differential ISUZU KB P190 2007 Workshop Owner's Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 475 of 6020

REAR AXLE 4B-31

φ

φφ

φ

194mm

RTW 54BSH000201

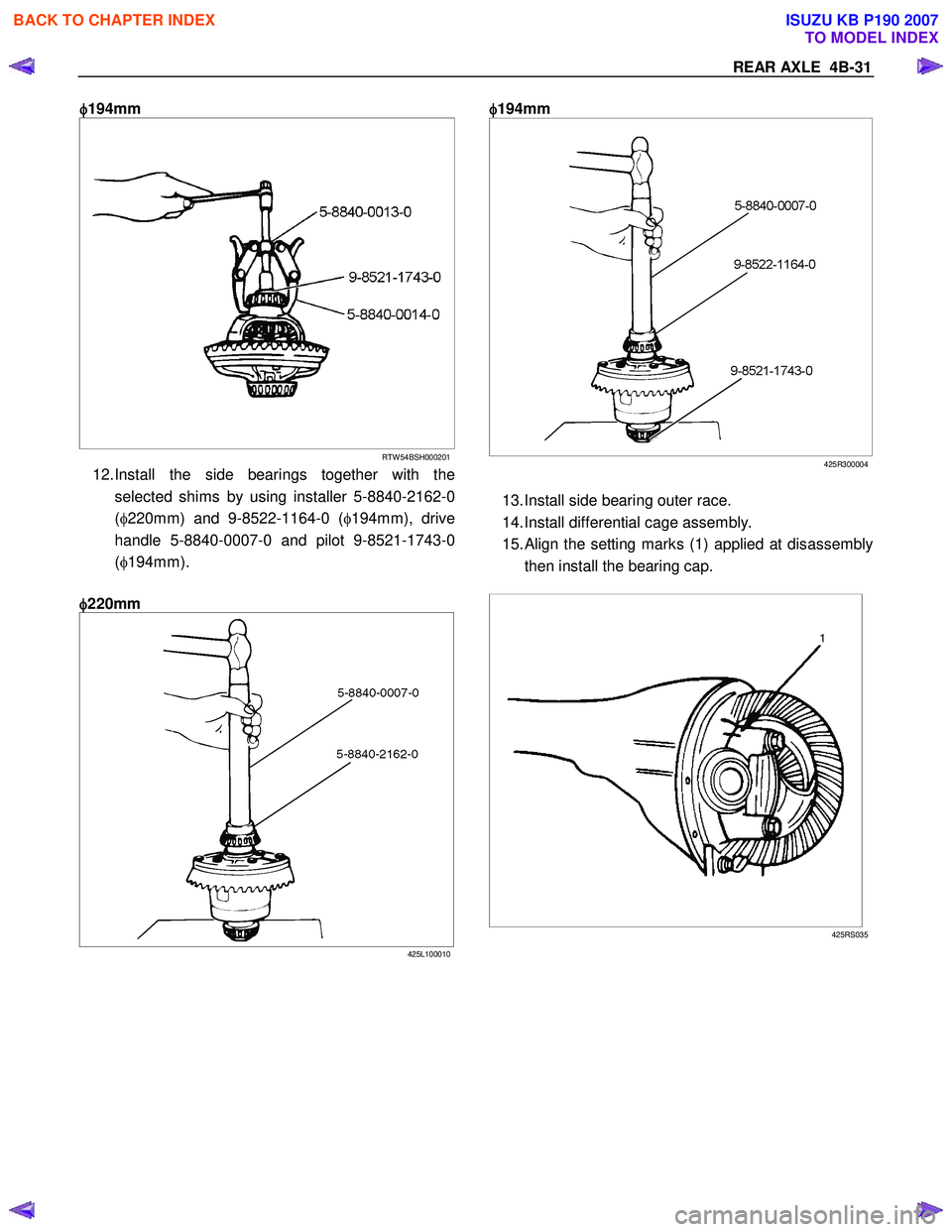

12. Install the side bearings together with the

selected shims by using installer 5-8840-2162-0

( φ 220mm) and 9-8522-1164-0 ( φ194mm), drive

handle 5-8840-0007-0 and pilot 9-8521-1743-0

( φ 194mm).

