differential ISUZU KB P190 2007 Workshop Workshop Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 538 of 6020

4C1-34 FRONT WHEEL DRIVE

12. Flange Nut and Washer

(1) Apply lubricant to the pinion threads.

(2) Tighten the nut to the specified torque using the pinion flange holder.

Pinion flange holder : 5-8840-0133-0

Torque N ⋅m (kgf ⋅m/lb ⋅ft

)

177 - 275 (18 - 28/130 - 202)

Discard used flange nut and install new one.

(3) Pinion bearing preload

(a) Measure the bearing preload by using a torque meter. Note the scale reading required to rotate the flange.

(b) continue tightening until the specified starting torque is obtained.

Starting Torque N⋅m (kgf ⋅m/lb ⋅in

)

0.63 - 1.13 (0.06 – 0.12/5 - 10)

13. Adjust Shim

(1)

Attach the side bearing to the differential assembly without

shims. Support the opposite side using a pilot to prevent

bearing damage.

1 Installer : 9-8522-1164-0

2 Drive handle : 5-8840-0007-0

3 Pilot : 9-8521-1743-0

(2) Insert the differential cage assembly with bearing oute

r

races into the side bearing bores of the carrier.

(3) Using two sets of feeler gauges, insert a feeler stock o

f

sufficient thickness between each bearing outer race and

the carrier to remove all end plat. Make certain the feele

r

stock is pushed to the bottom of the bearing bores.

Mount the dial indicator on the carrier so that the indicato

r

stem is at right angles to a tooth on the ring gear.

Dial indicator : 5-8840-0126-0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 541 of 6020

