ECU ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 516 of 6020

4C1-12 FRONT WHEEL DRIVE

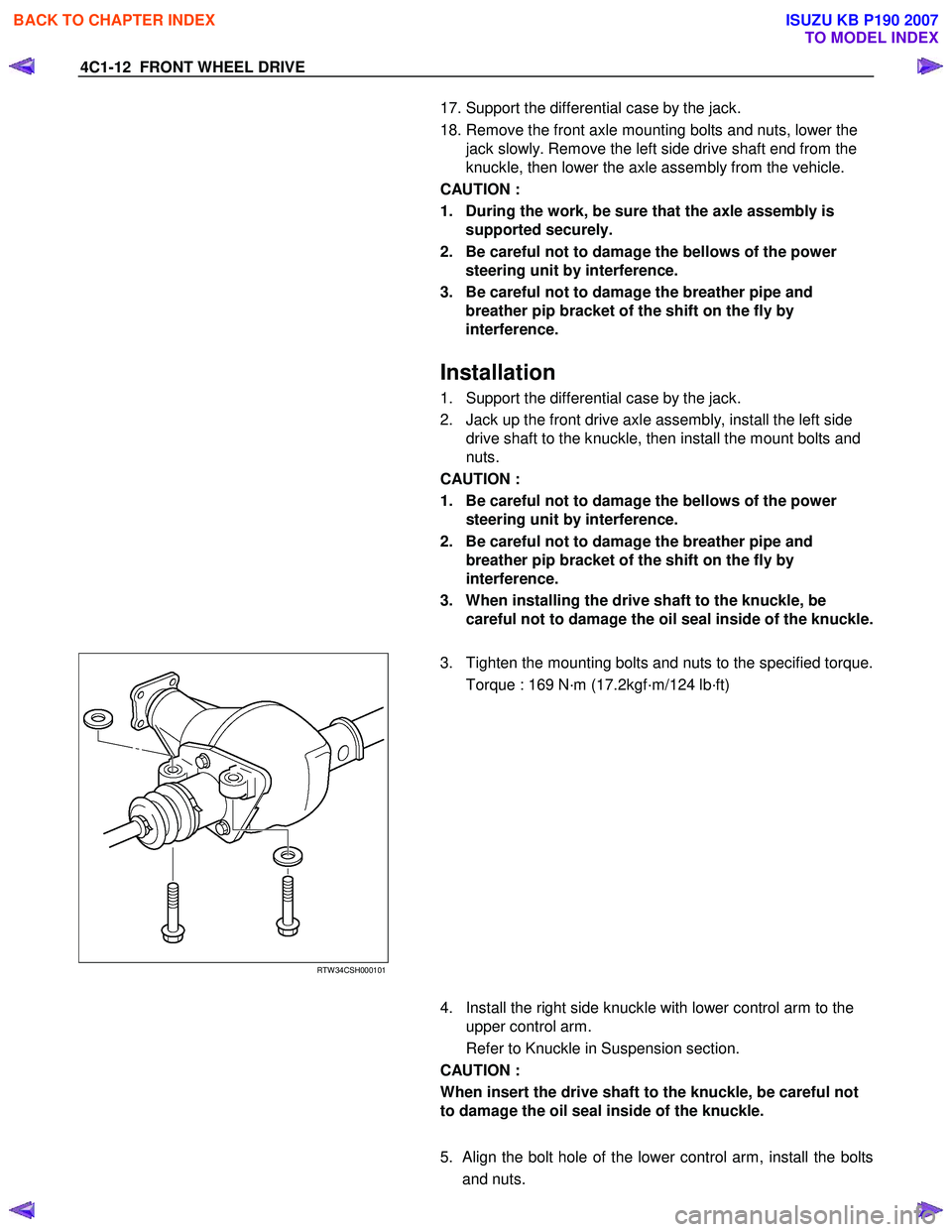

17. Support the differential case by the jack.

18. Remove the front axle mounting bolts and nuts, lower the jack slowly. Remove the left side drive shaft end from the

knuckle, then lower the axle assembly from the vehicle.

CAUTION :

1. During the work, be sure that the axle assembly is supported securely.

2. Be careful not to damage the bellows of the power steering unit by interference.

3. Be careful not to damage the breather pipe and breather pip bracket of the shift on the fly by

interference.

