check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1522 of 6020

6A-162 ENGINE MECHANICAL (4JK1/4JJ1)

Removal

1. Remove the oil pressure SW .

2. Remove the nipple; oil gallery.

3. Remove the nipple; oil pressure warning SW and gasket.

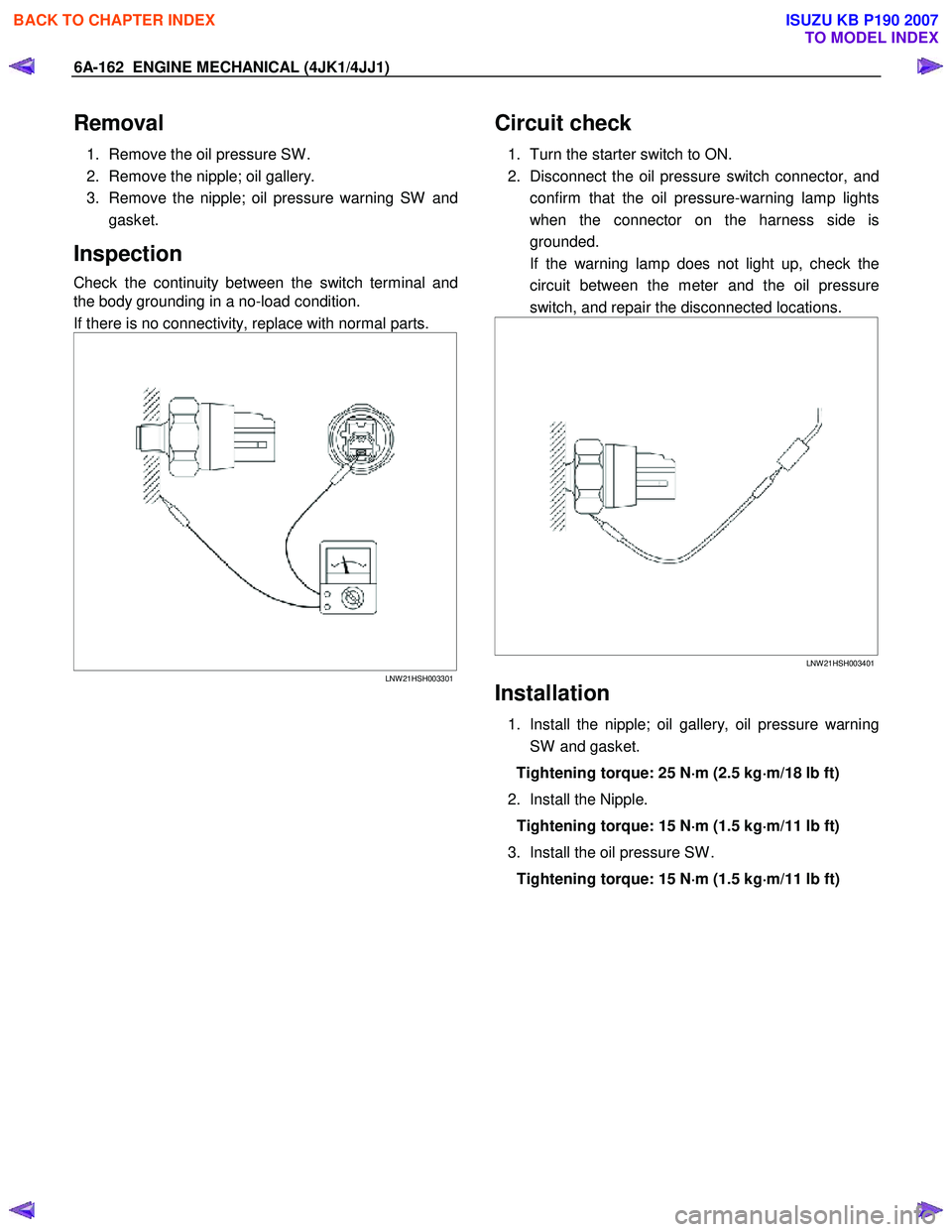

Inspection

Check the continuity between the switch terminal and

the body grounding in a no-load condition.

If there is no connectivity, replace with normal parts.

LNW 21HSH003301

Circuit check

1. Turn the starter switch to ON.

2. Disconnect the oil pressure switch connector, and confirm that the oil pressure-warning lamp lights

when the connector on the harness side is

grounded.

If the warning lamp does not light up, check the circuit between the meter and the oil pressure

switch, and repair the disconnected locations.

LNW 21HSH003401

Installation

1. Install the nipple; oil gallery, oil pressure warning

SW and gasket.