φ

φφ

φ

220mm

425L100010

φ

φφ

φ

194mm

425R300004

13. Install side bearing outer race.

14. Install differential cage assembly.

15.

Align the setting marks (1) applied at disassembly

then install the bearing cap.

425RS035

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 478 of 6020

4B-34 REAR AXLE

Differential Cage Assembly

Disassembled View

425R300005

Legend

1. Bolt

2. Ring Gear

3. Lock Pin

4. Cross Pin

5. Pinion Gear

6. Side Gear

7. Thrust W asher (for Side Gear)

8. Differential Cage

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 479 of 6020

REAR AXLE 4B-35

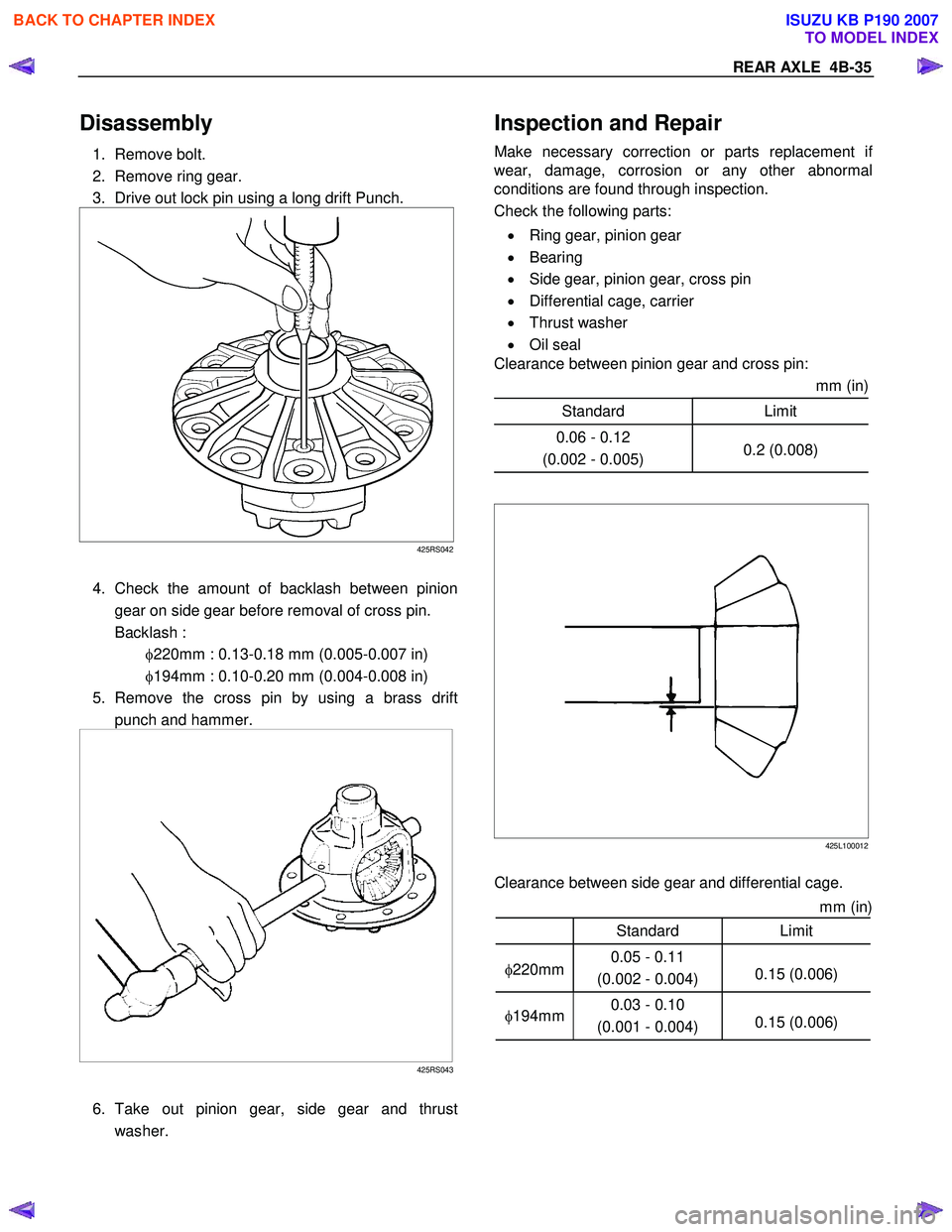

Disassembly

1. Remove bolt.

2. Remove ring gear.

3. Drive out lock pin using a long drift Punch.

425RS042

4. Check the amount of backlash between pinion gear on side gear before removal of cross pin.

Backlash : φ220mm : 0.13-0.18 mm (0.005-0.007 in)