Installation

1. Support the differential case by the jack.

2. Jack up the front drive axle assembly, install the left side drive shaft to the knuckle, then install the mount bolts and

nuts.

CAUTION :

1. Be careful not to damage the bellows of the power steering unit by interference.

2. Be careful not to damage the breather pipe and breather pip bracket of the shift on the fly by

interference.

3. When installing the drive shaft to the knuckle, be careful not to damage the oil seal inside of the knuckle.

RTW 34CSH000101

3. Tighten the mounting bolts and nuts to the specified torque.

Torque : 169 N·m (17.2kgf·m/124 lb·ft)

4. Install the right side knuckle with lower control arm to the

upper control arm.

Refer to Knuckle in Suspension section.

CAUTION :

When insert the drive shaft to the knuckle, be careful not

to damage the oil seal inside of the knuckle.

5.

Align the bolt hole of the lower control arm, install the bolts

and nuts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 522 of 6020

4C1-18 FRONT WHEEL DRIVE

Legend

1. UJ Case

2. Bellows

8. Install band. Note the setting direction. After installation,

check Standard Caulk Measure.

Discard the used band and install a new one.

Use the special tool pliers 5-8840-2745-0 to caulk the band to the specified value.

For both sides on UJ bellows.

Standard Caulk Measure

• 1.2mm (0.05in) <= (1), (2) <= 4.0mm (0.16in)

• (1) - (2) or (2) - (1) <= 0.4mm (0.016in)

9. Install another bellows and fix band.

Discard the used band and install a new one.

10. Install the ball guide with the smaller diameter side ahead onto the shaft.

11. Install ball retainer.

12. Using snap ring pliers, install the snap ring (1) securing the

ball retainer to the shaft.

Discard the used snap ring and install a new one.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 595 of 6020

BRAKE CON TROL SY STE M 5 A-2

DTC C0251 (Flash Code 51) Rear Hold Solenoid Valve Circuit ..................................... 5A-70

DTC C0252 (Flash Code 52) Rear Release Solenoid Valve Circuit ................................ 5A-70

DTC C0265 (Flash Code 65) Valve Relay Circuit Malfunction ........................................ 5A-72

DTC C0267 (Flash Code 67) Return Pump Circuit Malfunction ..................................... 5A-74

DTC C0271 (Flash Code 71) ECU Malfunction ................................................................ 5A-76

DTC C0276 (Flash Code 76) G Sensor Malfunction ........................................................ 5A-78

DTC C0277 (Flash Code 77) System Voltage Low .......................................................... 5A-80

DTC C0278 (Flash Code 78) System Voltage High.......................................................... 5A-80

DTC C0282 (Flash Code 82) 4 Wheel Drive State Input Signal Failure.......................... 5A-82

DTC C0285 (Flash Code 85) Control Module Vehicle Options Incorrect ...................... 5A-84

Special Tools .................................................................................................................. ... 5A-86