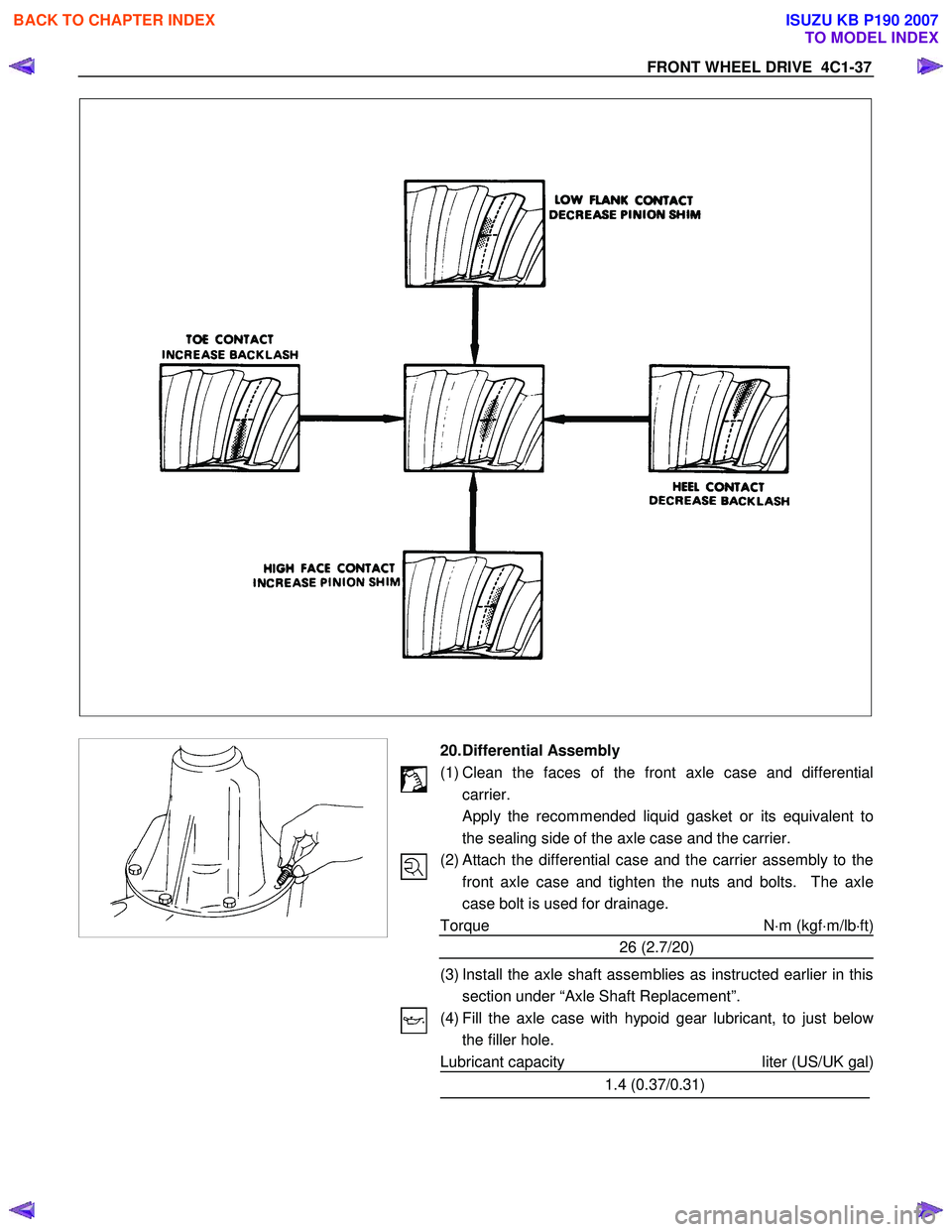

FRONT WHEEL DRIVE 4C1-37

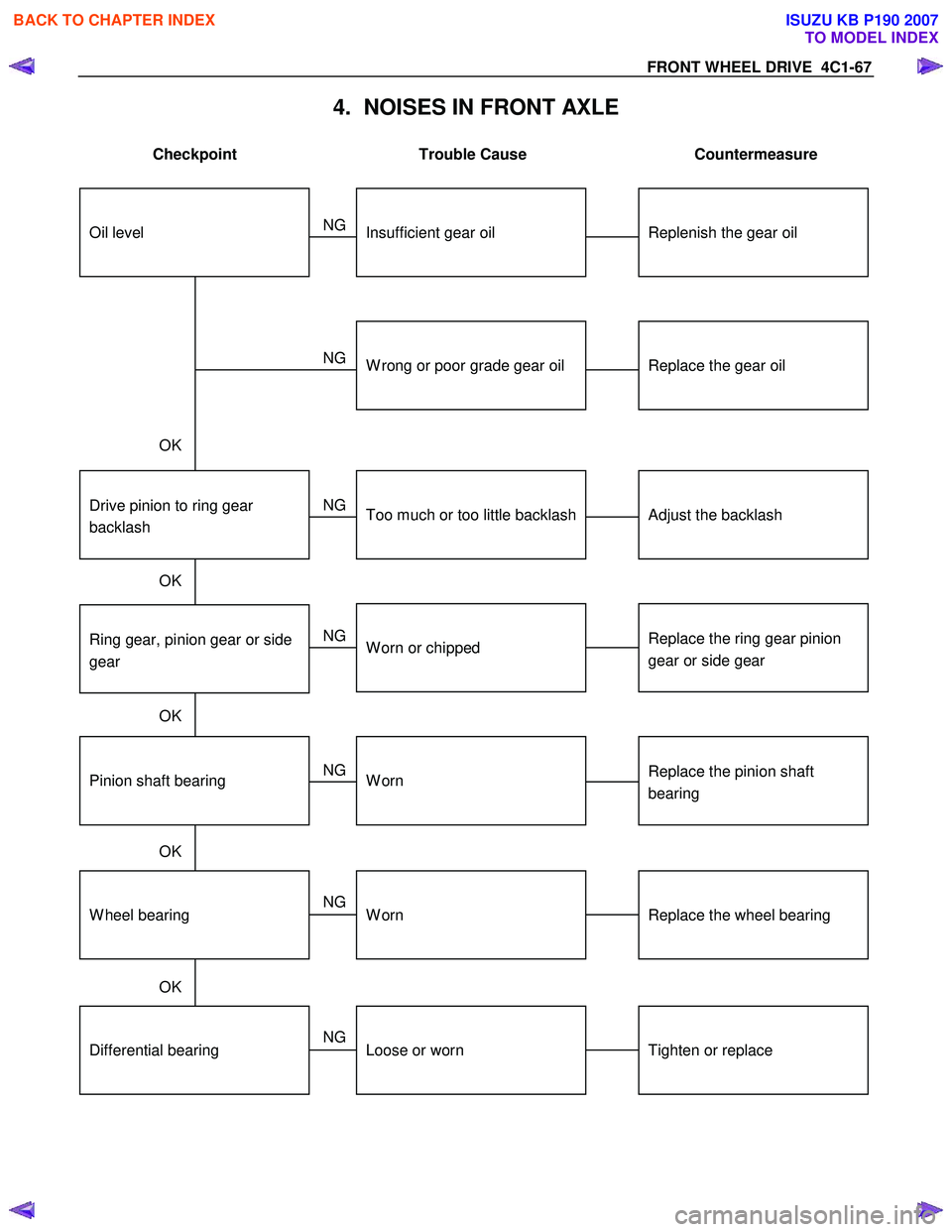

20. Differential Assembly

(1) Clean the faces of the front axle case and differential carrier.

Apply the recommended liquid gasket or its equivalent to

the sealing side of the axle case and the carrier.

(2)

Attach the differential case and the carrier assembly to the

front axle case and tighten the nuts and bolts. The axle

case bolt is used for drainage.

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

26 (2.7/20)

(3) Install the axle shaft assemblies as instructed earlier in this section under “Axle Shaft Replacement”.

(4) Fill the axle case with hypoid gear lubricant, to just belo

w

the filler hole.

Lubricant capacity liter (US/UK gal)

