ECU ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 962 of 6020

6B – 18 ENGINE COOLING

110RS005

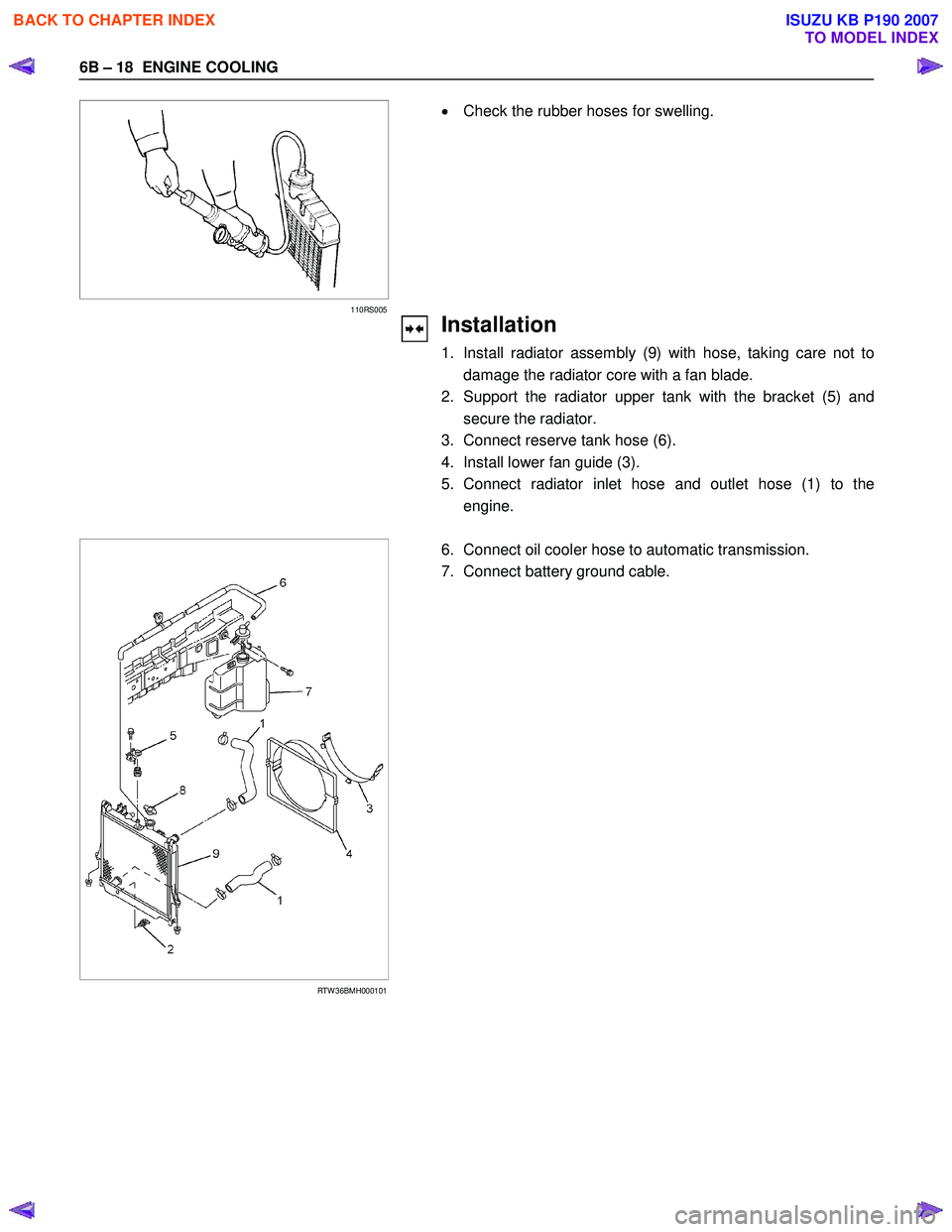

• Check the rubber hoses for swelling.