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 626 of 6020

BRAKE CONTROL SYSTEM 5A-33

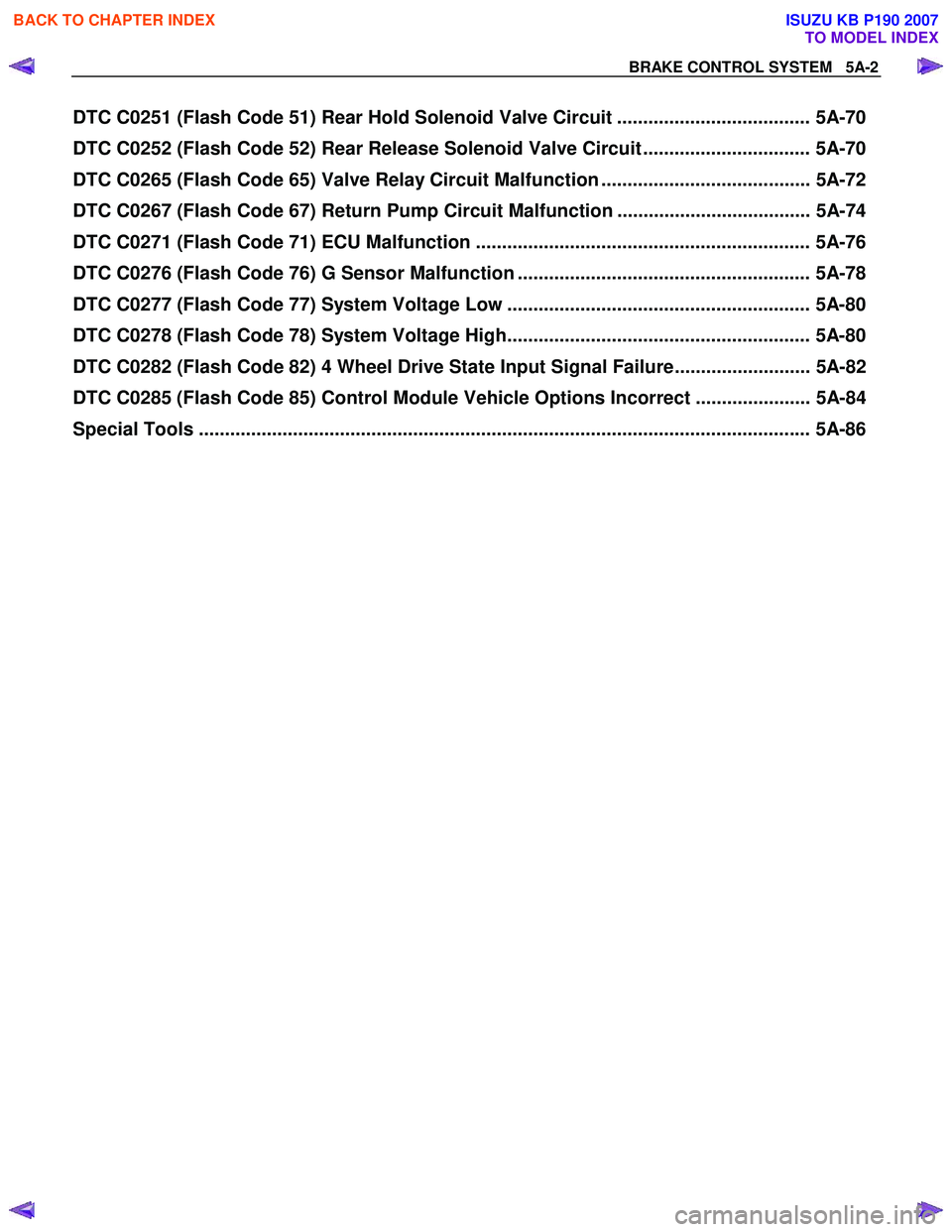

Diagnostic Trouble Codes

Choose and trace an appropriate flowchart by the

numbers listed below to find the fault and repair.

Note:

A DTC cannot be erased when the DTC is present.

Warning Lamp System Control Main Items

DTC

(Flash Code) Description

ABS Brake

(EBD) ABS EBD

-

(12) Normal Condition

× × -

C0221

(21) Front Right W heel Speed Sensor

Short Circuit or Circuit Open ×*A × Sensor or W iring

C0222

(22) Front Right W heel Speed Sensor

Signal Malfunction *B ×*A × Sensor or install condition

C0225

(25) Front Left W heel Speed Sensor Short

Circuit or Circuit Open ×*A × Sensor or W iring

C0226

(26) Front Left W heel Speed Sensor Signal

Malfunction *B ×*A × Sensor or install condition

C0231

(31) Rear Right W heel Speed Sensor Short

Circuit or Circuit Open ×*A × Sensor or W iring

C0232

(32) Rear Right W heel Speed Sensor

Signal Malfunction *B ×*A × Sensor or install condition

C0235

(35) Rear Left W heel Speed Sensor Short

Circuit or Circuit Open ×*A × Sensor or W iring

C0236

(36) Rear Left W heel Speed Sensor Signal

Malfunction *B ×*A × Sensor or install condition

C0238

(38) Front Speed Sensor Correlation

× × Vehicle , Sensor or Tire

C0241

(41) Front Right Hold Solenoid Valve Circuit

× × Solenoid (EHCU)

C0242

(42) Front Right Release Solenoid Valve

Circuit × × Solenoid (EHCU)

C0245

(45) Front Left Hold Solenoid Valve Circuit

× × Solenoid (EHCU)

C0246

(46) Front Left Release Solenoid Valve

Circuit × × Solenoid (EHCU)

C0251

(51) Rear Hold Solenoid Valve Circuit

× × Solenoid (EHCU)

C0252

(52) Rear Release Solenoid Valve Circuit

× × Solenoid (EHCU)

×

C0265

(65) Valve Relay Circuit Malfunction

×

× Relay (EHCU)

C0267

(67) Return Pump Circuit Malfunction

× Motor (EHCU)

C0271

(71) ECU Malfunction

× × EHCU

C0276

(76) G Sensor Malfunction

× × Sensor or W iring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 669 of 6020

5A-76 BRAKE CONTROL SYSTEM

DTC C0271 (Flash Code 71) ECU Malfunction

RTW 75ALF000301

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Ignition “OFF”.

