differential ISUZU KB P190 2007 Workshop Manual PDF

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2122 of 6020

6C-4 ENGINE FUEL (C24SE)

Fuel Metering

Engine Control Module (ECM) is in complete control of this fuel

delivery system during normal driving conditions.

The intake manifold function, like that of a diesel, is used onl

y

to let air into the engine. The fuel is injected by separate

injectors that are mounted over the intake manifold.

The Manifold Absolute Pressure (MAP) sensor measures the

changes in the intake manifold pressure which result from

engine load and speed changes, which the MAP senso

r

converts to a voltage output.

This sensor generates the voltage to change corresponding to

the flow of the air drawn into the engine.

The changing voltage is transformed into an electric signal and

provided to the ECM.

W ith receipt of the signals sent from the MAP sensor, Intake

Air Temperature sensor and others, the ECM determines an

appropriate fuel injection pulse width feeding such information

to the fuel injector valves to effect an appropriate air/fuel ratio.

The Multiport Fuel Injection system utilizes an injection system

where the injectors turn on at every crankshaft revolution. The

ECM controls the injector on time so that the correct amount o

f

fuel is metered depending on driving conditions.

Two interchangeable "O" rings are used on the injector that

must be replaced when the injectors are removed.

The fuel rail is attached to the top of the intake manifold and

supplies fuel to all the injectors.

Fuel is recirculated through the rail continually while the engine

is running. This removes air and vapors from the fuel as well

as keeping the fuel cool during hot weather operation.

The fuel pressure control valve that is mounted on the fuel rail

maintains a pressure differential across the injectors under all

operating conditions. It is accomplished by controlling the

amount of fuel that is recirculated back to the fuel tank based

on engine demand.

See Section "Driveability and Emission" for more information

and diagnosis.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2160 of 6020

6D3-12 STARTING AND CHARGING SYSTEM

Diagnosis

The EP regulator incorporates diagnostics which will illuminate

the warning lamp as a result of fault conditions in the generator

and external circuitry.

These conditions include:

1.

An open circuit in the regulator battery sensing wire (S

Terninal)

2. An open circuit or excessive voltage drop in the B+ cable.

3. An open circuit in the generator phase connection.

4. Overcharging of the battery.

5. Regulator output stage short circuit.

6. Open circuit rotor.

The regulator compares the voltage at B+ with the voltage at

the "S" terminal connceted to battery positive. If the voltage

differential exceeds a predetermined threshold, the regulator

will operate in backup mode to limit the output voltage to a safe

level. The warning lamp; will remain illuminated as along as

these conditions prevail.

Sources of high resistance which will trigger the warning lamp

are:

a. Poor contact in wiring harness connectors.

b. Poor contact between rectifier and regulator.

c. High resistance in fusible link assembly.

Caution:

When bench testing the generator it is important that the

warning lamp wattage of 2 watts is not exceeded.

Reversal of the "S" and "L" on the regulator will damage

the regulator.

The correct plug for the regulator is a 9 122 067 011 for the

Bosch tye and for the Shinagawa connector the number is

X02FW.

See appendix 1 for daignostic matrix.

Before testing or disassembling the generator please observe

the following points.

1. W hen testing the diodes with AC type testers the RMS.

Vlotage output must not exceed 12.0 volts, it is

recommended that the stator should be disconnected

during this test.

2. W here zener power diodes are used, the breakdown voltage should be tested to ensure all diodes have the

same zener voltage.

3. Insulation tests on the rotor and stator should use a voltage not exceeding 110v for a series test lamp. The rectifie

r

must be disconnected from the stator prior to testing.

