light ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4170 of 6020

UNIT REPAIR (AW30–40LE) 7A4–35

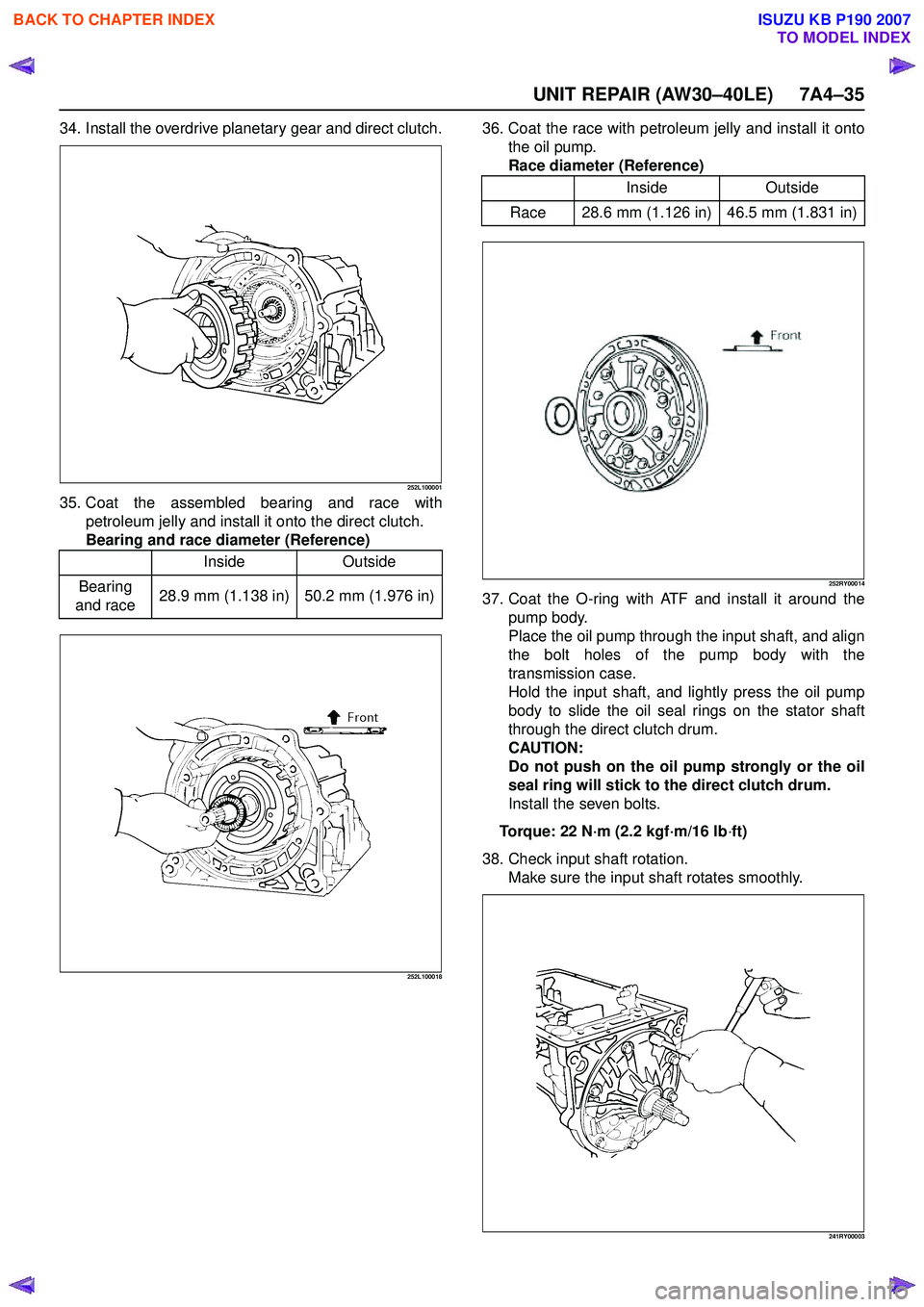

34. Install the overdrive planetary gear and direct clutch.

252L100001

35. Coat the assembled bearing and race withpetroleum jelly and install it onto the direct clutch.

Bearing and race diameter (Reference)

252L100018

36. Coat the race with petroleum jelly and install it onto the oil pump.

Race diameter (Reference)

252RY00014

37. Coat the O-ring with ATF and install it around the pump body.

Place the oil pump through the input shaft, and align

the bolt holes of the pump body with the

transmission case.

Hold the input shaft, and lightly press the oil pump

body to slide the oil seal rings on the stator shaft

through the direct clutch drum.

CAUTION:

Do not push on the oil pump strongly or the oil

seal ring will stick to the direct clutch drum.

Install the seven bolts.