2. Check the EHCU circuit for an open, short to ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open or short to

voltage.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 721 of 6020

5C-22 BRAKES

RTW 35CSH001001

•

••

•

Operation

1) Outline

W hen the LSPV (Load Sensing Proportioning Valve) detects a change in load weight, the load sensing spring

stretches.

Its reaction force is transmitted to the bottom of the load sensing valve to secure an optimum rear wheel cylinde

r

fluid pressure break point in proportion to the actual load

weight.

Besides, if the front brake system should fail, the device is designed to prevent the master cylinder fluid pressure from

decreasing and to apply it directly to the rear wheel cylinde

r

to obtain a sufficient braking performance.

RTW 35CSH001101

2) Bellow cutting point.

The Force (F) keeps the main piston (1) the rest position. The inlet pressure (A) and outlet pressure (B) are the same

as well as the inlet pressure (C) from front master cylinder.

The bypass piston (2) is kept on rest position by equilibrium

of the pressures (A) and (C) and the bypass spring load (3).

RTW 35CSH001201

3) Cutting point.

The cutting point is given by relation between force (F), that is the load applied by suspension of the vehicle and the

main piston area (1). The cutting point is achieved when the

force generated by hydraulic pressure is upper than the

force (F) given by the load suspension. The main piston (1)

moves from the rest position closing the valve. In this

moment the inlet pressure (A) is upper than the outlet

pressure (B). The bypass piston (2) continues on the rest

position by equilibrium of (A) and (C) pressure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 723 of 6020