Tightening torque: 25 N ⋅

⋅⋅

⋅

m (2.5 kg ⋅

⋅⋅

⋅

m/18 lb ft)

2. Install the Nipple. Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

3. Install the oil pressure SW . Tightening torque: 15 N ⋅

⋅⋅

⋅

m (1.5 kg ⋅

⋅⋅

⋅

m/11 lb ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1524 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-1

SECTION 6B

ENGINE COOLING

TABLE OF CONTENTS

Main Data and Specifications ............................. 6B-2

General Description............................................ 6B-3 Coolant Flow ................................................... 6B-3

W ater Pump .................................................... 6B-4

Thermostat ...................................................... 6B-4

Radiator ........................................................... 6B-5

Antifreeze Solution .......................................... 6B-5

Diagnosis............................................................ 6B-6

Draining and Refilling Cooling System ............... 6B-7

W ater Pump ....................................................... 6B-8 Removal .......................................................... 6B-8

Inspection and Repair ..................................... 6B-9

Installation ....................................................... 6B-9

Thermostat ......................................................... 6B-11 Removal .......................................................... 6B-11

Inspection and Repair ..................................... 6B-11

Operating Test of Thermostat ......................... 6B-11

Installation ....................................................... 6B-12

Radiator .............................................................. 6B-13 Radiator and Associated Parts........................ 6B-13

Removal .......................................................... 6B-14

Inspection and Repair ..................................... 6B-15

Radiator Cap ................................................... 6B-15

Radiator Core .................................................. 6B-15

Flushing the Radiator ...................................... 6B-15

Cooling System Leakage Check ..................... 6B-15

Installation ....................................................... 6B-16

Engine Coolant Change .................................. 6B-16

Fan Clutch with Cooling Fan .............................. 6B-17 Inspection and Repair ..................................... 6B-17

Special Tools................................................... 6B-18

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1530 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-7

Draining and Refilling Cooling System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order.

The engine coolant (EC) level should be between the

“MIN" and “MAX" lines of the reserve tank when the

engine is cold. If low, check for leakage and add EC up

to the “MAX" line.

There should not be any excessive deposit of rust o

r

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Remove the radiator skid plate.

2. Completely drain the cooling system by opening the drain plug at the bottom of the radiator.

RTW 56BSH000301

3. Remove the radiator cap.

WARNING:

To avoid the danger of being burned, do not

remove the cap while the engine and radiator are

still hot. Scalding fluid and steam can be blown out

under pressure.

4. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with soap and water. Flush it well with clean water,

then drain it. Install the reserve tank and hoses.

5. Refill the cooling system with the EC using a

solution that is at least 50 percent antifreeze.

Procedure for filling with coolant (in case of full change).

• Make sure that the engine is cool.

• Open radiator cap and pour coolant up to fille

r

neck.

• Pour coolant into reservoir tank up to “MAX" line.

• Tighten radiator cap and start the engine. Afte

r

idling for 2 to 3 minutes, stop the engine and

reopen the radiator cap. If the water level is lower,

replenish.

WARNING:

When the coolant is heated to a high temperature,

be sure not to loosen or remove the radiator cap.

Otherwise you might get scalded by hot vapor o

r

boiling water. To open the radiator cap, put a piece

of thick cloth on the cap and loosen the cap slowly

to reduce the pressure when the coolant has

become cooler.

• After tightening the radiator cap, warm up the

engine at about 2000 rpm. Set heater adjustment

to the highest temperature position, and let the

coolant circulate also into heater water system.

• Check to see the thermostat has opened through

the needle position of the water thermometer,

conduct a 5–minute idling again and stop the

engine.

• W hen the engine has been cooled, check fille

r

neck for water level and replenish if required.

Should extreme shortage of coolant be found,

check the cooling system and reservoir tank hose

for leakage.

• Pour coolant into the reservoir tank up to “MAX"

line.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1532 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-9

Inspection and Repair

The water pump is not disassembled type.

Make necessary parts replacement if extreme wear o

r

damage is found during inspection. Should any of the

following problems occur, the entire water pump

assembly must be replaced.

• Cracks in the water pump body.

• Coolant leakage from the sealed unit.

• Excessive radial play or abnormal noise in the fan

center when rotated by hand.

• Excessive thrust play in the fan center (Standard

play: less than 0.2 mm (0.0078 in)).

• Cracks or corrosion in the impeller.