Installation

1. Install radiator assembly (9) with hose, taking care not to damage the radiator core with a fan blade.

2. Support the radiator upper tank with the bracket (5) and secure the radiator.

3. Connect reserve tank hose (6).

4. Install lower fan guide (3).

5. Connect radiator inlet hose and outlet hose (1) to the engine.

RTW 36BMH000101

6. Connect oil cooler hose to automatic transmission.

7. Connect battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 979 of 6020

FUEL SYSTEM 6C – 15

140R100037

2. For removal of the quick connector, hold the quick

connector in one hand, and pull out the connector with the

other hand while pressing the square relieve button of the

connector, as illustrated.

NOTE: Do not use tools of any kind. Only use bare hands

when disconnecting the connector. Use a lubricant (light oil)

and/or push and pull the connector until the pipe is

disconnected.

140R100028

Cover the connectors that was removed with a plastic bag,

to prevent dust or rain water from entering.

140R100036

Reuse of Quick–Connector

• Replace the port and connector if scratch, dent or crack is

found.

• Remove any dirt build up on the port when installing the

connector. Replace the connector, if there is any forms o

f

rust, dent, scratch.

• After cleaning the port, insert it straight into the connecto

r

until it clicks. After it clicks, try pulling at 49N (5kgf) it out to

make sure that it is not drawn and is securely locked.

Assembling Advice

By applying engine oil or light oil to the pipe, port makes pipe

assembly easier. The pipe assembly should take place

immediately after applying oil (to prevent dust from sticking to

the pipe surface – which may decrease sealing ability). Test/Inspection After Assembling

1. Reconnect the battery negative cable.

2. Start the engine and observe the engine idle speed. The presence of dirt in the fuel system may affect the fuel

injection system.