5C-24 BRAKES

RTW 35CSH000201

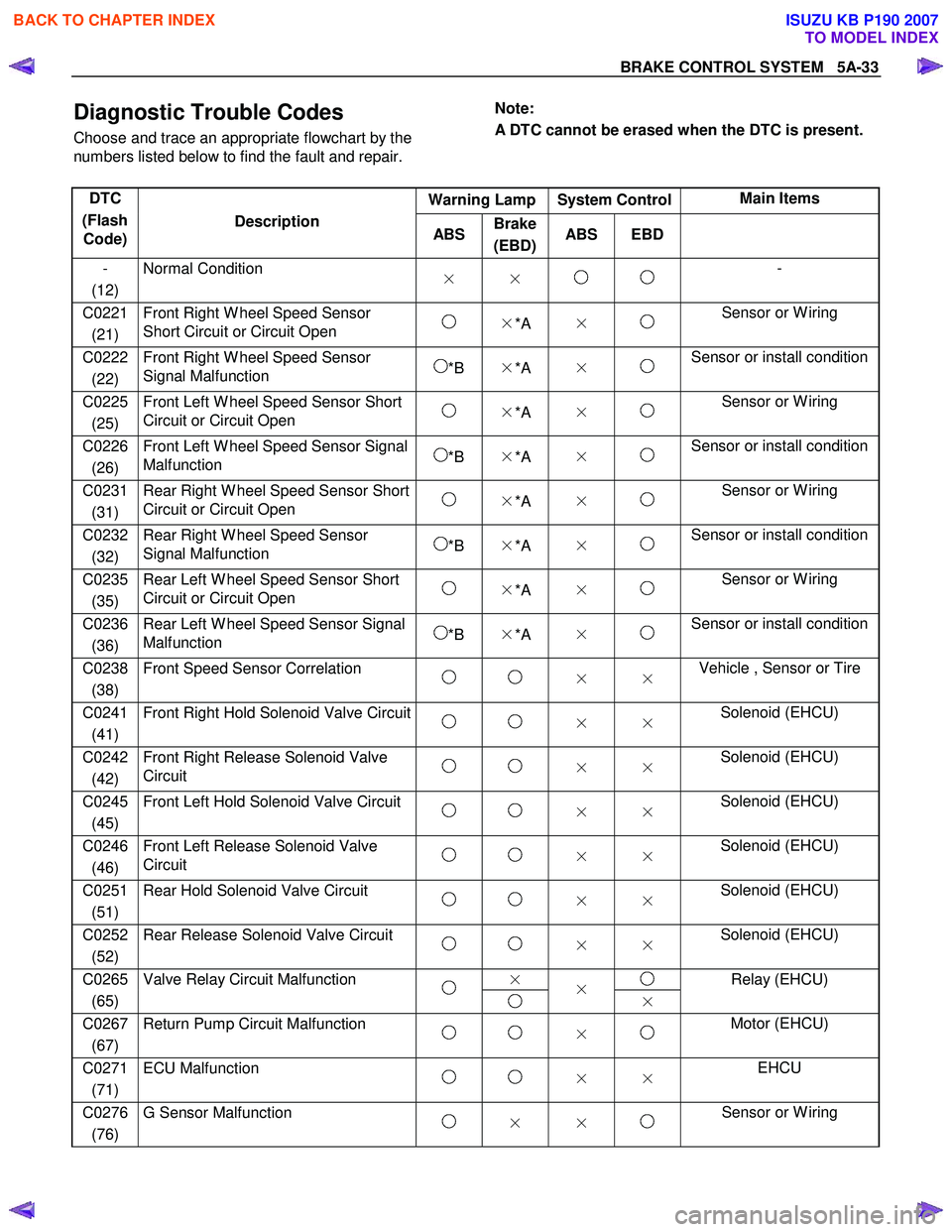

3) Rear wheel cylinder fluid pressure measurement

Step on the brake pedal until the fluid pressure of the front wheel cylinder gets to 9.8Mpa (100kg/cm

2), and

check the rear wheel cylinder fluid pressure. (Read the

value of the front wheel cylinder fluid pressure 2

seconds after the measurement. W hen measuring the

LSPV fluid pressure, keep the brake pedal pressed

down without stepping it down twice or releasing it.)

Rear W heel Cylinder Fluid Pressure MPa (kg/cm

2)

2W D 6.77 ±0.83 (69.0 ±8.5)

2W D (W ith High Ride

Suspension), 4W D 6.77

±0.83 (69.0 ±8.5)

RTW 35CSH000401

2. Oil Pressure Adjustment

1) LSPV spring length adjustment

Loosen the adjust nut of the LSPV spring joint, and adjust the length of the LSPV spring.

W hen the oil pressure is insufficient, turn the adjust nut clockwise to extend the span “A”. W hen the oil pressure

is too high, turn the adjust nut counterclockwise to

reduce the span “A”.

2) After adjustment, tighten the lock nut securely.

Lock Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

11-20 (1.1-2.0/8-14)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 734 of 6020

BRAKES 5C-35

9. Front Hub and Disc Assembly

For the removal procedure, refer to Section 4C “FRONT

W HEEL DRIVE”.

Important Operations - Installation

9. Front Hub and Disc Assembly

For the installation procedure, refer to the front hub and disc

reassembly procedure in Section 4C “FRONT W HEEL

DRIVE”.