Torque: 22 N ·m (2.2 kgf ·m/16 lb ·ft)

38. Check input shaft rotation. Make sure the input shaft rotates smoothly.

241RY00003

Inside Outside

Bearing

and race 28.9 mm (1.138 in) 50.2 mm (1.976 in)

Inside

Outside

Race 28.6 mm (1.126 in) 46.5 mm (1.831 in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4256 of 6020

CONSTRUCTION AND FUNCTION 7A1-17

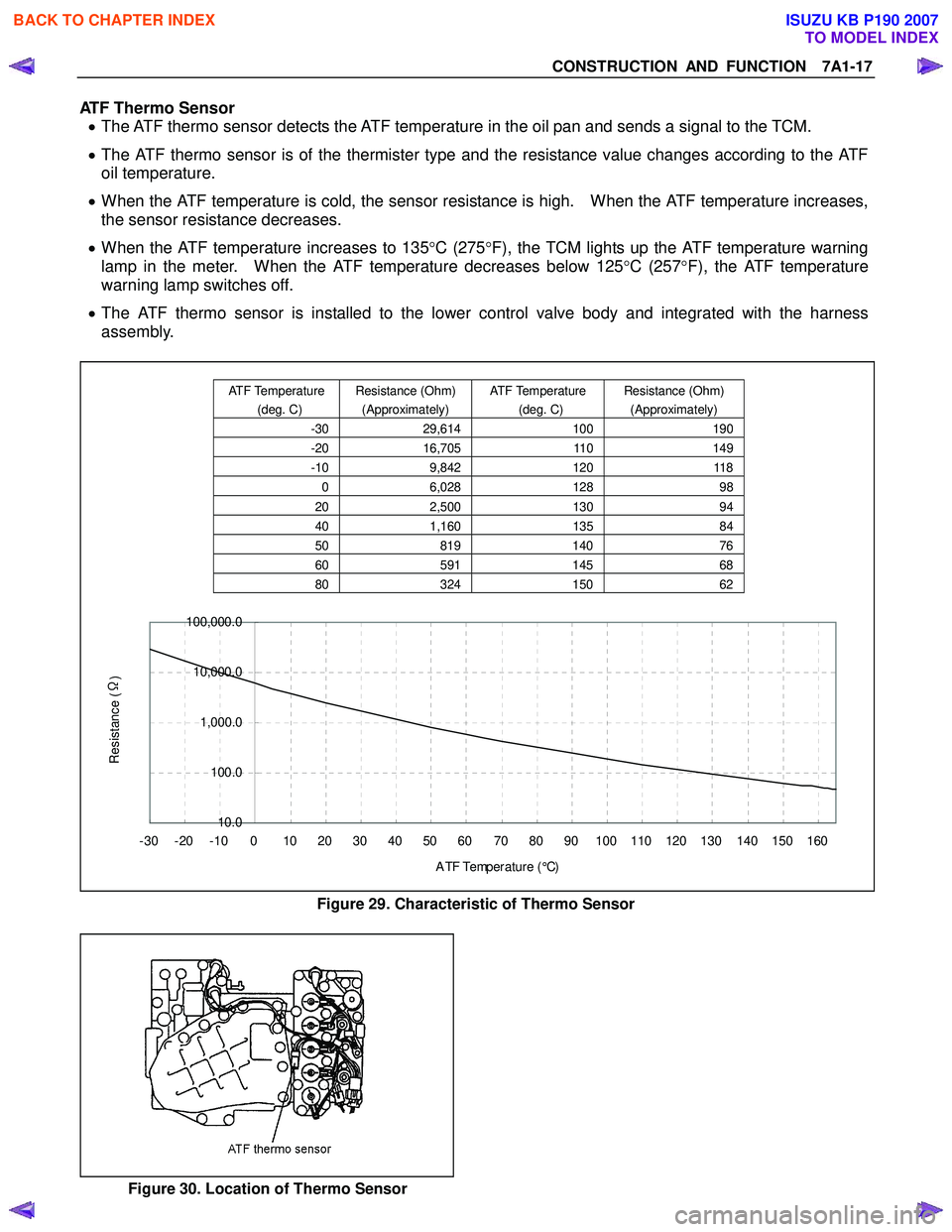

ATF Thermo Sensor • The ATF thermo sensor detects the ATF temperature in the oil pan and sends a signal to the TCM.

• The ATF thermo sensor is of the thermister type and the resistance value changes according to the ATF

oil temperature.

• When the ATF temperature is cold, the sensor resistance is high. When the ATF temperature increases,

the sensor resistance decreases.

• When the ATF temperature increases to 135 °C (275 °F), the TCM lights up the ATF temperature warning

lamp in the meter. When the ATF temperature decreases below 125 °C (257 °F), the ATF temperature

warning lamp switches off.

• The ATF thermo sensor is installed to the lower control valve body and integrated with the harness

assembly.

10.0

100.0

1,000.0

10,000.0

100,000.0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 A TF Temp er a t ur e ( °C)

Resistance (Ω

)

Figure 29. Characteristic of Thermo Sensor

Figure 30. Location of Thermo Sensor

ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately) ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately)

-30 29,614 100190

-20 16,705 110149

-10 9,842 120118

0 6,028 128 98

20 2,500 130 94

40 1,160 135 84

50 819 140 76

60 591 14568

80 324 15062

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4311 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-27

Power Drive Switch

This parameter displays the input state of the power

drive switch to the TCM. When the switch is pressed,

the scan tool displays On.

Power Drive Lamp

This parameter displays the commanded state of the

power drive lamp control circuit. The lamp should be

On when the scan tool indicates command On.

Brake Pedal Switch

This parameter displays the input state of the brake

pedal switch to the TCM. When the pedal is depressed,

scan tool displays On. Diagnostic Switch

This parameter displays the input state of the

diagnostic request switch to the TCM. When the data

link connector (DLC) terminal 11 is pulled low, the

check trans lamp blinks to indicate flash code.