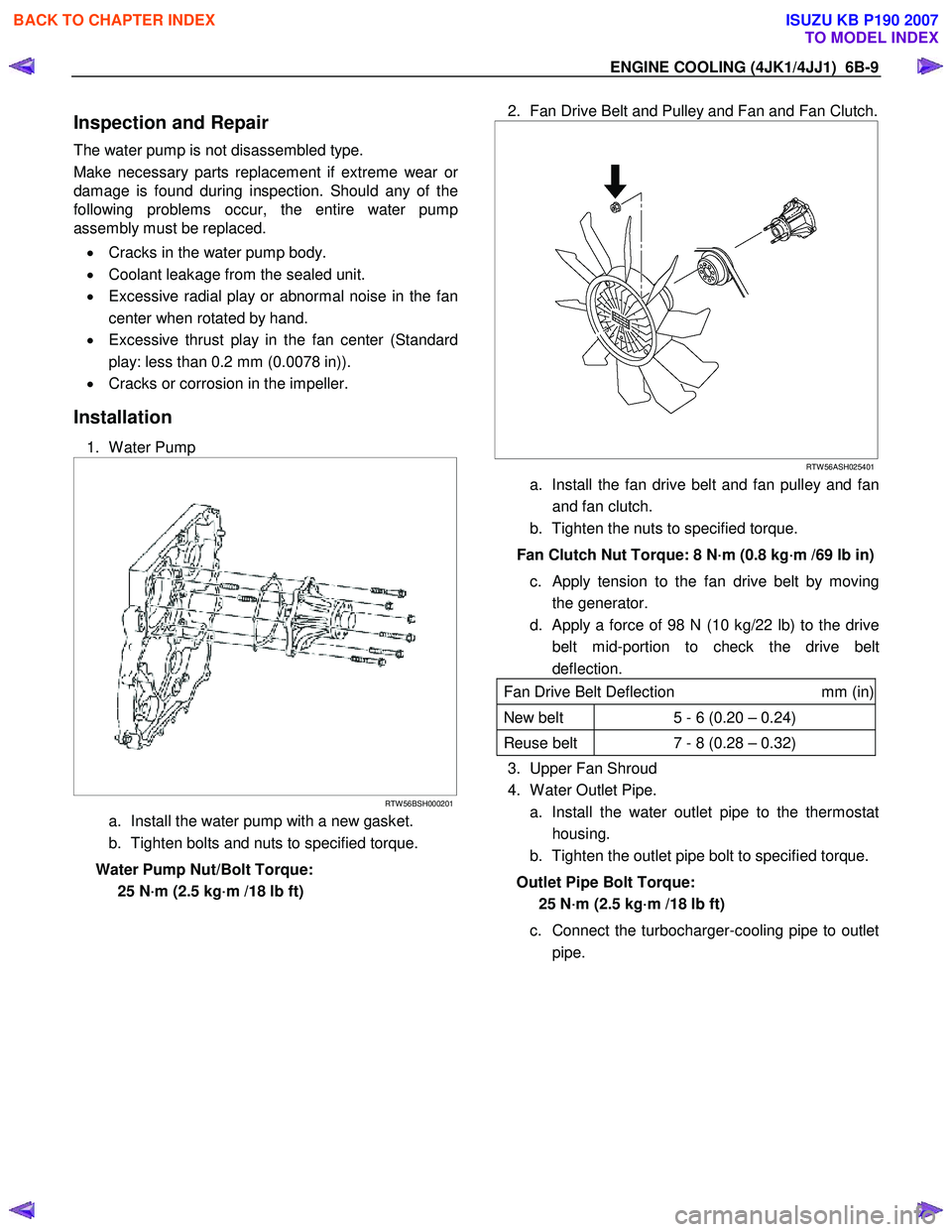

Installation

1. W ater Pump

RTW 56BSH000201

a. Install the water pump with a new gasket.

b. Tighten bolts and nuts to specified torque.

Water Pump Nut/Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

2. Fan Drive Belt and Pulley and Fan and Fan Clutch.

RTW 56ASH025401

a. Install the fan drive belt and fan pulley and fan

and fan clutch.

b. Tighten the nuts to specified torque.

Fan Clutch Nut Torque: 8 N·m (0.8 kg·m /69 lb in) c. Apply tension to the fan drive belt by moving the generator.

d. Apply a force of 98 N (10 kg/22 lb) to the drive belt mid-portion to check the drive belt

deflection.

Fan Drive Belt Deflection mm (in)

New belt 5 - 6 (0.20 – 0.24)

Reuse belt 7 - 8 (0.28 – 0.32)

3. Upper Fan Shroud

4. W ater Outlet Pipe.

a. Install the water outlet pipe to the thermostat housing.

b. Tighten the outlet pipe bolt to specified torque.

Outlet Pipe Bolt Torque: 25 N·m (2.5 kg·m /18 lb ft)

c. Connect the turbocharger-cooling pipe to outlet pipe.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1534 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-11

Thermostat

Read this Section carefully before performing any

removal and installation procedure. This Section gives

you important points as well as the order of operation.

Be sure that you understand everything in this Section

before you begin.

Removal

1. Remove the engine cover.

2. Radiator Upper Hose a. Partially drain the engine coolant.

b. Remove the radiator upper hose.

c. Remove the engine harness clip.

RTW 56FSH000101

3. W ater Outlet Pipe

a. Disconnect the turbocharger-cooling pipe from outlet pipe.

b. Loosen the fixing bolt and remove the wate

r

outlet bolt.