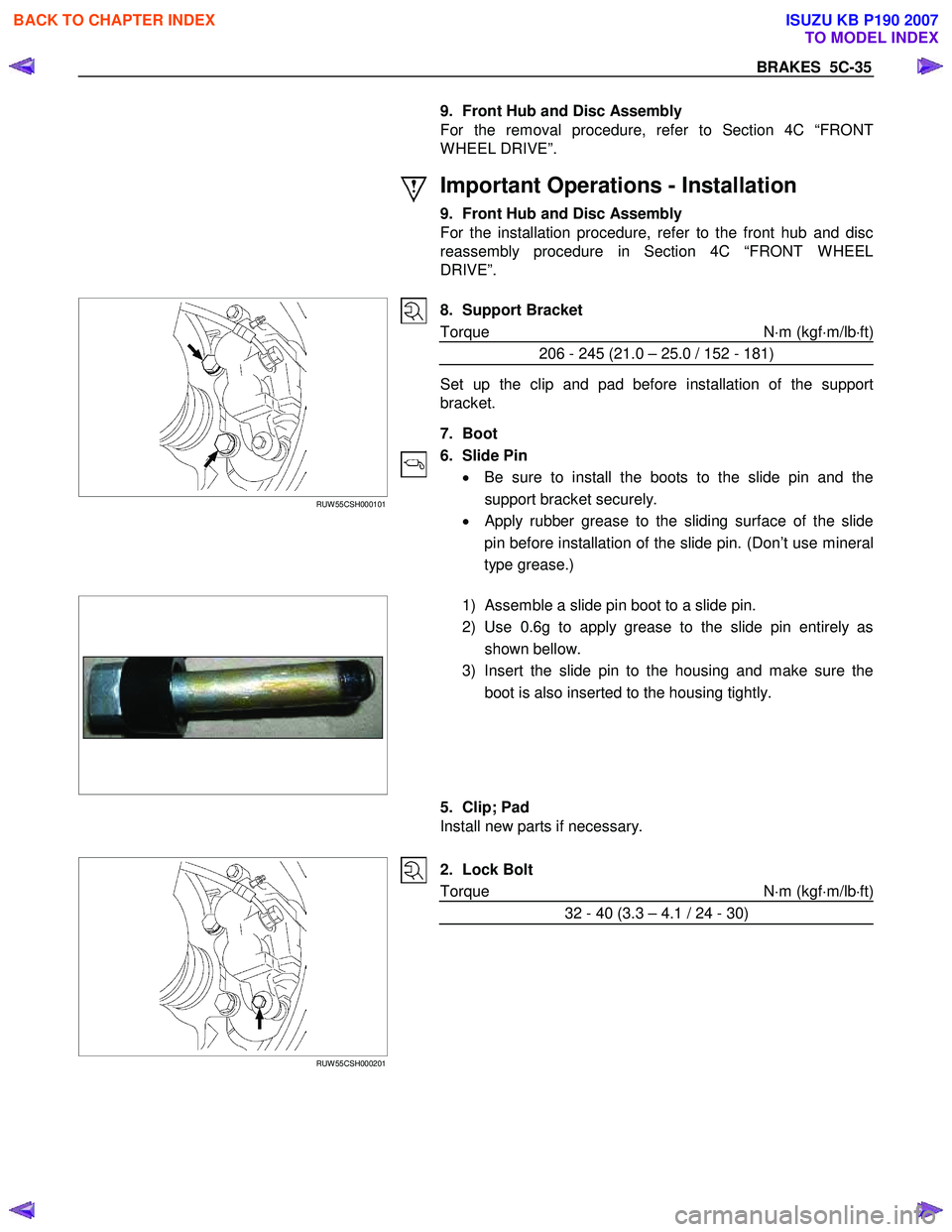

RUW 55CSH000101

8. Support Bracket

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

206 - 245 (21.0 – 25.0 / 152 - 181)

Set up the clip and pad before installation of the support

bracket.

7. Boot

6. Slide Pin • Be sure to install the boots to the slide pin and the

support bracket securely.

•

Apply rubber grease to the sliding surface of the slide

pin before installation of the slide pin. (Don’t use mineral

type grease.)

1) Assemble a slide pin boot to a slide pin.

2) Use 0.6g to apply grease to the slide pin entirely as shown bellow.

3) Insert the slide pin to the housing and make sure the boot is also inserted to the housing tightly.

5. Clip; Pad

Install new parts if necessary.

RUW 55CSH000201

2. Lock Bolt

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

32 - 40 (3.3 – 4.1 / 24 - 30)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 836 of 6020