Check Trans Lamp

This parameter displays the commanded state of the

check trans lamp control circuit. The lamp should be

On when the scan tool indicates command On.

Scan Tool Output Controls

Scan Tool

Output Control Descriptions

Lamp control Power Lamp Te s tThe purpose of this test is for checking whether the power drive lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control 3rd Start Lamp Te s t The purpose of this test is for checking whether the 3rd start lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control AT Oil Temperature

Lamp Test The purpose of this test is for checking whether the AT oil temperature lamp is operating

when commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Lamp control Check Light Te s t The purpose of this test is for checking whether the check trans lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not

operating when commanded ON.

Solenoid valve control Low & Reverse

Brake Solenoid The purpose of this test is for checking whether the low & reverse brake solenoid valve is

operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be

considered if not energizing when commanded ON.

Solenoid valve control 2-4 Brake

Solenoid Test The purpose of this test is for checking whether the 2-4 brake solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control High Clutch

Solenoid Test The purpose of this test is for checking whether the high clutch solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control Low Clutch

Solenoid Test The purpose of this test is for checking whether the low clutch solenoid valve is operating

when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be considered if

not energizing when commanded ON.

Solenoid valve control Pressure

Control

Solenoid (PCS) The purpose of this test is for checking whether the pressure control (PC) solenoid valve is

operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could be

considered if not energizing when commanded ON.

Solenoid valve control TCC Solenoid

Te s t The purpose of this test is for checking whether the torque converter clutch (TCC) solenoid

valve is operating when commanded ON. Faulty circuit(s) or a faulty solenoid valve could

be considered if not energizing when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4317 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-33

DTC P0560 (Flash Code 16)

Circuit Description

The TCM monitors the ignition voltage on the ignition

feed terminal to make sure that the voltage stays within

the proper range. If the TCM detects an excessively

low ignition voltage, this DTC will set.

Condition for Running the DTC • The ignition switch is ON.

• The engine speed is more than 1000 RPM.

Condition for Setting the DTC • The TCM detects that the ignition voltage feed circuit is less than 10 volts for 1 second.

Action Taken When the DTC Sets • The TCM blinks the Check Trans lamp when the diagnostic runs and fails.

During the vehicle running;

• The TCM holds the last gear position when the diagnostic runs and fails.

• The TCM inhibits lock up control. After the vehicle stopped;

• The TCM stops all shift solenoid valves and fixes to the 3rd gear. If a fail-safe valve problem is

detected, the shift solenoid valves are not stopped

but gear is fixed to the 3rd gear.

• The TCM stops PC solenoid valve.

Condition for Clearing the DTC • The TCM turns OFF the Check Trans lamp when the diagnostic runs and does not fail.

• A current DTC clears when the diagnostic runs and does not fail.

Diagnostic Aids • A charging system problem may set this DTC.

• The weakened battery may set this DTC.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing DTC P0560

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle.

4. Load the electrical system by turning ON the headlights, A/C, etc. while observing the DTC

Information with a scan tool.

Does the DTC fail this ignition? —

Go to Step 3 Go to Diagnostic

Aids

3 Test the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you find a charging system problem? —

Go to Step 4 Go to Step 5

4 Repair the charging system. Refer to Diagnosis of

The Charging System in the Charging System

Section.

Did you complete the repair? —

Go to Step 6 —

5 1. Turn OFF the ignition.

2. Disconnect the TCM harness connector.

3. Inspect for an intermittent, for poor connections and for corrosion at the harness

connector of the TCM (pins 5, 18 and 24 of C-

95).