φ194mm : 0.10-0.20 mm (0.004-0.008 in)

5. Remove the cross pin by using a brass drift punch and hammer.

425RS043

6. Take out pinion gear, side gear and thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage, corrosion or any other abnormal

conditions are found through inspection.

Check the following parts:

• Ring gear, pinion gear

• Bearing

• Side gear, pinion gear, cross pin

• Differential cage, carrier

• Thrust washer

• Oil seal

Clearance between pinion gear and cross pin:

mm (in)

Standard Limit

0.06 - 0.12

(0.002 - 0.005) 0.2 (0.008)

425L100012

Clearance between side gear and differential cage.

mm (in)

Standard Limit

φ220mm 0.05 - 0.11

(0.002 - 0.004) 0.15 (0.006)

φ

194mm 0.03 - 0.10

(0.001 - 0.004) 0.15 (0.006)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 480 of 6020

4B-36 REAR AXLE

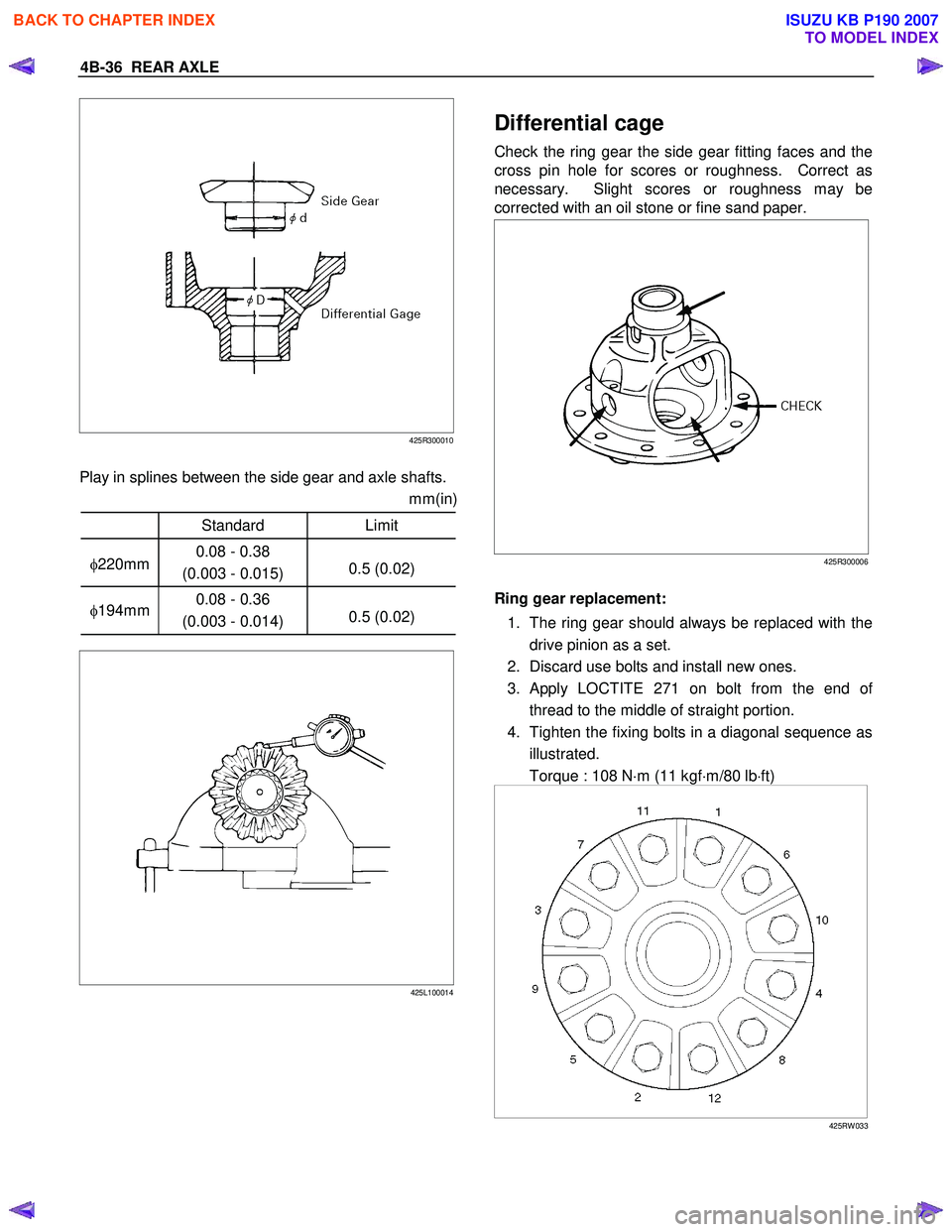

425R300010

Play in splines between the side gear and axle shafts. mm(in)

Standard Limit

φ220mm 0.08 - 0.38

(0.003 - 0.015) 0.5 (0.02)

φ

194mm 0.08 - 0.36

(0.003 - 0.014) 0.5 (0.02)

425L100014

Differential cage

Check the ring gear the side gear fitting faces and the

cross pin hole for scores or roughness. Correct as

necessary. Slight scores or roughness may be

corrected with an oil stone or fine sand paper.

425R300006

Ring gear replacement:

1. The ring gear should always be replaced with the drive pinion as a set.

2. Discard use bolts and install new ones.

3.

Apply LOCTITE 271 on bolt from the end of

thread to the middle of straight portion.

4. Tighten the fixing bolts in a diagonal sequence as illustrated.

Torque : 108 N ⋅m (11 kgf ⋅m/80 lb ⋅ft)