3. Check for fuel leakage from the connector.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 995 of 6020

FUEL SYSTEM 6C – 31

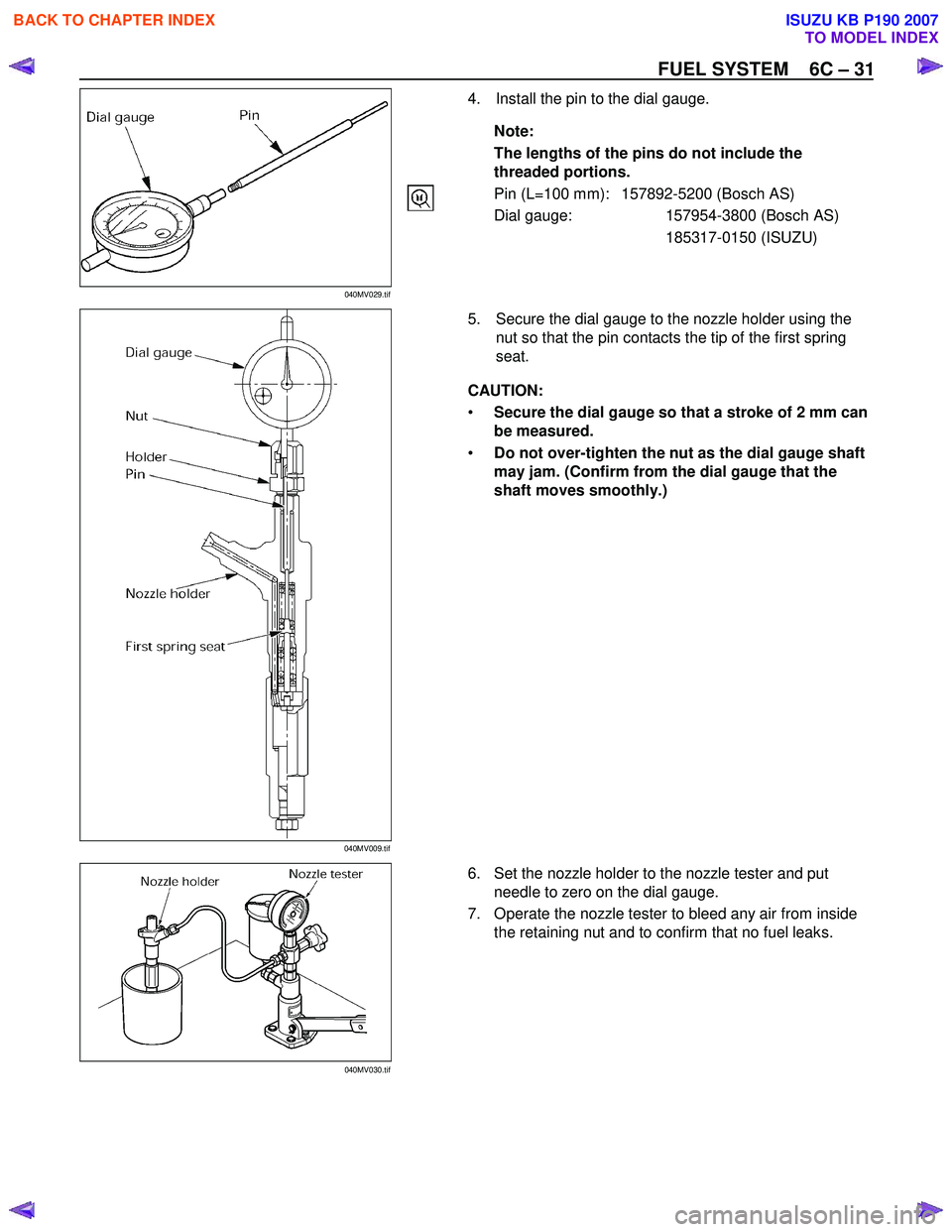

4. Install the pin to the dial gauge.

Note:

The lengths of the pins do not include the threaded portions.

Pin (L=100 mm): 157892-5200 (Bosch AS)

Dial gauge: 157954-3800 (Bosch AS)

185317-0150 (ISUZU)

5. Secure the dial gauge to the nozzle holder using the nut so that the pin contacts the tip of the first spring

seat.

CAUTION:

• Secure the dial gauge so that a stroke of 2 mm can

be measured.

• Do not over-tighten the nut as the dial gauge shaft

may jam. (Confirm from the dial gauge that the

shaft moves smoothly.)

