (pin 73 of C-58) and the ECM main relay

(pin 1 of X-12) for the following conditions:

• An open circuit

• High resistance or a poor connection at ECM or ECM main relay

2. Repair the circuit(s) as necessary.

Did you find and correct the condition? —

Go to Step 16 Go to Step 15

13 Repair the open in the ignition voltage circuit to the

ECM.

Did you complete the repair? —

Go to Step 16

—

14Replace the ECM main relay.

Did you complete the replacement? —

Go to Step 16—

Step Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1680 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-63

Engine Cranks but Does Not Run

Description

The Engine Cranks but Does Not Run diagnostic table

is an organized approach to identifying a condition that

causes an engine to not start. The diagnostic table

directs the service technician to the appropriate system

diagnosis. The diagnostic table assumes the following

conditions are met:

• The battery is completely charged and terminals are cleaned and tight.

• The engine cranking speed is normal.

• There is adequate fuel in the fuel tank.

• There is no fuel leak in the fuel line.

• There is no air in the fuel line.

• Filters (air, fuel) are clean.

• Fuse and slow blow fuse are normal. Diagnostic Aids

• If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

Circuit/ System Testing.

5. If the fuel rail pressure (FRP) regulator low side

circuits between the ECM and the FRP regulator are

shorted to ground, FRP Regulator Feedback will be

approximately 400mA lower as compared with normal.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing Engine Cranks but Does Not Run (1of 2)

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Crank the engine for the specified amount of time.

4. Monitor the DTC Information with a scan tool.

Does the scan tool display any DTCs that failed this

ignition? 15 seconds

Go to Applicable DTC Go to Step 3

3 1. Turn OFF the ignition.

2. Wait 1 minute for the fuel pressure to bleed down from the fuel rail.

3. Turn ON the ignition, with the engine OFF. DO NOT start the engine.

4. Observe the Fuel Rail Pressure parameter with a scan tool.

Does the scan tool indicate the specified value? 0 MPa (0 psi)

Go to Step 4 Go to Step 6

4 Notice:

If the vehicle has run out of fuel, air may

be trapped in the fuel system.

1. Make sure the fuel tank have adequate fuel and the fuel quality is good (take a sample).

2. Observe the Fuel Rail Pressure parameter on the scan tool while cranking over the engine

for 5 seconds.

Does the scan tool indicate more than the specified

value during crank? 20 MPa (2,900

psi)

Go to Step 9 Go to Step 5

5 Observe the FRP Regulator Feedback parameter

on the scan tool while cranking over the engine for

5 seconds.

Does the scan tool indicate more than the specified

value during crank? 1500 mA

Go to 2 of 2 Step 1 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007