4. W hen carrying out repairs to the charging system always disconnected the battery negative first, and reconnect it

last.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3276 of 6020

Engine Management – V6 – General Information Page 6C1-1–34

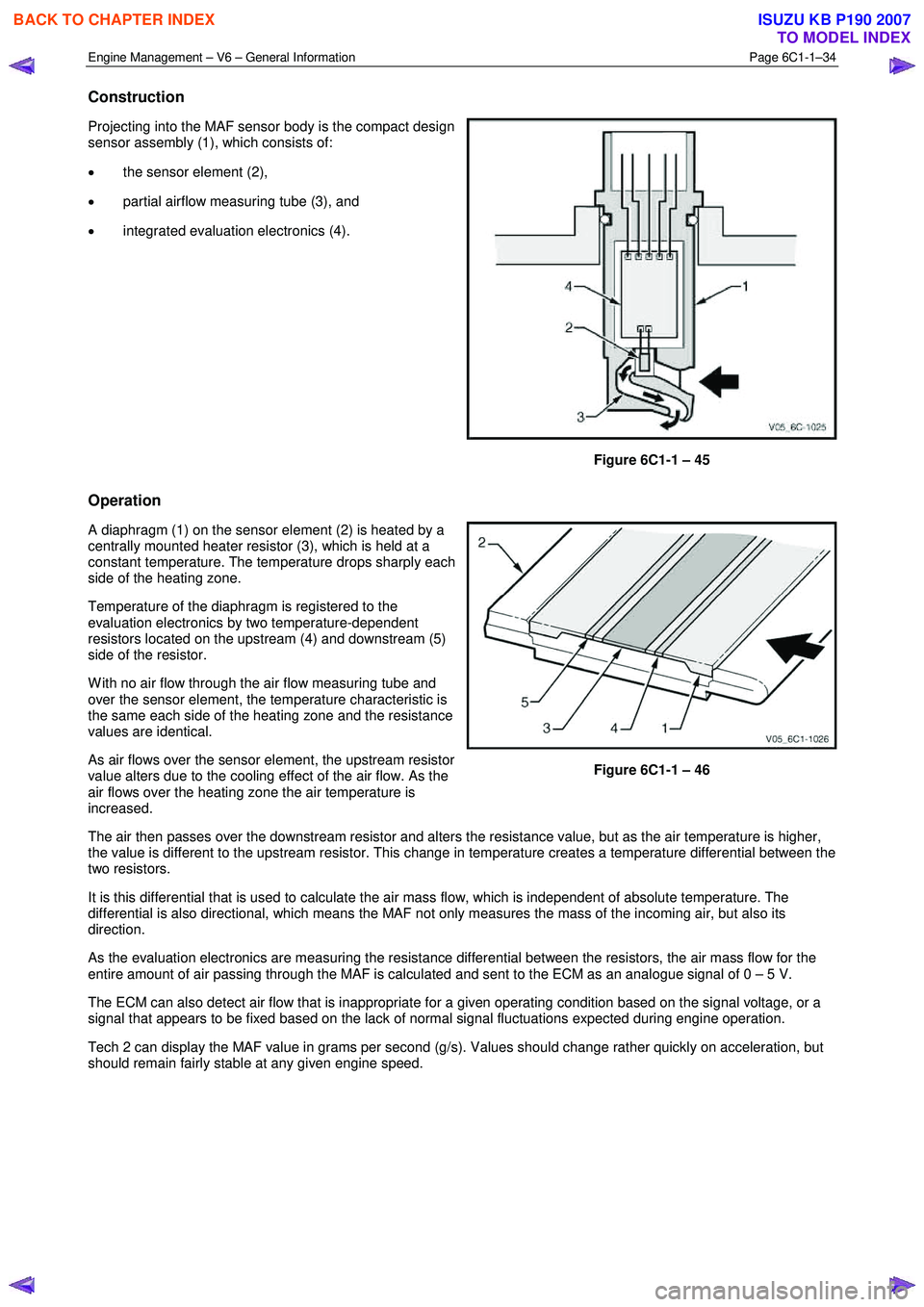

Construction

Projecting into the MAF sensor body is the compact design

sensor assembly (1), which consists of:

• the sensor element (2),

• partial airflow measuring tube (3), and

• integrated evaluation electronics (4).