1.4 (0.37/0.31)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 571 of 6020

FRONT WHEEL DRIVE 4C1-67

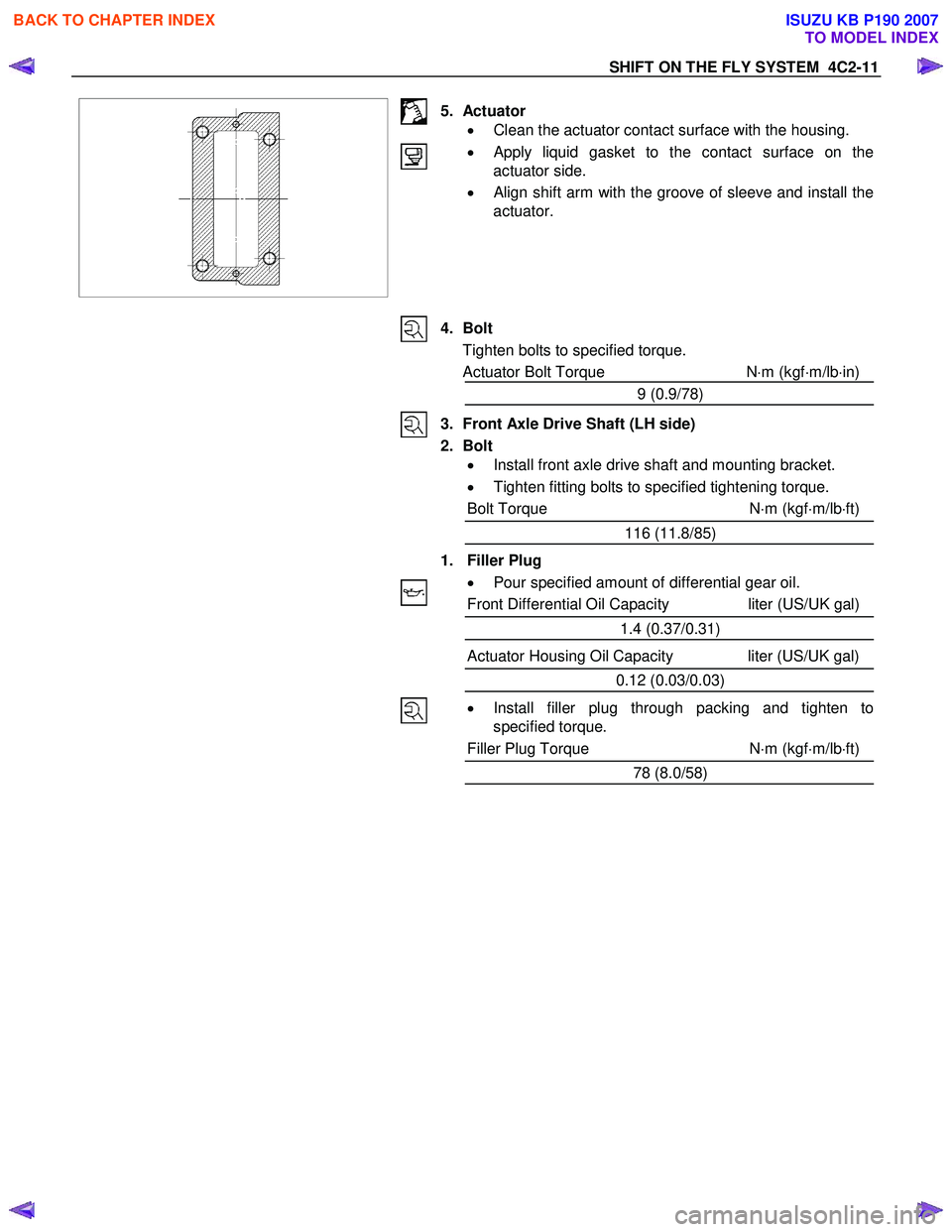

4. NOISES IN FRONT AXLE

Checkpoint Trouble Cause Countermeasure

Replenish the gear oilInsufficient gear oil

NG

Replace the wheel bearing

Replace the pinion shaft

bearing

Replace the ring gear pinion

gear or side gear

Replace the gear oil

W heel bearingWorn

Pinion shaft bearingWorn

W orn or chipped

W rong or poor grade gear oil

Ring gear, pinion gear or side

gear

Adjust the backlashDrive pinion to ring gear

backlashToo much or too little backlash

NG

NG

NG

NG

NG

OK

OK

OK

OK

Oil level

Tighten or replaceDifferential bearingLoose or worn

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 587 of 6020

SHIFT ON THE FLY SYSTEM 4C2-9

RTW 440SH000601

RTW 440SH000801

Dimension Check

Measure illustration sized A, B, and C

Limit mm (in)

A 64.3 (2.53)

B 6.7 (0.26)

C 6.7 (0.26)

RTW 440SH000701

Reassembly

15. Oil seal

Install the new oil seal which has been immersed in

differential gear oil, by using an oil seal installer.

Installer 5-8840-2407-0

Grip 5-8840-0007-0

412RS051

14. Needle Bearing

Force a new needle bearing into inner shaft by using a

special tool.

Installer : 5-8840-2408-0

Grip : 5-8840-0007-0

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 588 of 6020

4C2-10 SHIFT ON THE FLY SYSTEM

412RS044

13. Inner Shaft Bearing

• Place a new snap ring in inner shaft.

• Force a new inner shaft bearing into the inner shaft.

Installer : 5-8840-2197-0

12. Snap Ring

NOTE;

Be careful not to damage the inner shaft.

11.inner Shaft • Clean the housing contact surface of the front axle

case.

• Insert inner shaft assembly into the front axle case.

NOTE:

Be careful not to damage oil seal.

412RW 017

10. Snap Ring

Install snap ring in the groove of front axle case.

NOTE:

Be sure to install the snap ring properly.

9. Clutch Gear Apply differential gear oil to clutch oil.

8. Sleeve Apply differential gear oil to sleeve.

412RW 023

7. Housing

• Clean contact surface with the front axle and actuato

r

mounting surface.

•

Apply liquid gasket to the contact surface on the front

axle case and install in the housing.

6. Bolt

Tighten bolts to specified tightening torque.