4. Thermostat

Remove the thermostat from the thermostat housing.

Take care not to damage the thermostat.

RTW 56BSH000101

Legend

1. Front

2. Thermostat

3. Jiggle Valve

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

Operating Test of Thermostat

1. Completely submerge the thermostat in water.

2. Heat the water.Stir the water constantly to avoid direct heat being applied to the thermostat.

3. Check the thermostat initial opening temperature.

Thermostat Initial Opening Temperature °C (°F)

85 (185)

4. Check the thermostat full opening temperature.

Thermostat Full Opening Temperature °C (°F)

100 (212)

Valve Lift At Fully Open Position mm (in)

10 (0.39)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1538 of 6020

ENGINE COOLING (4JK1/4JJ1) 6B-15

Inspection and Repair

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is

discovered during inspection.

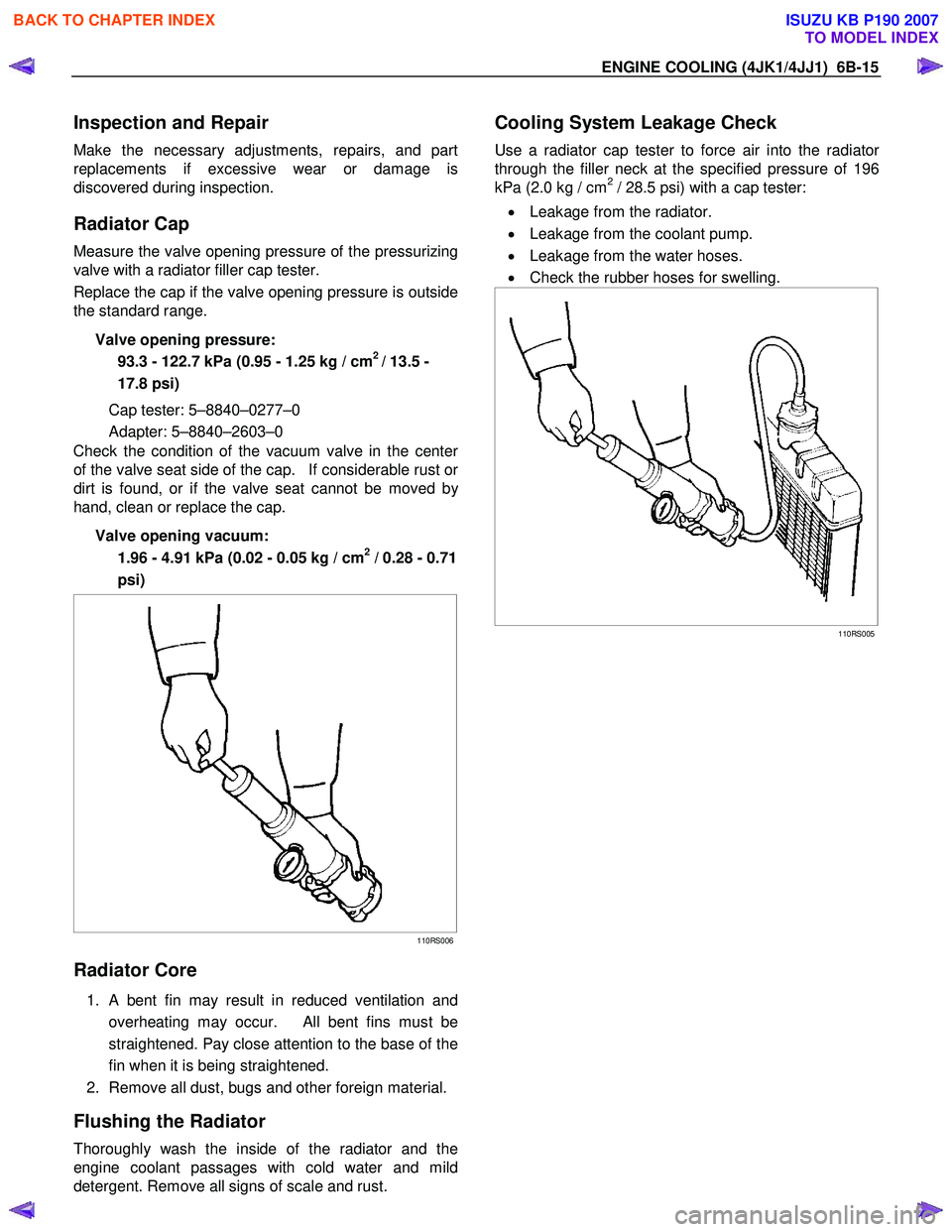

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure: 93.3 - 122.7 kPa (0.95 - 1.25 kg / cm

2 / 13.5 -

17.8 psi)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the cente

r

of the valve seat side of the cap. If considerable rust or

dirt is found, or if the valve seat cannot be moved by

hand, clean or replace the cap.