6. Set the nozzle holder to the nozzle tester and put needle to zero on the dial gauge.

7. Operate the nozzle tester to bleed any air from inside the retaining nut and to confirm that no fuel leaks.

040MV029.tif

040MV009.tif 040MV030.tif

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1096 of 6020

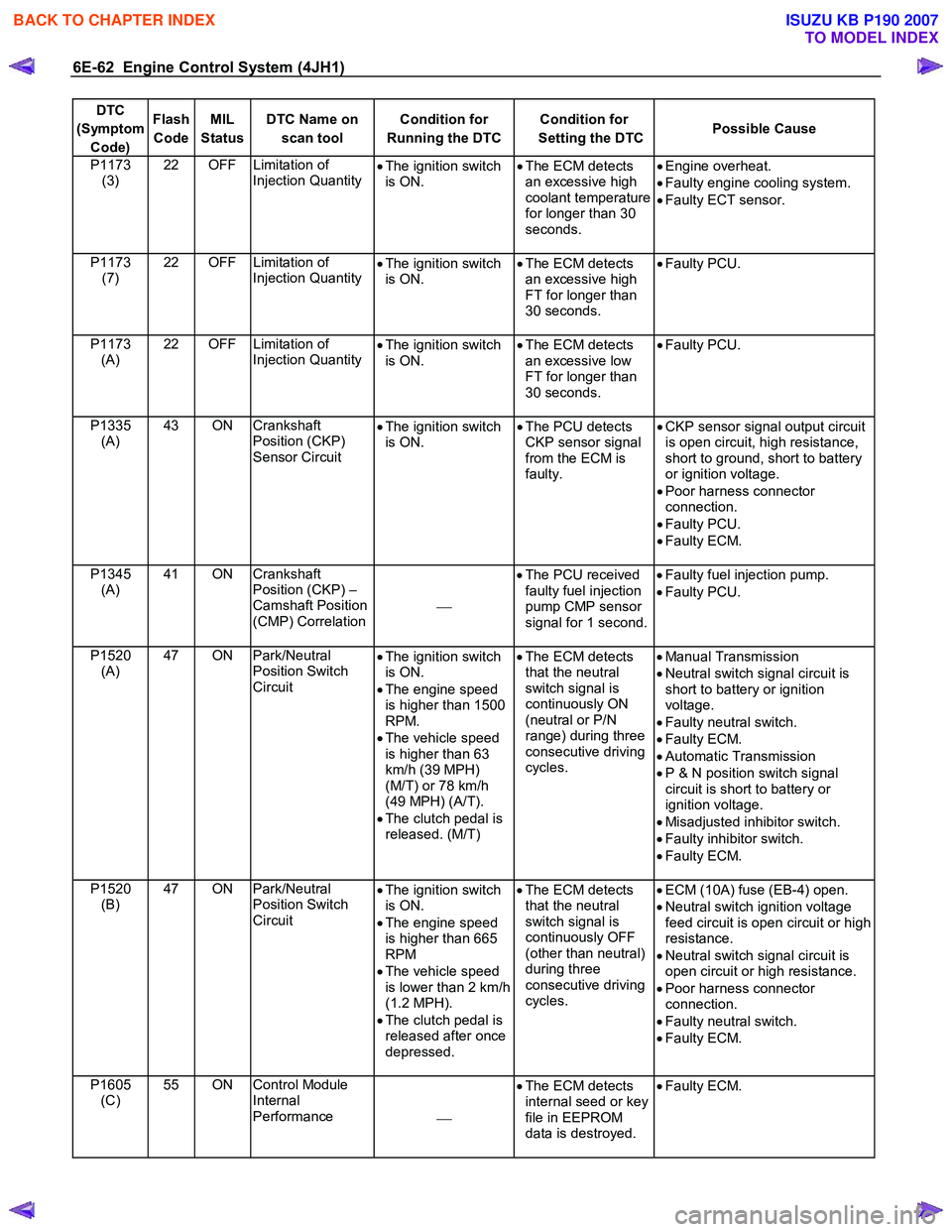

6E-62 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1173

(3) 22 OFF Limitation of

Injection Quantity •

The ignition switch

is ON. •

The ECM detects

an excessive high

coolant temperature

for longer than 30

seconds.

•

Engine overheat.

• Faulty engine cooling system.

• Faulty ECT sensor.

P1173 (7) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive high

FT for longer than

30 seconds.

•

Faulty PCU.

P1173 (A) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive low

FT for longer than

30 seconds.

•

Faulty PCU.

P1335 (A) 43 ON Crankshaft

Position (CKP)

Sensor Circuit •

The ignition switch

is ON. •

The PCU detects

CKP sensor signal

from the ECM is

faulty.

•

CKP sensor signal output circuit

is open circuit, high resistance,

short to ground, short to battery

or ignition voltage.

• Poor harness connector

connection.

• Faulty PCU.

• Faulty ECM.

P1345 (A) 41 ON Crankshaft

Position (CKP) –

Camshaft Position

(CMP) Correlation

•

The PCU received

faulty fuel injection

pump CMP sensor

signal for 1 second.

•

Faulty fuel injection pump.

• Faulty PCU.

P1520 (A) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 1500

RPM.

• The vehicle speed

is higher than 63

km/h (39 MPH)

(M/T) or 78 km/h

(49 MPH) (A/T).

• The clutch pedal is

released. (M/T)

•

The ECM detects

that the neutral

switch signal is

continuously ON

(neutral or P/N

range) during three

consecutive driving

cycles.

•

Manual Transmission

• Neutral switch signal circuit is

short to battery or ignition

voltage.

• Faulty neutral switch.

• Faulty ECM.

• Automatic Transmission

• P & N position switch signal

circuit is short to battery or

ignition voltage.

• Misadjusted inhibitor switch.

• Faulty inhibitor switch.

• Faulty ECM.

P1520 (B) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 665

RPM

• The vehicle speed

is lower than 2 km/h

(1.2 MPH).

• The clutch pedal is

released after once

depressed.