Housing Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

75 (7.6/55)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 589 of 6020

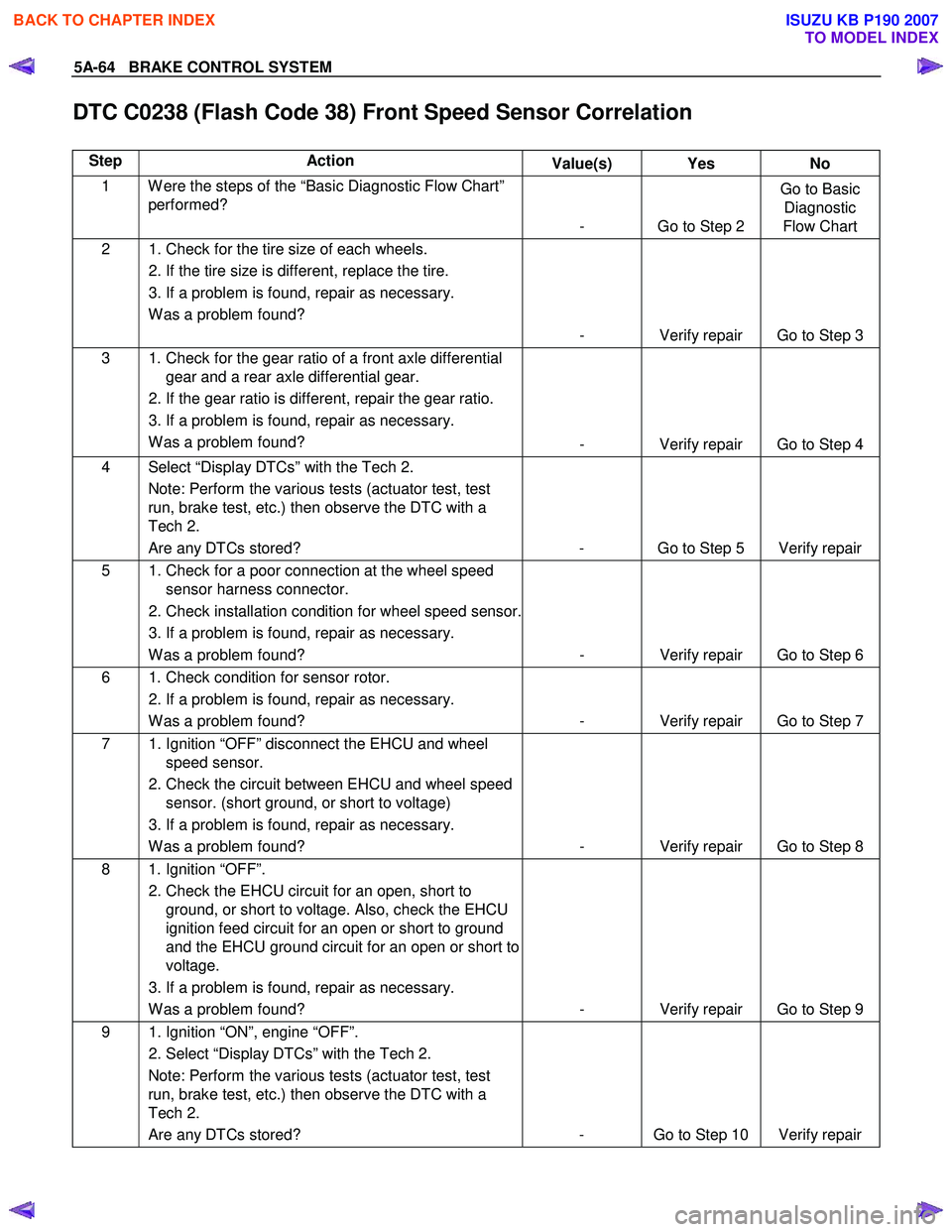

SHIFT ON THE FLY SYSTEM 4C2-11

5. Actuator • Clean the actuator contact surface with the housing.

•

Apply liquid gasket to the contact surface on the

actuator side.

• Align shift arm with the groove of sleeve and install the

actuator.

4. Bolt

Tighten bolts to specified torque.

Actuator Bolt Torque N⋅m (kgf ⋅m/lb ⋅in)

9 (0.9/78)

3. Front Axle Drive Shaft (LH side)

2. Bolt • Install front axle drive shaft and mounting bracket.

• Tighten fitting bolts to specified tightening torque.

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

116 (11.8/85)

1. Filler Plug • Pour specified amount of differential gear oil.

Front Differential Oil Capacity liter (US/UK gal)

1.4 (0.37/0.31)

Actuator Housing Oil Capacity liter (US/UK gal) 0.12 (0.03/0.03)

• Install filler plug through packing and tighten to

specified torque.