4. Repair the connection(s) as necessary.

Did you find and correct the condition? —

Go to Step 6 Go to Diagnostic

Aids

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4318 of 6020

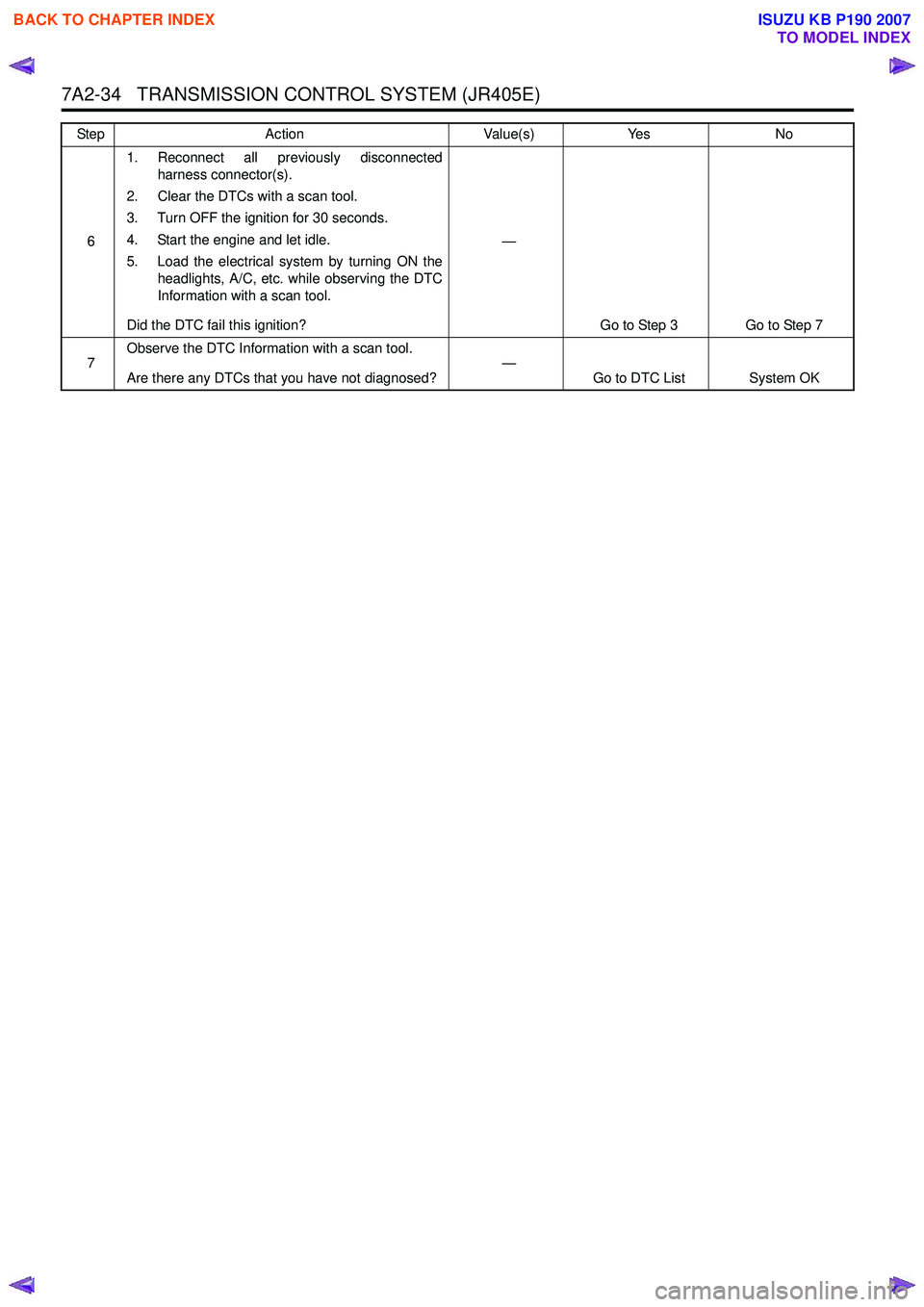

7A2-34 TRANSMISSION CONTROL SYSTEM (JR405E)

61. Reconnect all previously disconnected

harness connector(s).

2. Clear the DTCs with a scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and let idle.

5. Load the electrical system by turning ON the headlights, A/C, etc. while observing the DTC

Information with a scan tool.

Did the DTC fail this ignition? —

Go to Step 3 Go to Step 7

7 Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed? —

Go to DTC List System OK

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4373 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-89

Check Trans Lamp Inoperative, Always On or Always Blinking

Circuit Description

The Check Trans Lamp is located on the instrument

panel (IP) cluster. The Check Trans Lamp informs the

driver that a transmission control system fault has

occurred and that system requires service. The ignition

voltage is supplied to the Check Trans Lamp via meter

fuse. The TCM turns ON by grounding the lamp control

circuit. Check Trans Lamp Illumination

• The Check Trans Lamp illuminates for approximately 3 seconds when the ignition switch

is turned ON, with the engine OFF.

• The Check Trans Lamp blinks if the TCM detects a fault.

Schematic Reference: Transmission Controls

Schematics

Connector End View Reference: Transmission

Controls Connector End Views or TCM Connector End

Views

Circuit/ System Testing Check Trans Lamp Inoperative, Always On or Always Blinking

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Transmission Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Transmission Controls

2 1. Verify whether the instrument panel (IP)

cluster is operational.

2. Turn OFF the ignition for 30 seconds.

3. Turn ON the ignition, with the engine OFF.

Does the check trans lamp turn ON then turn OFF

after 3 seconds passed? —

Go to Intermittent Conditions Go to Step 3

3 Does the check trans lamp blink?

—Check for DTCs and

if none exist Go to

Step 4 Go to Step 6

4 1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Observe the Diagnostic Switch parameter with a scan tool.

Does the Diagnostic Switch parameter indicate

ON? —

Go to Step 5 Check for DTCs

5 Repair the short to ground between the TCM (pin

18 of C-94) and the data link connector (DLC) (pin

11 o f B - 5 8 ) .

Did you complete the repair? —

Go to Step 21 —

6 1. Perform the Check Light control with a scan

tool.

2. Command the lamp ON and OFF.

Does the check trans lamp turn ON and OFF with

each command? —

Go to Intermittent Conditions Go to Step 7

7 1. Turn OFF the ignition.