Valve opening vacuum: 1.96 - 4.91 kPa (0.02 - 0.05 kg / cm

2 / 0.28 - 0.71

psi)

110RS006

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the

fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the

engine coolant passages with cold water and mild

detergent. Remove all signs of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196

kPa (2.0 kg / cm2 / 28.5 psi) with a cap tester:

• Leakage from the radiator.

• Leakage from the coolant pump.

• Leakage from the water hoses.

• Check the rubber hoses for swelling.

110RS005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1547 of 6020

6C-6 FUEL SYSTEM (4JK1/4JJ1)

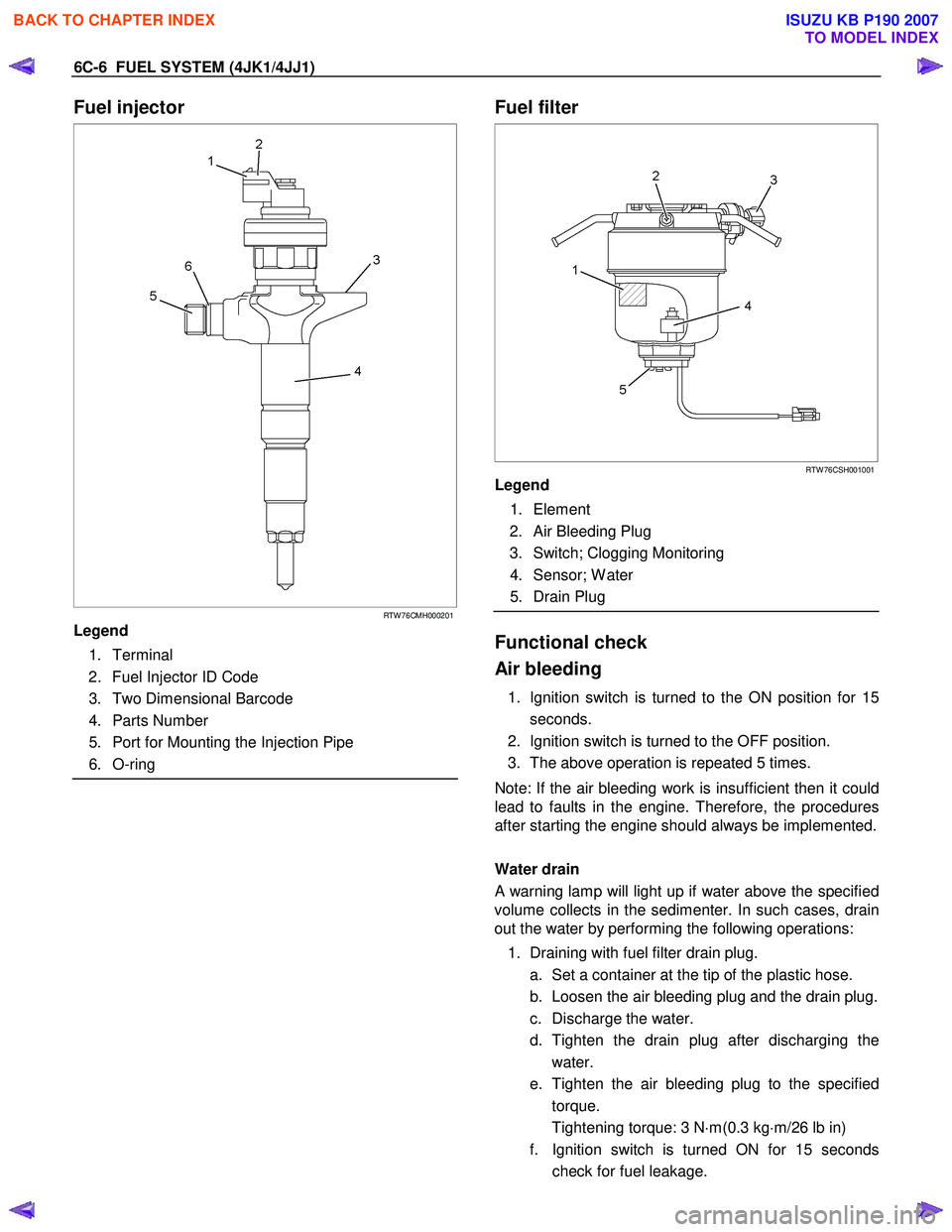

Fuel injector

RTW 76CMH000201

Legend

1. Terminal

2. Fuel Injector ID Code

3. Two Dimensional Barcode

4. Parts Number

5. Port for Mounting the Injection Pipe

6. O-ring

Fuel filter

RTW 76CSH001001

Legend

1. Element

2. Air Bleeding Plug

3. Switch; Clogging Monitoring

4. Sensor; W ater

5. Drain Plug

Functional check

Air bleeding

1. Ignition switch is turned to the ON position for 15 seconds.

2. Ignition switch is turned to the OFF position.

3. The above operation is repeated 5 times.

Note: If the air bleeding work is insufficient then it could

lead to faults in the engine. Therefore, the procedures

after starting the engine should always be implemented.