Figure 6C1-1 – 45

Operation

A diaphragm (1) on the sensor element (2) is heated by a

centrally mounted heater resistor (3), which is held at a

constant temperature. The temperature drops sharply each

side of the heating zone.

Temperature of the diaphragm is registered to the

evaluation electronics by two temperature-dependent

resistors located on the upstream (4) and downstream (5)

side of the resistor.

W ith no air flow through the air flow measuring tube and

over the sensor element, the temperature characteristic is

the same each side of the heating zone and the resistance

values are identical.

As air flows over the sensor element, the upstream resistor

value alters due to the cooling effect of the air flow. As the

air flows over the heating zone the air temperature is

increased.

Figure 6C1-1 – 46

The air then passes over the downstream resistor and alters the resistance value, but as the air temperature is higher,

the value is different to the upstream resistor. This change in temperature creates a temperature differential between the

two resistors.

It is this differential that is used to calculate the air mass flow, which is independent of absolute temperature. The

differential is also directional, which means the MAF not only measures the mass of the incoming air, but also its

direction.

As the evaluation electronics are measuring the resistance differential between the resistors, the air mass flow for the

entire amount of air passing through the MAF is calculated and sent to the ECM as an analogue signal of 0 – 5 V.

The ECM can also detect air flow that is inappropriate for a given operating condition based on the signal voltage, or a

signal that appears to be fixed based on the lack of normal signal fluctuations expected during engine operation.

Tech 2 can display the MAF value in grams per second (g/s). Values should change rather quickly on acceleration, but

should remain fairly stable at any given engine speed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4098 of 6020