Filler Plug Torque N⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 657 of 6020

5A-64 BRAKE CONTROL SYSTEM

DTC C0238 (Flash Code 38) Front Speed Sensor Correlation

Step Action Value(s) Yes No

1 W ere the steps of the “Basic Diagnostic Flow Chart”

performed?

- Go to Step 2 Go to Basic

Diagnostic

Flow Chart

2 1. Check for the tire size of each wheels.

2. If the tire size is different, replace the tire.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 3

3 1. Check for the gear ratio of a front axle differential gear and a rear axle differential gear.

2. If the gear ratio is different, repair the gear ratio.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 4

4 Select “Display DTCs” with the Tech 2.

Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 5 Verify repair

5 1. Check for a poor connection at the wheel speed sensor harness connector.

2. Check installation condition for wheel speed sensor.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 6

6 1. Check condition for sensor rotor.

2. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 7

7 1. Ignition “OFF” disconnect the EHCU and wheel

speed sensor.

2. Check the circuit between EHCU and wheel speed sensor. (short ground, or short to voltage)

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 8

8 1. Ignition “OFF”.

2. Check the EHCU circuit for an open, short to ground, or short to voltage. Also, check the EHCU

ignition feed circuit for an open or short to ground

and the EHCU ground circuit for an open or short to

voltage.

3. If a problem is found, repair as necessary. W as a problem found? - Verify repair Go to Step 9

9 1. Ignition “ON”, engine “OFF”.

2. Select “Display DTCs” with the Tech 2. Note: Perform the various tests (actuator test, test

run, brake test, etc.) then observe the DTC with a

Tech 2.

Are any DTCs stored? - Go to Step 10 Verify repair

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 842 of 6020

ENGINE MECHANICAL 6A – 37

REMOVAL AND INSTALLATION

Read this section carefully before performing any removal and installation procedure. This section gives

you important points as well as the order of operation. Be sure that you understand everything in this section before

you begin.

Removal

P1010011

1. Battery

1) Disconnect the battery cable and the grounding cable from the battery terminals.

2) Remove the battery clamp. Take care not to accidentally short the battery with the wrench or some

other tool.

3) Remove the battery.

4) Disconnect the battery cable at the starter motor and the ground cable at the cylinder body.

2. Engine Hood Apply setting marks to the engine hood and the engine

hood hinges before removing the engine hood. This will

facilitate reinstallation of the engine hood to its original

position.

3. Supporting the Vehicle 1) Jack up the vehicle.

2) Place chassis stands at the front and the rear of the vehicle.

4. Under cover (for 4x4 model) 5. Rear propeller shaft 1) Remove the propeller shaft flange yoke at the rear differential.

2) Remove the center bearing retainer bolts.

3) Remove the propeller shaft together with the center bearing from the transmission mainshaft spline.