Water drain

A warning lamp will light up if water above the specified

volume collects in the sedimenter. In such cases, drain

out the water by performing the following operations:

1. Draining with fuel filter drain plug. a. Set a container at the tip of the plastic hose.

b. Loosen the air bleeding plug and the drain plug.

c. Discharge the water.

d. Tighten the drain plug after discharging the water.

e. Tighten the air bleeding plug to the specified torque.

Tightening torque: 3 N ⋅m(0.3 kg ⋅m/26 lb in)

f. Ignition switch is turned ON for 15 seconds check for fuel leakage.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1548 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-7

g. Check that the warning lamp in the meter is off.

2. Draining with drain plug in engine room. a. W ith the engine off, open the engine hood and loosen the drain plug (1) located on the left

hand side of the engine room. (3-4 turns)

b. Turn the starter switch to the “ON” position fo

r

10 seconds, and then turn the starter switch to

the “OFF” position for 10 seconds. Then, once

again turn the starter switch to the “ON”

position for 10 seconds.

c. Tighten the drain plug firmly.

d.

After starting the engine, check that there is no

fuel leakage from the drain plug. Also check

that the water separator indicator has turned

off.

RTW 76CSH001301

NOTE:

• If the water separator requires frequent draining,

have the fuel tank drained at your ISUZU/GM

Dealer.

• Be sure to stop the engine when draining the fuel

tank.

• Confirm that there are no combustible materials

under the drain hose, and use a receptacle to

catch the drained water.

Engine starting cautions

• Before starting the engine, turn the ignition switch

to the “ON” position. W ait 15 seconds. Return the

switch to the “LOCK” position. Repeat this

procedure 5 times.

• After starting the engine, allow it to idle for 10

minutes.

Fuel Pump Functional Check

1. Turn the starter switch to “ON” position.

2. Touch the under portion of the Fuel Tank by the hand as shown in the following figure within 12

seconds.

RTW 56CSH003501

Legend

1. Touch this area by the hand

3. Make sure a vibration by the Fuel Pump is

detected.

Fuel Pump stops within 12 seconds of turning the starter switch to the “ON” position.

W hen the check is repeated, return the starte

r

switch to the “LOCK” position for 10 – 15 seconds

and perform procedures 1 – 3.

WARNING: FUEL PUMP FUNCTIONAL CHECK

MUST BE CONDUCTED UNDER THE FOLLOWING

CONDITIONS TO AVOID INJURY.

•

••

•

APPLY THE PARKING BRAKE.

•

••

•

STOP THE ENGINE.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1551 of 6020

6C-10 FUEL SYSTEM (4JK1/4JJ1)

Fuel System Check

Description

Conforms to a fuel leak. Engine acceleration raises fuel

pressure and which increases the leak.

Leak could be in the following pipes and locations.

• Between injectors and fuel rail.

• Between fuel rail and fuel supply pump.

• Between fuel supply pump and fuel filter.

• Between fuel filter and fuel tank.

• Between pressure limiter and fuel cooler.

• Between fuel cooler and fuel tank.

• Between injector over flow and leak off pipe.

Diagnostic Aids

Check the following items.

• Air in the fuel line

• Clogged fuel filter

• Fuel pipe malfunction (Crushing, breakage,

clogging, disconnection, etc.)

• Fuel cooler malfunction (Crushing, breakage,

clogging, disconnection, etc.)

• Fuel tank malfunction

• Injector malfunction

• Fuel supply pump malfunction

• Pressure limiter malfunction

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness.

Inspect the ECM harness and connector for imprope

r

mating, broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

ECU may set a DTC, if there is adequate air in fuel line.

Schematic Reference: Engine Controls Schematics

Step Action Value(s) Yes No

1 Check the fuel quantity. W as a problem found?

Go to Step 2 Add fuel and

Go to Step 2

2 Check the fuel quality.

1. Discharge the fuel from fuel tank

2. Replenish the tank with specified fuel

3. Bleed the air from the fuel system

4. Start the engine

Could the engine be started?

Go to Step 7 Go to Step 3

3 Bleed the air from fuel system. Refer to Fuel

System Air Bleeding in this section.

Is the action complete?

Go to Step 4

4 Check the main fuel filter for clogging.

Clean, repair, or replace as required.

Notice: Replacement of a fuel filter is checking

to a dealer.

Is the action complete?

Go to Step 5

5 Check the fuel line and fuel cooler for damage

and leakage.

Clean, repair, or replace as required.

• Crushed areas

• Breakage

• Cracks

• Loose connections

Is the action complete?

Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1556 of 6020

FUEL SYSTEM (4JK1/4JJ1) 6C-15

The fuel system consists of many tiny holes and spaces

that allow the movement of fuel from one place to

another. These holes and spaces are milled to

extremely high precision. This is especially true of the

fuel injector.

The fuel injector is very sensitive to foreign material.

Foreign material will result in fuel system breakdown.

Exercise great care not to allow the entry of foreign

material into the fuel system or fuel injector during the

removal and installation procedure.

Note: To avoid electric shock;

Set the switch to the 'OFF' position and disconnect the

negative battery cable before checking or repairing the

fuel injector, wiring or/and connectors.

Removal

1. Remove the cylinder head cover.

Refer to the removal procedure for the cylinde

r

head cover in this manual.

Remove the attachment bolt of the engine oil gauge

guide tube.

2. Loosen the fuel injector clamp fixing bolts and

remove the fuel injector.

If the fuel injector is difficult to remove, use the remover. Use a screwdriver to force the fuel

injector clamp off the fuel injector.

Note: Do not remove the fuel injector sleeve.

Note: Cover the areas exposed during parts removal to

prevent the entry of foreign material into the fuel

system.

3. Mark each fuel injector with the number of the cylinder from which it was removed. Store the fuel

injector in a safe place. Position the fuel injector so

that the nozzle is protected.

Note: Do not tamper with the electromagnetic portion of

the fuel injector. Reduced electromagnetic function will

result in injector failure.

Note: After replacement of the fuel injector, perform the

following procedure.

• All fuel injectors are replaced:

Remove the fuel injector ID code label on the cylinder head cover.

• Any fuel injector(s) is replaced:

Black out the replaced cylinder of the fuel injecto

r

ID code on the fuel injector ID code label with a

marking pen or equivalent.

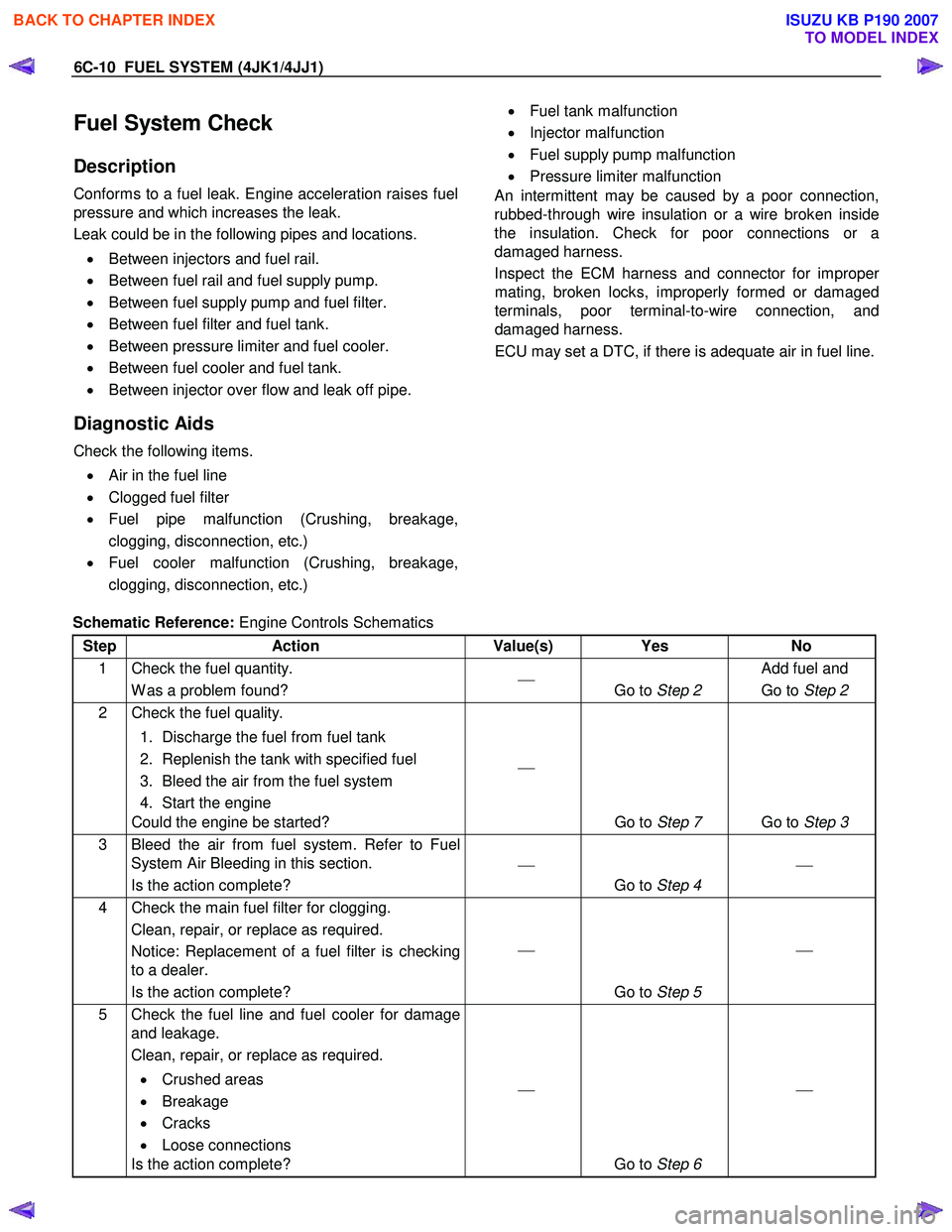

Installation

1. Install the new gasket and O-ring to each fuel

injector.