ON-VEHICLE SERVICE (AW30–40LE) 7A3-13

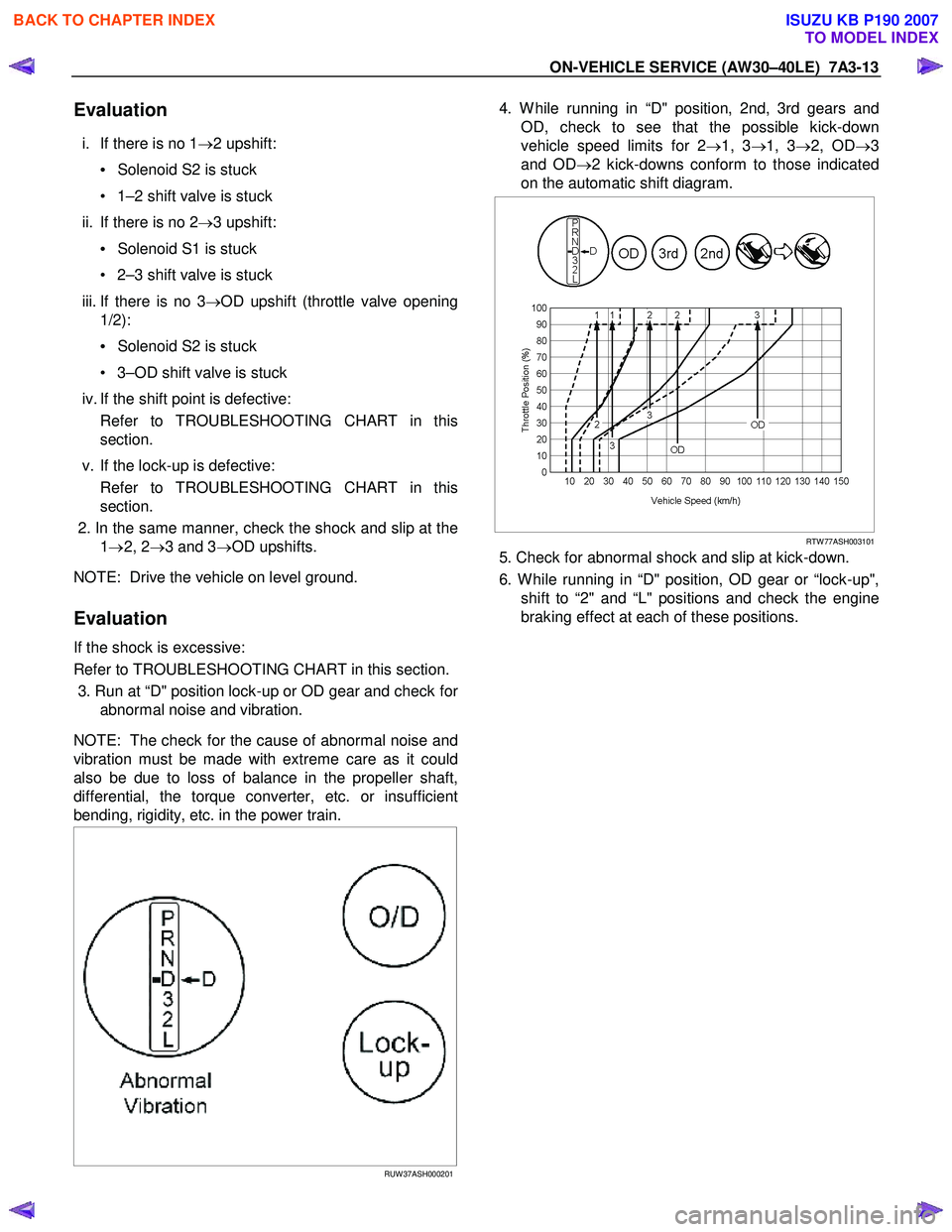

Evaluation

i. If there is no 1→2 upshift:

• Solenoid S2 is stuck

• 1–2 shift valve is stuck

ii. If there is no 2 →3 upshift:

• Solenoid S1 is stuck

• 2–3 shift valve is stuck

iii. If there is no 3 →OD upshift (throttle valve opening

1/2):

• Solenoid S2 is stuck

• 3–OD shift valve is stuck

iv. If the shift point is defective: Refer to TROUBLESHOOTING CHART in this

section.

v. If the lock-up is defective: Refer to TROUBLESHOOTING CHART in this

section.

2. In the same manner, check the shock and slip at the 1→ 2, 2 →3 and 3 →OD upshifts.

NOTE: Drive the vehicle on level ground.

Evaluation

If the shock is excessive:

Refer to TROUBLESHOOTING CHART in this section. 3. Run at “D" position lock-up or OD gear and check fo

r

abnormal noise and vibration.

NOTE: The check for the cause of abnormal noise and

vibration must be made with extreme care as it could

also be due to loss of balance in the propeller shaft,

differential, the torque converter, etc. or insufficient

bending, rigidity, etc. in the power train.

RUW 37ASH000201

4. W hile running in “D" position, 2nd, 3rd gears and

OD, check to see that the possible kick-down

vehicle speed limits for 2 →1, 3 →1, 3 →2, OD →3

and OD →2 kick-downs conform to those indicated

on the automatic shift diagram.

RTW 77ASH003101

5. Check for abnormal shock and slip at kick-down.

6. W hile running in “D" position, OD gear or “lock-up", shift to “2" and “L" positions and check the engine

braking effect at each of these positions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4125 of 6020

7A3-40 ON-VEHICLE SERVICE (AW30–40LE)