425RW 033

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 481 of 6020

REAR AXLE 4B-37

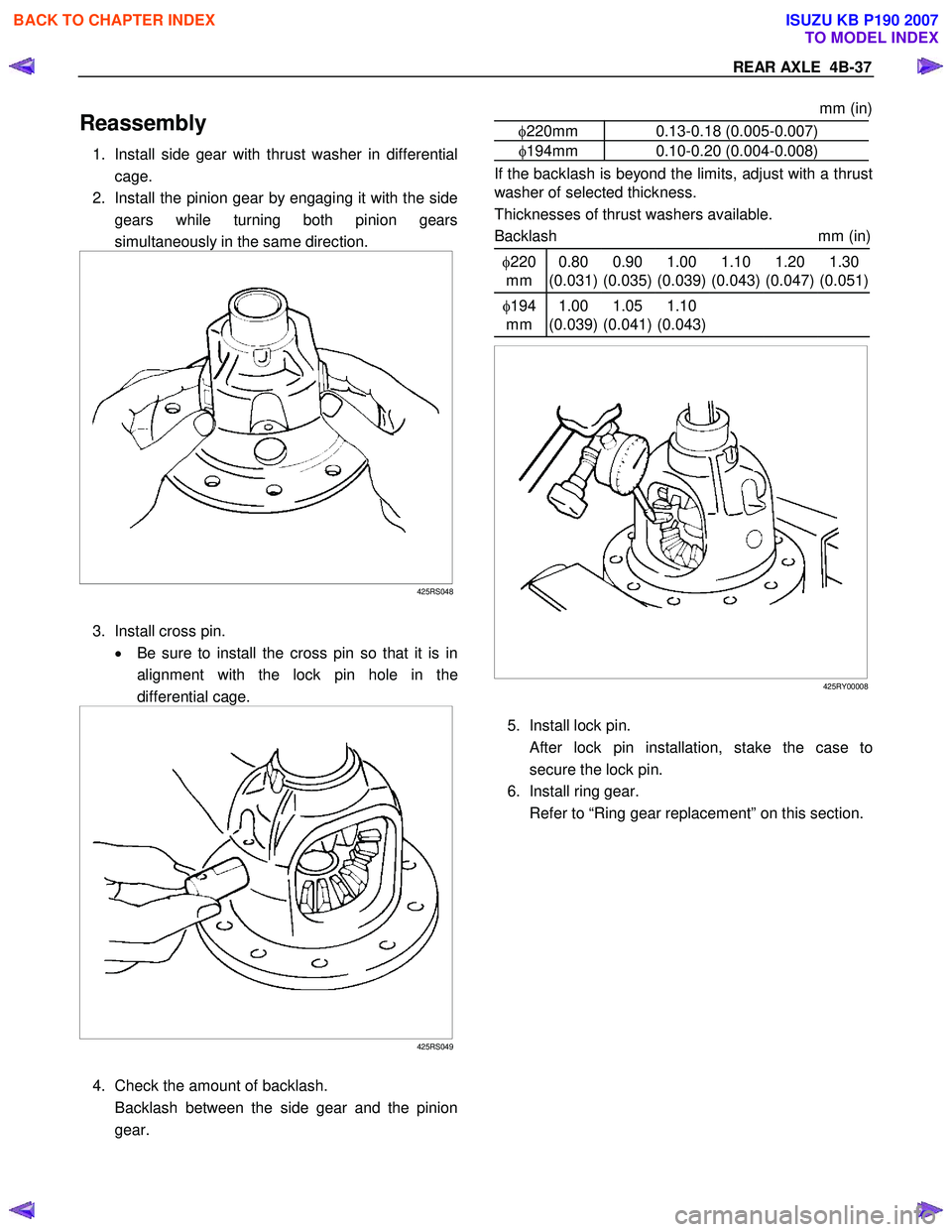

Reassembly

1. Install side gear with thrust washer in differential

cage.

2. Install the pinion gear by engaging it with the side gears while turning both pinion gears

simultaneously in the same direction.

425RS048

3. Install cross pin. • Be sure to install the cross pin so that it is in

alignment with the lock pin hole in the

differential cage.

425RS049

4. Check the amount of backlash.

Backlash between the side gear and the pinion gear.

mm (in)

φ220mm 0.13-0.18 (0.005-0.007)

φ194mm 0.10-0.20 (0.004-0.008)

If the backlash is beyond the limits, adjust with a thrust

washer of selected thickness.

Thicknesses of thrust washers available.

Backlash mm (in)

φ220

mm 0.80

(0.031) 0.90

(0.035) 1.00

(0.039) 1.10

(0.043) 1.20

(0.047) 1.30

(0.051)

φ 194

mm 1.00

(0.039) 1.05

(0.041) 1.10

(0.043)

425RY00008

5. Install lock pin.

After lock pin installation, stake the case to

secure the lock pin.

6. Install ring gear.

Refer to “Ring gear replacement” on this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 482 of 6020

4B-38 REAR AXLE

LIMITED SLIP DIFFERENTIAL (LSD)

Disassembled View

425R300007

Legend

1. Screw

2. Differential Cage B

3. Thrust W asher

4. Spring Plate

5. Spring Plate

6. Friction plate

7. Friction disc