F06R300006 P1010002

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1672 of 6020

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-55

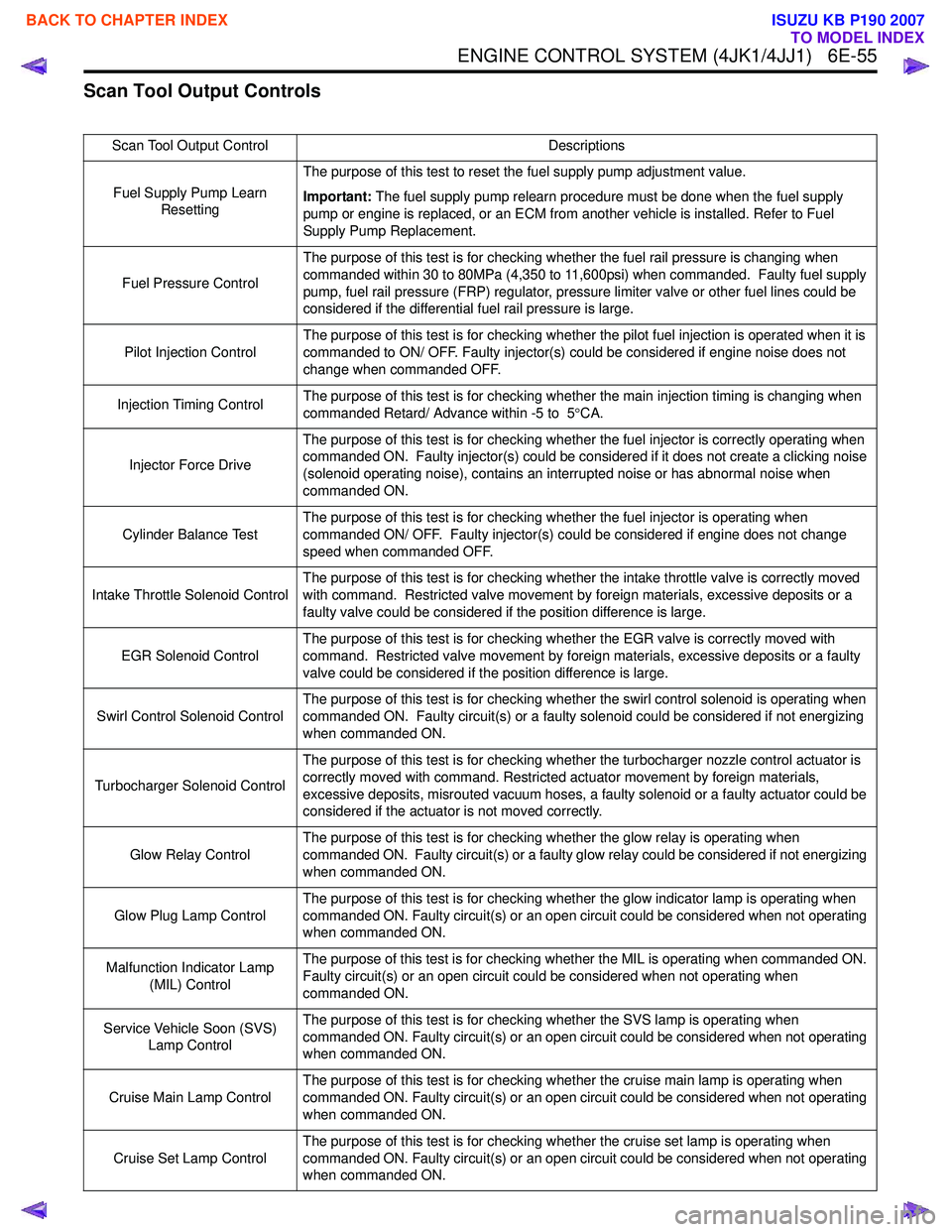

Scan Tool Output Controls

Scan Tool Output ControlDescriptions

Fuel Supply Pump Learn Resetting The purpose of this test to reset the fuel supply pump adjustment value.

Important: The fuel supply pump relearn procedure must be done when the fuel supply

pump or engine is replaced, or an ECM from another vehicle is installed. Refer to Fuel

Supply Pump Replacement.

Fuel Pressure Control The purpose of this test is for checking whether the fuel rail pressure is changing when

commanded within 30 to 80MPa (4,350 to 11,600psi) when commanded. Faulty fuel supply

pump, fuel rail pressure (FRP) regulator, pressure limiter valve or other fuel lines could be

considered if the differential fuel rail pressure is large.

Pilot Injection Control The purpose of this test is for checking whether the pilot fuel injection is operated when it is

commanded to ON/ OFF. Faulty injector(s) could be considered if engine noise does not

change when commanded OFF.

Injection Timing Control The purpose of this test is for checking whether the main injection timing is changing when

commanded Retard/ Advance within -5 to 5 °CA.

Injector Force Drive The purpose of this test is for checking whether the fuel injector is correctly operating when

commanded ON. Faulty injector(s) could be considered if it does not create a clicking noise

(solenoid operating noise), contains an interrupted noise or has abnormal noise when

commanded ON.

Cylinder Balance Test The purpose of this test is for checking whether the fuel injector is operating when

commanded ON/ OFF. Faulty injector(s) could be considered if engine does not change

speed when commanded OFF.

Intake Throttle Solenoid Control The purpose of this test is for checking whether the intake throttle valve is correctly moved

with command. Restricted valve movement by foreign materials, excessive deposits or a

faulty valve could be considered if the position difference is large.