2. Inspect the Meter (10A) fuse in the cabin fuse block.

Is the Meter (10A) fuse open? —

Go to Step 8 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4375 of 6020

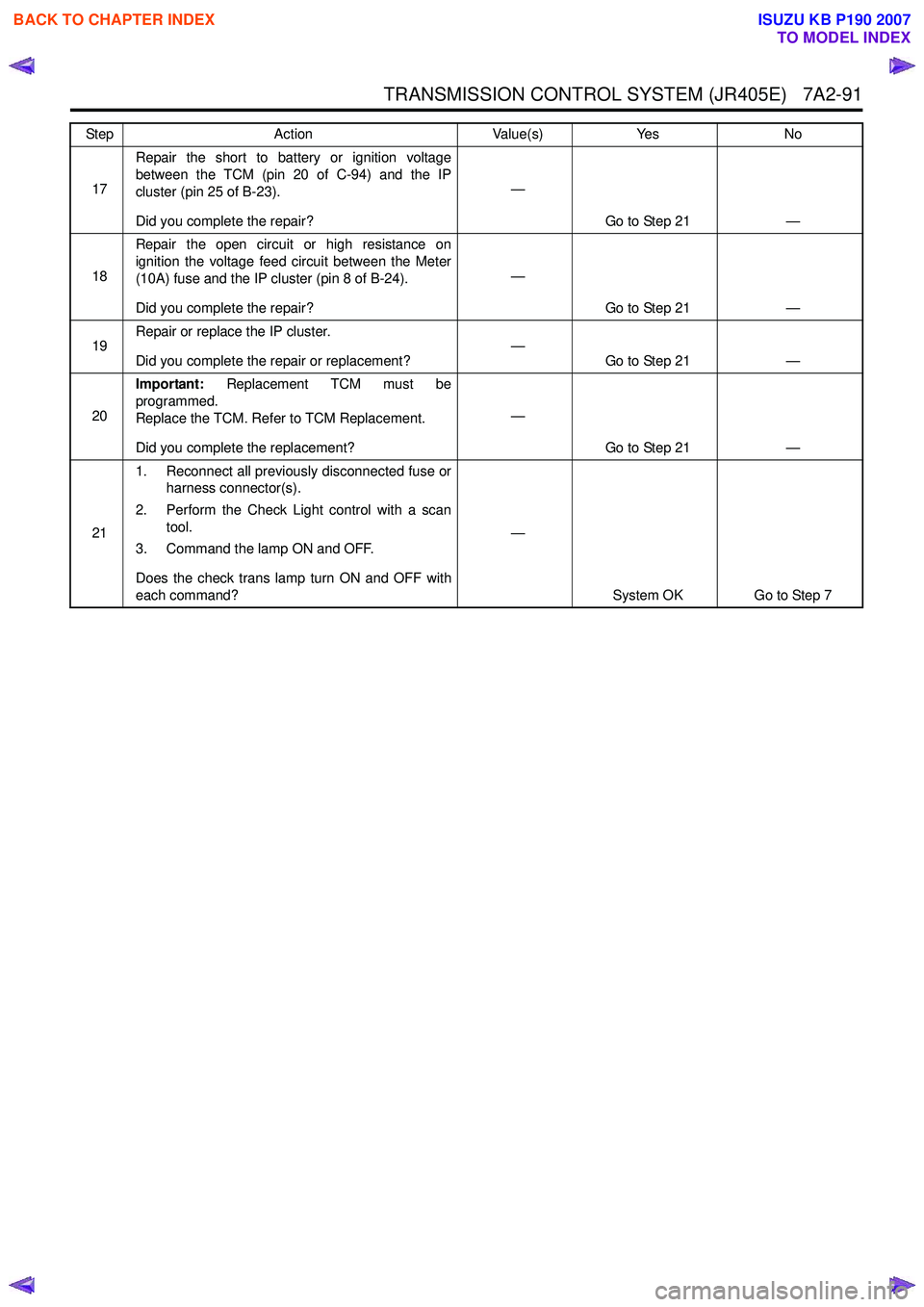

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-91

17Repair the short to battery or ignition voltage

between the TCM (pin 20 of C-94) and the IP

cluster (pin 25 of B-23).

Did you complete the repair? —

Go to Step 21 —

18 Repair the open circuit or high resistance on

ignition the voltage feed circuit between the Meter

(10A) fuse and the IP cluster (pin 8 of B-24).

Did you complete the repair? —

Go to Step 21 —

19 Repair or replace the IP cluster.

Did you complete the repair or replacement? —

Go to Step 21 —

20 Important:

Replacement TCM must be

programmed.

Replace the TCM. Refer to TCM Replacement.

Did you complete the replacement? —

Go to Step 21 —

21 1. Reconnect all previously disconnected fuse or

harness connector(s).

2. Perform the Check Light control with a scan tool.

3. Command the lamp ON and OFF.

Does the check trans lamp turn ON and OFF with

each command? —

System OK Go to Step 7

Step

Action Value(s)Yes No

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4376 of 6020

7A2-92 TRANSMISSION CONTROL SYSTEM (JR405E)