ENGINE MECHANICAL 6A – 31

VALVE CLEARANCE ADJUSTMENT

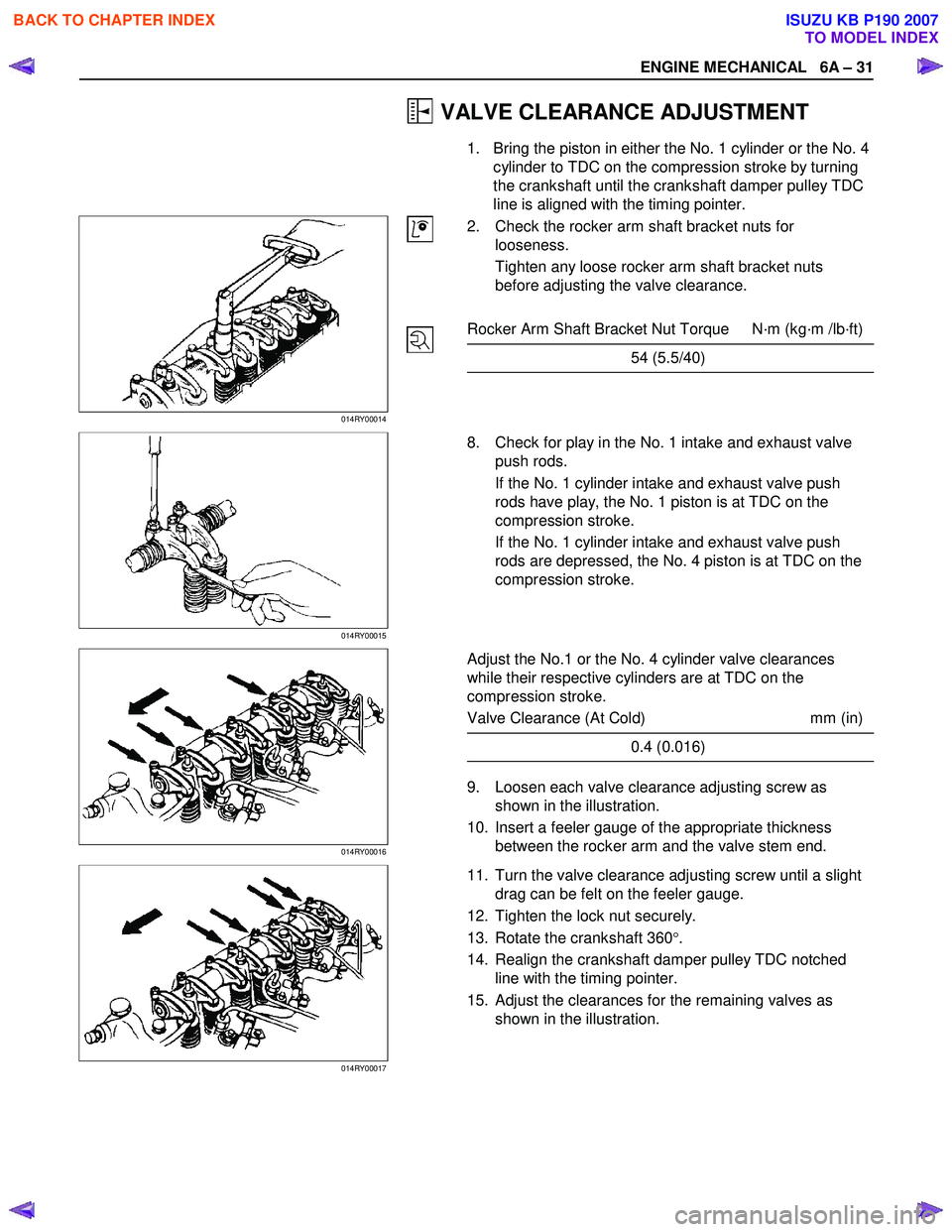

1. Bring the piston in either the No. 1 cylinder or the No. 4 cylinder to TDC on the compression stroke by turning

the crankshaft until the crankshaft damper pulley TDC

line is aligned with the timing pointer.

014RY00014

2. Check the rocker arm shaft bracket nuts for

looseness.

Tighten any loose rocker arm shaft bracket nuts

before adjusting the valve clearance.

Rocker Arm Shaft Bracket Nut Torque N·m (kg·m /lb·ft)

54 (5.5/40)

014RY00015

8. Check for play in the No. 1 intake and exhaust valve

push rods.

If the No. 1 cylinder intake and exhaust valve push

rods have play, the No. 1 piston is at TDC on the

compression stroke.

If the No. 1 cylinder intake and exhaust valve push

rods are depressed, the No. 4 piston is at TDC on the

compression stroke.

014RY00016

Adjust the No.1 or the No. 4 cylinder valve clearances

while their respective cylinders are at TDC on the

compression stroke.

Valve Clearance (At Cold) mm (in)

0.4 (0.016)

9. Loosen each valve clearance adjusting screw as

shown in the illustration.

10. Insert a feeler gauge of the appropriate thickness between the rocker arm and the valve stem end.

014RY00017

11. Turn the valve clearance adjusting screw until a slight

drag can be felt on the feeler gauge.