Note: Do not reuse the clips (3).

RTW 66CSH000101

Legend

1. Fuel Injector

2. Leak Off Pipe

3. Clip

4. O-ring

5. Gasket

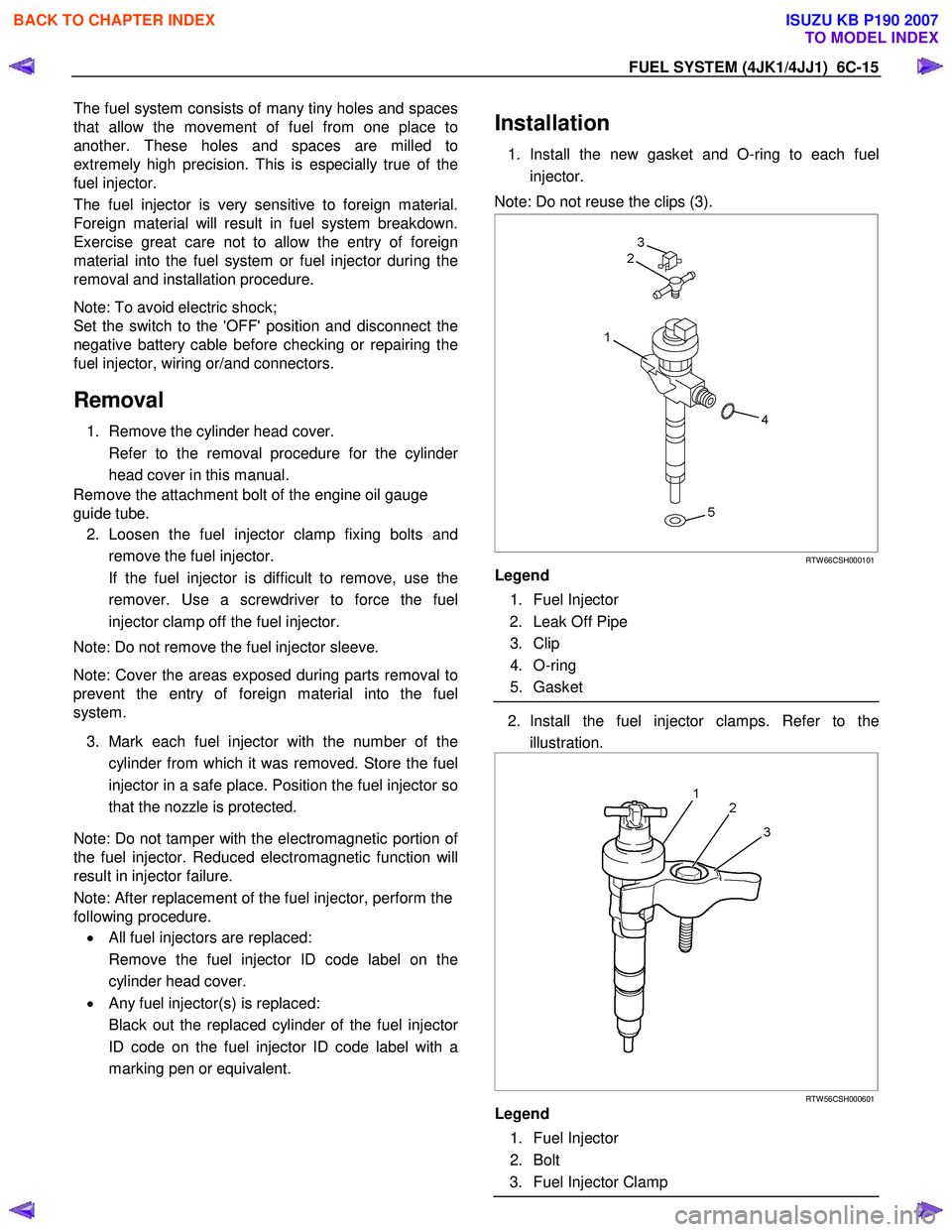

2. Install the fuel injector clamps. Refer to the

illustration.

RTW 56CSH000601

Legend

1. Fuel Injector

2. Bolt

3. Fuel Injector Clamp

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007