•

The ECM detects

that the neutral

switch signal is

continuously OFF

(other than neutral)

during three

consecutive driving

cycles.

•

ECM (10A) fuse (EB-4) open.

• Neutral switch ignition voltage

feed circuit is open circuit or high

resistance.

• Neutral switch signal circuit is

open circuit or high resistance.

• Poor harness connector

connection.

• Faulty neutral switch.

• Faulty ECM.

P1605 (C) 55 ON Control Module

Internal

Performance •

The ECM detects

internal seed or key

file in EEPROM

data is destroyed.

•

Faulty ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1097 of 6020

Engine Control System (4JH1) 6E-63

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

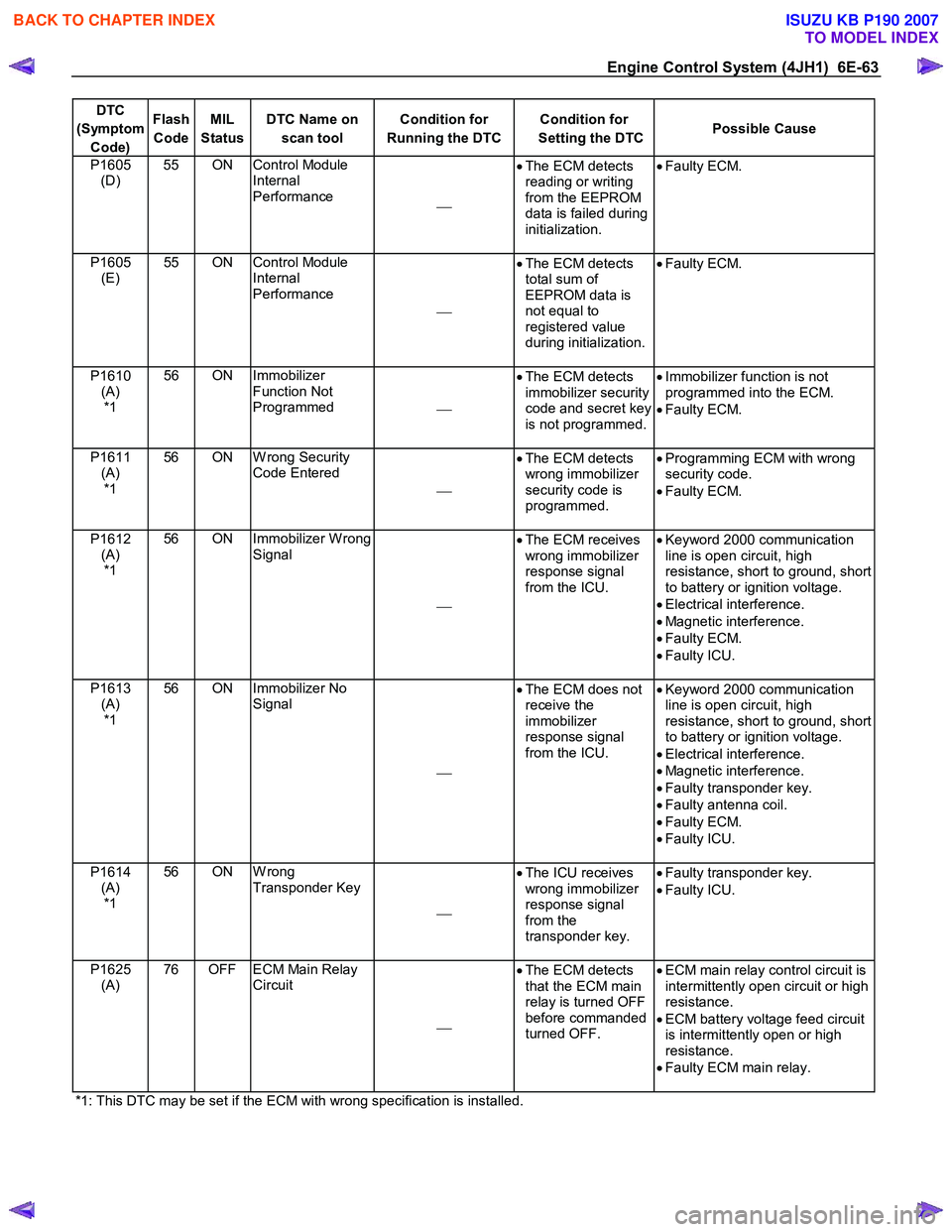

P1605

(D) 55 ON Control Module

Internal

Performance •

The ECM detects

reading or writing

from the EEPROM

data is failed during

initialization.