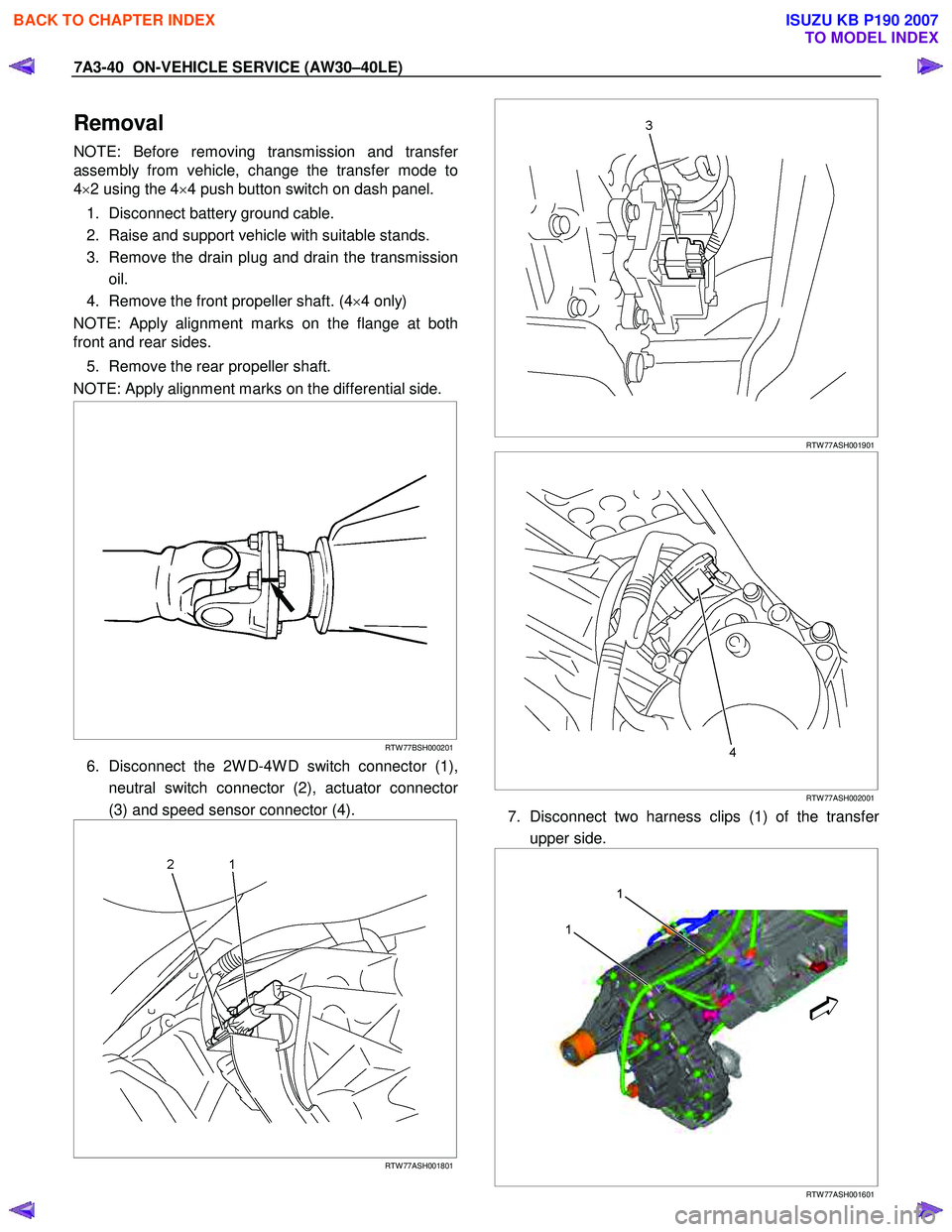

Removal

NOTE: Before removing transmission and transfer

assembly from vehicle, change the transfer mode to

4 ×2 using the 4 ×4 push button switch on dash panel.

1. Disconnect battery ground cable.

2. Raise and support vehicle with suitable stands.

3. Remove the drain plug and drain the transmission oil.

4. Remove the front propeller shaft. (4 ×4 only)

NOTE: Apply alignment marks on the flange at both

front and rear sides.

5. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the differential side.

RTW 77BSH000201

6. Disconnect the 2W D-4W D switch connector (1),

neutral switch connector (2), actuator connecto

r

(3) and speed sensor connector (4).