8. Friction plate

9. Friction disc

10. Pressure Ring

11. Side Gear

12. Pinion and Pinion Shaft

13. Side Gear

14. Pressure Ring

15. Friction Disc

16. Friction Plate

17. Friction Disc

18. Friction Plate

19. Spring Plate

20. Spring Plate

21. Thrust W asher

22. Differential Cage A

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 483 of 6020

REAR AXLE 4B-39

Disassembly

• Prepare a side gear holder : 5-8840-2682-0 as

shown in the left figure, clamp it with a stock vice,

and set a differential.

425R300008

1. Screw • Apply a setting mark to the differential cage A

and differential cage B remove the bolt using

the press.

• Loosen four screws fixing differential cage A

to cage B equally and remove them.

425RS055

2. Remove differential cage A and B.

3. Remove thrust washer and two spring plates.

4. Remove friction plate and friction disc.

5. Remove friction plate and friction disc.

6. Remove pressure ring and side gear.

7. Remove pinion and pinion shaft.

8. Remove side gear and pressure ring.

9. Remove friction disc and friction plate.

10. Remove friction disc and friction plate.

11. Remove two spring plates and thrust washer.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 484 of 6020

4B-40 REAR AXLE

Inspection and Repair

Make all necessary adjustments, repairs, and part

replacements if wear, damage, rust or other problems

are discovered during inspection.