•

Faulty ECM.

P1605

(E) 55 ON Control Module

Internal

Performance

•

The ECM detects

total sum of

EEPROM data is

not equal to

registered value

during initialization.

•

Faulty ECM.

P1610

(A) *1 56 ON Immobilizer

Function Not

Programmed •

The ECM detects

immobilizer security

code and secret key

is not programmed.

•

Immobilizer function is not

programmed into the ECM.

• Faulty ECM.

P1611 (A) *1 56 ON W rong Security

Code Entered

•

The ECM detects

wrong immobilizer

security code is

programmed.

•

Programming ECM with wrong

security code.

• Faulty ECM.

P1612 (A) *1 56 ON Immobilizer W rong

Signal

•

The ECM receives

wrong immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty ECM.

• Faulty ICU.

P1613 (A) *1 56 ON Immobilizer No

Signal

•

The ECM does not

receive the

immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty transponder key.

• Faulty antenna coil.

• Faulty ECM.

• Faulty ICU.

P1614 (A) *1 56 ON W rong

Transponder Key

•

The ICU receives

wrong immobilizer

response signal

from the

transponder key.

•

Faulty transponder key.

• Faulty ICU.

P1625 (A) 76 OFF ECM Main Relay

Circuit

•

The ECM detects

that the ECM main

relay is turned OFF

before commanded

turned OFF.

•

ECM main relay control circuit is

intermittently open circuit or high

resistance.

• ECM battery voltage feed circuit

is intermittently open or high

resistance.

• Faulty ECM main relay.

*1: This DTC may be set if the ECM with wrong specification is installed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1100 of 6020

6E-66 Engine Control System (4JH1)

DTC P0100 (Symptom Code 7) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed. A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) provides 5 volts

reference voltage through the reference circuit to the

MAF sensor. The ECM monitors the voltage on the 5

volts reference circuit. If the ECM detects an

excessively high MAF sensor 5 volts reference voltage,

this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the MAF sensor 5 volts

reference circuit voltage is more than 5.2 volts fo

r

0.5 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the MAF sensor 5 volts reference circuit between

the ECM and the sensor is normal, the sensor signal

voltage low DTC P0100 (Symptom Code B) will set.

DTC P0100 (Symptom Code 7) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the mass air flow (MAF) sensor harness connector.

3. Start the engine and let idle for 30 seconds.

4. Monitor the DTC Information with the scan tool.

Does DTC P0100 (Symptom Code B) set, but not

DTC P0100 (Symptom Code 7)?

Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1102 of 6020

6E-68 Engine Control System (4JH1)

DTC P0100 (Symptom Code 9) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed. A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) provides 5 volts

reference voltage through the reference circuit to the

MAF sensor. The ECM monitors the voltage on the 5

volts reference circuit. If the ECM detects an

excessively low MAF sensor 5 volts reference voltage,

this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the MAF sensor 5 volts

reference circuit voltage is less than 4.6 volts fo

r

0.5 seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

•

The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the MAF sensor 5 volts reference circuit between

the ECM and the sensor is normal, the sensor signal

voltage low DTC P0100 (Symptom Code B) will set.

DTC P0100 (Symptom Code 9) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the mass air flow (MAF) sensor harness connector.

3. Start the engine and let idle for 30 seconds.

4. Monitor the DTC Information with the scan tool.

Does DTC P0100 (Symptom Code B) set, but not

DTC P0100 (Symptom Code 9)?