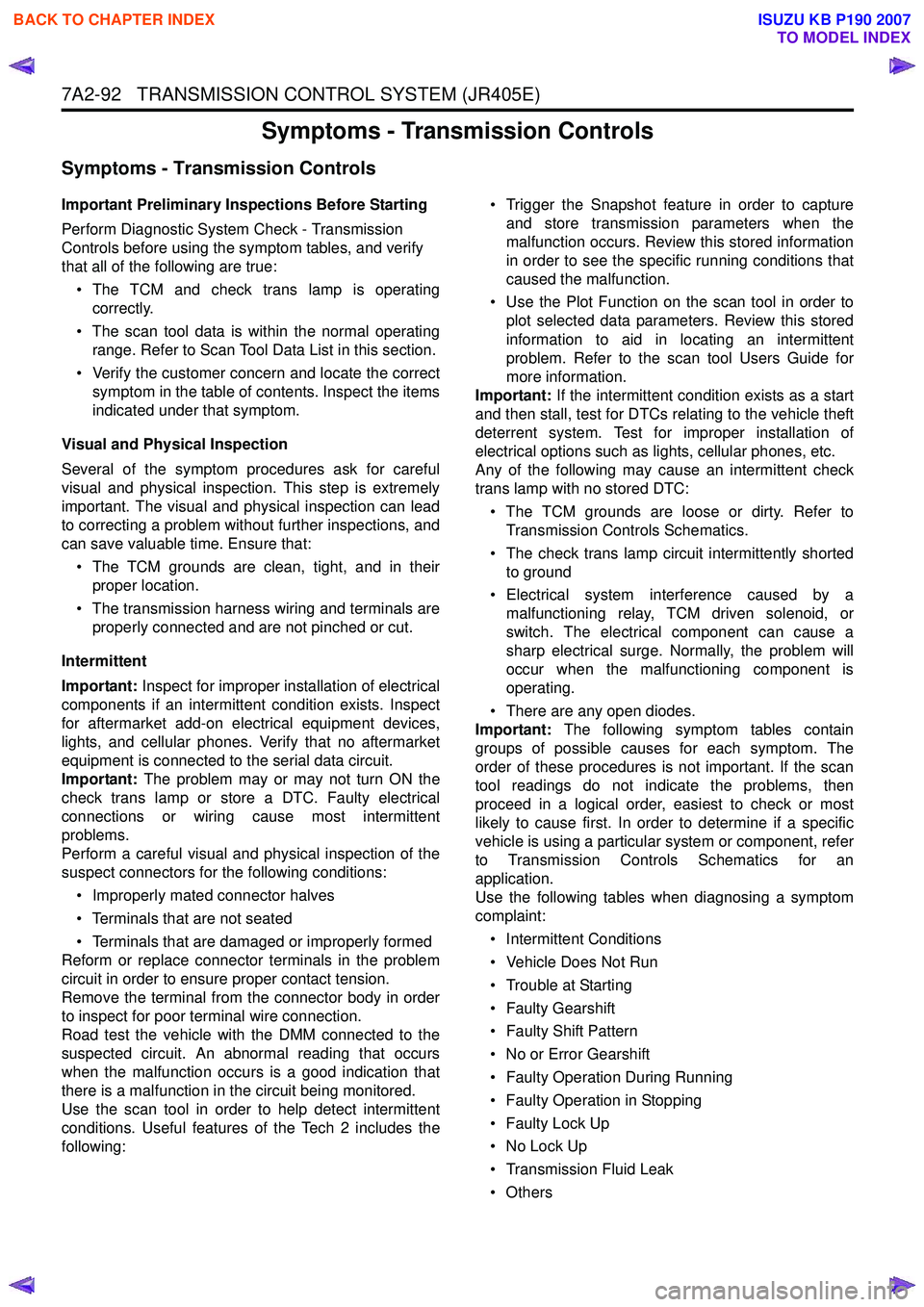

Symptoms - Transmission Controls

Symptoms - Transmission Controls

Important Preliminary Inspections Before Starting

Perform Diagnostic System Check - Transmission

Controls before using the symptom tables, and verify

that all of the following are true:

• The TCM and check trans lamp is operating correctly.

• The scan tool data is within the normal operating range. Refer to Scan Tool Data List in this section.

• Verify the customer concern and locate the correct symptom in the table of contents. Inspect the items

indicated under that symptom.

Visual and Physical Inspection

Several of the symptom procedures ask for careful

visual and physical inspection. This step is extremely

important. The visual and physical inspection can lead

to correcting a problem without further inspections, and

can save valuable time. Ensure that:

• The TCM grounds are clean, tight, and in their proper location.

• The transmission harness wiring and terminals are properly connected and are not pinched or cut.

Intermittent

Important: Inspect for improper installation of electrical

components if an intermittent condition exists. Inspect

for aftermarket add-on electrical equipment devices,

lights, and cellular phones. Verify that no aftermarket

equipment is connected to the serial data circuit.

Important: The problem may or may not turn ON the

check trans lamp or store a DTC. Faulty electrical

connections or wiring cause most intermittent

problems.

Perform a careful visual and physical inspection of the

suspect connectors for the following conditions:

• Improperly mated connector halves

• Terminals that are not seated

• Terminals that are damaged or improperly formed

Reform or replace connector terminals in the problem

circuit in order to ensure proper contact tension.

Remove the terminal from the connector body in order

to inspect for poor terminal wire connection.

Road test the vehicle with the DMM connected to the

suspected circuit. An abnormal reading that occurs

when the malfunction occurs is a good indication that

there is a malfunction in the circuit being monitored.

Use the scan tool in order to help detect intermittent

conditions. Useful features of the Tech 2 includes the

following: • Trigger the Snapshot feature in order to capture

and store transmission parameters when the

malfunction occurs. Review this stored information

in order to see the specific running conditions that

caused the malfunction.

• Use the Plot Function on the scan tool in order to plot selected data parameters. Review this stored

information to aid in locating an intermittent

problem. Refer to the scan tool Users Guide for

more information.

Important: If the intermittent condition exists as a start

and then stall, test for DTCs relating to the vehicle theft

deterrent system. Test for improper installation of

electrical options such as lights, cellular phones, etc.