RTW 77ASH001801

RTW 77ASH001901

RTW 77ASH002001

7. Disconnect two harness clips (1) of the transfer

upper side.

1

1

RTW 77ASH001601

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4392 of 6020

7A2-108 TRANSMISSION CONTROL SYSTEM (JR405E)

B12: Noise or Vibration Occurs at Starting

C1: Engine Race Up (Slipping) When Gearshift is Up from 1st to 2nd

C2: Engine Race Up (Slipping) When Gearshift is Up from 2nd to 3rd

C3: Engine Race Up (Slipping) When Gearshift is Up from 3rd to 4th

C4: Engine Race Up (Slipping) When Gearshift is Down from 4th to 3rd

C5: Engine Race Up (Slipping) When Gearshift is Down (or Kick-down) from 4th to 2nd

C6: Engine Race Up (Slipping) When Gearshift is Down (or Kick-down) from 3rd to 2nd

C7: Engine Race Up (Slipping) When Gearshift is Down (or Kick-down) from 4th or 3rd to 2nd

C8: Engine Race Up (Slipping) Others

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low clutch, reverse clutch, low one-way clutch or low & reverse brake for

slipping.

Checks

Action

ChecksAction

Definition:

Noise or vibration occurs in the vicinity of the transmission at starting.

Diagnosis Hints Cause other than transmission is suspected. Reproduce the running condition using

a lift up, chassis dynamo, etc. to investigate the origin of the noise and vibration.

Additional Checks • Inspect the differential gear noise.

• Inspect the propeller shaft noise.

• Inspect the tires for unbalanced or poor uniformity.

Checks Action

Definition: • Engine speed-up occurs when the accelerator pedal is stepped on for acceleration, and the gear is shifted up.

• Engine speed-up occurs when the accelerator pedal is stepped on for acceleration, and the gear is shifted down or for kick-down during steady run.

• Engine speed-up occurs when the accelerator pedal is stepped on for acceleration, and the gear is shifted down or for kick-down during steady run.

Diagnosis Hints Slipping of the clutch is suspected. Gear ratio error DTC might be set.

Transmission Fluid Checks Inspect the transmission fluid for the following conditions. If the transmission fluid is

extremely blacked, contaminated or smells burnt, slipping of clutch is suspected.

• Low quantity

• Contamination

•Smell

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure. Refer

to Line Pressure Test in Test Instruction section.

Stall Speed Checks Inspect the stall speed in forward ranges. Refer to Stall Test in Test Instruction

section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4399 of 6020

TRANSMISSION CONTROL SYSTEM (JR405E) 7A2-115

F3: Noise or Vibration Occurs During in R, D, 3, 2 or L Range

F4: Engine Brake Does Not Apply in L Range

F5: Engine Stalls Before Vehicle Stops from Running

G1: Vehicle Moves in P Range or Parking is Not Disengaged in Other Than P Range

Diagnosis Hints The same causes as in category No. “C1 - C8: Engine Race Up (Slipping)”

are suspected. When the condition of No. C1 - C8 grows worse, No. F2

results.

Checks Action

Definition:

Noise or vibration occurs in the vicinity of the transmission during running.

Diagnosis Hints Cause other than transmission is suspected. Reproduce the running

condition using a lift up, chassis dynamo, etc. to investigate the origin of the

noise and vibration.

Additional Checks • Inspect the differential gear noise.

• Inspect the propeller shaft noise.

• Inspect the tires for unbalanced or poor uniformity.

Checks

Action

Checks Action

Definition:

The engine brake does not apply, allowing the vehicle to run freely when the accelerator pedal is released at low speed in L

range.

Diagnosis Hints • Slipping of the clutch is suspected. Gear ratio error DTC might be set.

Line Pressure Checks Inspect the line pressure in forward ranges for a possible dropped pressure.

Refer to Line Pressure Test in Test Instruction section.