12. Tighten the lock nut securely.

13. Rotate the crankshaft 360 °.

14. Realign the crankshaft damper pulley TDC notched line with the timing pointer.

15. Adjust the clearances for the remaining valves as shown in the illustration.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 897 of 6020

6A – 92 E NGINE MECHANICAL

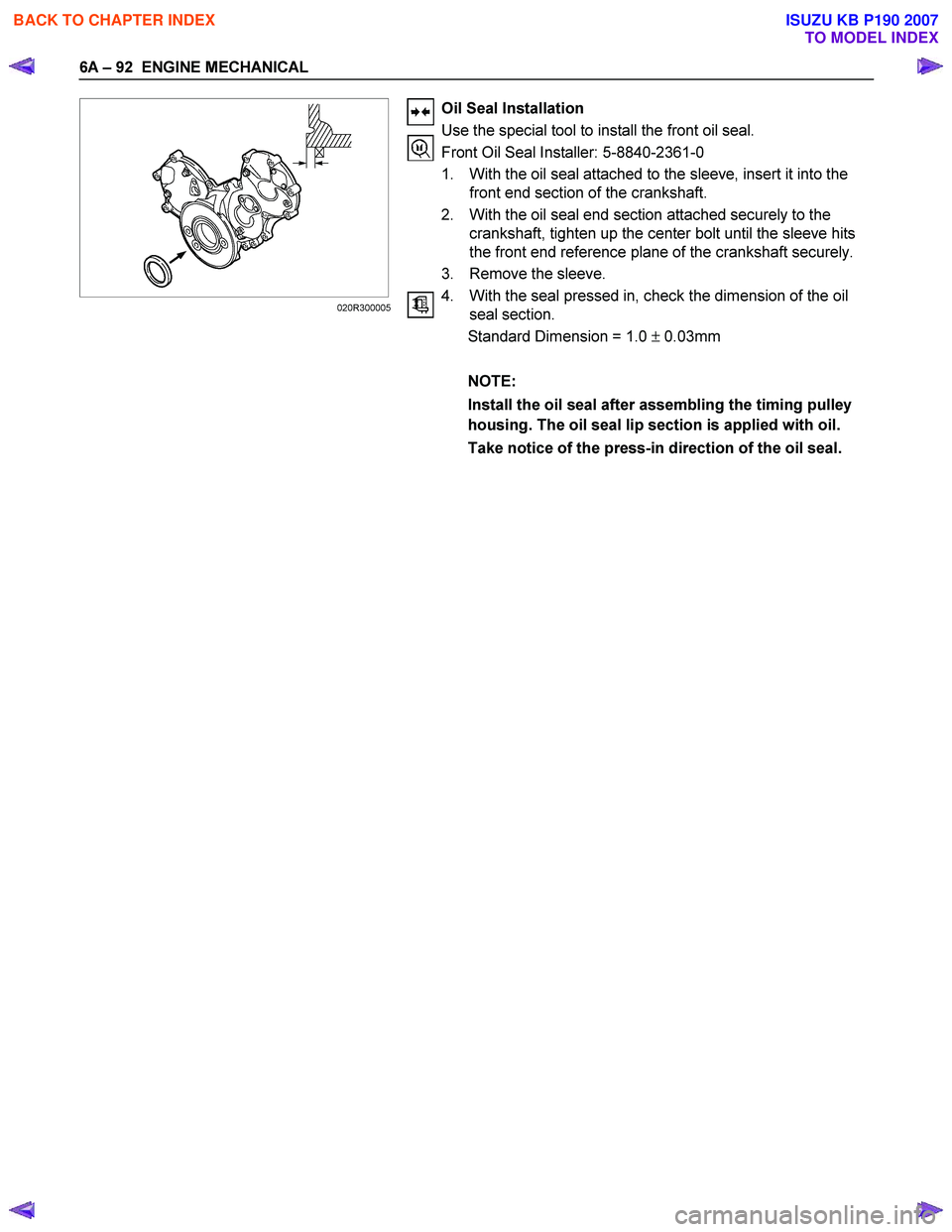

Oil Seal Installation

Use the special tool to install the front oil seal.

Front Oil Seal Installer: 5-8840-2361-0

1. With the oil seal attached to the sleeve, insert it into the front end section of the crankshaft.

2. With the oil seal end section attached securely to the crankshaft, tighten up the center bolt until the sleeve hits

the front end reference plane of the crankshaft securely.

3. Remove the sleeve.

4. With the seal pressed in, check the dimension of the oil seal section.

Standard Dimension = 1.0 ± 0.03mm

NOTE:

Install the oil seal after assembling the timing pulley

housing. The oil seal lip section is applied with oil.

Take notice of the press-in direction of the oil seal.

020R300005

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007