EGR Solenoid Control The purpose of this test is for checking whether the EGR valve is correctly moved with

command. Restricted valve movement by foreign materials, excessive deposits or a faulty

valve could be considered if the position difference is large.

Swirl Control Solenoid Control The purpose of this test is for checking whether the swirl control solenoid is operating when

commanded ON. Faulty circuit(s) or a faulty solenoid could be considered if not energizing

when commanded ON.

Turbocharger Solenoid Control The purpose of this test is for checking whether the turbocharger nozzle control actuator is

correctly moved with command. Restricted actuator movement by foreign materials,

excessive deposits, misrouted vacuum hoses, a faulty solenoid or a faulty actuator could be

considered if the actuator is not moved correctly.

Glow Relay Control The purpose of this test is for checking whether the glow relay is operating when

commanded ON. Faulty circuit(s) or a faulty glow relay could be considered if not energizing

when commanded ON.

Glow Plug Lamp Control The purpose of this test is for checking whether the glow indicator lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Malfunction Indicator Lamp (MIL) Control The purpose of this test is for checking whether the MIL is operating when commanded ON.

Faulty circuit(s) or an open circuit could be considered when not operating when

commanded ON.

Service Vehicle Soon (SVS) Lamp Control The purpose of this test is for checking whether the SVS lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Cruise Main Lamp Control The purpose of this test is for checking whether the cruise main lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

Cruise Set Lamp Control The purpose of this test is for checking whether the cruise set lamp is operating when

commanded ON. Faulty circuit(s) or an open circuit could be considered when not operating

when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1907 of 6020

6E-290 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

DTC P2227 (Flash Code 71)

Circuit Description

The barometric pressure (BARO) sensor is located on

the intake manifold. The BARO sensor is a transducer

that varies voltage according to changes the barometric

pressure. Within the ECM, the diagnostic compares the

BARO sensor input to the boost pressure sensor input.

If the ECM detects that the inputs are not within a

specified amount of each other, this DTC will set.

Condition for Running the DTC • DTCs P0101, P0102, P0103, P0107, P0108, P0116, P0117, P0118, P0122, P0123, P0500,

P0501, P0638, P0652, P0653, P0698, P0699,

P2100, P2101, P2103, P2228 and P2229 are not

set.

AND following conditions are met for longer than 3

seconds.

• The ignition switch is ON.

• The engine coolant temperature is more than 5 °C

(41 °F).

• The engine speed is less than 800 RPM.

• The fuel injection quantity is less than a predetermined value.

• The accelerator pedal is not depressed.

• The vehicle is not running.

• The engine run time is longer than 5 seconds. Condition for Setting the DTC

• The ECM detects that the differential pressure between the barometric pressure and the boost

pressure is more than 10 kPa (1.5 psi) for 10

seconds.

Action Taken When the DTC Sets • The ECM illuminates the MIL when the diagnostic runs and fails. Refer to DTC Type Definitions for

Action Taken When the DTC Sets - Type A.

• The ECM limits fuel injection quantity.

• The ECM inhibits EGR control.

• The ECM inhibits cruise control.

Condition for Clearing the DTC • Refer to DTC Type Definitions for Condition for Clearing the MIL/ DTC - Type A.

Diagnostic Aids • If an intermittent condition is suspected, refer to Intermittent Conditions in this section.

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or ECM Connector End Views

Circuit/ System Testing DTC P2227

Step Action Value(s)Yes No

1 Did you perform the Diagnostic System Check -

Engine Controls? —

Go to Step 2 Go to Diagnostic

System Check -

Engine Controls

2 1. Install a scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the DTC Information with a scan tool.

Is DTC P0107, P0108, P2228 or P2229 also set? —

Go to Applicable DTC Go to Step 3

3 1. Turn ON the ignition, with the engine OFF.

2. Compare the Boost Pressure parameter to the Barometric Pressure (BARO) parameter with

a scan tool.

Are both parameter within the range specified of

each other? 10 kPa (1.5

psi)

Go to Diagnostic Aids Go to Step 4

4 Determine the outside barometric pressure from

your location specified in the altitude vs barometric

pressure table. Refer to Altitude vs Barometric

Pressure.

Is the BARO parameter on the scan tool close to

the outside barometric pressure? —

Go to Step 5 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007