Control Valve Body Checks Inspect the valve body for the following conditions.

• Faulty operation

• Sticking spool valve

• Sticking shift solenoid valve. Perform function check. Refer to On- Vehicle Service section.

• Clogged hydraulic circuit

Clutch and Brake Checks Inspect the low & reverse brake for slipping.

Sensor Checks Inspect the input shaft speed (ISS) sensor and output shaft speed (OSS)

sensor for faulty operation.

Checks Action

Definition:

The engine stalls simultaneously with the vehicle when the brake pedal is stepped on to stop the vehicle during running.

Diagnosis Hints The same causes as in category No. “B5: Engine Stalls When Selector Lever

is Changed from N to R, D, 3, 2 or L Range” is suspected.

Checks Action

Definition:

Vehicle moves even though it stops on a slope and P range is selected.

Vehicle does not move even though a position other than P range is selected, and the accelerator pedal is being stepped on.

Diagnosis Hints If the vehicle moves in N range, refer to category No. “B1: Vehicle Runs in

N Range”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4410 of 6020

7A2-126 TRANSMISSION CONTROL SYSTEM (JR405E)

• Sticking of low & reverse brake solenoid valve

• Refer to symptom diagnosis No. A2: Vehicle Dose Not Run in R Range

6. If there is no parking. • Faulty parking pawl

• Refer to symptom diagnosis No. G1: Vehicle Moves in P Range or Parking Gear in Not

Disengaged other than P Range.

Notice: The check for the cause of abnormal noise and

vibration must be made with extreme care as it could

also be due to loss of balance in the propeller shaft,

differential, the torque converter, etc. Or insufficient

bending, rigidity, etc. in the powertrain.

Shift Speed Chart 1. All upshifts have a solid green line with:• 1-2 has black filled diamond plot points