Go to Step 5 Go to Step 4

4 1. Test the 5 volts reference circuit between the engine control module (ECM) (pin 83 of C-57

connector) and the MAF sensor (pin 4 of C-116

connector) for the following conditions: • A short to ground

• A short to the low reference circuit

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Step 6

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1104 of 6020

6E-70 Engine Control System (4JH1)

DTC P0100 (Symptom Code B) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed. A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) monitors the MAF

sensor signal for voltage outside the normal range o

f

the MAF sensor. If the ECM detects an excessively low

MAF sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM calculated MAF is lower than -18.6 kg/h

for 5 seconds. This indicates the ECM detects that

the MAF sensor signal voltage is smaller than a

predetermined range during engine run.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL that the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • W rong direction of MAF sensor installation will

cause this DTC to set.

• Contaminated or restricted MAF sensor will cause

this DTC to set.

• The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

7. If the MAF sensor signal circuit between the ECM

and the sensor is short to ground or any low reference

circuits, the sensor 5 volts reference voltage low DTC

P0100 (Symptom Code 9) will set.

8. If the MAF sensor signal circuit between the ECM

and the sensor is normal, the sensor signal voltage high

DTC P0100 (Symptom Code C) will set.

DTC P0100 (Symptom Code B) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the ECM (10A) fuse (EB-

4) or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1107 of 6020

Engine Control System (4JH1) 6E-73

DTC P0100 (Symptom Code C) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed.

A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) monitors the MAF

sensor signal for voltage outside the normal range o

f

the MAF sensor. If the ECM detects an excessively high

MAF sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM calculated MAF is higher than 984 kg/h

for 10 seconds. This indicates the ECM detects

that the MAF sensor signal voltage is higher than a

predetermined range during engine run.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the MAF sensor signal circuit between the ECM

and the sensor is normal, the sensor signal voltage lo

w

DTC P0100 (Symptom Code B) will set.

DTC P0100

(Symptom Code C) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the mass air flow (MAF) sensor harness connector.

3. Start the engine and let idle for 30 seconds.

4. Monitor the DTC Information with the scan tool.

Does DTC P0100 (Symptom Code B) set, but not

DTC P0100 (Symptom Code C)?

Go to Step 4 Go to Step 5

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1109 of 6020

Engine Control System (4JH1) 6E-75

DTC P0105 (Symptom Code 1) (Flash Code 34)

Circuit Description

The vacuum pressure sensor is installed to the

turbocharger wastegate control hose and it detects the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The vacuum pressure sensor is a

transducer that varies voltage according to changes in

the vacuum pressure inside the vacuum hose. The

vacuum pressure sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Vacuum pressure sensor signal circuit

The engine control module (ECM) supplies 5 volts to

the vacuum pressure sensor on the 5 volts reference

circuit. The ECM also provides a ground on the lo

w

reference circuit. The vacuum pressure sensor provides

a signal to the ECM on the vacuum pressure signal

circuit which is relative to the vacuum pressure changes

in the turbocharger wastegate valve control hose. The

ECM should detect a low signal voltage at a high

vacuum pressure and high signal voltage at a lo

w

vacuum pressure. The ECM monitors the vacuum

pressure sensor signal for voltage outside the normal

range of the vacuum pressure sensor. If the ECM

detects an excessively high vacuum pressure senso

r

signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vacuum pressure

sensor signal voltage is more than 4.4 volts for 3

seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses a barometric pressure of 615 hPa

for turbocharger wastegate valve control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the vacuum pressure sensor signal circuit between

the ECM and the sensor is normal, the sensor signal

voltage low DTC P0105 (Symptom Code 2) will set.

DTC P0105 (Symptom Code 1) (Flash Code 34)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Disconnect the vacuum pressure sensor harness connector.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with the scan tool.

Does DTC P0105 (Symptom Code 2) set, but not

DTC P0105 (Symptom Code 1)?

Go to Step 4 Go to Step 6

4 1. Turn OFF the ignition. 2. Connect a test lamp between the low reference circuit of the vacuum pressure sensor harness

(pin 2 of C-124 connector) and battery voltage.

Does the test lamp illuminate?

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007