Any of the following may cause an intermittent check

trans lamp with no stored DTC:

• The TCM grounds are loose or dirty. Refer to Transmission Controls Schematics.

• The check trans lamp circuit intermittently shorted to ground

• Electrical system interference caused by a malfunctioning relay, TCM driven solenoid, or

switch. The electrical component can cause a

sharp electrical surge. Normally, the problem will

occur when the malfunctioning component is

operating.

• There are any open diodes.

Important: The following symptom tables contain

groups of possible causes for each symptom. The

order of these procedures is not important. If the scan

tool readings do not indicate the problems, then

proceed in a logical order, easiest to check or most

likely to cause first. In order to determine if a specific

vehicle is using a particular system or component, refer

to Transmission Controls Schematics for an

application.

Use the following tables when diagnosing a symptom

complaint:

• Intermittent Conditions

• Vehicle Does Not Run

• Trouble at Starting

• Faulty Gearshift

• Faulty Shift Pattern

• No or Error Gearshift

• Faulty Operation During Running

• Faulty Operation in Stopping

• Faulty Lock Up

• No Lock Up

• Transmission Fluid Leak

•Others

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4378 of 6020

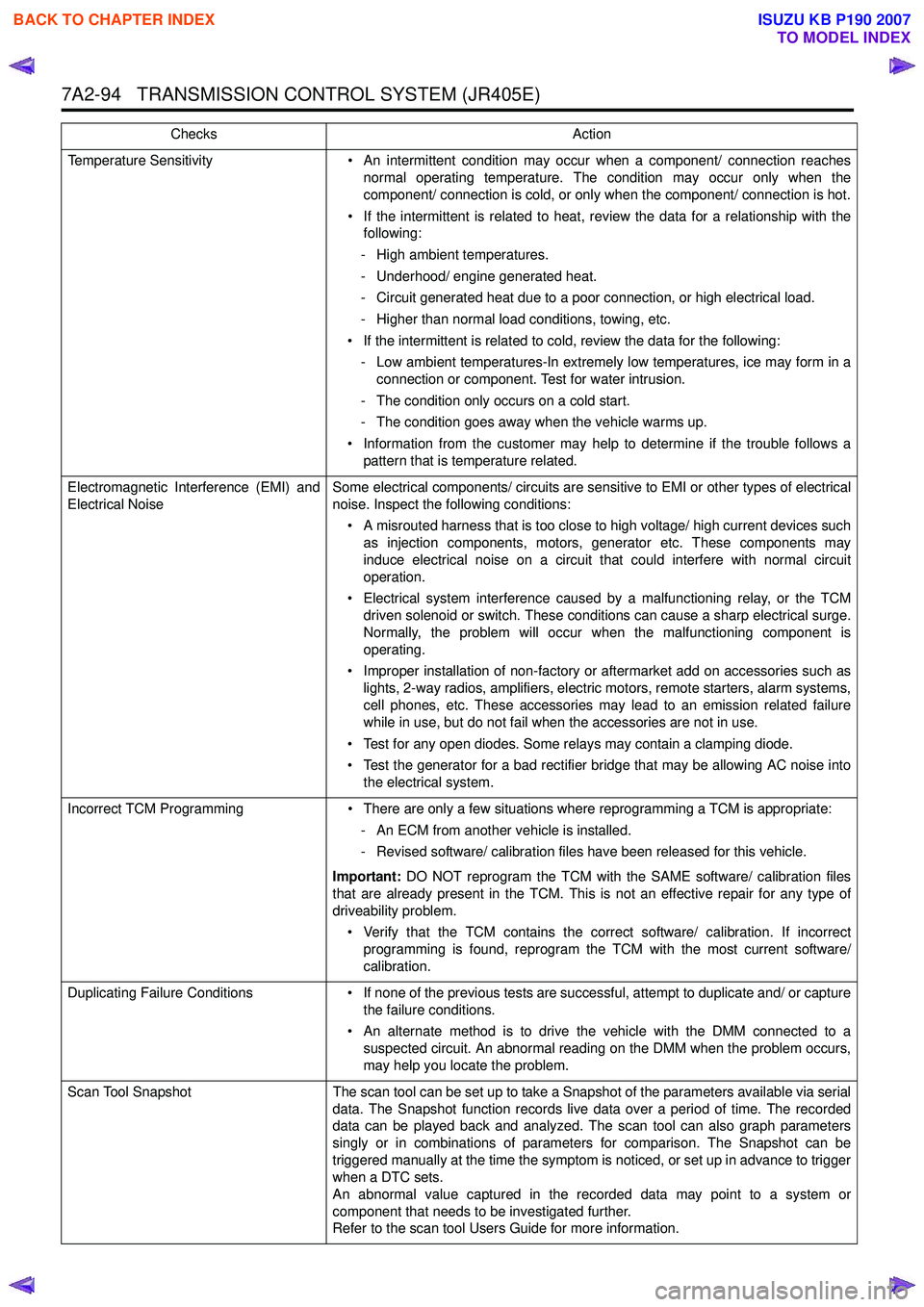

7A2-94 TRANSMISSION CONTROL SYSTEM (JR405E)

Temperature Sensitivity• An intermittent condition may occur when a component/ connection reaches

normal operating temperature. The condition may occur only when the

component/ connection is cold, or only when the component/ connection is hot.