• 2-3 has black filled squre plot points

• 2-4 has back filled circular plot posints

2. All donwshift have a sloid blue line with:

• 2-1 has white filled diamonf plot points

• 3-2 has white filled squre plot points

• 4-3 has white filled circular plot points

3. Torque converter clutch apply points have a dashed orange line with:

• 2nd apply has black filled diamond plot points

• 3rd apply has black filled squre plot points

• 4th apply has black filled circulat plot points

4. Torque converter clutch release points have a dashed pink line with:

• 2nd release has white filled diamond plot points

• 3rd release has white filled squre plot points

• 4th release has white filled circulat plot points

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4611 of 6020

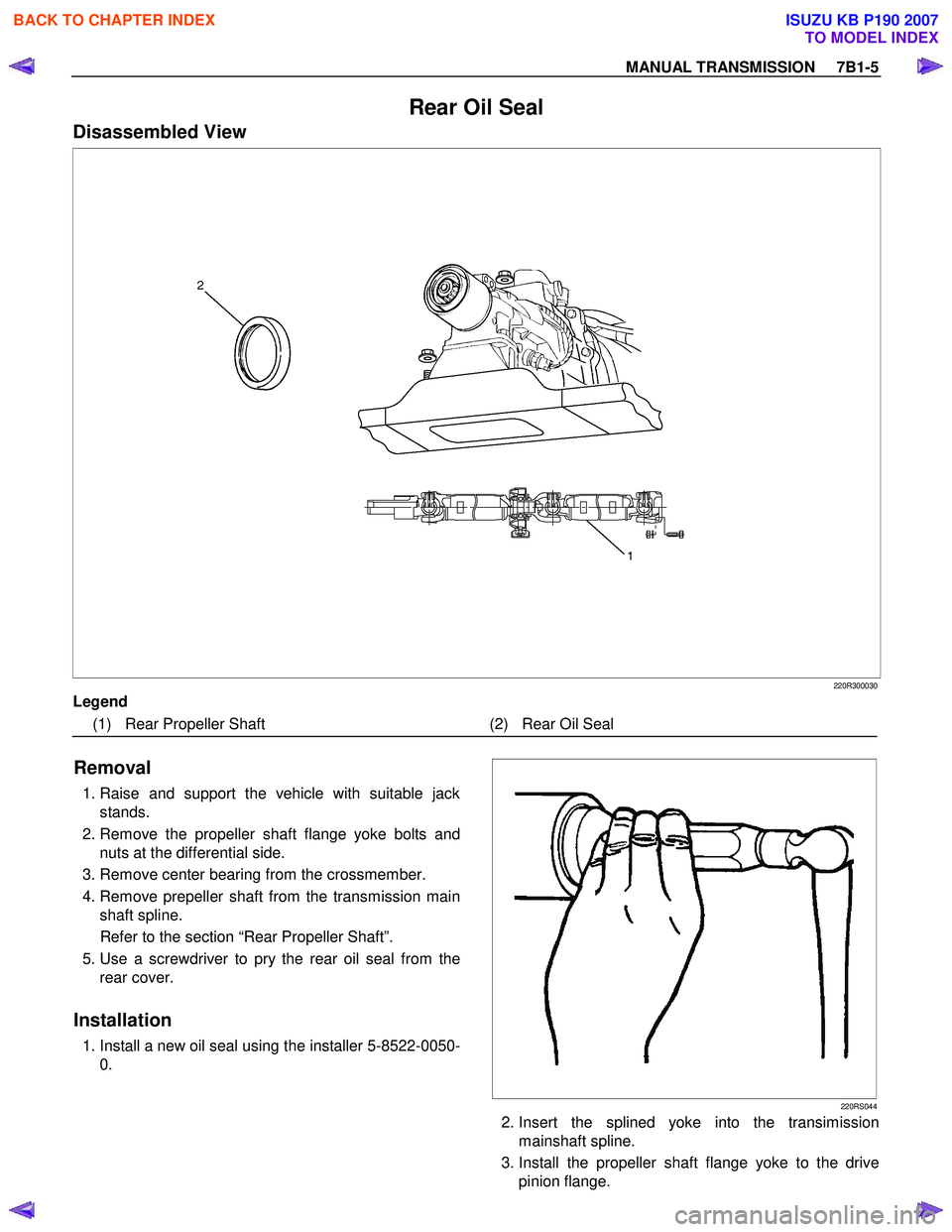

MANUAL TRANSMISSION 7B1-5

Rear Oil Seal

Disassembled View

220R300030

Legend

(1) Rear Propeller Shaft (2) Rear Oil Seal

Removal

1. Raise and support the vehicle with suitable jack

stands.

2. Remove the propeller shaft flange yoke bolts and nuts at the differential side.

3. Remove center bearing from the crossmember.

4. Remove prepeller shaft from the transmission main shaft spline.

Refer to the section “Rear Propeller Shaft”.

5. Use a screwdriver to pry the rear oil seal from the rear cover.

Installation

1. Install a new oil seal using the installer 5-8522-0050- 0.

220RS044

2. Insert the splined yoke into the transimission

mainshaft spline.

3. Install the propeller shaft flange yoke to the drive pinion flange.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4615 of 6020

MANUAL TRANSMISSION 7B1-9

6. Remove the gear control lever.

7. Raise and support the vehicle with suitable stands.

8. Remove the rear propeller shaft.

NOTE: Apply alignment marks on the flange at the

differential side.

401RS023

9. Loosen the front exhaust pipe fixing nuts at the engine side but do not remove them. (Diesel engine

only)

RTW 67BSH000101

10. Disconnect the harness connectors and clips on the

transmission.

• Neutral Switch

• Back up Switch

• Car Speed Sensor

11. Remove the fuel pipe bracket with pipes from the transmission.

Diesel engine

220R300012

Legend

(1) Bolt

(2) Nut

(3) Fuel Pipe Assembly

C24SE

Scan-1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007