Visual Check

Inspect the following parts for wear, damage or other

abnormal conditions.

• Friction disc

• Friction plate

• Spring plate

1 Sliding surface

2 Protrusion

425RS056

Pressure ring

Check the parts for damage or other abnormal

conditions.

3 Sliding surface for friction disc

If dents or damages are discovered, grind them with oil stone, and repair them with compound on

surface plate.

4 Sliding surface of pressure ring inner surface and pinion gear.

5 Sliding surface of pressure ring bore and sidegear.

6 sliding surface of pressure ring and side gear.

7 Sliding surface of pressure ring and pinion shaft.

8 Mating surface to differential cage A.

9 Burrs or dents on sliding surface of pressure ringand rear differential cage should be repaired,

using oil stone.

425RY00022

• Thrust W asher

10 Groove on side gear circumference small burrs of

dens should be repaired, using oil stone.

11 Sliding surface between side gear and thrust washer.

425RY00024

• Differential cage A and B

12 Contact surface to spring plate

13 Differential cage A and B contact surfaces to

thrust washers Small burrs or dents should be

repair, using oil stone.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 486 of 6020

4B-42 REAR AXLE

425RS063

Reassembly

Adjustment of Clearance between

Friction Disc and Plate

1. Measuring depth of differential case

mm(in)

Standard (A-B) 80.58 (3.17)

(C) 10.58 (0.42)

425RS064

2. Measuring overall length of pressure ring, friction disc and plate assembly

• Assemble pinion shaft with pressure ring, then

friction disc and plate.

• Measure length between plates at both ends

over V-shape groove. (D)

425 RS065

3.

After A, B, C and D dimensions are measured,

perform adjustment with the following procedure.

• Measure spring plate :

1.75 mm (0.069 in) × 4 pcs (E)

• Measure thickness of plate spring

Standard dimension :

1.75 mm (0.069 in) × 2 pcs (F)

4. Select a friction disc or plate so that ((A-B+C) - (D+E) = 0.06 to 0.20 mm (0.002 to 0.008 in.) and

also the difference in total dimension of friction

disc and plate and spring plate (left/right side)

does not exceed 0.05 mm (0.002 in.).

Thickness : 1.65, 1.75, 1.85 mm (0.065, 0.069, 0.073 in)

Adjusting Backlash of Side Gear in

Axial Direction

1. Measuring depth of differential case mm(in)

Standard (F-B) 82.03 (3.23)

(G) 12.03 (0.47)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 487 of 6020

REAR AXLE 4B-43

425RS066

2. Measuring dimension between thrust washers at both ends.

Assemble side gear, pinion, pinion shaft pressure

ring and thrust washer.

• Eliminate clearance by pushing pressure ring

against the pinion shaft in axial direction.

• Eliminate backlash by connecting side gear to

the pinion.

• Measure dimension between thrust washers

at both ends. (H)

425RS067

3. After each dimension is measured, perform adjustment with the following procedure.

Adjust so that ((F-B) + G-H) = 0.05 to 0.2 mm (0.002 to 0.008 in).

Also, select a proper thrust

washer so that the dimension difference from

back face of the pressure ring to thrust washer

(left/right side) does not exceed 0.05 mm (0.002

in).

Thickness : 1.5, 1.6, 1.7 mm (0.059, 0.063, 0.067 in)

Note :

When reassembling, sufficiently apply gear oil on

every part, especially on sliding surface.

1. Install thrust washer in differential cage A and B.

2.

Assemble spring plate, friction plate and

friction disc as following illustration.

• Install spring plate with dished side turned

to the differential cage side.

425R300009

Legend

1. Friction Plate

2. Spring Plate

3. Friction Disc

4. Install pressure ring and side gear. • Fit two side gears in two pressure rings, one

from under a ring and the other from above a

ring.

• Fit two pairs of a friction disc and a friction

plate under it on and under these two

pressure rings.

5. Set pinion and pinion shaft on differential cage

A

assembly.

6. Assemble differential cage A and B.

7.

Align the setting marks on differential cage A and

B and tighten screws in diagonal order evenly.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007