• If the intermittent is related to heat, review the data for a relationship with the following:

- High ambient temperatures.

- Underhood/ engine generated heat.

- Circuit generated heat due to a poor connection, or high electrical load.

- Higher than normal load conditions, towing, etc.

• If the intermittent is related to cold, review the data for the following: - Low ambient temperatures-In extremely low temperatures, ice may form in a connection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern that is temperature related.

Electromagnetic Interference (EMI) and

Electrical Noise Some electrical components/ circuits are sensitive to EMI or other types of electrical

noise. Inspect the following conditions:

• A misrouted harness that is too close to high voltage/ high current devices such as injection components, motors, generator etc. These components may

induce electrical noise on a circuit that could interfere with normal circuit

operation.

• Electrical system interference caused by a malfunctioning relay, or the TCM driven solenoid or switch. These conditions can cause a sharp electrical surge.

Normally, the problem will occur when the malfunctioning component is

operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights, 2-way radios, amplifiers, electric motors, remote starters, alarm systems,

cell phones, etc. These accessories may lead to an emission related failure

while in use, but do not fail when the accessories are not in use.

• Test for any open diodes. Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the electrical system.

Incorrect TCM Programming • There are only a few situations where reprogramming a TCM is appropriate:

- An ECM from another vehicle is installed.

- Revised software/ calibration files have been released for this vehicle.

Important: DO NOT reprogram the TCM with the SAME software/ calibration files

that are already present in the TCM. This is not an effective repair for any type of

driveability problem.

• Verify that the TCM contains the correct software/ calibration. If incorrect programming is found, reprogram the TCM with the most current software/

calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/ or capture

the failure conditions.

• An alternate method is to drive the vehicle with the DMM connected to a suspected circuit. An abnormal reading on the DMM when the problem occurs,

may help you locate the problem.

Scan Tool Snapshot The scan tool can be set up to take a Snapshot of the parameters available via serial

data. The Snapshot function records live data over a period of time. The recorded

data can be played back and analyzed. The scan tool can also graph parameters

singly or in combinations of parameters for comparison. The Snapshot can be

triggered manually at the time the symptom is noticed, or set up in advance to trigger

when a DTC sets.

An abnormal value captured in the recorded data may point to a system or

component that needs to be investigated further.

Refer to the scan tool Users Guide for more information.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4423 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-139

Repair Instructions

Transmission Controls Module (TCM) Replacement

Description

The following A - C steps provide an overview

procedure to replace and reprogram a TCM. Each A -C

steps is explained further in this section.

A. Replace the old TCM with the new TCM.

B. Program the latest software and calibrations into the

new TCM using the Service Programming System

(SPS) if released. If not released, do not perform this

and skip to Step C.

C. Program the vehicle identification number (VIN) into

the TCM.

A. Removal and Installation

Removal Procedure 1. Disconnect the negative battery cable.

2. Disconnect the TCM harness connectors (1).

3. Loosen nuts (2) and remove the TCM (3) from the bracket (4).

Installation Procedure

Follow the removal steps in the reverse order. Be sure

that the connectors are securely fastened.

B. Programming Software and Calibrations

Program the latest software/ calibrations if released.

Refer to Service Programming System (SPS)

Description and SPS (Remote Procedure) or SPS

(Pass-Thru Procedure) in this section. If not released,

do not perform this and skip to Step C.

C. Programming Vehicle Identification Number

(VIN) Notice:

If you have performed SPS in the previous

step, VIN has prgrommaned already. Programming VIN

is not necessary in this step.

1. Install a scan tool.

2. Turn ON the ignition, with the engine OFF.

3. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

4. If you installed a new, skip to step 8. If you installed a reused TCM from another vehicle or incorrect

VIN is programmed before, the TCM might be

locked already. In order to get programming

approval, the on-screen displays a message to

user. Get programming approval from the TIS

2000 using the following procedure:

a. Connect a scan tool to the terminal that installed TIS 2000 with the latest software and

the hardware key is plugged into port.

b. Turn ON the scan tool and keep at title screen.

c. Launch the TIS application.

d. Select the Security Access at the main screen.

e. Highlight the “Tech 2" on the Diagnostic Tool Selection screen and click “Next”.

f. Click “Close” on the Security Access Enabled screen.

g. Turn OFF the scan tool.

h. Disconnect the scan tool from the terminal.

5. Install a scan tool to the vehicle.

6. Turn ON the ignition, with the engine OFF.

7. Select Diagnostics > appropriate vehicle identification > AT JR405E > Programming >

Program VIN.

8. Input 17 digits of correct VIN.

9. After complete the programming, turn OFF/ ON the ignition.

10. Select Diagnostics > Lock ECU.

11. Follow the on-screen instructions and turn OFF/ ON the ignition.

Service Programming System (SPS)

Description

The service programming system (SPS) allows a

technician to program a control module through the

data link connector (DLC). The information transfer

circuit that is used at the DLC is the same serial data

circuit used by the scan tool for retrieving DTCs,

displaying data, clearing DTCs etc. This procedure

offers the ability to install software/ calibrations

matched to a particular vehicle.

Most control modules have two types of memory. The

software/ calibrations reside in the flash memory. The

two types of memory are listed below:

1

3 42

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007